1. 引言

从能源贮量来看,我国富煤少油,煤炭资源的高效利用对保障我国能源供应具有重要意义[1] 。通过将煤转化成合成气(CO和H2的混合物)、再利用催化剂合成醇类燃料,是一种有效利用劣质煤的技术手段,其中的低碳醇是指C1~C6的醇类混合物,既不含芳香族,也不含硫,可以用作清洁液态燃料和基础化学原料,应用前景十分广阔。

采用浸渍法制备催化剂时,多种活性组分既可共浸渍,也可分次浸渍到载体上,但浸渍方式和浸渍次序都会对催化剂的反应性能产生影响[2] 。对于CO加氢反应,李晨等发现对Al2O3载体先浸渍Zr、再共浸渍Co和Ru所得到的催化剂具有最好的反应活性和C5+烃选择性[3] ;Chu等人发现共浸渍制备的CuCo/SiO2催化剂表现出高的总醇产率,醇选择性高达51.5% [4] 。对于低碳醇合成反应,C2+醇的生成需要催化剂表面分子态吸附CO和解离吸附CO的量相匹配[5] -[8] ,即两类CO吸附中心要协同作用,才能提高低碳醇合成催化剂的反应性能,这需要对催化剂的制备方法展开细致研究。本文选择SiO2作为载体,采用不同的浸渍次序负载Cu、Zn和Fe,对所得到的催化剂进行了反应性能测试和表征研究。

2. 方法

2.1. 催化剂制备

采用等体积浸渍法制备催化剂,Cu、Zn和Fe的原料都选用分析纯的硝酸盐(国药集团化学试剂有限公司)。首先将SiO2(青岛海洋化工厂,150~280 mm)迅速倒入Cu(NO)3·3H2O溶液中浸渍,并对其超声处理[9] ,再在120℃干燥,然后在500℃焙烧;再用上述程序依次浸渍Zn、Fe,得到Cu-Zn-Fe催化剂(简记为:C-Z-F)。按照相同的方法分别制备Cu-Fe-Zn催化剂(C-F-Z)、Zn-Cu-Fe催化剂(Z-C-F)、Zn-Fe-Cu催化剂(Z-F-C)、Fe-Zn-Cu催化剂(F-Z-C)、Fe-Cu-Zn催化剂(F-C-Z)和CuZnFe共同浸渍催化剂(CZF)。其中的Cu、Zn和Fe的负载量分别为25.4、26.2和1.3 wt%。

2.2. 催化剂活性评价

将催化剂放入固定床反应器,用常压氢气还原后,在280℃、3.0 MPa、V(N2):V(CO):V(H2) = 1/8/16和6.0 L/(h∙g-cat.) 条件下进行活性评价。反应产物中的液态部分由冷阱收集。采用配有热导检测器的GC-9860色谱和TDX-01色谱柱(Φ3 mm × 3 m)在线分析反应尾气中的N2、CO、CH4和CO2的体积分数,使用内标法计算CO转化率及CO2和CH4选择性[10] 。

2.3. 催化剂表征

利用荷兰帕纳科公司生产的X’Pert PRO仪器分析催化剂的体相结构,采用Cu Kα光源(λ = 0.154056 nm);程序升温还原(H2-TPR)是在自制设备上进行,0.1 g催化剂在流量为40 ml/min的氢氩混合气(H2含量5%)中以10℃/min升到900℃。

3. 结果与讨论

3.1. 不同浸渍顺序对催化剂反应性能影响

表1汇总了各催化剂的反应性能,其中CZF催化剂具有最高的CO转化率和CO2选择性。比较以不同次序分浸制备的催化剂,可以发现Zn的负载次序不影响催化剂反应活性(CO转化率),说明Zn是以结构助剂发挥作用的,但Cu和Fe的浸渍顺序明显影响着催化剂活性,其中先Fe后Cu的浸渍次序优于先Cu后Fe;F-Z-C和F-C-Z具有最低的CO2选择性。

3.2. 催化剂的晶相结构

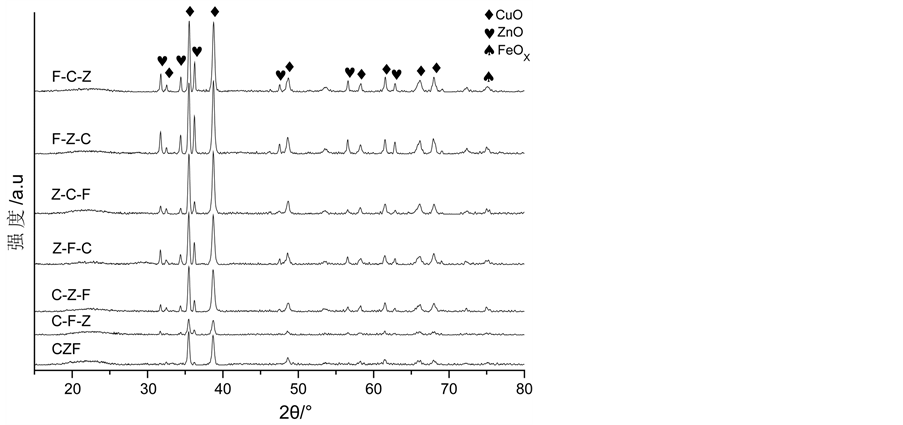

催化剂的晶相结构如图1所示,Cu和Zn分别以CuO(PDF:45-0937)和ZnO(PDF:36-1451)晶型存

Table 1. The influence of impregnation sequence on catalyst activity and selectivity

表1. 不同浸渍顺序对催化剂活性和选择性的影响

Figure 1. XRD of the catalysts with different impregnation sequence of Cu, Zn and Fe

图1. 不同Cu、Zn和Fe浸渍顺序催化剂的XRD谱图

在,由于Fe2O3和Fe3O4的衍射峰位置相互接近,而且催化剂中的Fe含量很低,无法准确判断它的晶型,以FeOX表示。同一个催化剂中的CuO衍射峰强度明显高于ZnO和FeOX的,考虑到催化剂中Cu和Zn含量相近,Zn在载体上的分散度可能远高于Cu。CuO、ZnO和FeOX三种晶体的衍射峰强度都受浸渍方式影响,其中催化剂C-F-Z中的衍射峰强度最弱,但催化剂CZF中只观察到CuO衍射峰,对照表1中的催化剂活性数据,Zn在载体上的分散度越高,催化剂的反应活性也越高。选择2θ = 38.7˚、32.7˚和74.9˚衍射峰的半高宽,利用谢乐公式分别计算各催化剂中的CuO、ZnO和FeOX晶粒大小,结果如表2所示。

催化剂C-F-Z和C-Z-F具有相近的CuO晶粒大小,并比其它催化剂中的小,其原因是由于硝酸铜溶液的pH值在2.2左右,SiO2的等电点在2~3之间[11] -[13] ,Cu与载体发生强吸附作用,部分形成难还原CuSi氧化物,导致CuO的晶粒度小。催化剂CZF中只检测到CuO,表明Zn和Fe在其中高度分散,增加了Cu、Zn和Fe间的相互接触,使得它的反应活性远高于其它催化剂[10] 。

3.3. 催化剂的还原性能

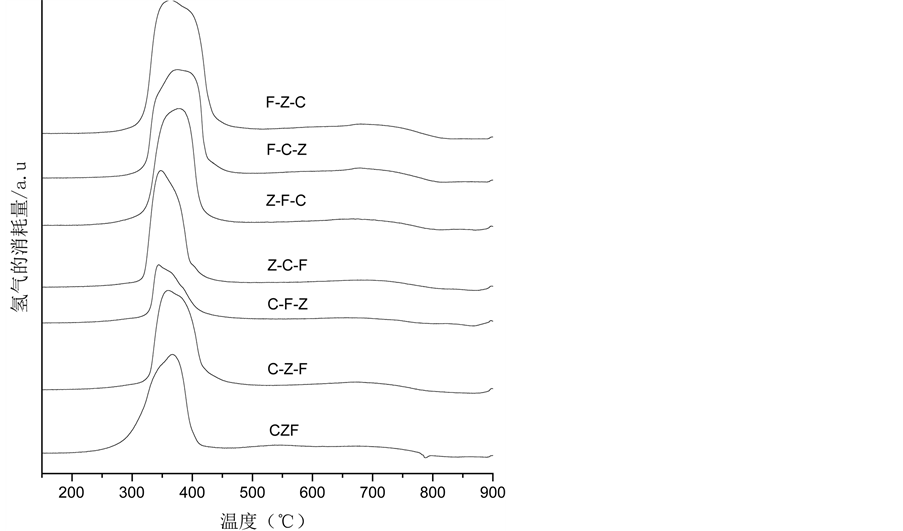

图2是不同催化剂的H2-TPR结果,其中低于500℃的峰主要是CuO还原引起的,共浸催化剂CZF的还原温度区间低于分浸催化剂,图1的结果显示催化剂CZF中Cu、Zn和Fe间的相互接触最充分,还原后得到的活性中心最多,因此其活性最高[10] 。

分浸制备的催化剂C-Z-F和C-F-Z的起始还原温度相同,但前者的还原峰面积远比后者大,C-Z-F中的FeOX被还原的量更多,由于FeOX是水汽变换反应活性中心[14] ,使得C-Z-F的CO2选择性低于C-F-Z;金属Fe的出现加强了CO与H2按费托反应机理发生反应[15] ,造成CH4选择性较高。

催化剂Z-F-C的耗氢峰起始温度比Z-C-F催化剂低,峰面积比Z-C-F催化剂大,即Z-F-C的还原度高于Z-C-F,这是由于Z-F-C中的Cu为最后浸渍,在催化剂表面分布的CuO多,由CuO还原得到的金属Cu可以促进 FeOX还原[16] [17] ,加强了费托反应发生,引起催化剂Z-F-C的反应活性和CH4选择性较高。

催化剂F-Z-C的还原情况类似于F-C-Z,两个催化剂上的由还原生成的活性中心数相近,所以它们表现出相似的反应性能。

4. 结论

共浸制备的催化剂反应活性高于分浸制备的催化剂,这是由于前者的Cu和Fe接触程度最高和易于还原引起的。对于以不同次序分浸制备的催化剂,Zn的负载次序不影响催化剂反应活性,但先Fe后Cu的浸渍次序优于先Cu后Fe;催化剂中的FeOX还原度高时,导致CH4选择性高,反之加强了CO2选择性。Zn在载体上的分散度远高于Cu。

Table 2. The grain size of CuO, ZnO, FeOX in the catalysts

表2. 催化剂中的CuO、ZnO、FeOX晶粒度

Figure 2. Influence of Cu, Zn and Fe impregnation sequence on the reduction of catalysts

图2. Cu、Zn和Fe浸渍顺序对催化剂还原性能的影响

致 谢

感谢浙江省自然科学基金(LY14B030003)和国家科技支撑计划(2014BAD02B05)对本工作的支持。

NOTES

*通讯作者。