1. 引言

影响430铁素体不锈钢性能的因素除化学成分、铁素体晶粒尺寸、晶体织构外,还有钢中的夹杂物。有关430不锈钢夹杂物控制的研究成果已在生产中获得大量应用[1] -[5] 。以往主要在LF炉喂入硅钙线对钢液中的MgO-Al2O3尖晶石夹杂物进行钙处理,为此,存在生产成本高、操作困难和硅钙线易断的问题。随着市场竞争日益激烈,在430铁素体不锈钢的生产中要求既能提高工艺效果、确保质量水平,又能降低成本。本文采用在AOD出钢过程中随钢流加入硅钙合金球的方式,研究硅钙合金球对430不锈钢钢水质量的影响,以期为现场生产提供理论指导。

2. 生产工艺

430铁素体不锈钢冶炼以高炉铁水为原料,经过铁水罐脱磷、脱硅处理后,直接兑入AOD转炉进行

冶炼。AOD转炉采用FeSi (w(Si) = 77%)合金预脱氧,AOD出钢过程中随钢流加入硅钙合金球进行终脱氧,每炉加入100 kg,硅钙合金球的成分见表1所示。AOD工序处理完毕后,送到LF进行精炼。LF精炼过程加入一定量的CaO和CaF2造渣,精炼渣二元碱度控制在2.3~2.5之间,底吹氩气量控制在0.15~0.20 m3/min之间,当成分和温度达到要求后,将钢液运至连铸平台进行浇铸。430铁素体不锈钢的成分见表2所示。

3. 试验方法

冶炼过程中,在AOD出钢前、AOD出钢后和连铸中包取钢样,在AOD出钢后取渣样。对所取钢样进行全氧含量和夹杂物的检测与分析。分析方法如下:

1) 全氧含量测定。每个钢样在相同部位取一个试样,上下表面打磨后,冲小圆柱,测定T[O]含量。

2) 夹杂物成分测定。将钢样切割、研磨、抛光,制成15 mm × 15 mm试样。通过扫描电镜能谱分析方法对夹杂物进行形貌观察,并分析夹杂物的成分。

分别取加硅钙合金球和不加硅钙合金球的3炉430不锈钢试样进行检测和分析。

4. 结果及分析

4.1. 对AOD炉渣流动性的影响

对加硅钙合金球和不加硅钙合金球AOD出钢后钢包中炉渣进行观察,如图1所示。从图中可以看出,加入硅钙合金球的炉次,AOD出钢10分钟后观察,钢包内的炉渣比较松散,结成直径2厘米左右的球块状,无大的结块现象。不加硅钙合金球的炉次,钢包内的炉渣连成一片,有大的结块现象发生。

Table 1. Chemical composition of calcium silicon alloy (wt%)

表1. 硅钙合金球成分(质量分数)%

Table 2. Chemical composition of 430 ferrite stainless steel (wt%)

表2. 430铁素体不锈钢化学成分(质量分数)%

(a)

(a) (b)

(b)

Figure 1. The effect of calcium silicon alloy on slag fluidity; (a) Using calcium silicon alloy; (b) No-using calcium silicon alloy

图1. 对炉渣流动性的影响;(a) 加硅钙合金球;(b) 不加硅钙合金球

4.2. 对AOD出钢前后全氧降低量和渣中Cr2O3含量的影响

AOD出钢采用钢渣混出,在出钢过程中Si的还原反应还在进行,因此炉渣中Cr2O3含量和钢水中全氧含量都是一个降低的过程。不加硅钙合金球的炉次,AOD出钢前后全氧降低量为56 ppm,AOD出钢后炉渣中Cr2O3含量为0.58%。加硅钙合金球后,AOD出钢前后全氧降低量多6 ppm,AOD出钢后炉渣中的Cr2O3含量低0.07%,具体见图2所示,说明AOD出钢过程加硅钙合金球起到了一定深脱氧的作用。

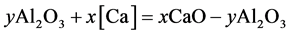

4.3. 加硅钙合金球后夹杂物的成分

430不锈钢AOD冶炼采用硅铁进行还原,硅铁中含有一定量的Al,Al和钢水中的溶解O形成Al2O3夹杂物,熔点较高,不易被炉渣吸附,导致后续产品线鳞缺陷的发生[4] [5] 。加入硅钙合金球后,钢液中夹杂物的成分见图3所示,从图中可以看出,夹杂物的类型为CaO-SiO2-Al2O3,没有Al2O3和MgO-Al2O3尖晶石夹杂物的存在,说明加入硅钙合金球可以起到钙处理的作用。加入硅钙合金球后,钢水中会发生以下反应:

(1)

(1)

4.4. 加硅钙合金球后中间包中夹杂物的大小

加硅钙合金球后,对连铸中间包中夹杂物的形貌进行分析,如图4所示。从图4中可以看出,所观察到的夹杂物都呈现为球状,夹杂物尺寸都小于15 μm,满足430不锈钢钢水质量要求。

Figure 2. The effect of calcium silicon alloy on Cr2O3 content of slag and the total oxygen decreased value before and after AOD tapping

图2. 使用硅钙合金球对渣中Cr2O3含量和AOD出钢前后全氧降低量的影响

Figure 3. The inclusion type in the liquid steel using calcium silicon alloy

图3. 加硅钙合金球后夹杂物的成分

Figure 4. The inclusion morphology in the tundish using calcium silicon alloy

图4. 加硅钙合金球后中间包中夹杂物的形貌

5. 结论

1) 硅钙合金球对改善AOD炉渣流动性有一定作用。

2) 使用硅钙合金球的炉次跟未使用的炉次相比,AOD出钢前后全氧的降低量多6 ppm,AOD出钢后炉渣中的Cr2O3含量低0.07%。

3) 使用硅钙合金球的炉次,钢水中夹杂物类型为CaO-SiO2-Al2O3,中包中夹杂物尺寸都小于15 μm,满足430不锈钢钢水质量要求。