摘要:

针对大型设备吊装干涉碰撞、吊装操作人员难以操作、吊装人员风险高、工艺路径难以优化等难题,采用三维实体模型,虚拟真实的吊装环境,引入人机工程,分析模拟吊装过程。通过对主辅吊车站位、设备摆放、吊装工艺路径、人员配置、人员操作等优化,清晰再现了模拟吊装过程,在较短的时间内一次性完成吊装,降低了吊装操作人员的风险,实现了吊装的高效行、安全行和合理性,节约了吊装成本。

Abstract:

Hoisting collision, difficult lifting operation, high risk for lifting operators, difficulty in optimization of process path are all problems of large equipment hoisting. By using 3D solid model, inventing real lifting environment, and introducing the ergonomics, we analyzed and simulated the hoisting process. Through optimizations of main and auxiliary cranes’ position, equipment’s placement, hoisting process, staffing, and personnel operation, we clearly reproduced the simulation process of lifting. In a relatively short period of time, we completed a one-time lifting, reduced the risk of lifting operation, realized the efficient, safe and rational operation, and finally saved the lifting cost.

1. 引言

随着我国石油化工、煤化工、煤液化的高速发展,石油化工装置中的关键设备向重型、大型方向发展。采用重型吊车或液压吊装系统是我国当前发展的方向,以双机抬吊法或三机抬吊法成为吊装主流工艺。大型设备的吊装,应考虑人的因素。人员的站位、人员的操作往往带有一定的风险性,这些风险因素应尽可能的降低。在有限空间内吊装,操作人员的可操作性、可达性对吊装至关重要;复杂结构件的吊装,需要操作人员配合起重吊车完成,人员的站位、操作应达到最合理的优化配置。吊装技术是石油石化工程建设施工领域的核心技术,目前在大型塔器吊装领域一直存在着吊装方案确定周期长计算精度低、吊装过程预判难、过程模拟真实性差、地面加固计算误差大等难题。具体的吊装领域存在的问题有:

目前在吊装分析模拟领域,存在软件种类繁杂且功能单一、兼容性差、重复建模的问题。

解决外形不规则和结构复杂设备的重心惯性矩、强度稳定性和局部应力等手工计算精度差、效率低的难题。

解决吊装真实过程中干涉情况无法预判的难题。

提前发现和解决吊装过程中偏心引起的设备旋转以及翻转作业引起的冲击载荷,避免吊装中碰撞和吊车折臂等事故发生。

解决因履带吊车接地比压估算不准引起的吊装场地加固不足的难题,避免吊车倾覆事故发生。

CO2吸收塔自重为222 t,内径为Φ3000 mm,高度为359,300 mm,壁厚66 mm + 3 mm。梯子平台自重为12 t,工艺管线自重为6 t。吊装时吸收塔总重为240 t。吸收塔距离周围构筑物最近为5 m,场区构筑物多,四周有地上管廊,吊装作业环境复杂。通过人机工程模拟,吸收塔吊装一次完成,实现了精确、高效、安全、合理的吊装,节约了吊装成本。

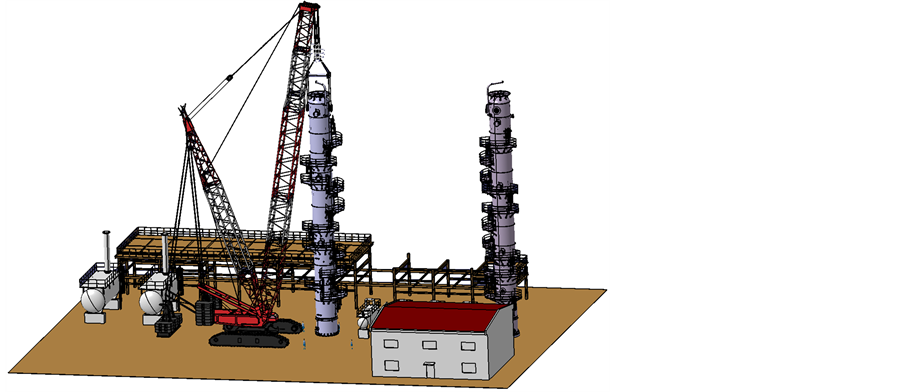

2. 吊装虚拟仿真技术

吊装虚拟仿真系统是将仿真与虚拟技术应用于吊装领域。利用软件平台建立三维实体模型模块,在交互界面中进行装配,按照真实的环境位置约束和固定各模型模块的几何位置,对整个吊装过程模拟、验证、对比和优化,进而采用数字化手段制定和修改吊装方案,并逐步取代传统的吊装方案编制方法,如图1 [1] 。

三维实体模型模块包括起重吊车模型模块、大型设备模型模块、设备附件模型模块、平衡梁模型模块、索具模型模块、周围构筑物模型模块等。建立多种结构不同的模型模块,保存相对应的目录下,通过参数修改法生成新的模型,即在软件中利用已有的模型通过修改模型参数的方法得到新模型,节省了

Figure 1. Virtual simulation system of lifting

图1. 吊装虚拟仿真系统

建模时间,提高了工作效率。在软件中直接导入各模型模块,快速的生成虚拟环境 [2] [3] 。

3. 人机工程的引入

在DELMIA软件内,把建立的人体模型引入到虚拟环境模型结构中,对整个吊装过程进行人机工程分析。不仅仅设备要进行运动分析,而且要对操作人员在吊装过程中的行走路线、人员的姿态、操作人员的动作进行全面的模拟。

针对大型设备的吊装过程,开发了设备吊装的人机工程分析软件模块。软件共分3个模块:

1) 大型设备吊装分析人体模型工作台;

2) 大型设备吊装人体分析工作台;

3) 大型设备吊装任务模拟工作台。

4. 人机工程应用

在吊装过程中,吊装路径周围的构筑物、管廊等应设为关键点,配置监护人员,以防止设备磕碰。指挥信号的传递、起重吊车司机的视野往往会给大型设备吊装带来风险,这决定了吊装指挥人员之间的站位、视野范围的重要性。大型设备吊装需要操作人员配合、检查,具有偏心结构的大型设备在吊装时需要牵引机牵引、人力配合;底部带螺栓孔的大型设备在钢丝绳下降就位前,需要操作人员旋转大型设备一定的角度,符合施工工艺图纸;有限空间内吊装时,操作人员的可操作性、可达性配合会影响吊装的顺利实施。因此,吊装过程的虚拟仿真,人力的合理布置、操作配合,操作人员实现可操作性、可达性,人员风险的降低,实现吊装的高效、安全,是人机工程研究的重点。

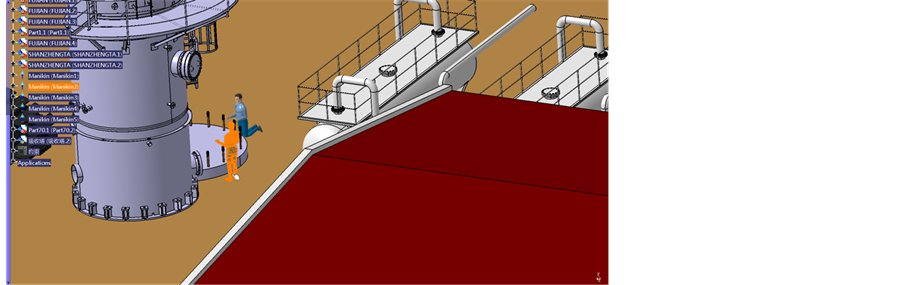

4.1. 大型设备吊装分析人体模型工作台

在虚拟吊装环境中,进入大型设备吊装分析人体模型工作台,调入人体模型,合理的布置人员,并给定每个人员的视野。吸收塔在吊装过程中,需要人员旋转配合,观察吊装高度;设备底部与地脚螺栓顶部必须有一定距离。图2为虚拟环境人体模型插入,图3为人体模拟位置局部放大图。

4.2. 大型设备吊装人体分析工作台

人体模型插入后,分析人员的操作性、可达性。人体分析工作台主要针对人体的视野、人员的动作、

Figure 3. Local amplification model of the human body position

图3. 人体模型位置局部放大

人员的站位进行合理的优化。操作人员的视野范围,周围构筑物的阻挡都会通过人体模型的眼睛视觉观察显示出来,尤其是起重吊车司机的视野。在虚拟环境下模拟视野调整、指挥,获得全面的视角。图4、图5为对操作人员分析,确定人员站位、视野。

4.3. 大型设备吊装任务模拟工作台

进入大型设备吊装任务模拟工作台,根据运动学原理对整个吊装过程进行人机工程模拟。人员的指挥、操作配合与吊装运动模拟相结合,实现人机工程一体化、规范化,指导吊装的顺利完成。图6为人机工程模拟图,吊装指挥人员指挥操作,图7操作人员操作视野图。

5. 实时干涉检测

碰撞检测的目的是判断虚拟环境中不同对象之间是否干涉。从几何上讲,碰撞检测表现为两个结构体在运动过程中相交重合。虚拟场景中的碰撞检测计算,包括起重吊车与大型设备之间的相交检测,以及起重吊车、大型设备与周围环境的相交检测。在吊装过程中,当两个结构体发生碰撞时,碰撞部位高亮显示,并提示是否继续进行模拟。干涉检查方法请参考文献 [3] [4] 。

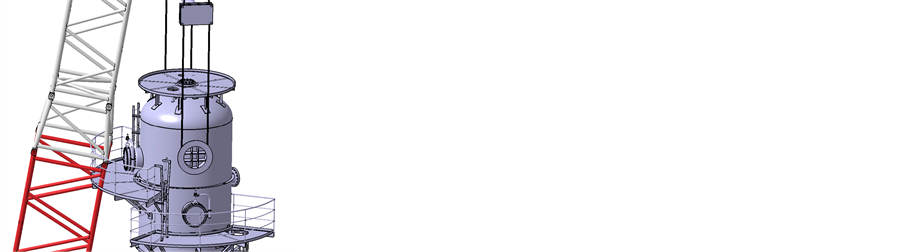

吊装前,为了降低施工成本,需要将塔的梯子平台、工艺管线,甚至连保温铁皮都会在地面进行安装后整体吊装,给吊装增加了难度。因此,需要对吊装过程分析(主辅吊车桅杆、钢丝绳和履带与大型设备产生干涉),旋转过程分析(大型设备与周围环境干涉和地脚螺栓之间的干涉),大型设备下落就位分析(大型设备下部的排污管与地脚螺栓干涉)。

在吊装前中,单独依靠人为的判断是否存在结构件之间的干涉是不够的。只有在虚拟环境中,通过人机工程模拟吊装过程,进行实时干涉检测,确保大型设备的安装就位,避免了高空作业。提前发现问

题,对吊装方案进行改进优化。

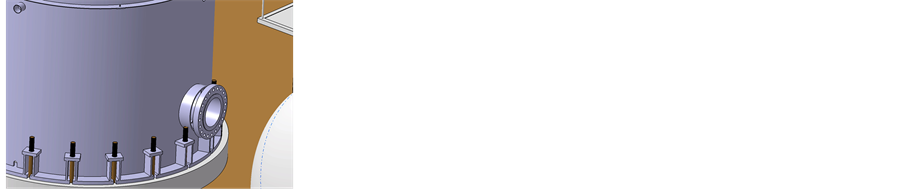

图8表示在吊装过程中,设备梯子平台在吊装前已经拆除一部分,大型设备旋转就位时,随着设备旋转过程中,梯子平台与臂杆发生了干涉,这在吊装之前是发现不了的,因此,这部分梯子平台应该提前拆除。图9表示在设备就位穿过地脚螺栓时,地脚螺栓过长,局部与设备本体干涉,设备无法就位,螺母无法安装。因此,两个地脚螺栓应提前切割,确保了吊装顺利完成。

6. 人机工程输出文件

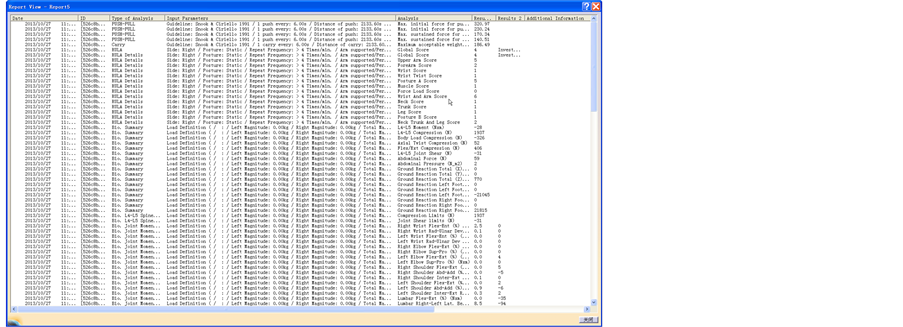

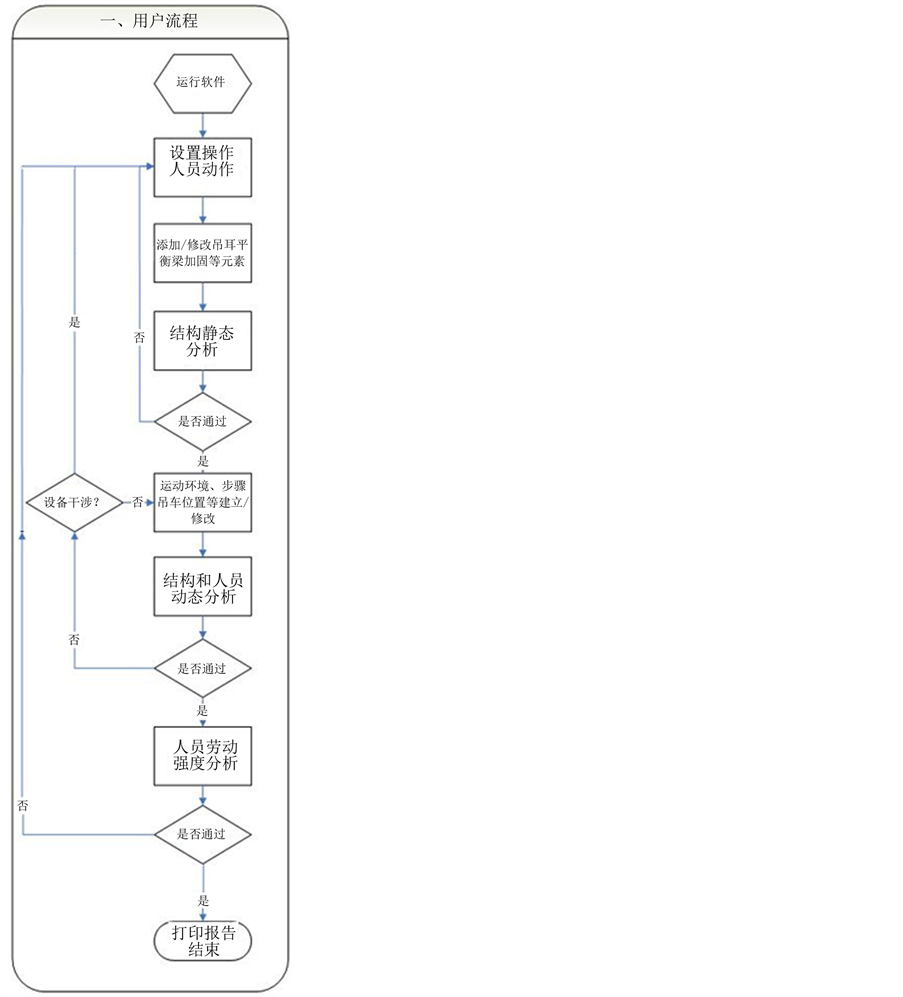

人机工程输出文件包括人机工程报告、仿真视频录像、图片、起重机站位与立面图等。人机工程模拟完成后,所有人员的动作参数均能生成报告。对于生成后的报告,可以在DELMIA软件内查看,也可以使用文本编辑器,在其他的编辑器,如WORD、记事本、写字板内查看,如图10所示。根据人机工程模拟过程生成吊装录像、图片,进行指导施工。软件的整体人机工程分析流程图如图11所示。

Figure 8. Ladder platform interfere with crane main bar

图8. 梯子平台与起重机主杆干涉

Figure 9. The anchor bolts interfere with absorption tower

图9. 地脚螺栓与吸收塔干涉

Figure 10. The ergonomics engineering analysis report

图10. 人机工程分析报告显示

Figure 11. Flowchart of the ergonomics engineering analysis

图11. 软件的整体人机工程分析流程图报

7. 结论

通过人机工程应用于大型设备吊装,全视野、全方位模拟操作人员在吊装过程中的行走路线、人员姿态及动作,清晰再现了模拟吊装过程,实现了吊装关键部位和环节的全面覆盖,解决了诸如高空人员难以检查、过程干涉难以发现,人为动作可操作性判断困难等技术难题,节约了吊装成本,实现了吊装的高效性、安全性、可行性和合理性。对于需操作工人所完成的一些动作操作,在计算上人机模拟。当操作工人实际操作时,只需按照人机工程模拟的动作和过程进行操作即可完成。提高了操作工人的效率,增加了操作工人的熟练度。并广泛应用于施工前培训和指导施工。