摘要:

在Al-0.5Mg (0.5%Mg)、Al-0.5Mg-0.2In (0.5%Mg 0.2%In)两种合金中添加不同含量的Zn元素,通过多种分析测试方法,来探究Zn、In元素对合金阳极合金组织、腐蚀性能、放电性能、电化学性能的影响,并分析得出最优的合金成分。In元素对于本实验的试样是一种非常重要的元素,加入In后,铝合金阳极活化能力、电化学性能显著提高,开路电位、放电电压快速稳定;铝合金缺陷减少,表面氧化膜变得疏松且不完整;析氢自腐蚀变弱,腐蚀速率明显降低,腐蚀表面平整。Zn则能够细化合金晶粒,使铝合金组织变得致密,减少合金缺陷,抑制铝合金析氢自腐蚀;但会降低铝合金活性,随着Zn含量的增加,开路电位、放电电压正移。当In含量为0.2%,Zn含量为0.2%时,Al-0.5Mg-0.2In-0.2Zn合金具有最好的综合性能,其OCP (Open Circuit Potential)为−1.716 V (vs. Hg/HgO),腐蚀速率为0.064 mg•cm−2•min−1,10 mA恒流放电单体电池电压可达1.527 V。

Abstract:

In this paper, two alloys of Al-0.5Mg (0.5% Mg) and Al-0.5Mg-0.2In (0.5% Mg 0.2% In) were added with Zn of different contents. Through a variety of analysis methods, the impact of Zn and In ele-ment on alloy structure, corrosion property, discharge performance, and electrochemical perfor-mance of alloy anode, has been explored, and the optimal alloy composition has also been obtained by analysis. In plays an important role in this experiment; after In adding, the activation capacity of aluminum alloy anode and the electrochemical performance were enhanced significantly, while the open circuit potential and the discharge voltage were rapidly stabilized; aluminum alloy defects were reduced, and surface oxide film became loose and incomplete; hydrogen evolution corrosion weakened significantly and corrosion rate lowered. Zn can refine alloy grain, so as to make aluminum alloy organization dense, reduce the alloy defects and inhibit hydrogen evolution corrosion, but at the same time it would reduce aluminum alloy activity, and the open circuit potential and discharge voltage would positively shift as the increasing content of Zn. With the In content of 0.2% and Zn content of 0.2%, Al-0.5Mg-0.2In-0.2Zn alloy has the best overall performance; its Open Circuit Potential (OCP) is −1.716 V (vs. Hg/HgO); the corrosion rate is 0.064 mg•cm−2•min−1; and 10-mA constant discharge cell voltage can reach to 1.527 V.

1. 前言

近年,由于各个行业的不断发展,用电量逐步增加,各种因为发电造成的污染越来越严重。尤其是以煤炭、石油为主的传统能源对社会环境造成了巨大污染,这引起了人类对环境保护和新能源的关注。如今雾霾可以说是城市环境的头号杀手,雾霾不仅危害人类的身心健康,降低人类的寿命,还导致许多其他的社会问题。正因如此,推动清洁无污染的新能源汽车势在必行。而且对于家庭小范围的用电情况,铝空气电池可以发展用于替换干电池,减少对于环境的污染。铝空气电池消耗物取自于空气中的氧气,铝做为阳极材料,产物是氢氧化铝,而且氢氧化铝可以重复冶炼利用。

铝–空气电池所需的工作溶液一般有中性盐溶液或碱性溶液两种,前者主要是NaCl、NH4Cl溶液等,而后者则通常使用NaOH或KOH等溶液。中性铝–空气电池只能适用于小电流密度的放电,比如应急指示灯等;而碱性铝–空气电池则主要适用于大电流密度的放电,例如动力型电源等。典型的铝空气电池系统由铝阳极、空气阴极以及碱性或中性电解质构成,半电池电化学反应如下:

阳极:

阴极:

全电池放电反应为:

在碱性电解液中,由于铝金属在电解质中的腐蚀作用,放电时还会伴随析氢反应出现:

有相当一部分的铝与碱性电解液反应生成氢气,降低了铝阳极的利用率,同时消耗电解液影响电池寿命。

我国对铝–空气电池用的铝阳极合金材料的研究相对比较晚,大概始于20世纪80年代后期。在90年代初期,史鹏飞等 [1] 制备出了Al-Mg-In-Mn-Bi五元阳极铝合金材料,在碱性溶液中的阳极铝合金利用率达到了91%,而且在大电流放电性能比较优异。1999年,许文江等 [2] 研究二元阳极铝合金材料的性能,结果表明In、Sn、Ga、Bi这四种合金元素能够使铝阳极的开路电位负移,Ce、Mg、Bi这三种元素则能够提高铝合金的耐腐蚀性,但同时也会降低其输出电压。2003年,卢凌彬等 [3] 研究了Zn对Al-In阳极合金性能的影响,添加一定量的Zn能够有效降低阳极的极化现象并且能极大提高合金阳极的利用率。2004年,齐公台等 [4] 研究了RE元素对于阳极铝合金的性能的影响,发现了该稀土元素具有细化晶粒的作用,但是对铝阳极合金的电化学性能没有太大改善,且Al-5Zn-1Mg-0.15In-0.1Sn-0.3RE六元合金的综合性能比较好。2005年,张燕等 [5] 制备出了Al-0.2Ga-0.1Sn-1Mg四元阳极合金,他认为Sn、Ga、Mg合金元素的加入能够提高合金的电化学活性,并降低铝阳极合金的自腐蚀析氢速率和极化程度。舒方霞等制备出了比较适用于强碱性溶液的Al-Mg-Sn-Ga和Al-Mg-In-Ga-Pb等合金,发现其性能比较好。张盈盈 [6] 研究了Al-Ga-Mg系列合金,发现了当提高Ga元素的含量时,铝阳极合金的开路电位会负移,表明其活性提高。2006年,中南大学的韩红涛等 [7] 在Al-5Zn-0.05In-0.1Sn四元合金的基础上,通过添加不同含量的稀土元素Ce,来对阳极铝合金的结构和性能进行研究,发现了当Ce元素的含量小于0.5%时,其对合金的枝晶的细化作用比较好;其合金Al-5Zn-0.05In-0.1Sn-0.3Ce在25℃、4 mol/LNaOH电解液中在电流密度为50 mA∙cm−2的恒电流下铝-空气电池的放电电压达到了1.118 V。游文等 [8] 制备了Al-Ga-In-Zn-Mg-Mn和Al-Ga-In-Sn-Zn-Mg-Mn等两种成分的铝合金,之后还经过热处理再将铝合金轧制成板材,发现这些铝阳极合金在80℃、4 mol/L NaOH + 2.8 mol/L NaAlO2电解液中,铝–空气电池的电流密度为800 mA∙cm−2时其稳态电位能够达到−1.53 V以上。2008年,尹延西等 [9] 采用Al-In-Bi-Ga-Pb五元铝阳极合金作为基础,制备出了添加Mn、Mg、Sn等多种元素的多元铝阳极合金,最后得到的结果表明了当电解液温度为20℃、浓度为5mol 的NaOH溶液中,添加的Mn、Mg、Sn这三种元素都能够让铝合金阳极的电位负移,其中添加Mg元素后的合金开路电位是最负的,达到了−1.84 V (vs.SCE),但添加Mn会使铝合金自腐蚀速率增大。2010年,王乃光等 [10] 制备出了具有较好的性能的Al-0.5Mg-1Sn-1Ga-1In铝合金阳极,发现该五元合金在80℃、4.5% (wt.%) NaOH电解液中的开路电位约达到了−1.845 V,其性能非常好。2012年,张纯等 [11] 采用了正交试验法,制备出了九种Al-Mg-Sn-Hg系列的铝阳极合金并对它们进行了性能测试,最后得出的结果表明,元素Hg能够活化铝合金阳极并且能够抑制自腐蚀析氢;Sn则会影响铝合金阳极的耐蚀性;Mg则在放电过程中对铝阳极合金的腐蚀均匀性有非常大的影响。2013年,邵海洋等 [12] 制备出了具有非常不错的性能Al-0.5Mg-0.1In-0.1Sn-0.1Si五元阳极铝合金,发现该铝合金在4 mol/L的NaOH电解液中的开路电位、自腐蚀速率分别达到了−1.80 V (vs. Hg/HgO)和0.105 mg∙cm−2∙min−1。2015年,熊亚琪等 [13] 提出了铝–水体系中铝的电化学腐蚀导致铝阳极极化偏移理论,并通过实验证明了该理论的正确性,并且组装完成了使用原型离子膜空气电极的铝–空气电池,通过对其进行放电测试后得出的结果显示,当电流为1 mA时,电池恒流放电时的放电电压下降的很快,分析其原因是由于电池的正负极活性物质没有得到很充分的激活,因此恒流放电时其电极极化比较大,当电池放电半小时后其放电容量达到了0.502 mAh。2016年,王诚等 [14] 使用含Sn、Ga、In等元素的铝合金阳极,并将金属铝阳极加工成超细晶材质,发现在电解质溶液中添加铝腐蚀抑制剂可在一定程度上提高铝电极效率。

本文的研究内容主要为以Al-Mg及Al-Mg-In合金为基础合金,通过添加不同含量的合金元素Zn,制备出两个系列的铝阳极合金,并通过性能和组织测试,研究In元素和Zn元素对铝阳极合金组织、腐蚀性能和电化学性能影响。从而筛选出一个比较好的合金元素配比,力求得到自腐蚀速率小、综合电化学性能较好的铝–空气电池用铝阳极合金。

2. 实验

2.1. 实验设计

铝阳极进行合金化处理能够有效提高铝阳极的综合性能,有研究表明,当添加多种合金元素时,铝合金能够充分的发挥其中各个元素之间的协同优势,从而能够弥补只添加了单独一种合金元素所带来的不利影响。因此,相比二元铝合金阳极,多元铝合金阳极常常具有更加优异的综合性能。

有研究 [15] 发现,Mg是一种影响铝阳极电化学性能最主要的元素之一,当Mg含量较低时,其能够大大的提高铝合金阳极的电化学性能和腐蚀性能;In则对铝合金阳极自腐蚀析氢有较大的影响,In含量较高时,在强碱性电解液中铝合金阳极对自腐蚀析氢有很优秀的抑制作用。当铝合金阳极的成分为:1.0%Ga,1.0%In 0.5%Mg和1.0%Sn,时,其晶粒较细,且分散较好,并且该合金的稳定电位达到−1.845 V、腐蚀电流密度则达到11.22 mA/cm−2,析氢速率也比较低,为1.077 × 10−3 mL/(mm2∙min)。但是,单质Sn,Ga,In的价格比较高,这不仅不利于铝–空气电池的推广,还会提高铝–空气电池的成本,使得其失去成本优势。由于Zn与In相似,具有抑制铝合金在强碱溶液中自腐蚀的能力,为了达到既能降低铝合金成本的同时不降低其电化学性能的目的。本实验将采用Zn来代替部分In的方法来降低铝合金的成本。同时,Ga和Sn在电池中只是起到了一个活化作用,为了进一步节约成本,在该实验中取消这两种元素。由以上分析得出的该实验采用的成分设计如表1所示。

固定阴极不变,为了减少杂质的引入,选用99.95%的纯铝(中国铝业)作为铝合金的原料,铟锭、镁锭、锌粒(上海攀田粉体材料有限公司)的纯度分别为99.99%、99.99%,99.99%。一个直径20 mm,高80 mm的石墨材质的圆筒形模具。每炉的炉料大概需要150 g左右。根据表1中比例数据进行配料,使用酒精和丙酮将铝锭表面的油污清洗干净,并与模具一起放入干燥箱中充分干燥以去除水分。合金元素量少且熔炼时易燃烧,采用铝箔包覆(质量计算在内)。采用中频感应炉进行熔炼:

1) 将烘干且称量好的铝锭加入石墨坩埚中,打开感应炉(恒远机电中频感应炉),并调到适当的加热功率,使得铝锭在5~6 min左右全部熔化。

Table 1. The composition design of the experiment

表1. 各实验的成分设计

2) 将称量好且用铝箔包覆的合金元素迅速压入已完全熔化的铝液中,持续加热的同时不断进行搅拌使得合金元素快速熔化且保证铝液成分充分均匀。

3) 静置一分钟后将铝液上层杂质扒除,之后迅速浇入已准备好待用的两个模具中,待自然冷却后从模具中取出合金。

4) 按以上步骤将8个合金样品依次熔炼完成。

5) 将熔炼完成的各个合金试样用去离子水和酒精洗干净后待用。

6) 将合金试样用导线连接并用AB胶封装,固定表面积。

2.2. 实验数据分析

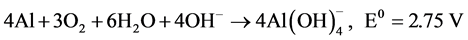

使用武汉科斯特仪器有限公司的CS电化学工作站进行测试分析,图1和图2为合金试样在4M NaOH电解液中的开路电位曲线图。从该图中可以看出,刚开始时各合金的开路电位非常低,其原因主要是合金表面存在着氧化膜,随着氧化膜的逐渐分解导致电压逐渐升高。样品的开路电压分别稳定在1# 1.870 V、2# 1.755 V、3# 1.605 V、4# 1.806 V、5# 1.756 V、6# 1.716 V、7# 1.725 V、8# 1.655 V。在1#到3#随着Zn含量的增加,铝合金的开路电压反而会降低。因为铝合金中的Mg会与Zn形成化合物,从而减少了Mg元素在铝合金中的固溶,反而会降低铝合金的开路电位。分析4#~8#可知,当In存在时,Zn的增加也会使合金的开路电位降低。通过对1#和6#、2#和7#、3#和8#进行对比可以发现,In元素的加入会使合金的开路电位降低。

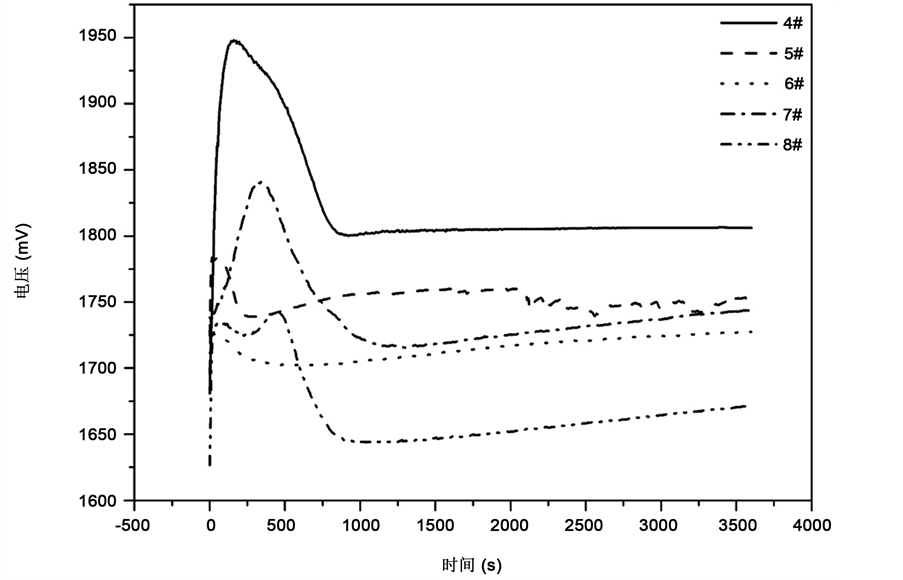

图3和图4是样品固定表面积外加恒电流10 mA放电、4M NaOH溶液为电解液时各铝合金的恒流放电曲线图。1#~3#的曲线呈现不断上升的趋势,原因是铝阳极表面腐蚀不均匀导致阳极反应面积增大,

Figure 1. Open-circle voltage of 1#-3#

图1. 1#~3#开路电压

Figure 2. Open-circle voltage of 4#-8#

图2. 4#~8#开路电压

Figure 3. Constant-current discharge of 1#-3#

图3. 1#~3#恒流放电曲线

Figure 4. Constant-current discharge of 4#-8#

图4. 4#~8#恒流放电曲线

使得曲线不断上升。可知未加In元素的铝合金阳极放电时达到稳定电位所需的时间比加入In后的铝合金要长,其原因是In能较大程度的活化铝合金阳极,使其快速达到稳定电位。对比1#、2#、3#可以得出,Zn含量的增加能使铝合金的稳定放电电位正移,Zn元素与合金中的Mg元素形成第二相从而减少了铝合金中固溶的Mg元素,使得其稳定放电电位下降。加入In后的4#~8#也呈现出稳定放电电位逐渐下降的趋势,在有In存在时,Zn元素含量的增加依然会使得合金的稳定放电电位正移。

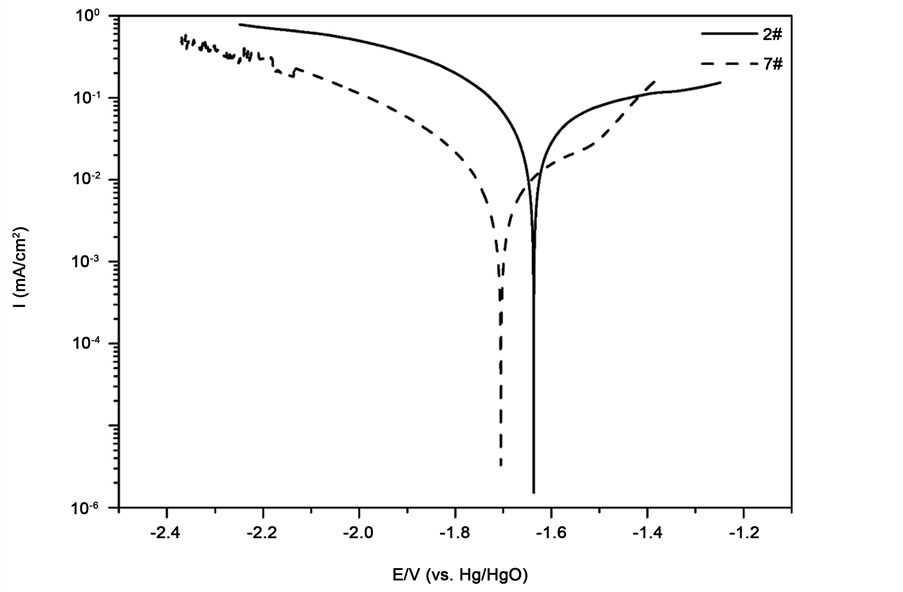

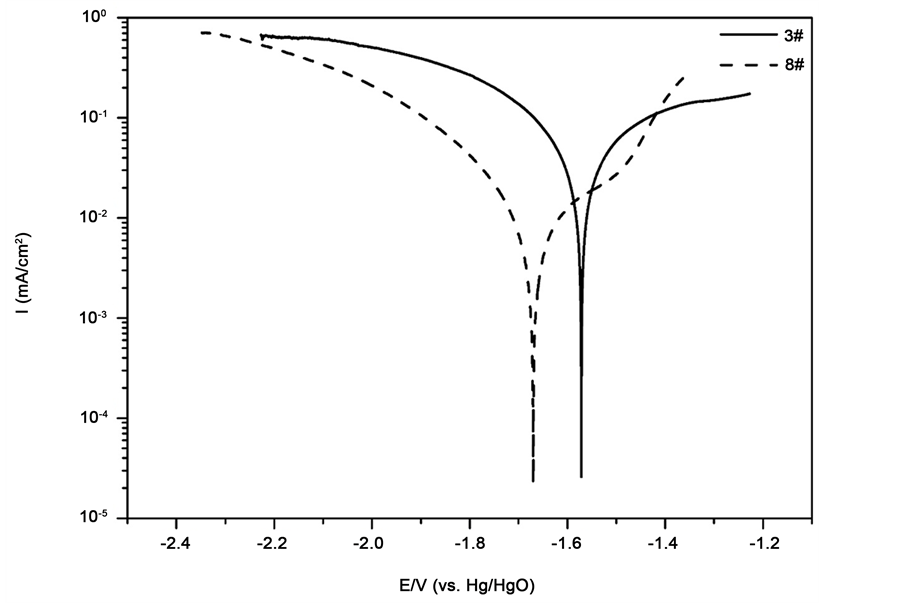

表2是对极化曲线中的各个极化曲线通过电化学工作站的Tafel外推法拟合出的各自的合金腐蚀参数。从图5、图6、表2中可以看出,随着Zn元素含量的增加,合金试样的腐蚀电位Ecorr逐渐正移,Ecorr越正,表明其合金试样更不容易发生活化分解。因此,当合金中不含Zn元素时,其活化溶解能力也是最好的。通过分析比较图7、图8、图9可以看出,向铝合金中添加0.2%的In后,阳极合金腐蚀电位负移,同时,Icorr和腐蚀速率显著减小,表明合金的活性增强、耐腐蚀性变好。在1#、2#、3#的铝合金基础上再添加0.2%的In时分别能够使阳极合金腐蚀电位负移。可见,Zn元素能够使铝合金阳极的腐蚀电位正移,降低铝合金阳极的活性,相反,少量的In元素则能使铝合金阳极腐蚀电位负移,从而增加其活化溶解能力,提高其活性。

3. 结论

In元素是一个很重要的元素,其作用有活化铝合金,提高铝合金电化学性能,破坏氧化膜并大大增加铝合金阳极抑制析氢自腐蚀能力,同时还有减少合金缺陷,促使腐蚀表面均匀的功能。Zn元素能够使铝合金组织更加致密,抑制铝合金析氢自腐蚀,但会降低铝合金活性,随着Zn含量的增加其开路电位

Figure 5. Polarization curve of 1#-3#

图5. 1#~3#极化曲线

Figure 6. Polarization curve of 4#-8#

图6. 4#~8#极化曲线

Figure 7. Polarization curve of 1# and 6#

图7. 1#6#极化曲线

Figure 8. Polarization curve of 2# and 7#

图8. 2#7#极化曲线

Figure 9. Polarization curve of 3# and 8#

图9. 3#8#极化曲线

Table 2. Thecorrosion parameters of alloy specimens of 1#-8#

表2. 1#~8#各合金试样腐蚀参数

和放电电压将会正移。当In含量为0.2%,Zn含量为0.2%时,Al-0.5Mg-0.2In-0.2Zn合金具有最好的综合性能,腐蚀速率为0.064 mg∙cm−2∙min−2,10 mA恒流放电电压可达1.527 V。

*通讯作者。