1. 引言

Ni3Si金属间化合物具有高熔点(Tm = 1523 K)、高强度、低密度、优异的高温抗氧化能力及抗腐蚀能力等特点,作为一种高温结构材料应用前景广阔,但研究表明限制该材料实际应用的最大障碍在于其脆性[1] -[3] 。在高温时使用的缺点是这类材料的低的延展性、低的断裂韧性及较差的高温抗蠕变性能。目前主要有无序化处理、合金化、组织控制、复合化等脆性改善措施[4] -[6] 。平衡共晶反应可以使金属间化合物和高延展性的相在液固相变时结合在一起获得共晶自生复合材料。共晶自生复合材料具有相界面结合强度高、良好的热稳定性及第二相均匀分布等优点,可以有效地改善Ni3Si金属间化合物的脆性[7] [8] 。

在定向凝固过程中,合金在一定的晶体学方向上发生取向,即择优取向。定向凝固中的择优取向是优先形核和优先长大两者相结合的原因,由于通常情况下一般都是随机形核,故可以认为是优先长大的结果。优先长大可描述为在不同晶粒中进行生长竞争时所发生的取向选择过程,取向选择的驱动力是生长过程中的各向异性,这使它按一定的方向生长,生长中的各向异性主要来自动态原子吸附各向异性、表面张力各向异性、溶质原子再分配系数各向异性和导热各向异性,它们都会对定向凝固时的择优取向产生影响[9] 。定向凝固条件下形成的定向晶体沿晶格常数最大的方向生长即晶体沿非致密方向生长,相界面能最低,所需的形核功最小。透射电镜是研究材料微观组织结构最常用也是最有效的方法之一。由于透射电镜分辨率高、放大倍数大、而且使用较为方便。因此,已被广泛的应用于材料的组织观察、结构分析、界面观察、以及未知相的确定等微观分析领域。为了明确第二相和基体相的位向关系规律,在透射电镜上进行选区操作,衍射光斑区域内样品由基体和第二相两相组成。分别选区基体,第二相,基体和第二相的界面结合处,分别获得它们两相的单个和合成电子衍射图谱。实际上,两相的合成电子衍射图就是两相晶体的倒易点阵平面的叠加。由于晶体的点阵具有对称性,两种晶体间的同一类型的取向关系可能会有多种具体的表现形式,但两相间的位向关系是确定的。因此,利用两相之间合成电子衍射图就可确定它们之间的位向关系规律。本文采用透射电镜研究了定向凝固技术制备的Ni-Ni3Si共晶自生复合材料的显微组织结构和晶体学最优生长方向。

2. 实验材料及方法

依据Ni-Si相图,配制Ni-11.5 wt% Si共晶合金,采用真空自耗电弧熔炼技术熔配母合金,线切割成Φ6 × 30 mm的试棒若干。采用Bridgman定向凝固技术制备不同凝固速率的Ni-Ni3Si共晶自生复合材料。定向凝固的试样经常规金相技术处理,采用5%的盐酸 + 水 + 氯化铁溶液腐蚀,然后采用OLYMPUS GX51光学电镜观察凝固组织特征和相形态及分布。由于凝固速率R = 40 µm/s时得到的组织取向性好而层片间距较小,因此选取凝固速率为R = 40 µm/s时的Ni-Ni3Si共晶组织试样。研究表明定向凝固的Ni-Si合金中有亚稳相Ni31Si12,因此对试样进行900℃退火30分钟,得到具有Ni相和Ni3Si两相的稳定共晶组织[7] ,线切割成Ф6 × 2 mm试样若干,经砂纸打磨成20~50微米厚的试样,将试样用环氧树脂粘在Φ3 mm的铜网上,放入Gatan PIPS 691离子减薄仪中,减薄4小时,获得透射电镜样品。采用JEM-200CX型透射电镜观察Ni-Ni3Si共晶的组织形貌和选区电子衍射获得的衍射花样。

3. 结果与讨论

对未定向凝固(真空自耗电弧熔炼)以及Bridgman定向凝固后的Ni-Ni3Si复合材料的初始过渡区及稳态生长区进行分析,如图1所示。其中黑色相为基体Ni相,白色相为化合物相[10] 。

图1(a)表明未定向凝固的组织为树枝晶组织,这是因为在真空自耗电弧熔炼时热流的方向性不明显,所以获得的是树枝晶组织。在定向凝固起始阶段择优取向表现较弱,难以获得规则排列的共晶复合材料结构,组织非常粗大且取向不明显,如图1(b)所示。而当晶体生长趋于稳定时,在高温度梯度定向凝固条件下,在系统要求降低界面能的趋势推动下,择优取向的晶体生长需要的过冷度较小,使晶体中两相逐步转向有利的择优取向,使所有晶体沿一个方向生长,如图1(c)所示。研究表明,共晶两相间的特殊位向关系和最小相间界面能有关,而优先长大方向和固–液界面能有关,凡是有利于最小固–液界面能的晶向均为长大的优先取向。

Figure 1. Microstructure of the Ni-Ni3Si eutectic composite [10] : (a) As-cast alloy; (b) Transitional zone; (c) Stable growth zone

图1. Ni-Ni3Si共晶复合材料的组织形貌[10] :(a) 未定向凝固组织;(b) 定向凝固的初始过渡区;(c) 稳态生长区

图2是在透射电子显微镜下的凝固速率为R = 40 µm/s时的Ni-Ni3Si共晶组织,从图中可以明显的看出,定向凝固Ni-Ni3Si共晶为规则层片状共晶组织。

晶体长大的速度与晶向有关,晶体长大的优先方向是密排晶面所形成的锥体的主轴方向。晶体生长时这些方向的生长线速度是最大的,这是由于液相原子易于向固相原子排列密度较小的晶面上聚集堆放,所以在垂直于这些晶面的方向上晶体长大速度最大。原子排列密度较小的晶面,其原子配位数较少,易于以粗糙界面形式出现,其长大按粗糙界面的连续长大方式进行,因此长大速度很快。对于不同的晶系,其晶体学长大方向是不一样的。

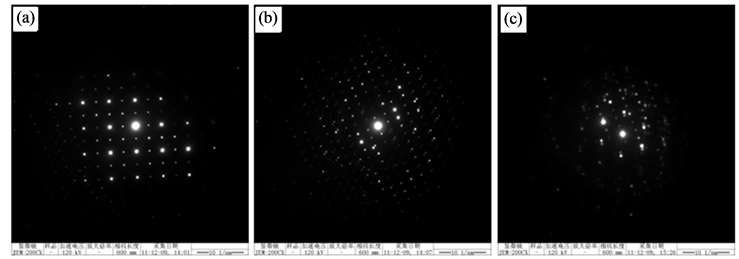

图3为Ni-Ni3Si共晶组织定向凝固试样在透射电子显微镜上作选区电子衍射获得的衍射斑点图。其中图3(a)-(c)分别是基体相Ni、Ni3Si金属间化合物相、Ni与Ni3Si金属间化合物相相界面结合处的衍射花样。

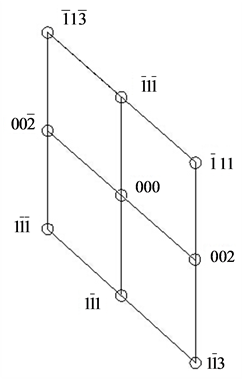

采用尝试–校核法[11] 并借助Carine软件在单晶衍射花样标定的基础,对基体Ni相和Ni3Si金属间化合物相的衍射花样进行标定,分别获得基体Ni相和Ni3Si金属间化合物相的晶面指数,再根据右手螺旋法则计算晶带轴的方向。并根据两相的晶面夹角来标定两相结合界面的位向关系。如图4所示,其中O为基体Ni,·为Ni3Si金属间化合物相,其晶体学择优方向为[110]Ni//[211]Ni3Si,( )Ni//(

)Ni//( )Ni3Si。因此Ni相的[110]和Ni3Si相的[211]重合,且相应的倒易投影面重合。

)Ni3Si。因此Ni相的[110]和Ni3Si相的[211]重合,且相应的倒易投影面重合。

Figure 2. Microstructure of the Ni-Ni3Si eutectic observed by TEM (R = 40 µm/s)

图2. 透射电子显微镜下的Ni-Ni3Si共晶组织形貌(R = 40 µm/s)

Figure 3. The electron diffraction patterns: (a) Ni matrix; (b) Ni3Si compound; (c) The interface between Ni and Ni3Si

图3. 电子衍射图:(a) 基体相Ni;(b) Ni3Si金属间化合物相;(c) Ni与Ni3Si相界面结合处

(a) Ni基体相 (b) Ni3Si金属间化合物相

(a) Ni基体相 (b) Ni3Si金属间化合物相 (c) 两相结合界面

(c) 两相结合界面

Figure 4. The calibration results of the electron diffraction patterns

图4. 电子衍射图的标定结果

低界面能是自生复合材料具有高稳定性的条件,低能界面由合适的原子互相匹配和两相之间原子密度几乎相等的择优取向的晶面组成。定向凝固时那些优先生长的方向与轴向温度梯度一致时,其长大速度最快。在具有一定抽拉速率的温度梯度场内,各取向晶体竞相生长,在生长过程中抑制了大部分晶体的生长,保留了与热流方向大体平行的单一取向的柱状晶继续生长,有的直至铸件顶部。因此,在层片状Ni-Ni3Si共晶中,二相间有着一定择优取向,表明共晶两相长大方向在某一晶体学方向上是优先的,这种择优取向是由系统自动减小其总界面能所致。定向凝固共晶复合材料的界面形状和相的分布都具有规则性,意味着其组成相之间必有择优的取向关系。这种特殊的结晶学关系的存在已被组成相之间低界面能的界面形成所证实,并且已用来解释许多自生复合材料具有高的热稳定性的现象。Cantor [12] 研究了自生复合材料在定向凝固过程中产生特殊的结晶学关系的现象,指出可能存在介于两相的严格取向外延生长和完全独立生长之间的行为,而且在择优结晶学关系的倾向性与显微组织的规则性之间很难建立起某种联系。他认为许多自生复合材料的横截面形状和相的分布都有规则性,这就是说其组成相之间必有择优的取向关系。

4. 结论

1) Ni-Ni3Si共晶是具有层片组织的规则共晶组织,规则排列的Ni3Si化合物均匀分布在Ni基体上。

2) Ni-Ni3Si共晶的晶体学择优方向为[110]Ni//[211]Ni3Si,( )Ni//(

)Ni//( )Ni3Si,系统的自由能最低,自生复合材料具有高的稳定性。

)Ni3Si,系统的自由能最低,自生复合材料具有高的稳定性。

致谢

感谢国家自然科学基金委、陕西省科技厅、西安建筑科技大学对该研究的资助。感谢西北工业大学凝固技术国家重点实验室的杨新宇博士、王海峰博士对实验分析的支持与帮助。

基金项目

国家自然科学基金资助项目(51201121);陕西省自然科学基础研究计划项目(2012JQ6004);西安建筑科技大学科技计划资助项目(RC0907)。