1. 引言

陶瓷材料是既钢铁、有色金属、有机材料之后的第四大材料。氧化锆陶瓷材料由于其具有低密度、高强度、高硬度、低膨胀系数以及耐磨、耐腐蚀、隔热、化学稳定性好等优良特性,在能源、航天、计算机,机械加工等领域日益显示出广阔的应用前景,是工程材料和功能材料常用的陶瓷材料[1] [2] 。使用氧化锆制成的坩埚可加热到2430℃,在冶炼稀有、难熔贵金属及合金方面无可替代。钇稳定氧化锆陶瓷与人体具有高度生物相容性,同时又具备高强度的特性,作为医疗种植体广泛应用在医疗卫生领域。全稳定的氧化锆氧传感器具有良好的氧离子导电性,使得在汽车尾气和电厂燃煤锅炉的燃烧控制上起到决定作用。在日常生活领域,氧化锆可制成各种刀具取代传统金属刀具,有陶瓷钢的美誉。

陶瓷制造水平的好坏主要取决于陶瓷粉体的制造,高性能、微细晶粒的陶瓷粉体是决定陶瓷生产和制造水平的关键环节。以往生产氧化锆粉体以电熔法、化学法为主。近年随着技术不断进步,逐步被化学共沉淀法、水解水热法、有机凝胶网格法等先进的纳米粉料制造方法所取代。这样制造出的氧化锆粉体,晶粒尺寸更加细小,晶型生长更加完整,使氧化锆陶瓷制造水平得到飞速发展。本文主要介绍化学共沉淀法、水解水热法以及有机凝胶网格法等粉体制造方法。

2. 化学共沉淀法

包含一种或多种离子的可溶性盐溶液,当加入沉淀剂(如 ,

, ,

, 等)后,或于一定温度下使溶液发生水解,形成不溶性的氢氧化物、水合氧化物或盐类从溶液中析出,并将溶剂和溶液中原有的阴离子洗去,经热分解或脱水即得到所需的氧化物粉料。该方法可分为共沉淀法、均匀沉淀法[3] 和多元醇沉淀法。其中共沉淀法又可分为单相共沉淀法[4] 和混合物共沉淀法[5] 。

等)后,或于一定温度下使溶液发生水解,形成不溶性的氢氧化物、水合氧化物或盐类从溶液中析出,并将溶剂和溶液中原有的阴离子洗去,经热分解或脱水即得到所需的氧化物粉料。该方法可分为共沉淀法、均匀沉淀法[3] 和多元醇沉淀法。其中共沉淀法又可分为单相共沉淀法[4] 和混合物共沉淀法[5] 。

以ZrOCL2∙8H2O为基体溶解于去离子水中,达到饱和状态,溶好后的溶液通过320目的尼龙滤网,过滤掉ZrOCL2∙8H2O中的杂质,根据需要制造的氧化锆品种确定YCL3的数量(不同YCL3加入量可制造出3Y,5Y,8Y等不同稳定性的氧化锆)。

氯化钇选用分析纯试剂,YCL3溶解于温水中,将ZrOCL2∙8H2O和YCL3的混合溶液置于反应器中,用搅拌机匀速搅拌,直至两种液体充分融合,再用雾化器将NH3∙H2O雾化并喷入反应器中,使ZrOCL2∙8H2O和YCL3混合液在反应器中迅速反应,形成沉淀Zr(OH)4和Y(OH)3。通过搅拌机匀速搅拌,使Zr(OH)4和Y(OH)3混合均匀。

反应刚开始时由于生成沉淀物较多,搅拌较为困难,可适当降低搅拌机转速,提高搅拌机功率,随着搅拌的持续进行,混合原料会很好的悬浮于液体中,保持连续搅拌30分钟以上,直至混合的悬浊液达到细腻的粥状,这样可使氧化钇在后续的物相反应中更好的与氧化锆形成稳定的立方相或四方相,从而达到稳定氧化锆的目的。

反应完成后,将反应后的物料加入高速离心机脱水、脱氯。其中脱氯过程相对比较困难,需多次反复加入去离子水冲洗,并通过高速离心机脱水。对高速离心机甩出的水分采用硝酸银溶液(稀硝酸酸化)检测,如有白色沉淀产生,说明氯离子未完全脱掉,需继续加入去离子水冲洗,直到检测中没有白色沉淀产生为止。

将脱水、脱氯后的物料放入同材质的匣钵中加热烧制到1000℃。烧制过程中升温要缓慢,并保证炉温均匀,使氧化钇和氧化锆充分融合,形成均匀的固溶体。

化学共沉淀法无法使氧化锆完全由单斜晶型转化为稳定的立方或四方晶型,其转化率可达到75%~95%。在稳定好的粉体中,含有部分单斜氧化锆,单斜氧化锆的含量将对后续陶瓷制品的性能产生影响,所以在使用中有必要通过X射线衍射光谱(XRD)对材料中单斜相的含量进行分析。单斜相含量过高,在制造过程中会产生相变,进而导致陶瓷体积发生变化,这种体积的改变会使陶瓷体产生微小裂纹,从而导致产品碎裂。煅烧使材料脱水,同时氧化钇和氧化锆会结合形成稳定的四方或立方晶型。烧制过程中材料会板结在一起,晶体在微观结构上产生团聚现象。通过透射电子显微镜(TEM)观察,晶体互相团聚,形成尺寸大约在100纳米的晶体。为避免产生较大尺寸晶体,此时需将烧制好的物料放入气流磨中充分研磨,使其成为细粉,尽可能破坏其团聚结构,为下一步造粒提供基础粉体,并最终形成钇稳定纳米氧化锆气流粉体。

采用共沉淀法制作氧化锆粉体颗粒,需加热至1000℃,在此温度下会使氧化锆晶粒过度生长,对下一步生产制品时产生不利影响。用此方法生产的3Y氧化锆粉体,稳定性较低,在高温、高湿环境中抗老化性能较差。

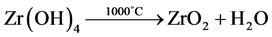

由图1、图2可看出粉体有团聚现象产生,晶粒直径为100纳米左右,随着粉料经气流磨研磨,团聚现象得到改善。

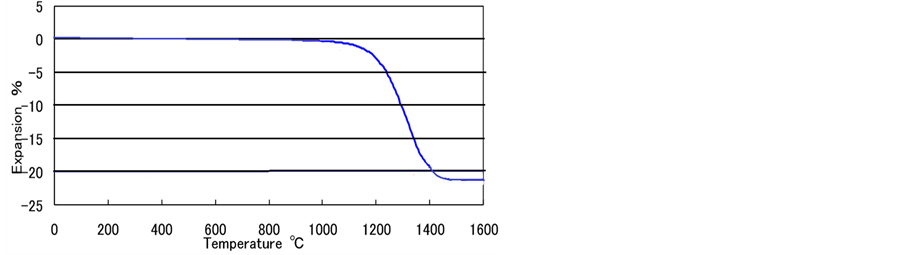

由图3可看出氧化锆制品烧结密度随着胚体密度提高而提高,直到接近其理论密度。

反应方程(未配平)

3. 水热法制备氧化锆粉

通过在高温高压下的水溶液或水蒸气等流体中进行有关化学反应,是制备和改善无机材料产物的先进而成熟的技术。自1982年开始用水热反应制备超细微粉的水热法己引起国内外的重视。目前水热合成法制备晶体己经实现了工业化生产,并成为单晶生产的主要方法之一[6] 。水热法可分为氧化水热、沉淀水热、合成水热、还原水热、分解水热和结晶水热等力一法,适用于纳米金属氧化物和金属复合氧化物陶瓷粉末的制备与合成。

共沉淀法制备氧化锆粉体,由于结晶温度高,造成晶粒生长较大,对制造陶瓷制品有较大的影响。水热法可解决共沉法的不足,其生产配料与共沉法完全一致(不再详述)。工艺方面,主要将ZrOCL2∙8H2O和YCL3的混合溶液置于高压反应釜中,同时喷入NH3∙H2O,并迅速搅拌,生成共沉体。保持反应釜搅拌机持续运行30分钟后,对反应釜加温至200℃,同时加压至1.8 MPA,进行均匀搅拌使其充分反应。在加压条件下氢氧化锆在200℃时分解为氧化锆,同时与氧化钇发生物相反应。由于反应时温度和压力合适,可直接生成氧化钇稳定氧化锆。此过程反应温度较低,有一定压力,可生成具有良好的四方或立方晶型的晶体,晶粒发育完全,晶粒尺寸细腻,稳定度高。制造出的粉料经脱水、脱氯可得到下一步生产的物料。水热法中物料脱氯过程还是较为复杂,需用离子水反复冲洗,同时用稀硝酸酸化的硝酸银溶液检测冲洗后的水分,直到没用白色沉淀为止。经过高速离心机甩干后的原料经烘箱烘干即可得到高品质的纳米氧化锆粉体。水热法由于粉料没有经过高温煅烧,不会产生过度团聚,省去了后续的气流磨的

Figure 1. Zirconia powder morphology by coprecipitation method

图1. 共沉淀法稳定氧化锆粉体形貌

Figure 2. Zirconia particle size distribution by coprecipitation method

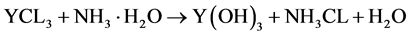

图2. 共沉法稳定氧化锆粒度分布

Figure 3. Sintering performance by coprecipitation method

图3. 共沉法稳定氧化锆(3Y)烧结性能

过程,且形成的粉料晶粒团聚较小(0.1微米),团聚粒径比采用共沉法小很多。

后续造粒过程中,水热法生产的粉体,由于粒径较小,在液体中分散时,粒子受到的各种作用(重力、

液态介质之间作用、粒子自身的布朗运动等),对粒子在液体中分散影响很小。小颗粒粉料可提高粉料在液体中的稳定度,使得各种有机体可均匀包裹粉料。这样造粒形成粉料,在后期陶瓷体成型,烧结环节都会比较容易。

从图4、图5看出,水热法形成的粉体粒度较小,分散性很好,粉料之间很少团聚。

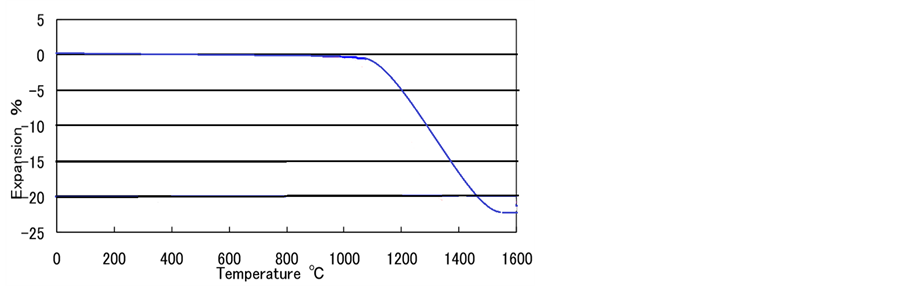

从图6看出,氧化锆制品烧结密度随胚体密度提高而提高,直到接近理论密度,烧结温度更低。

4. 凝胶网格法

凝胶网格法生产纳米氧化锆,是采用凝胶固相反应合成复合粉体技术。生产设备简单,效率高,只是无法达到水热法的生产效果。其工艺技术路线为:

Figure 4. Zirconia powder morphology by hydrothermal synthesis

图4. 水热法稳定氧化锆粉体形貌

Figure 5. Zirconia particle size distribution by hydrothermal synthesis

图5. 水热法稳定氧化锆晶体粒度分布

原料(纳米单斜氧化锆,氯化钇,去离子水,有机单体,交联剂,分散剂等)→搅拌并充分混合→形成稳定高固相浆料→加入引发剂→凝胶化→煅烧合成→气流磨碎→喷雾造粒→成品粉料。

凝胶网格法主要依靠原料通过接触面进行元素扩散来完成。在选择氧化锆粉体时需粒度细,比表面积大的粉体,这样可以加快反应速度,使元素充分扩散。

凝胶主要是有机单体和引发剂反应使凝胶固化,交联剂起空间网格结构,其煅烧温度为600℃,比共沉法煅烧温度低,晶体生长的不会太大。由于煅烧会带来粉体间团聚、板结,所以在煅烧后需用气流磨进行研磨,使其成为细粉。通过X射线衍射光谱(XRD)分析可以看出有较完全的晶型转化。凝胶网格法无需脱氯,生产成本大幅降低。

5. 氧化锆粉体造粒

采用上述方法制备的氧化锆粉体通过气流磨研磨,得到粒径大约2 u的粉体,加入去离子水,同时加入2.5%WT的PVA(聚乙烯醇)作为结合剂,0.3%WT的硬脂酸作为润滑剂,0.2%WT的DEHP作为塑化剂,0.3%WT作为分散剂(中京油脂公司提供)均匀搅拌。通过超声分散,使粉体没有形成团聚,有机材料均匀包裹在粉体颗粒上,使其固含量达到30%VOL,同时使固体物质充分悬浮于液体中,将混合的液体通过压力喷雾,在雾滴下落过程中迅速干燥,由于表面张力的作用使干燥后颗粒成现圆球状。从图7、图8看出,

Figure 6. Sintering performance by hydrothermal synthesis

图6. 水热法稳定氧化锆(3Y)烧结性能

由此生成的粉料具有很高的流动性,使后续装填复杂模具极为简单,得到稳定的造粒粉体。

通过上述方法制造的氧化锆粉体,微观为多晶微晶结构,晶型生长完整,晶粒细腻。粉体适用于生物陶瓷产品,可用来制作不同的氧化锆陶瓷,产品具有高强度,高抗老化性,高韧性等良好特性。

6. 方法对比

共沉淀法:沉淀剂的过滤、洗涤剂溶液的PH值、浓度、水解速度、干燥方式、热处理等均影响微粒的大小。操作简单,易引入杂质,难以制备粒径小的纳米微粒。

水热法:水热条件下离子反应和水解反应得到加速和促进,使一些在常温常压下反应速度很慢的热力学反应,在水热条件下可实现快速反应。生成粒子纯度高、分散性好、晶形好且大小可控。

凝胶网格法:特别适合于制备非晶态材料。化学均匀性好,纯度高,颗粒细,可容纳不溶性组分或不沉淀组分,体材料烧结性差,干燥时收缩大。

7. 展望

纳米材料在各个学科应用都十分广泛,随着技术不断进步,必然会有更新更好的制备方法,希望能在结构、组成、排布、尺寸、取相等方面有更大的突破,制备出适合各领域发展需要,有更多功能的纳米材料。本文主要目的在于找到一种合适的方法,制备出具有良好特性的氧化锆粉体。晶粒尺寸、晶型对氧化锆后期成品有较大影响。如果制备出晶型生长完整,晶粒细腻的氧化锆粉体,可以大大的提高气敏材料的选择性及稳定性,纳米氧化锆制备方法的一个重要方向就是提高粒度的控制能力。