1. 引言

注塑成型是一门工程技术,它所涉及的内容是将塑料转变为有用并能保持原有性能的制品。注塑成型的重要工艺条件是影响塑料塑化、流动和冷却的温度、压力和相应的各个作用时间[1] 。由于注塑成型周期短,自动化程度高,可成型复杂制品和小型制品,所以广泛用于塑料制品的生产中。但随着塑料制品用途日益广泛,注塑模具工艺空前发展,依靠人工经验来设计模具已经不能满足需要[2] 。因此,设计人员越来越利用注塑模流分析技术来辅助塑料模具的设计,探索缺陷产生的内在机理和预测制品可能产生缺陷的位置和种类,并用于指导产品和模具的设计及改进、注塑成型工艺的调整,从而达到优化塑件结构、降低材料成本、缩短生产周期、减少修模次数和优化注射工艺参数的目的。本文利用分析软件Moldflow为分析平台,对端套注塑成型进行模拟分析,并根据对塑件的浇口、流道系统、冷却系统、翘曲系统等模拟分析结果,提出针对性改善意见,为最终的模具设计制造提供依据。

2. 塑件材料及成型性能

本研究对象为端套(Pot head),塑件属于带孔圆形薄壁类零件。精度要求为MT7,材料为THERMELT 867(聚酰胺热熔胶)。

THERMELT 867是一种聚酰胺热熔胶。它主要的特点是:固化时间短;中等露置时间;在应用温度下粘度很低;在应用温度下有良好的浸润性;良好的耐高、低温性能;获UL 94-V0认证。它主要运用的场合:电线终端及线束固定;电子器件在线路板上的安装;灌封、线圈固定;电线加固;电子元件塑封,见表1。

3. 模流分析前处理

在进行模流分析,首先必须将待分析件的模型建立出来,同时并转换成Moldflow可以任识的格式。如图1所示,将Creo模型转换成stl格式。

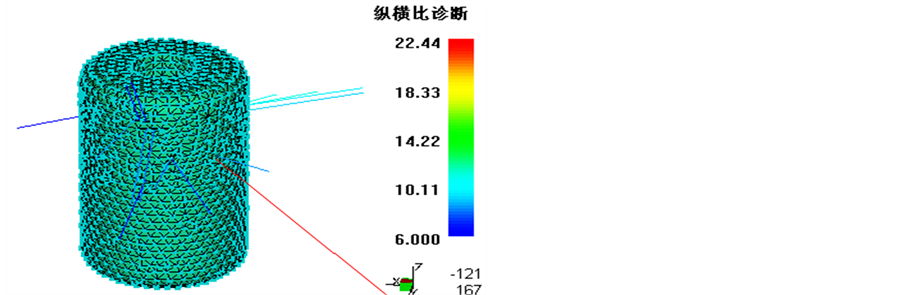

在Moldflow中,对所研究的塑件进行网格划分、统计、诊断并修复网格缺陷,。通过对网格进行统计如图2所示和纵横比诊断如图3所示,发现最小横纵比为1.16,最大横纵比22.44,平均横纵比1.74,纵横比比较均匀,其中在拐有倒圆角的地方,纵横比非常大,这不利于塑料熔体在型腔里的流动。利用网格工具对网格进行修改,使得各项网格信息均符合流动分析要求,其中匹配百分比为和相互百分比为达到90%以上。

Table 1. Main specifications of THERMELT 867

表1. THERMELT 867的主要技术指标

Figure 1. Convert to stl format

图1. 转换成stl格式

Figure 2. Mess statistics

图2. 网格统计

网格划分达到要求之后,进行浇口位置设定、冷却管道的铺设以及填充材料的选择等,为接下来对最佳浇口和三大系统的分析做好准备。

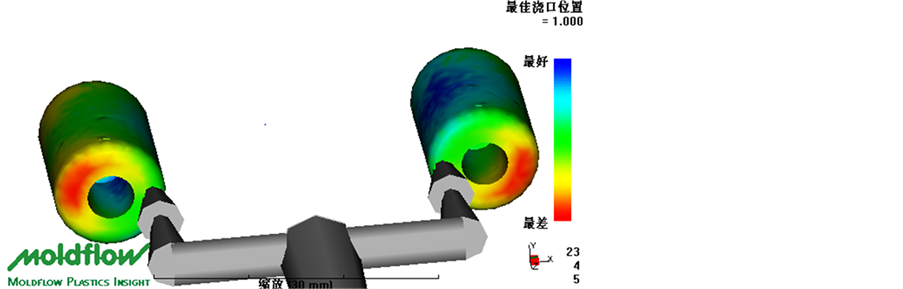

4. 最佳浇口位置分析

浇口是连接分流道和型腔的进料通道。它具有两个功能:第一,对塑料熔体流入型腔起着控制作用;第二,当注塑压力撤销后,封锁型腔,使型腔中尚未冷却固化的塑料不会倒流[3] 。进行浇口分析,可以得到优化的浇口位置,避免由于浇口位置不当或随意性而引起的后续分析的大幅失真[4] 。浇口类型的选择取决于制品外观的要求、尺寸和形状的制约以及所使用的塑料种类等因素。本研究的塑件为了满足生产节拍的需要,采用一腔两模方式。此外,在内部有标准线束填充,端套外边缘对表面要求高。所以按照如图4所示建立选择浇口位置,即设在端套底部边缘。通过最佳浇口分析结果,发现塑件基本能顺利的完成整个制品的注射。所以,以上浇口位置选择满足要求。

5. 结果与讨论

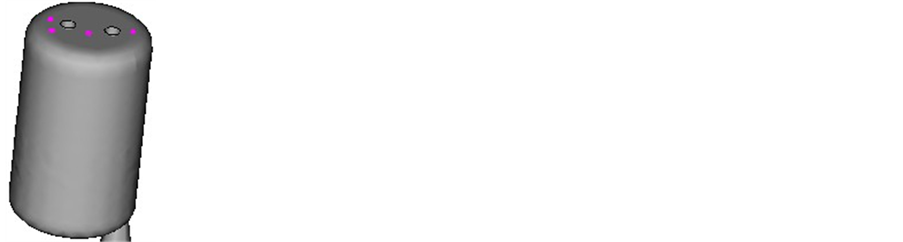

5.1. 气穴位置

气穴也称为气泡或气孔,往往是指因为气体没有及时的排除导致填充不完全的现象。这些气体若不能顺利排出,则可能因充填时气体被压缩而产生高温,引起塑件局部碳化烧焦,同时,这些高温高压的气体也有可能挤入塑料熔体内而使塑件产生气泡、空洞或填充不足等缺陷[5] 。所以,在气孔容易产生的地方,我们会适当增加排气口,从而使塑件完整的填充。从图5中可以看出,气穴的位置集中在顶部和

Figure 3. Aspect ratio diagnosis

图3. 纵横比诊断

Figure 4. The best gate location

图4. 最佳浇口位置

地步外缘部位,这根熔料的流动有关,因为熔料从一头向另外一头填充。但分析结果显示气穴数目不多,可以考虑不需要额外气孔来排气。

5.2. 填充时间

填充分析是指从注塑开始到型腔被充满整个过程的流动前沿位置分析。该分析用来预测制件的填充行为是否合理,是否平衡,是否能完全填充。图6为Moldflow对填充时间的分析结果,由图可知,塑件完成注射所需时间为3.291 S。从塑件底部的浇口位置,慢慢向顶部填充,能够较均匀、较快的完成整个塑件的注射。

5.3. 熔接痕位置

由图7可以看出,熔接痕的位置主要集中在中间部位,跟线束接触处。所以,在实际情况下,可以适当增加注塑压力、保压压力等来消除熔接痕。

5.4. 制品温度

制品冷却通常占成型周期的绝大部分时间,因此控制成型周期提高产能,加速制品冷却时至关重要。

Figure 5. Hole position

图5. 气孔位置

Figure 6. The filling time

图6. 填充时间

Figure 7. Weld line distribution

图7. 熔接痕位置

熔融塑料在高温下被注射入型腔后,需要经历从高温到室温的冷却过程,在这期间,会释放出大量的热量。如果冷却不均匀,很容易影响到制品的外观、尺寸精度和力学性能。这样,设计时就需要对冷却系统加以重视。由Moldflow分析结果如图8,整个制品的平均温度较低,冷却效果已经达到目标值。所以设计的冷却回路较为合理。

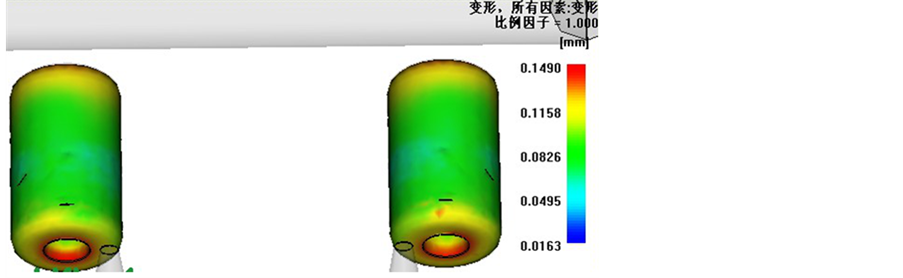

5.5. 翘曲变形

翘曲是指在成型过程中不均匀的内部应力导致的制件缺陷,注塑产生翘曲的原因在于收缩不均。制品上不同区域的收缩不均匀、厚度方向上的收缩不均匀或者材料分子取向平行和垂直方向上不均匀都会导致翘曲。而影响翘曲的主要因素有冷却变形、取向因素变形、角效应变形等。在这样综合作情况下,造成整个塑件的变形。由图9中可以看出,在所有因素的综合作用下,端套内部变形比较大,但由于注塑时会有线束通过,能对变形起到一定的控制作用。

6. 塑件模具设计

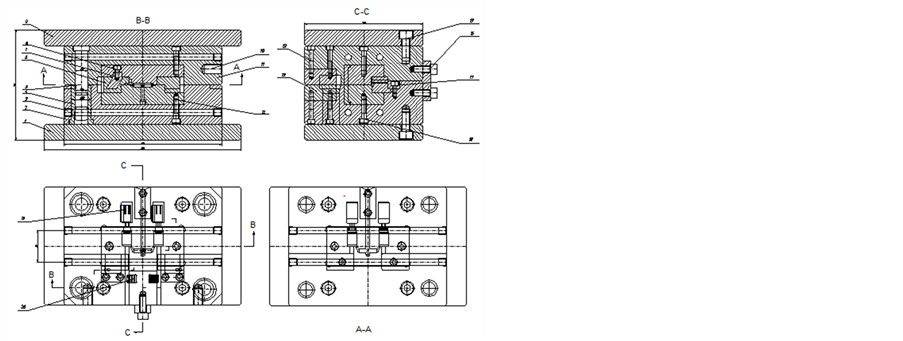

通过Moldflow对整个注塑过程中浇注、冷却和翘曲模拟分析,验证了模具设计的合理性,同时找出了设计过程中没有考虑到的或在实际生产中可能发生的问题,并及时对模具设计进行调整,从而能达到更好的实践生产要求。根据以上的分析,最佳浇口位置能满足了整个塑件注塑过程,填充时间适应了生产节拍,其次冷却系统中冷却效果已达到要求,最后,塑件的成型以及变形在一定的条件下,能达到塑件质量以及外观要求。综上,最终模具设计的二维和三维图,如图10所示。

Figure 8. Temperature of products

图8. 制品温度

Figure 9. Deformation analysis of all the factors

图9. 所有因素:变形分析

Figure 10. Assembly drawing of the mold

图10. 模具总装配图

7. 结束语

通过使用Moldflow软件对端套注塑过程进行分析,验证了塑件的最佳浇口位置。并通过分析塑料在注塑过程中气穴位置、填充时间、熔接痕位置、制品温度和翘曲变形的模拟结果,得出在设计的冷却回路和线束的作用下,适当增大注塑压力或保压压力,使塑件能够在规定的时间内较好地完成整个制品的注塑的结论。总之,利用Moldflow对注塑过程中浇注、冷却和翘曲系统进行分析,判断出可能的问题,针对性的加以修正,以达到合理设计的要求。提高了模具的质量,减少了试模次数,缩短了模具设计周期,从而满足了实际生产的要求。