1. 引言

随着工业化进程的快速推进,我国钢铁产量逐年增长,预计到“十二五”末我国生铁年产量可能接近8亿吨,消耗铁矿石将达到13亿吨。我国铁矿石资源相对匮乏,大量铁矿石需要进口,进口的铁矿石具有含铁品位高、有害杂质少等优点,但存在Al2O3含量较高的不足,其含量往往是国内精矿粉的2~4倍,铁矿石中Al2O3含量逐步升高已成为当前及未来炼铁工艺难以避免的问题。在高含量Al2O3铁矿石使用量不断升高的背景下,高炉渣中Al2O3含量已超过传统炼铁学给出的15%极限值,渣中Al2O3含量在16%~19%范围内波动较为普遍,这一状况无疑对炼铁工艺产生不容忽视的负面影响。

国内外关于炉渣中Al2O3的研究很多,Hyuk Kim等人研究表面在1773 K下,碱度为1.0和1.3的炉渣粘度随着Al2O3的增加有升高的趋势,但在Al2O3含量相同时,其变化规律是一致的。这表明炉渣中Al2O3含量对渣粘度的影响比碱度对渣粘度的影响更显著[1] 。此外,日本的研究工作表明,当炉渣中Al2O3含量超过13%时,炉渣粘度依然随着Al2O3含量增加而降低,直到其含量达到15%左右,炉渣粘度才达到一个最低值[2] ,而日本使用的是高Al2O3 (13%)、低MgO (4%~7%)渣型,入炉矿石品位也很高,碱度(CaO/SiO2) = 1.2~1.3。济钢通过对炉渣性能的研究,得出了渣中(Al2O3) ≤ 17%时,(MgO)在9%~10%时,能明显降低炉渣黏度;当渣中(A12O3) ≥ 17%时,(MgO)达到10%以上时,能明显降低炉渣黏度,改善炉渣流动性[3] 。安钢通过高炉高Al2O3炉渣冶炼的综合分析表明,Al2O3的含量在17%到20%的范围内,炉渣熔点随着Al2O3含量增加而逐渐增加,炉渣粘度随着Al2O3含量的增加而升高,每增加0.1%的Al2O3含量,炉渣粘度增加约0.008~0.035 Pa∙S[4] 。通过对唐钢炼铁厂的研究表明,炉渣中的Al2O3含量不宜超过16%[5] 。

本文基于高炉物质守恒原理,结合某钢厂高炉实际生产数据,解析高炉含铁炉料成分变化对高炉终渣成分的影响;进而以CaO-SiO2-Al2O3-MgO四元系终渣为研究对象,采用FactSage热力学软件理论解析综合炉料终渣中Al2O3对其熔化温度和粘度的影响,为深入研究高含量Al2O3铁矿石条件下高铝渣改性方法提供理论基础和技术依据。

2. 实验

2.1. 原料

根据某钢厂高炉的实际生产数据,该厂高炉入炉原料为烧结矿、球团矿和块矿,其中球团矿包括PUK球团矿、PSC-1球团矿、PSC-2球团矿、CVRD球团矿四种,块矿包括SISHEN块矿、罗布河块矿两种,计算中原始配比选取为烧结矿65.97%、球团矿18.05%、块矿15.98%,所选用各种矿成分组成如表1所示。

考虑该厂高炉实际炉料使用情况,将原料按照一种烧结矿、一种球团矿、一种块矿的形式进行配料组合,共得到8种不同矿石组合,依次记为A1、A2、B1、B2、C1、C2、D1、D2,各组组成如表2所示。然后根据入炉原料实际配比,采取烧结矿65.97%、球团矿18.05%、块矿15.98%的配比,通过各矿石的成分计算得到混合矿原料中各元素的比例,如表3示。

2.2. 仪器

研究的主要仪器为FactSage数据处理系统[6] 。

2.3. 试验方法

通过高炉物料平衡计算[7] ,理论上得到高炉终渣渣量及成分。首先,根据Fe平衡算出不同配料下的矿石消耗量;然后,以某钢厂日平均出铁量以及高炉生产的焦比、小焦比、煤比、熔铁比、灰比等数据,计算得出对应的铁水流量、焦炭流量、煤粉流量、熔剂流量和炉尘流量;最后,采用控制变量法,在不同原料组成,不同碱度下,考察Al2O3含量变化对炉渣熔化温度和粘度的影响规律及碱度变化对炉渣熔化温度和粘度的影响规律。

3. 结果及讨论

3.1. 物料平衡计算

炉渣主要成分为CaO、SiO2、Al2O3、MgO、MnO等,该类组分主要来源于混合矿、焦炭、煤粉和熔剂,在生产过程中,这些成分的流失主要集中在炉尘、炉渣以及元素相互反应消耗等。因此,根据前面计算的各物质流量,可以得出炉渣成分的计算含量,如表4所示。

3.2. 基于FactSage热力学软件的高炉渣高温性能理论计算

采用控制变量法,在不同原料组成,碱度分别为1.0、1.1下,考察Al2O3含量变化对炉渣熔化温度和粘度的影响规律及碱度变化对炉渣熔化温度和粘度的影响规律。

以矿石组合A1组(烧结矿 + PUA + SISHEN)为研究对象,考察炉渣中Al2O3成分变化对炉渣熔化温度及粘度的影响规律。将A1组计算所得的实际渣相组成进行碱度调整,得到四元渣系在碱度分别为1.0和1.1的成分组成,如表5所示。

由表5可知,碱度为1.0时,Al2O3含量为14.85%;碱度为1.1时,Al2O3含量为14.76%。根据宝钢高炉实际生产数据和以往研究经验,确定考察Al2O3含量的变化范围分别为10.85%~18.85%和10.76%~ 18.76%,步长为1.00%。调整Al2O3时,为了减少单一调整Al2O3所产生的系统误差,CaO、SiO2、MgO的含量依据Al2O3含量的变化进行同比例修正。具体修正公式如下:

式中: ——调整后CaO的含量,%;

——调整后CaO的含量,%;

Table 1. Mineral compositions (%)

表1. 矿石组成成分(%)

Table 2. Raw material combination

表2. 原料配料组合

Table 3. Compositions of mixed mineral/%

表3. 混合矿成分/%

Table 4. The calculation results of the quantities and compositions of the slag

表4. 渣量及成分计算结果

Table 5. Composition of quaternion slag

表5. 四元渣系成分

——调整之前CaO的含量,%;

——调整之前CaO的含量,%;

——调整后SiO2的含量,%;

——调整后SiO2的含量,%;

——调整后SiO2的含量,%;

——调整后SiO2的含量,%;

——调整后MgO的含量,%;

——调整后MgO的含量,%;

——调整后MgO的含量,%;

——调整后MgO的含量,%;

——调整后Al2O3的含量,%;

——调整后Al2O3的含量,%;

——调整后Al2O3的含量,%。

——调整后Al2O3的含量,%。

在每种矿石组合下,经过调整Al2O3含量,在碱度为1.0和1.1时,分别得到了9组不同的四元渣系成分。在此基础上,采用相同的方法,考察八种不同矿石组合下的四元渣系成分。通过计算液相线温度和1200℃~1520℃温度范围内的粘度,考察液相线温度随着Al2O3含量变化的趋势,以及不同温度下炉渣粘度随着Al2O3含量变化的趋势。通过FactSage热力学软件计算,得到A1组的液相线温度随Al2O3变化的规律,结果如表6、表7所示,粘度随Al2O3含量变化的规律如表8、表9所示。

以上为矿石组合A1组的炉渣液相线温度与粘度计算结果,其他各组矿石组合的四元渣系计算方法与过程类似,得到的数据结果分析与A1组相似。

Table 6. The calculation results of liquidus temperature under the change of Al2O3 (A1/Sinter + PUK + SISHEN, R = 1.0)

表6. Al2O3变化时液相线温度计算结果(A1/Sinter + PUK + SISHEN, R = 1.0)

Table 7. The calculation results of liquidus temperature under the change of Al2O3 (A1/Sinter + PUK + SISHEN, R = 1.1)

表7. Al2O3变化时液相线温度计算结果(A1/Sinter + PUK + SISHEN, R = 1.1)

Table 8. The calculation results of slag viscosity under the change of Al2O3 (A1/Sinter + PUK + SISHEN, R = 1.0)/Pa∙S

表8. Al2O3变化时炉渣粘度计算结果(A1/Sinter + PUK + SISHEN, R = 1.0)/Pa∙S

Table 9. The calculation results of slag viscosity under the change of Al2O3 (A1/Sinter + PUK + SISHEN, R = 1.1)/Pa∙S

表9. Al2O3变化时炉渣粘度计算结果(A1/Sinter + PUK + SISHEN, R = 1.1)/Pa∙S

3.3. Al2O3含量对液相线温度影响规律理论解析

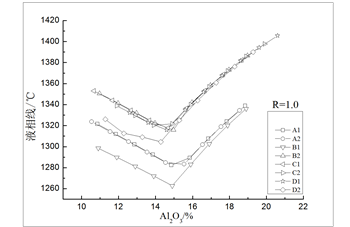

根据上述计算,得到不同矿石组成、碱度分别为

1.0和1.1下的四元渣系随组分Al2O3变化的液相线温度数据,得到如图1所示结果。

由图1可以看出,在不同矿石组成及不同炉渣碱度下,液相线温度都随着Al2O3的增加呈现先降低后升高的趋势。当Al2O3含量在14%~15%时,每条液相线温度曲线都出现一个拐点,在拐点处液相线温度达到最低。由于液相线温度代表熔化温度,熔化温度低,炉渣流动性较好,有利于高炉顺行。这表明终渣适宜的Al2O3含量为14%~15%,此时炉渣的液相线最低,流动性最好。此外,碱度为1.1时的炉渣液相线温度明显高于碱度1.0时的炉渣液相线温度,碱度对炉渣的流动性有一定的影响,表明终渣碱度越高,熔化温度就越高。

出现上述变化规律的原因为在A12O3含量 > 15%的CaO-SiO2-MgO-Al2O3系相图中,渣相已发生变化,在高炉渣成分范围内有黄长石、镁硅钙石和尖晶石(MgO、A12O3)等相存在。由于尖晶石区的扩大和钙铝黄长石的增加,液相线温度低于1450℃的黄长石区域缩小。因此,随着A12O3含量的增加,炉渣的熔化性温度升高。另外,高A12O3含量的碱性渣中,容易出现尖晶石,尖晶石为高熔点矿物,并且结晶能力很强,在炉渣熔体中最早结晶出来,形成以固溶体质量状态存在于炉渣熔体中,造成炉渣流动性差。因此,随着渣中A12O3含量增高,其相应的熔化性温度也会升高。

3.4. Al2O3含量对炉渣粘度影响规律理论解析

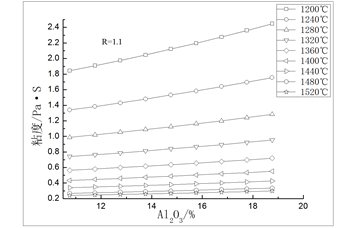

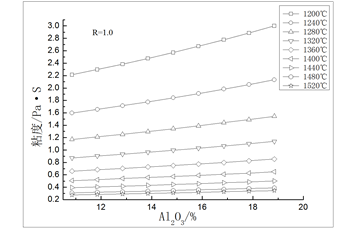

根据计算得到不同矿石组合、碱度分别为1.0和1.1下的四元渣系随组分Al2O3变化的炉渣粘度数据,作图后得到如图2所示结果。

由图2可知,在相同的碱度和温度下,随着炉渣中Al2O3含量的增加,炉渣粘度逐渐升高;温度越低,随着Al2O3含量的增加粘度增大的趋势变小。此外,比较图2中a)和b),同一温度与同一Al2O3含量下,碱度升高,终渣粘度略有降低。

出现上述变化规律的主要原因为A12O3是一种弱酸性氧化物,在碱性渣中能够形成类似于SiO2那样的复合阴离子 。并且,A13+可以部分取代

。并且,A13+可以部分取代 中的Si4+,形成硅-铝-氧复合阴离子。因此,

中的Si4+,形成硅-铝-氧复合阴离子。因此,

(a)

(a) (b)

(b)

Figure 1. The liquidus temperature of quaternion slag under the change of Al2O3 with basicities at 1.0 and 1.1 based on A1~D2

图1. A1~D2组四元渣系液相线温度随Al2O3含量变化图

(a)

(a) (b)

(b)

Figure 2. The viscosity of quaternion slag under the change of Al2O3 with basicities at 1.0 and 1.1 based on A1

图2. A1组四元渣系在R = 1.0和R = 1.1的粘度随Al2O3含量变化图

随着渣中A12O3含量的增加,熔渣的粘度增大,流动性下降。

4. 结论

1) 随着Al2O3含量的增加,炉渣液相线先降低后升高,当Al2O3含量为14%~15%时,对应炉渣液相线温度最低。

2) 碱度升高,炉渣液相线温度升高;相反,碱度降低,炉渣粘度降低。当Al2O3含量为14%~15%时,炉渣碱度控制在1.0左右时,炉渣液相线温度最低。

3) 炉渣中Al2O3含量大于16%,MgO含量在5%~10%范围变化时,炉渣液相线先升高后降低,但变化幅度较小;

项目基金

国际海域资源调查与开发“十二五”资助项目(No. DY125-11-T-02),长沙矿冶研究院基金资助项目(No. A2012- 102),湖南省自然科学基金资助项目(No. 14JJ4065)。

NOTES

*通讯作者。