1. 引言

近年来随着我国高速铁路的快速发展,列车在高速行驶时的安全可靠性越来越被各方引起重视 [1] 。因为列车在高速运行时,车体一直处于随时间变化而重复的载荷中,即承受着交变动载,尤其是车体材料的焊接接头在交变动载中会产生微观和宏观的塑性变形,这种塑性变形会降低材料继续承载的能力并引起裂纹 [2] ,随着裂纹的逐步扩展会最终导致断裂。这种断裂现象远远没有达到材料及接头的抗拉强度及屈服强度,是疲劳断裂,这种低于设计载荷的疲劳断裂一旦发生往往是灾难性的。因为所有的疲劳断裂均在低应力水平瞬间失效,在此之前并不能被检测和发现,因此是工程应用中必须重视和研究的技术指标。

根据大量的资料统计,疲劳失效约占失效金属结构的90% [2] [3] 。在高速列车车体中,存在数量众多的铝合金焊接接头,因此接头的疲劳可靠性决定着高速列车运行的安全可靠性。大量研究表明,金属材料的疲劳性能与其表面完整性(主要包括表面硬度、残余应力场、位错密度、组织结构、表面粗糙度等)密切相关 [4] 。喷砂或者喷丸强化技术能在材料表层引入残余压应力,降低疲劳有效拉应力,阻碍裂纹从表面萌生、扩展,提高疲劳裂纹的萌生寿命;此外,较大的残余压应力具有裂纹闭合效应,能有效阻碍裂纹的扩展,提高裂纹扩展寿命。但过大的喷砂或喷丸强度,会使得材料表面的粗糙度增大 [5] ,造成局部区域应力集中,甚至产生微裂纹,成为疲劳源,从而引起材料的过早断裂。因此研究不同表面强化处理对车体铝合金焊接接头的疲劳裂纹扩展速率的影响,对预测车体铝合金焊接接头的使用寿命,保证列车安全可靠运行具有重要意义。本文以高速列车车体用A7N01铝合金MIG焊接头为研究对象,通过比较不同表面处理工艺对其疲劳裂纹扩展速率的影响,为表面强化处理工艺在车体上的应用提供数据支撑。

2. 试验材料及方法

2.1. 试验材料及焊接工艺

试验材料选用高速列车常用的铝合金材料A7N01S-T5,其中S代表挤制型材,T5代表高温成型过程中快速冷却然后进行人工时效。将型材加工成尺寸为350 mm × 150 mm × 8 mm的铝板,试板焊接采用双脉冲MIG焊,对接接头,V型坡口,单边角度为35˚,顿边为1 mm。焊接填充材料为ER5356焊丝,焊丝直径为1.2 mm。焊接保护气为纯度99.999%的高纯氩气,保护气体流量为25 L/min。为了保证焊接质量,进行焊接时环境的相对湿度严格控制在70%以下。焊前对坡口打磨清洗,去除试板表面油污和氧化膜的干扰。A7N01S-T5铝合金母材和ER5356焊丝的化学成分如表1所示,焊接工艺参数如表2所示。

焊接结束后,对焊接试板分别进行不同工艺表面强化处理,1号试板不进行任何处理;2号试板进行双面喷钢丸强化处理,钢弹丸直径为0.6 mm,喷丸覆盖率为100%;3号试板采用60目棕刚玉进行双面喷砂处理。

2.2. 试验方法

采用HVS-30型维氏硬度计测量焊接接头表面各区域的硬度值,测试点从焊缝中心向母材区域依次分布,测试点之间的间隔距离为2 mm,测试所用载荷为3 kg,载荷持续时间为15 s。采用 Zeiss-A1M 数码金相显微镜进行金相组织观察,所使用腐蚀液为混合酸溶液(体积比HF:HCl:HNO3:H2O = 2:3:5:90)。

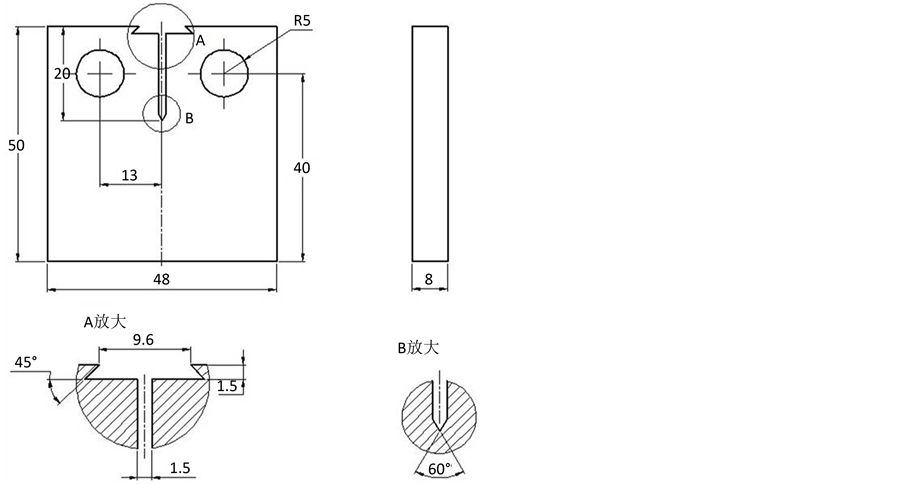

疲劳裂纹扩展速率实验根据GB/T 6398-2000《金属材料疲劳裂纹扩展速率试验方法》制取标准紧凑拉伸CT试样,试样尺寸如图1所示。预制疲劳裂纹和疲劳裂纹扩展均在疲劳裂纹扩展试验平台上进行。采用较大载荷预制疲劳裂纹,确保预制疲劳裂纹长度在1.5 mm~2.5 mm。预制疲劳裂纹结束后,采用较小载荷进行疲劳裂纹扩展,同时采用引伸计对缺口张开位移V进行测量。试验完成后将试样打断,使用体视显微镜对断口进行检查并测定预制裂纹长度和终止裂纹长度。试样预制疲劳裂纹结束后,进行疲劳裂纹扩展试验。接头各区域设置不同的加载力,加载力通过前期试验探索确定,各区域加载力如表3所示。试验数据的处理根据标准GB/T 6398-2000进行。

3. 实验结果及分析

3.1. 金相组织分析

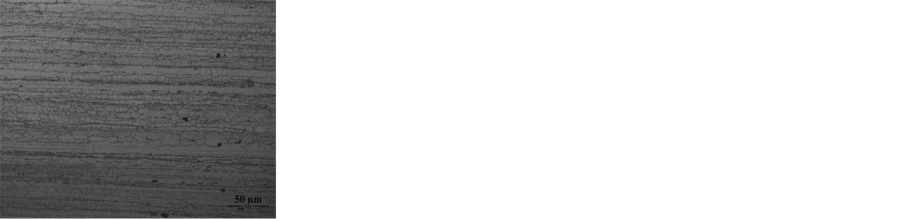

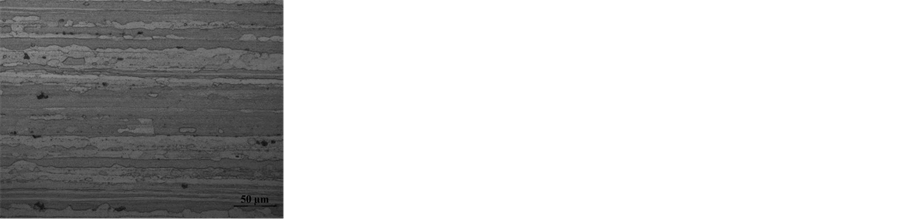

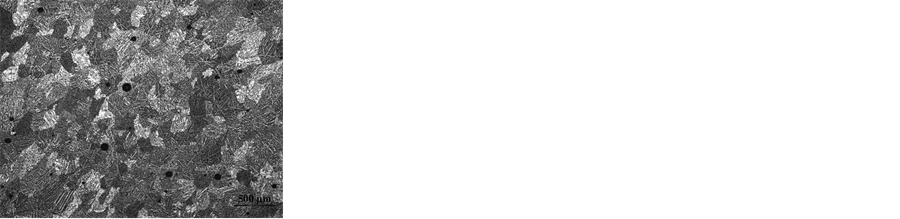

图2为A7N01S-T5铝合金MIG焊接头不同区域的金相组织。焊接接头各区域显微组织差异主要是由于焊接过程中热输入的不同以及焊丝成分与母材成分不同所致。焊缝是焊丝与母材熔化后急剧冷却而形成的结晶组织,焊接熔池的体积很小而且周边被母材金属包围,熔池内的温度梯度非常大,所以焊缝是在极大的过冷度条件下冷却结晶后的非平衡组织。焊缝组织如图2(a)所示,焊缝组织主要为均匀的等轴晶和部分柱状晶,晶粒内为雪花状的树枝晶清晰可见。此外,焊缝存在有一定量的气孔,气孔直径在10~40 um之间,气孔的存在会在一定程度上引发应力集中,对接头承载产生不利影响。热影响区的组织

Table 1. Chemical composition of base material and welding wire (wt%)

表1. 焊接母材及焊丝主要化学成分(wt%)

Table 2. Welding process parameters

表2. 焊接工艺参数

Table 3. Fatigue crack propagation test force

表3. 疲劳裂纹扩展加载力

Figure 1. Sample size of fatigue crack propagation rate

图1. 疲劳裂纹扩展速率试样尺寸

(a) (b) (c)

(a) (b) (c)

Figure 2. The microstructure of A7N01S-T5 aluminum alloy MIG welding joint. (a) Weld; (b) HAZ; (c) base metal

图2. A7N01S-T5铝合金MIG焊接头金相组织。(a) 焊缝;(b) 热影响区;(c) 母材

仍然呈现纤维状,但其形态与母材差别较大,纤维化组织明显变粗,纤维化组织内部的细小晶粒几乎消失。固溶区的纤维化组织颜色较母材明显变深,深灰色的杂质相条带难见踪迹,见图2(b)。母材显微组织如图2(c)所示,母材组织呈纤维状,组织沿挤压方向被明显拉长,在纤维化组织内部存在大量细小晶粒。在母材组织中,深灰色的杂质相条带彼此平行,清晰可见。细小的点状相为η'(MgZn2)相,η'(MgZn2)相在晶粒内弥散析出。

3.2. 不同表面处理对接头表层硬度影响

经过不同表面处理的焊接接头的表层硬度曲线如图3所示。从图中可以发现,三种处理状态的硬度曲线分布趋势基本一致,母材硬度值最高,热影响区硬度值次之,焊缝硬度值最低。焊缝因为使用的是Al-Mg系焊丝,本身强度较低,所以硬度值低。在距离焊缝中心25 mm左右的热影响区域,焊缝峰值温度较高,固溶温度以上停留时间较短,第二相部分溶解于基体,主要发生η'(MgZn2)相的聚集与长大,导致过时效现象的发生,硬度下降明显,出现软化区,硬度值降低。经过不同表面强化处理后,焊接接头各区域的表层硬度都有一定程度的提高。经过表面强化处理后,铝合金表层发生塑性形变,致使表层晶粒产生滑移,增加了亚晶粒内位错密度 [6] ,从而提高了表面硬度。其中喷钢丸处理后,接头表层硬度提高程度显著大于喷砂处理后的硬度,最大硬度值达到132 HV,这是由于喷钢丸的强度比喷砂大,试样表面变形强化程度比喷砂的大,加工硬化效果比喷砂的更强,并且在试样表面形成的残余压应力也更大,所以喷钢丸处理后的硬度比喷砂处理后的硬度高。

3.3. 不同表面处理对焊接接头疲劳裂纹扩展速率的影响

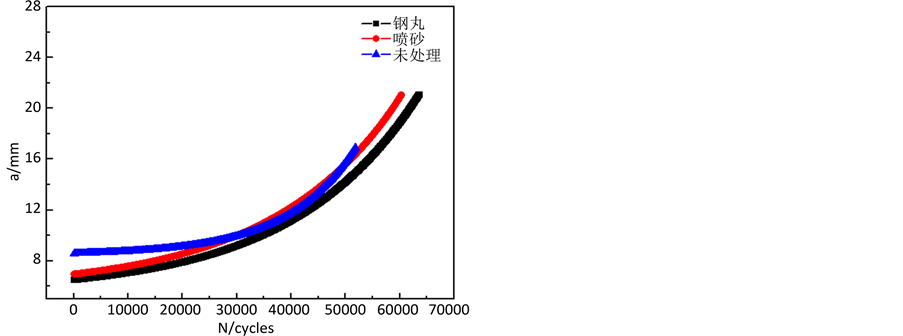

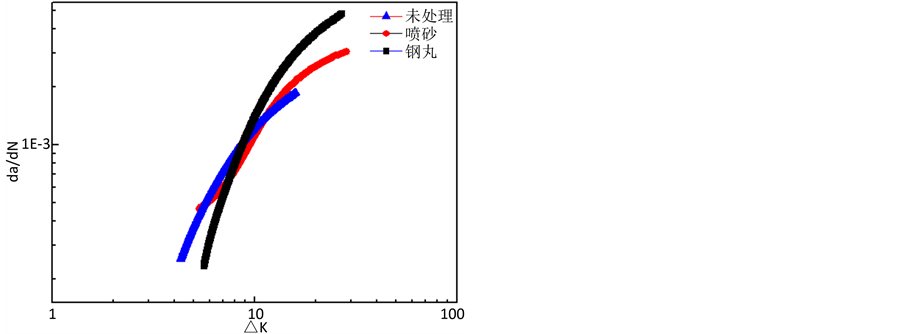

根据疲劳裂纹扩展速率试验的数据,利用origin作图软件作出A7N01铝合金焊接接头各区域经过不同表面处理后的a-N对比曲线和裂纹扩展da/dN-△K曲线。图4所示为不同表面处理后母材疲劳裂纹扩展速率对比曲线。通过各区a-N曲线的斜率可以发现裂纹扩展速率是随着循环次数的增加越来越大,见图4(a)。

A7N01铝合金经不同表面处理后母材的da/dN和∆K之间的关系置于同一双对数坐标中进行比较,如图4(b)所示。通过对比可以发现,其规律与a-N曲线分析结果一致。总体表现为疲劳裂纹扩展速率随着应力强度因子∆K的增加而不断增加,∆K为控制疲劳裂纹扩展宏观规律的主要因素。在低应力强度因子范围内,喷钢丸、喷砂、未经处理母材的初始疲劳裂纹扩展速率差值较大,未经处理的母材的疲劳裂纹扩展速率总是大于喷砂、喷钢丸处理的母材,其中喷钢丸处理后母材的疲劳裂纹扩展速率最小;但是随着应力强度因子∆K的增大,这种差值逐渐缩小,喷钢丸处理的母材疲劳裂纹扩展速率逐渐增大,并首先超过喷砂处理,而后超过未经处理;同样,喷砂处理后母材的疲劳裂纹扩展速率也随着应力强度因子∆K增大而增大,并最后超过未经处理的母材。根据Paris提出的疲劳裂纹扩展速率公式,通过线性拟合计算得到疲劳裂纹扩展速率材料常数C和m,母材喷钢丸处理后C = 6.03 × 10−7,m = 3.38,

Figure 3. Comparison of hardness of welded joints after different surface treatment

图3. 不同表面处理后焊接接头硬度对比

(a) (b)

(a) (b)

Figure 4. Comparison of fatigue crack growth rate of base metal after different surface treatment. (a) The base metal fatigue crack spreads a-N curve; (b) Base material crack growth da/dN-△K curve

图4. 不同表面处理后母材疲劳裂纹扩展速率对比。(a) 母材疲劳裂纹扩展a-N曲线;(b) 母材裂纹扩展da/dN-△K曲线

求得da/dN = 6.03 × 10−7·(ΔK)3.38;母材喷砂处理后C = 4.17 × 10−7,m = 3.41,求得da/dN = 4.17 × 10−7·(ΔK)3.41;母材未经处理C = 1.74 × 10−7,m = 3.52,求得da/dN = 1.74×10−7·(ΔK)3.52。

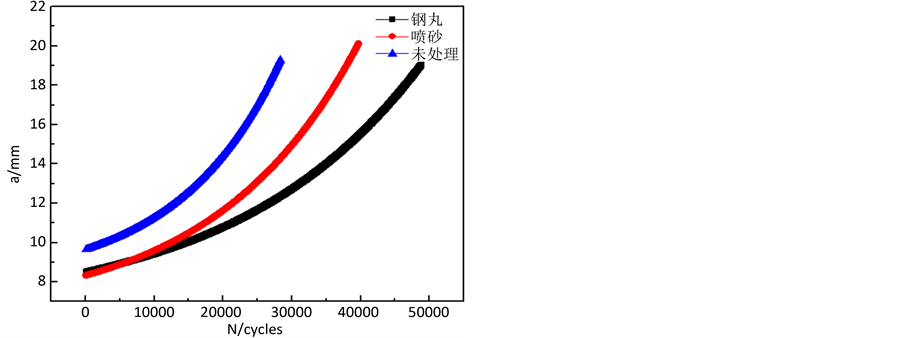

图5是不同表面处理后热影响区疲劳裂纹扩展速率的对比曲线。其中图5(a)是不同表面处理后热影响区疲劳裂纹扩展a-N曲线的对比图,从图中可以看到,热影响区的疲劳裂纹开始萌生并扩展时,未经处理的热影响区裂纹扩展速率最大,启裂时初始裂纹长度也最大,同时寿命最短;而喷钢丸处理的热影响区的疲劳裂纹扩展速率要小于未经处理的,同时寿命最长;喷砂处理后,启裂的初始裂纹长度最短,但是疲劳寿命处于喷钢丸和未处理之间。

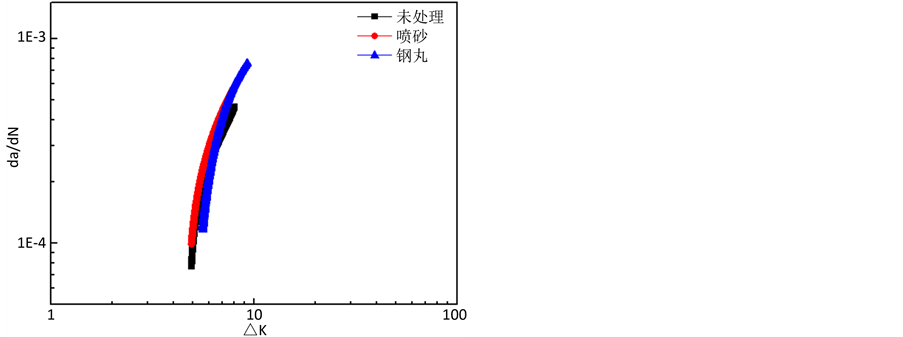

A7N01铝合金经不同表面处理后热影响区的da/dN和∆K之间的关系置于同一双对数坐标中进行比较,如图5(b)所示。从图中可以看出,三条曲线差别都不是特别大,未经处理的热影响区的曲线最靠左边,喷砂处理的曲线处于中间,而喷钢丸处理的曲线处于最右边,这说明在低应力轻度因子范围内,未经处理的热影响区的疲劳裂纹扩展速率总是大于喷砂、喷钢丸处理的影响区,其中喷钢丸处理后热影响区的疲劳裂纹扩展速率最小;但是随着应力强度因子∆K的增大,喷钢丸处理的热影响区疲劳裂纹扩展速率逐渐增大,并超过未经处理的;同样,喷砂处理后热影响区的疲劳裂纹扩展速率也随着应力强度因子∆K增大而增大,并最后超过未经处理的热影响区。根据Paris提出的疲劳裂纹扩展速率公式,通过线性拟合计算得到疲劳裂纹扩展速率材料常数C和m,热影响区喷钢丸处理后C = 2.63 × 10−7,m = 3.55,可以求得da/dN = 2.63 × 10−7·(ΔK)3.55;热影响区喷砂处理后C = 2.28 × 10−7,m = 3.58,可以求得da/dN = 2.28 × 10−7·(ΔK)3.58;热影响区未经处理C = 1.93 × 10−7,m = 3.62,求得da/dN = 1.93 × 10−7·(ΔK)3.62。

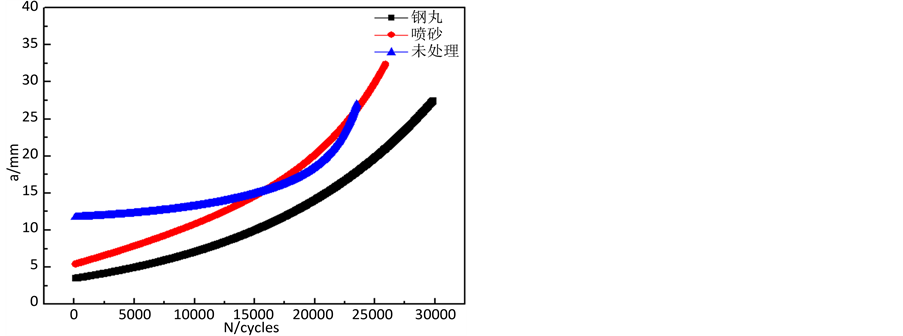

图6是不同表面处理后焊缝中心疲劳裂纹扩展速率的对比,其中图6(a)是不同表面处理后焊缝中心疲劳裂纹扩展a-N曲线的对比图,从图中可以看出,当疲劳裂纹开始扩展时,未经处理的焊缝中心的裂纹长度最大,喷钢丸的最小。

A7N01铝合金经不同表面处理后焊缝的da/dN和∆K之间的关系置于同一双对数坐标中进行比较,如图6(b)所示。从图中可以看出,这说明在低应力轻度因子范围内,未经处理的焊缝的疲劳裂纹扩展速率总是大于喷钢丸处理的影响区,其中喷钢丸处理后焊缝的疲劳裂纹扩展速率最小;但是随着应力强度因子∆K的增大,喷钢丸处理的焊缝疲劳裂纹扩展速率逐渐增大,并超过未经处理。而喷砂处理后焊缝的疲劳裂纹扩展速率刚开始时大于未经处理,但是随后被未经处理的焊缝的扩展速率超过,随着应力强度因子∆K增大,最后又超过未经处理的焊缝。根据Paris提出的疲劳裂纹扩展速率公式,通过线性拟合计

(a) (b)

(a) (b)

Figure 5. Comparison of fatigue crack growth rate of HAZ after different surface treatment. (a) The HAZ fatigue crack spreads a-N curve; (b) HAZ crack growth da/dN-△K curve

图5. 不同表面处理后HAZ疲劳裂纹扩展速率对比。(a) HAZ疲劳裂纹扩展a-N曲线;(b) HAZ裂纹扩展da/dN-△K曲线

(a) (b)

(a) (b)

Figure 6. Comparison of fatigue crack growth rate of weld after different surface treatment. (a) The weld fatigue crack spreads a-N curve; (b) Weld crack growth da/dN-△K curve

图6. 不同表面处理后焊缝疲劳裂纹扩展速率对比。(a) 不同表面处理后焊缝疲劳裂纹扩展a-N曲线;(b) 不同表面处理后焊缝裂纹扩展da/ dN-△K曲线

算得到疲劳裂纹扩展速率材料常数C和m,焊缝喷钢丸处理后C = 1.88 × 10−7,m = 3.83,求得da/dN = 1.88 × 10−7·(ΔK)3.88;焊缝喷砂处理后C = 1.61 × 10−7,m = 3.89,求得da/dN = 1.61 × 10−7·(ΔK)3.89;焊缝未经处理C = 1.13 × 10−7,m = 3.95,求得da/dN = 1.13 × 10−7·(ΔK)3.95。

3.4. 分析讨论

对A7N01铝合金焊接接头各区域的疲劳裂纹扩展速率进行对比可以发现,各区域喷钢丸处理后,在疲劳裂纹刚开始扩展时,各区域的裂纹扩展速率是最低的,但是当应力强度因子∆K增大到一定程度后,喷钢丸处理的裂纹扩展速率又将超过喷砂处理和未处理;而喷砂处理后,在疲劳裂纹刚开始扩展时,各区域的疲劳裂纹扩展速率大于喷钢丸处理、小于未处理,同样当应力强度因子∆K增大到一定程度后,喷砂处理的裂纹扩展速率将小于喷钢丸处理、大于未处理。

出现上述现象的原因是由于表面处理可以使接头各区域产生加工强化和残余压应力 [5] 。喷钢丸处理对试样的冲击强度要大于喷砂处理的,对试样的加工硬化效果也是大于喷砂处理,从处理后试样的次表面硬度变化可以看出,喷钢丸处理后试样的次表面硬度比未处理的硬度总体上都提高了20 HV,喷砂处理后整体提高了大约10 HV。外表面强化处理引入的残余压应力使得外加拉应力与残余压应力叠加合成的最大“有效拉应力”降低,即间接提高了材料本身疲劳裂纹萌生的临界应力强度幅值。当拉应力幅值小于残余压应力时(即叠加后为负值),试样表面处于压应力状态;当拉应力水平低于材料的疲劳强度极限时,试样所处的这种应力状态将阻碍表面疲劳裂纹源的萌生,延长疲劳裂纹源的萌生期,从而提高结构的疲劳寿命 [6] 。但是,当随着应力强度因子∆K增大,裂纹尖端的应力集中增大,造成的局部拉应力远远大于裂纹未扩展的时候,则残余压应力带来的优势逐渐消失;此外,表面强化处理将会造成试样表面粗糙度增加,试样表面粗糙度对疲劳裂纹有很大的影响,所以会有在疲劳裂纹刚开始扩展时,喷钢丸各区域的裂纹扩展速率是最低的,但是当应力强度因子∆K增大到一定程度后,喷钢丸和喷砂处理的裂纹扩展速率又超过未处理的。

4. 结论

(1) A7N01S-T5铝合金MIG焊接头焊缝组织主要为均匀的等轴晶和部分柱状晶,晶内位树枝晶,焊缝的显微组织与其他区域有明显差别。热影响区的组织仍然呈现纤维状,但其形态与母材差别较大,纤维化组织明显变粗,纤维化组织内部的细小晶粒几乎消失。母材组织呈纤维状,其纤维化组织内部存在大量细小晶粒,η'(MgZn2)相在晶粒内弥散析出。

(2) A7N01S-T5铝合金MIG焊接头经过表面强化处理后各区域的硬度均有一定程度的提高,其中经钢丸强化处理的接头表面硬度值最高,喷砂处理的次之,未处理的最低。

(3) 当应力强度因子∆K范围较小时,喷丸处理的接头各区域的疲劳裂纹扩展速率最低,喷砂处理的次之,未处理的最高;当应力强度因子∆K增大到一定程度后,喷丸处理的接头各区域的疲劳裂纹扩展速率增长至三者中最大,喷砂处理的次之,未处理的最低。