摘要:

为了在中频感应炉利用废钢代替纯铁冶炼出超低碳铁素体不锈钢,采用各种废钢进行了超低碳铁素体不锈钢的生产实践。结果表明,通过吹氧工艺可以使C降低到0.025%;钢中Si含量降低到0.005%是吹氧冶炼超低碳钢的必要条件;吹氧后进行硅铁钢液脱氧,配合硅钙、粘土块熔渣改质,使熔渣碱度变为0.8~1.2,降低初始FeO和Cr

2O

3含量,可以有效解决熔渣熔点高、熔渣结壳等生产难题。

Abstract:

To use scrap instead of pure iron in intermediate frequency induction furnace smelting ultra low carbon ferrite stainless steel, a variety of scraps were used in ultra low carbon ferrite stainless steel production practice. The results show that, the content of carbon can be reduced to 0.025% by oxygen blowing process, it is necessary condition that silicon content reduced to around 0.005% in oxygen blowing smelting ultra low carbon steel, and it can effectively solve the production pro- blems such as high slag melting point and molten slag crusting by ferrosilicon deoxidization after oxygen blowing, cooperating with the calcium silicon and clay piece of slag modification, making slag basicity 0.8 to 1.2, and lowering initial FeO and Cr2O3 content.

1. 引言

超低碳铁素体不锈钢,与普通铁素体不锈钢相比,要求具有良好的冷加工性能、焊接性和耐蚀性能,钢中C、N含量严重影响着钢的三者性能。降低C、N含量可以降低钢的屈服强度和加工硬化倾向,改善钢的塑性、冷变形性能、和焊接性能;此外降低碳氮含量,钢的耐蚀性显著提高;因此超低碳铁素体不锈钢要求钢中C ≤ 0.03%、N ≤ 0.04% [1] 。在中频感应炉(简称中频炉)采用废钢冶炼过程中,废钢等原材料成分复杂多变,同时在冶炼环节存在诸多增碳、增氮环节,严重影响着中频炉生产超低碳铁素体不锈钢的产品质量,中频炉企业往往采用工业纯铁作为原料生产超低碳铁素体不锈钢,成本较采用废钢大幅增加。因此在实践中如果开发出利用废钢冶炼超低碳不锈钢相关工艺,同时分析和解决采用废钢冶炼超低碳铁素体不锈钢存在的问题十分必要。

2. 超低碳铁素体不锈钢的技术要求

铁素体不锈钢0Cr13成分技术要求:C ≤ 0.08%,Si ≤ 1%,Mn ≤ 1%,P ≤ 0.04%,S ≤ 0.03%,Cr 12.5%~14.5%,N ≤ 0.04%。超低碳铁素体不锈钢内控要求C ≤ 0.03%,碳含量越低越好。

3. 生产设备与生产工艺

生产设备采用500 kg中频炉,钢水装入量420 kg,炉衬材料采用镁质预制坩埚。炼钢原料采用废钢,废钢主要包括碳素钢、低合金钢、硅钢废料等。合金原料采用微碳铬铁、硅铁、锰铁。熔炼渣采用CaO-CaF2渣系,按照4:1比例钢水量的2%随炉加入。在生产中需要对钢液进行吹氧脱碳,因500 kg中频炉本体不带吹氧装置,需要配套中频炉作业现场,制作吹氧装置,自制吹氧装置连接高压管道氧气,包括氧气减压阀、手动阀、耐压胶管和吹氧无缝钢管等部件,其中无缝钢管折成120˚~135˚弯管。

在废钢冶炼超低碳铁素体不锈钢的生产实际中,存在以下几个问题。1) 废钢中碳含量远大于超低碳铁素体不锈钢要求,对钢液进行吹氧脱碳能否降低到0.03%以下,且后续合金化等操作工艺对钢液增碳的影响。2) 铬铁在加入后钢液的烧损和增碳、增氮问题。3) 铬在氧化后形成的铬氧化物熔点高、粘度大,一方面造成钢液大量铬的损失,另一方面极易在中频炉渣线部分结壳,造成生产困难甚至中断。4) 中频炉炉衬烧结层厚度一般较小,吹氧作业极易造成炉衬局部过热和烧穿,造成漏钢事故,同时吹氧作业过程需要操作人员站立在炉口操作,吹氧脱碳过程火花喷溅易造成人员烧伤。

针对存在的问题,制定了中频炉冶炼超低碳铁素体不锈钢的生产工艺,1) 随炉配入底渣;对钢水隔热保温,防止钢液增氮。2) 钢水熔化后进行取初始样,根据钢中碳含量,制定吹氧时间。3) 吹氧时,首先打开管道阀门,保证吹氧管通畅,然后调整到吹开钢水压力,吹氧管垂直插入钢水后,边吹氧边均匀搅拌,禁止氧管直对炉衬吹氧,吹氧管熔化至一米时,更换吹氧管继续吹氧。4) 吹氧结束后取样分析钢水成分,当碳含量降低到0.03%以下后进行扒渣,加入硅铁钢水脱氧后再加入微碳铬铁,同时加入硅钙粉对顶部熔渣表面还原。5) 炉渣颜色变浅后,加入后续合金,合金全部为超低碳合金,防止钢水增碳。6) 取样、测温,合金元素成分合格后,出钢浇注;7) 熔炼过程中所用石灰、萤石、微碳铬铁经过高温烘烤,减少搅拌用钢棒用量,控制一次性纸质测温热电偶测温使用次数,减少钢水增碳。

4. 生产结果及过程分析

中频炉生产铁素体不锈钢过程中严格按照工艺路线操作,共计生产18炉,17炉成分合格,其中1炉(炉号ZP02)碳成分超出超低碳内控标准,改判为普通铁素体不锈钢0Cr13。对冶炼过程中吹氧降碳工艺过程进行在线炉前取样化验,分别抽取有代表性的四炉冶炼过程数据进行分析。数据见表1。

4.1. 吹氧降碳过程分析

在炉号ZP01中,当初始钢中C 0.045%、Si 0.008%、Mn 0.083%时,吹氧4分钟后钢中C降低为0.027%,Si降低为0.0035%,Mn降低为0.028%。说明此成分下进行吹氧作业发生了C、Si、Mn的氧化反应,可以通过吹氧降低钢中碳含量到超低碳的范围。

在炉号ZP02中,钢水初始成分C 0.057%、Si 1.21%、Mn 0.26%,吹氧8分钟后,钢中C微弱增加到0.061%,Si降低到0.47%,Mn降低到0.12%。说明此阶段进行吹氧发生了Si、Mn的氧化反应,C未参与氧化反应,通过吹氧降低钢C含量到超低碳的可行性未知。在未采取继续吹氧脱碳的工艺条件下,进行了后续脱氧、合金化任务,造成本炉次碳含量超标。

在炉号ZP06中,钢水初始成分C 0.12%、Si 0.20%、Mn 0.27%,吹氧6分钟后,C降低为0.035%,Si降低为0.0036%,Mn降低为0.026%。说明此成分下进行吹氧发生了C、Si、Mn的氧化反应;继续吹氧4分钟后,C降低为0.025%,Si、Mn几乎未发生变化。说明第二阶段吹氧主要发生了C的氧化反应。

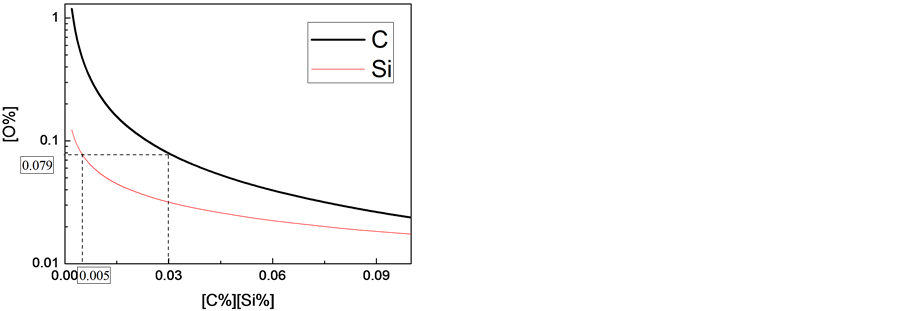

在炉号ZP07中,钢水初始成分元素含量较低。对钢水吹氧3分钟后,钢水中C、Si含量并未明显降低,C含量反而有微弱的增加。说明此成分在此环境下,钢水中碳含量达到了最低值。在吹氧时,C、Si、Mn降低程度与各自氧化反应的能力直接相关,为了表征三者氧化能力,根据三元素氧化反应化学式(1)~(3)的热力学数据 [2] ,计算出了在1 atm大气压下,1600℃时的氧化平衡图,见图1、图2。

(1)

(1)

(2)

(2)

(3)

(3)

从图1可知,同等含量下,Mn平衡氧含量最高,氧化能力最弱,C氧化能力次之,Si氧化反应能力最强,因此在吹氧时,一般首先氧化Si。在冶炼超低碳吹氧过程中,要保证C含量降低到0.03%以下,必须首先降低钢中Si含量。图2中与0.03%C平衡的氧含量为0.079%,对应Si的平衡含量为0.005%左右,要保证钢中C降低到0.03%以下,钢中Si要降低到0.005%。在炉号ZP06中当钢中Si较低时,继续吹氧,可以降低钢中C含量,而炉号ZP02中吹氧作业钢中C含量未降低。因此在采用废钢冶炼超低碳钢时,根据钢中C、Si含量决定吹氧时间,只有当钢中Si降低到0.005%左右时,在钢中吹氧才能降低到超低碳范围,钢中Si降低到0.005%是冶炼超低碳钢的必要条件。

Table 1. Date of decarburization process in medium frequency induction furnace

表1. 中频感应炉吹氧脱碳过程数据

Figure 1. Oxidation equilibrium of carbon, silicon and manganese at 1600˚C under 1 atm

图1. 1 atm、1600℃时C、Si、Mn氧化平衡

Figure 2. Oxidation equilibrium of 0.03% carbon and silicon at 1600˚C under 1 atm

图2. 1 atm、1600℃时0.03% C和Si氧化平衡

4.2. 熔渣改质过程分析

在MgO炉衬采用CaO-CaF2渣系时,钢水吹氧加入Cr后,熔渣粘度变稠,熔渣极易结壳,在进行熔渣改质后,问题得到解决。研究发现,部分Cr氧化形成Cr2O3,其熔点2275℃,与CaO形成的复合物CaO∙Cr2O3熔点高达1930℃,在氧化性顶渣中,Cr2O3与FeO形成的高熔点尖晶石相FeO Cr2O3熔点1630℃;这些高熔点高粘度的渣相造成熔渣粘度增大、熔点升高,极易造成渣顶和炉衬渣线部位结壳,严重影响了生产顺行。为此,需要对熔渣进行改质,改变熔渣组成和物相。在CaO-SiO2-Cr2O3渣系图中 [3] ,w(Cr2O3) < 5%时在CaO∙SiO2附近存在一个低熔点复合相区域,利用这一特点进行熔渣改质。

具体措施为,首先对吹氧后氧化性顶渣进行扒渣,减少渣中FeO总量;加入钢水脱氧剂、硅铁进行钢水脱氧,脱氧产物通过上浮进入顶渣,可以降低熔渣碱度;对熔渣加入硅钙粉进行扩散脱氧,加入汤道砖、中注管等破碎的粘土块进行熔渣碱度调节。根据相关文献 [4] ,使熔渣CaO:SiO2二元碱度保持在0.8~1.2之间时可以有效增加熔渣中低熔点橄榄石,减少高熔点2CaO·SiO2。此外控制初始氧化渣中Cr2O3小于5%,可以避免FeO·Cr2O3高熔点尖晶石相的析出。因此通过扒渣、添加粘土块和硅铁脱氧产物上浮,可以调整渣中碱度在0.8%~1.2%之间,降低初始渣中Cr2O3和FeO含量;利用硅钙熔渣脱氧,可以进一步还原渣中Cr2O3和FeO到1%以下,一方面大幅提高了Cr和后续合金元素的收得率,减少了钢水夹杂,另一方面达到熔渣改质的目标,使生产顺行。

5. 结论

1) 本文在中频感应炉中采用各种废钢作为原料冶炼超低碳铁素体不锈钢,进行了吹氧降碳和熔渣改质的工艺实践,结果表明,通过大气下吹氧工艺,可以使C降低到0.025%。

2) 钢中Si含量降低到0.005%是中频炉吹氧冶炼超低碳钢的必要条件。

3) 吹氧后进行硅铁钢液脱氧,配合硅钙、粘土块熔渣改质,使熔碱度渣变为0.8~1.2,降低初始FeO和Cr2O3含量,可以有效解决熔渣熔点高、熔渣结壳等生产难题。