1. 引言

在钢中加入一定量的钛,可以细化晶粒,显著提高钢的强度和其他特性[1] -[3] 。但将金属钛直接加入到钢中十分困难。因为金属钛比重低(仅为4.5 g/cm3,而铁的比重为7.8 g/cm3),熔点又高(1690℃,而铁的熔点为1535℃),又易氧化,直接加入会在钢液面上大量氧化烧掉,且不易控制含量,因此不适合以纯金属状态在炼钢时直接加入。为此冶金工作者们研究制出了金属钛和铁的合金,即“钛铁合金”,以钛铁合金的形式将其加入到钢中。钛铁合金根据含钛量不同可分为三种[4] :低钛铁合金(含钛量~30%);中钛铁合金(含钛量~40%);高钛铁合金(含钛量~70%)。高钛铁合金由于熔点低(1070℃~1130℃),比重适宜(5.4 g/cm3),含杂质量少,最适合用作特种钢冶炼的脱氧精炼剂和晶粒细化剂,它在提高军用、航空等高级合金钢的质量方面,有着不可取代的作用,是一种质量导向合金。

近年来包芯线喂丝法在钢铁精炼中得到越来越广泛的应用[5] ,该法是将铝、硅钙等精炼剂以金属丝的形式迅速插入到钢液不同深度位置,不但能提高合金组元的收得率,而且能够实现其在钢液中的均匀分布,对钢材的晶粒细化和晶粒均匀化起到重要的作用。因此,如果将高钛铁合金制成粉体,再加入到钢管中制成钛铁合金包芯线,辅以喂丝机就有可能将钛铁合金直接插入到钢液不同深度位置,不但能提高钛的收得率,而且能够实现钛在钢液中的均匀分布,同时钢的微观晶粒会显著细化、均匀化,并显著提高钢材的强度和耐蚀性能,这也是目前冶金领域研究热点之一,即“氧化物冶金”[2] 。我国作为钢铁生产大国,整体冶炼技术水平已达到世界先进水平。但在高端合金钢、结构钢等深加工方面,与欧美发达国家相比仍存在较大差距。目前所能生产的各类结构用钢和合金钢性能与发达国家存在较大差距。这与我国特钢整体精炼水平较低有关,目前特种钢冶炼尚未大规模采纳国外发达国家普遍应用的包芯线精炼工艺,同时适合包芯线用的高质量超细钛铁合金粉体还是空白。因此,开发低氧低残留高品质超细钛铁合金粉规模化生产方法是满足我国未来特种合金钢精炼需求的必然选择。

目前,国际市场对高钛铁合金(含钛~70%)的需求量较大,发达国家高钛铁合金使用比例已达钛铁合金总需求量的70%以上,且多采用包芯线喂丝法添加,而我国高钛铁合金的使用量仅为钛铁合金使用总量比例的10% [1] [6] 。2015年中国炼钢用钛铁合金预期需求量在50万吨以上,按照发达国家的高钛铁占钛铁合金70%比例(钢铁精炼的必然要求)估算,要满足中国当前不锈钢、管线钢、汽车板钢、船板钢需求,若都采用先进的包芯线喂丝技术话,每年将有35万吨左右的高钛铁合金包芯线缺口。

2. 国内外高钛铁合金的应用现状

2.1. 国内外高钛铁市场概述

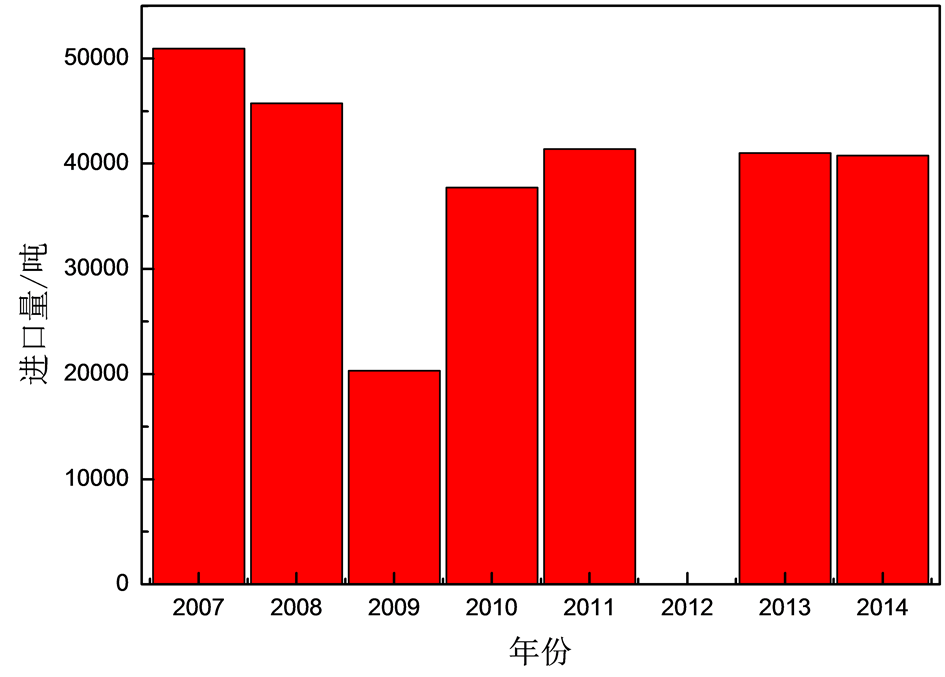

图1是欧盟2007~2014年高钛铁进口量 [7] 。由图1可以看出,2008年以前世界高钛铁的需求量强劲,其中2007年进口量为50,945吨,2008年为45,734吨。但是2008年以后世界高钛铁合金市场陷入低迷状态,2009年以后高钛铁合金的需求量显著降低,2009~2011年欧盟市场高钛铁合金的交易量分别为20,321吨,37,755吨,41408吨;美国2012年进口量7200吨。近两年欧盟高钛铁市场有所回暖,基本维持在40,000吨左右。

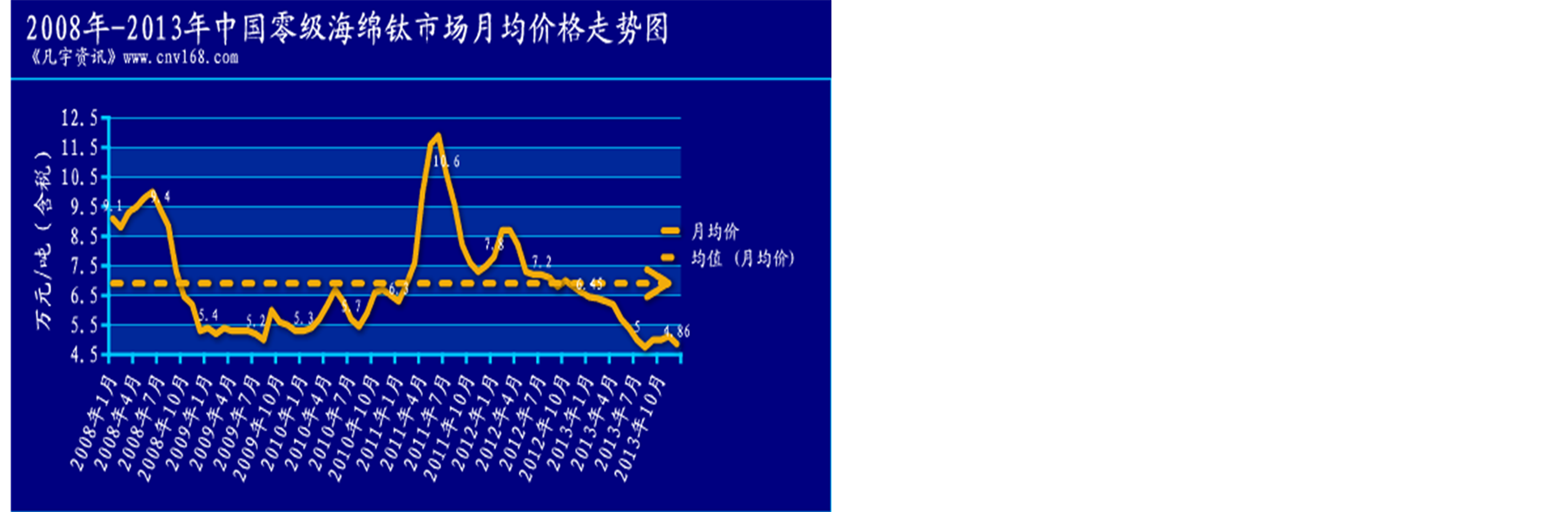

与2007年以前世界高钛铁合金市场的火爆市场相比,2008年以后世界钛铁合金市场进入了寒冬期。例如,2005年高钛铁合金价格一度飙升到21美元/公斤(合人民币20万元/吨以上)以上,一度跌到3美元/公斤左右(见图2)。这对中国的炉外铝热法生产的高钛铁合金企业是一个致命打击,2005年前后曾经如

雨后春笋建立起来的生产线,几乎一夜之间全部关停,广西、四川、辽宁等地的炉外铝热法生产线相继关闭。曾经一度因价格优势走俏欧美市场的中国炉外铝热法高钛铁,因产品中氧含量高(高达12.0%以上),

Figure 1. Imports of high titanium ferro of EU from 2007 to 2014

图1. 2007~2014年欧盟高钛铁进口量

Figure 2. Price trend of high titanium ferro of the world since 2005

图2. 2005年以来世界高钛铁价格走势[7]

铝、硅残留高,遭到众多厂家退货。例如,北海特种铁合金公司一次被退回400吨,最终该公司2008年不得不把其5000吨产能的高钛铁生产线全部关停。目前,国内外已无炉外法高钛铁生产线。

目前,炉外铝热法只能生产中、低钛铁等低端产品,且越来越多的厂家采用炉外铝热法取代传统的矿热炉碳热还原法生产低碳残留的中、低钛铁。我国钢铁工业所采购钛铁精炼剂绝大多数是采用矿热炉碳热还原法和炉外铝热法生产的30 TiFe (低钛铁)及小部分40 TiFe (中钛铁)。现有钢铁企业采购的高钛铁也是采用废钛材为原料真空重熔法生产,采用的中频炉或真空炉等。尽管国外也以废钛为原料采用真空重熔法生产高钛铁,但是国外的高钛铁质量明显优于中国的高钛铁的质量,尤其是铝、硅、锰等残留量明显低于中国的高钛铁(详见表1和表2),铝、硅残留量高已成为限制其在特种钢精炼中应用的技术瓶颈。

Table 1. Grade and composition of ferrotitanium of China (GB/T3282-2012)

表1. 我国钛铁牌号及成分(GB/T3282-2012)

Table 2. Grade and composition of ferrotitanium of international/ASTM A324-08 (2013)

表2. 国际钛铁牌号和成分/ASTM A324-08 (2013)

*化学成分中除钛外各元素均为最高极限。

国外还有采用有衬电渣炉冶炼高钛铁的[8] [9] ,其氧含量可以降低到1%以下,甚至有报道说可以控制到0.5%以下。而我国高钛铁的氧含量高达2%~4%。因此,中国的高钛铁与欧美相比毫无竞争力。尽管受钢铁行业不景气的影响,高钛铁价格在走低,但发达国家高钛铁价格仍维持在5.6美元/公斤(人民币35,000元/吨),而国内价格仅为人民币30,000~32,000元/吨之间,差距明显。由此可见,产品质量差已成为制约我国高钛铁行业发展的技术瓶颈。

从目前国内外高钛铁价格走势看,并不是理性或者合理的价格,价格偏低也是造成高钛铁市场低迷的直接原因。原因来之两个方面:一是近年来上游海绵钛价格一直走低,废钛材价格处于低价位运行。图3是2008年以来海绵钛价格走势,可以看出2012年以来海绵钛价格已低于6.5万元/吨的合理价位。尽管2015年以来海绵钛价格有所回升,但仍处于4.5万元/吨左右的成本价运行。二是下游钢铁企业的刻意压价是造成高钛铁价格低迷的根本原因。由于钢铁行业不景气,钢铁企业一直在压缩生产成本,他们通过提高钛铁质量指标(比如钛含量降低要降价,铝硅残留量升高要降价)来刻意压低价格,加上我国高钛铁本身质量不理想,因此价格一直走低,这是极不正常的。但未来随着钢铁行业回暖及特种钢的市场需求量越来越大,可以预计2016年以后,高钛铁及其包芯线价格应回到4.8~5.0万元/吨的合理价位。加上未来特种钢等对低氧、低残留等高品质高钛铁的强劲需求,高钛铁及其包芯线价格有望回到5.5~6.0万元/吨的理性价位时代。

图4和图5是国内典型钢厂采购不同品位钛铁精炼剂采购量一个对比情况。图4列举国内几个典型钢厂高钛铁的采购量,首钢高钛铁的月采购量最大仅200吨,其余都在80吨以下。图5某典型钢厂2014年某月份低钛铁采购量,与高钛铁采购量不足百吨(除首钢外)相比,国内钢厂低钛铁的消耗量远大于高钛铁消耗量。即使是同一个企业低钛铁的消耗量也明显大于高钛铁的消耗量,比如鞍钢低钛铁消耗量是高钛铁消耗量的5倍,河北钢铁低钛铁消耗量是高钛铁消耗量的将近4倍,而建龙钢铁全部采用低钛铁(月采购量高达700吨)。

深层分析低钛铁消耗量远大于高钛铁消耗量的原因,根本原因是高钛铁质量不理想(氧含量高是根本),而不仅仅是表面上看到的低钛铁绝对价格。我国高钛铁氧含量过高,造成实际精炼温度偏高钛、收率偏低,综合效果并不理想。因此大多数企业退而求其次而采用中、低钛铁。那些必须采用高钛铁的企业对高钛铁的质量提出了苛刻要求,比如涟钢(涟源钢铁)、鞍钢、马钢(马鞍山钢铁)等明确提出高钛铁低碳、低硅等要求,一旦不能满足,他们就会大幅压价。因此,开发规模化生产低氧低残留高品质高钛铁是我国高钛铁工业未来发展的关键所在,也是保障我国钢铁工业快速发展的必然选择。

我国生产钛铁产品的企业主要分布在辽宁、河南、四川、江苏、河北、山东、广西广东、北京、上

Figure 3. Price trend of sponge titanium of China from 2008 to 2013

图3. 2008~2013年中国海绵钛价格走势

Figure 4. High titanium ferro purchases of typical steel Co. in some month of 2014

图4. 典型钢厂2014年某月份高钛铁采购量

Figure 5. Low titanium ferro purchases of typical steel Co. in some month of 2014

图5. 典型钢厂2014年某月份低钛铁采购量

海等地,其中辽宁有59家、河南31家、四川30家、江苏29家、河北27家、山东22家、广西14家。行业集中度低、技术水平落后已成为制约钛铁工业发展的关键。目前高中低三个系列总产量超过5000吨/年的企业几乎没用。高钛铁厂家主要集中在辽宁、河南等省,产量超过千吨/年的企业也没有。因此,实现钛铁工业的规模化发展,尤其是高品质钛铁规模化生产是实现其可持续发展的关键。

2.2. 国内外高钛铁产品概况

国家标准GB/T 3282-2006中钛铁主要有30,40,70等不同钛含量的钛铁合金,并依据杂质含量细分为7个牌号。国家标准GB/T 3282-2012中对钛铁标准进行了重新修订,主要包括30,40,50,60,70和80等不同钛含量的钛铁合金,并依据杂质含量细分为十五个牌号,其化学成分见表1。

目前国内消费市场并没有做如此细分,国内钢铁企业招标采购仍旧按照30、40、70等三个系列进行区分,目前也没有厂家在规模生产50、60、80系列的钛铁合金。国内80系列的钛铁合金应该是抚顺特殊钢等企业由于对钛铁中残留杂质要求苛刻,实际采购不到符合其精炼用的高品质高钛铁,而变通使用的纯钛丝包芯线,采用喂丝法加入可以将钛铁精炼剂直接插入到钢液不同深度位置,不但提高了钛收得率,降低了成本,而且能够实现钛在钢液中的均匀分布。因此,如果将高钛铁合金制成粉体,再加入到钢管中制成钛铁合金包芯线,辅以喂丝机就有可能将钛铁合金直接插入到钢液不同深度位置,不但能提高钛的收得率,而且能够实现钛在钢液中的均匀分布,对钢材的晶粒细化和晶粒均匀化起到重要的作用,钢材的晶粒细小化和均匀化直接影响钢材的强度和耐蚀性能,所以高钛铁合金是特钢冶炼过程的一种质量导向合金。使用包芯线加钛生产工艺可以制得高质量的、性能均匀的特种合金钢。在欧美发达国家,其军工用合金钢、各类结构钢和高端船舶用钢的晶粒细化和钛元素添加均采用包芯线喂丝法进行,而我国由于钛铁合金生产方法落后,尚无法大规模生产高端合金钢所需要的高钛铁合金粉体。因此,开发低氧低残留高品质超细钛铁合金规模化生产方法,尤其是用来生产不同品位钛铁包芯线用高品质超细钛铁粉末规模化生产方法,是满足未来特种合金钢精炼的必然选择。

目前发达国家国际钛铁牌号和成分仍旧按照ISO 5454-1980(E)标准,进行区分,最新的国际标准为ASTM A324-08(2013)标准,钛铁依化学成分分为四个等级,见表2。按产地主要分为欧盟和俄罗斯两个主要地区,其中俄罗斯的高钛铁中铝残留量偏高,这是真空重熔精炼过程中加入铝脱氧造成的,因此俄罗斯的高钛铁价格也是偏低的。这与我国的钛铁标准是有明显区别的,目前我国钛含量55%以下的中、低钛铁的发展趋势是以金红石为原料采用炉外铝热还原法直接制备,因此其中铝、硅、锰残留量都明显放宽。即使是钛含量大于60%的高钛铁,其中铝的控制标准也在放宽,这也是为了满足真空重熔精炼过程中加铝脱氧的需求。因此,当国际高钛铁市场的低迷时,我国铝热法高钛铁彻底失去了价格优势,不得不相继关闭。

3. 高钛铁生产方法

3.1. 真空重熔法制备高钛铁 [8] - [10]

重熔法是目前工业上制备优质高钛铁的唯一方法,该法以废钛材或海绵钛为原料加铁重熔,一般采用感应炉重熔,也有用自耗电极电弧炉冶炼或通保护气体在电炉中用辐射热熔炼或用钢水兑海绵钛生产高钛铁。美国是世界上钛轧制以及航空加工件废料最多的国家,日本残钛主要以钛加工材废料为主,欧洲则以大量的航空加工件废料为主。因此,像俄罗斯、西欧等发达国家主要采用真空重熔法生产高钛铁。其技术指标如表3所示。实际情况是俄罗斯的高钛铁中氧含量控制较好,但铝残留量偏高。

该法生产的高钛铁质量稳定,近年来重熔法工艺有了新的发展,出现了有衬电渣炉熔炼制备高钛铁的工艺,试验工艺如图6所示。该工艺是结合电渣重熔的原理和优点发展而来的,随着重熔精炼工艺的优化,制备的高钛铁的品质进一步提高,据报道高钛铁中的氧含量可控制在0.1%的超低水平,很好地满足了军工、航天等领域对优质高钛铁的需求,该工艺目前并没工业化推广应用。

我国重熔法生产的高钛铁氧含量、铝残留量都偏高,因此国外几乎已不再进口中国的高钛铁,国内市场的高钛铁价格受其质量影响,一路在下跌,目前已有厂家报出26000元/吨低于其成本价的超低价格,这是极不正常的,因此废钛材原料成本在上涨。同时受废钛材来源有限的影响,我国重熔法生产高钛铁企业规模都较小,500吨/年规模的企业都很少,因此其产品质量波动大,严重恶化了其生存空间。

3.2. 炉外铝热还原法 [11] - [13]

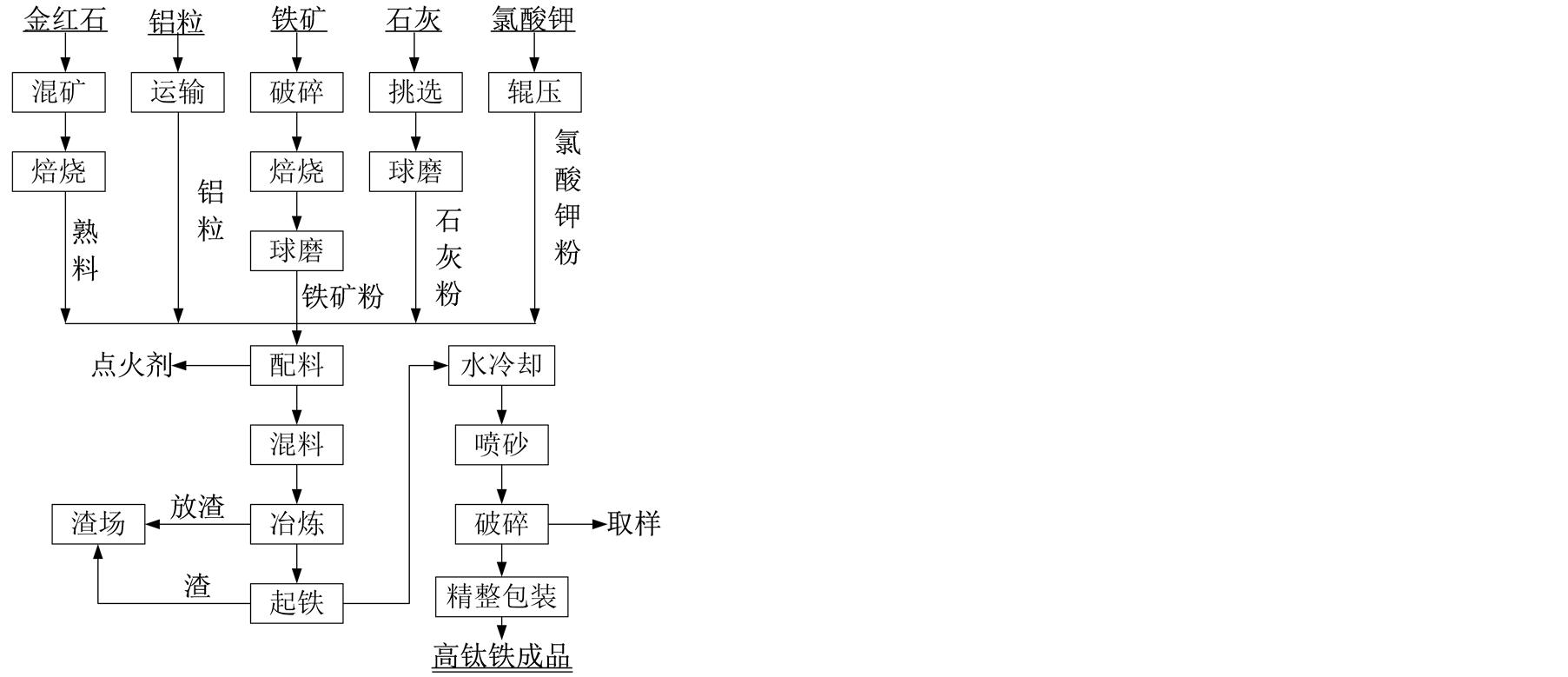

金属热还原法是用金属(如铝、镁、钙等)做还原剂还原另一种金属的氧化物从而得到金属产品的方法。由于还原反应放出的能量,能保证反应的顺利进行和渣金分离,而不需要在电炉里冶炼,故也称炉外法。又因为此法在绝大多数情况下是用铝做还原剂,故又称为炉外铝热法。但现在许多厂家已在电炉内进行还原生产,电-铝热法已逐渐代替了炉外铝热法。铝热法生产钛铁的原料有钛精矿、铝粒、铁矿、石灰和发热剂,铝热法生产高钛铁的流程如图7所示。

Table 3. Standards of high titanium ferroalloy via remelting method (mass%)

表3. 重熔法制备高钛铁的技术指标(质量分数%)

Figure 6. Flow diagram to produce high-titanium-ferrous via remelting process

图6. 重熔法制备高钛铁工艺流程

Figure 7. Flow diagram to produce high-titanium-ferrous via aluminothermy

图7. 铝热还原法制备高钛铁试验工艺示意图

钛精矿首先在回转窑中进行干燥预处理,除去其中的水分和有机杂质。同时利用焙烧后所含的热量增加混合炉料的温度,提高炉料的单位热效应值。所用铝粒平均直径为0.6~1.5 mm,过细的铝粒含Al2O3相对增加,阻碍反应顺利进行。过粗会减少反应物间接触面积,没有参加反应的铝进入合金从而使合金含铝量增大。硅化物的形成能有效阻止铝化物的生成,这既可使铝的还原作用增加,又可以使铝尽可能少进入合金中。所以采用含有适量硅的A3牌号铝对提高钛铁各项指标有良好作用。通过添加硅铁也可起到相同的效果,并调整合金成分。

石灰作为溶剂配入炉料中。CaO能与反应生成的Al2O3结合形成复杂氧化物铝酸钙,从而降低炉渣的熔点,改善其流动性。此外,CaO的碱性强于TiO,可阻止TiO与Al2O3的结合,有利于提高钛的回收率。钛铁生产所用的石灰应为新烧石灰,块状存储时间不得超过24 h,粉状不得超过8 h。

用铝热法还原金红石中的各种氧化物,其单位炉料反应热在2037.75kJ·kg−1左右,而炉料中的石灰和过剩的铝都会降低整个炉料的单位热效应,为了使铝热反应能自发进行,得到好的经济技术指标,就必须提高单位炉料反应热量。一般采用氯酸钾作为发热剂进行补热。实际情况是传统的炉外铝热还原法生产的高钛铁存在着氧含量高,钛的回收率低,以及Al、Si等杂质元素含量不达标等缺点。其中氧含量高达5%~10%,有的甚至超过10%,这是重熔法和铝热还原法生产高钛铁的最大的差别。

2005年前后在国际高钛铁市场牛市时,炉外法高钛铁在我国得到了极大的发展,辽宁、山东和广西等地建立了大量的铝热法生产线。四川峨眉铁合金厂以含TiO290%左右的天然金红石为原料,采用炉外铝热还原法生产高钛铁,经20 kg级、200 kg级和500 kg级等三个阶段半工业性试验,取得了较佳工艺技术条件和较好的技术指标,生产出含钛73.77%的高钛铁,钛的回收率达到78.83%,但产品中Al含量较高,Mn、P、S、C等含量不稳定。2008年随着北海特种铁合金公司2000吨/年高钛铁生产线的关闭,国内外已没有以金红石为原料采用炉外法生产高钛铁合金工厂,仅有一些厂家进行过小规模试验或生产。目前,中国在采用铝热法生产低钛铁和中钛铁取得了不错的效果。

北京有色金属研究总院通过选用适当的原料,采用炉外铝热还原法制得了质量较好的产品,除氧含量外,其余成分全部达到出口产品的要求。但产品中氧含量很高,在4%~8%范围内,研究了多种脱氧方案均未获成功。国外也有炉外法生产高钛铁合金的报导,南非Mintek公司采用直流转移等离子加热的铝热还原制备高钛铁试验,在隔绝空气条件下进行可降低氮含量,但不能降低氧含量,因此认为一次还原不能制取低氧含量的高钛铁[14] [15] 。

3.3. 新型铝热还原直接制备低氧高钛铁

由于铝热还原法生产高钛铁的工艺简单、设备投资低、生产成本仅为真空重熔法的三分之二,因此多年来一直备受关注。尤其是在中国,受废钛材来源的制约,真空重熔法生产高钛铁发展一直受限。铝热还原法直接规模化制备钛基合金作为一种短流程低能耗制备方法一直是世界钛工业者多年来的追求,近年来中国在新型铝热还原法直接制备低氧高钛铁合金研究方面取得了重大突破,为其工业化应用开辟了新途径。

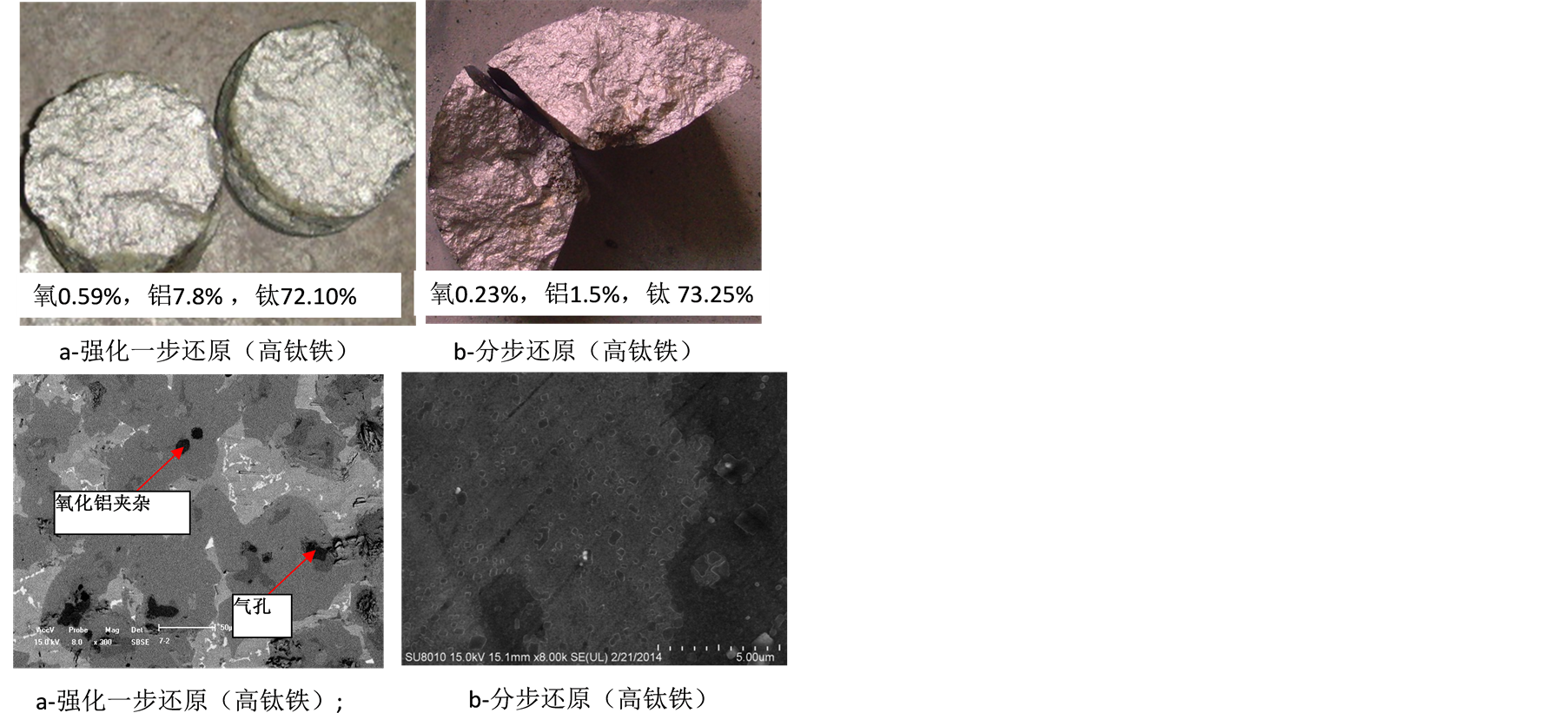

东北大学的豆志河、张廷安等人开发出分步深度还原直接制备低氧低残留高钛铁的新方法,破解了传统炉外铝热法生产低氧高钛铁时热力学平衡极限的瓶颈问题[16] -[20] 。即,要想降低氧含量就要配过量铝,那么合金中铝硅残留量就会升高。采用高配铝系数进行强化铝热还原制备低氧高钛铁时,实现了钛氧化物的彻底还原脱氧,成功制备出高钛铁的氧含量<1.00%,但合金中铝残留量高达8.50%。如何实现低氧、低铝高钛铁制备的技术突破,是制约铝热法制备优质钛基合金的技术瓶颈。提出先在低配铝系数时进行铝热还原得到高温熔体,然后直接进行二次深度还原制备低氧低残留优质高钛铁的新思路,取得了极大成功。由图8可知,采用分步还原所制备的高钛铁氧含量由一步强化还原的0.59%降低到0.23%,铝含量由7.80%降低到1.5%,合金中夹杂物被有效去除,合金的微观结构变得的均匀致密。目前,正在进行吨级规模的扩试试验。

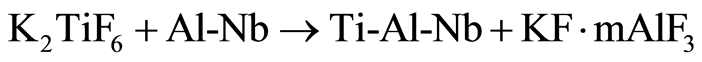

深圳市新星轻合金材料股份有限公司2015年成功开发出具有自主知识产权的新型铝热还原法生产低氧高钛铁合金超细粉体新方法[21] 。该方法是以氟钛酸钾为原料,以Al-Fe合金为还原剂,在密闭容器中保护气氛下进行还原生产出高铁铁合金粉体,还原温度为700℃~900℃。反应原理如下:

所制备的高钛铁粉体的化学成分如表4所示。由表可看出,该方法所制备高钛铁中铝<4.0%、硅<0.5%,氧<2.0%以下,其粒度仅为100~200目。该方法无论是生产工艺还是生产装备,均属全球性的首创,该方法和产品的研发成功为我国低氧高钛铁生产的生产提供了强有力的技术支撑。填补了我国钢铁工业急需的高品质钛铁包芯线用低氧优质钛铁超细高钛铁粉体生产的空白。同时在不改变生产装备及操作工艺前提下,通过改变还原剂种类和用量还可实现Ti粉、Ti-Al合金粉、Ti-Al-V合金以及Ti-Al-Nb合金的直接制备。

由图9可以看出,该法制备的高钛铁合金粉粒度均匀细小,均在5 µm以下。EDS结果知颗粒为纯净的TiFe相,其中Ti为62.14%,Fe为37.86%。目前,该公司正在筹备建设12,000吨/年规模的工业生产线,该生产线的建设将会很好满足我国钢铁工业急需的低氧优质高钛铁及高钛铁包芯线急需的低氧高钛铁合金粉的需求,同时为我国未来自主生产结构钢、特种钢以及军事工业用的特种合金钢提供了急需的优质高钛铁合金。该生产线的建成将极大提升我国钛铁工业的技术和装备水平,将极大提升我国高钛铁工业的国际竞争力。

Figure 8. Morphology photos of high titanium ferroalloy prepared by deep step reduction method

图8. 分步深度还原制备的高钛铁形貌照片

Table 4. Chemical composition of high titanium ferro powders prepared by the new thermite reduction inK2TiF6/(mass%)

表4. 氟钛酸钾介质中新型铝热还原法制备高钛铁粉体的化学成份(质量分数%)

4. 我国高钛铁市场前景展望

目前,我国生产钛铁产品的企业主要分布在辽宁、河南、四川、江苏、河北、山东、广西广东、北京、上海等地,共250多家。目前高中低三个系列总产量超过5000吨/年的企业几乎没有。高钛铁厂家主要在辽宁、河南等省,产量均未超过千吨/年。

而生产高钛铁的企业主要分布在辽宁、河南等地,所有企业均采用真空重熔法生产高钛铁,规模都未超过1000吨/年,500吨/年规模的都很少。行业集中度低、生产规模化小、技术装备水平落后,由此导致的产品质量差、产品质量不稳定已成为制约企业发展空间的技术瓶颈。

近年来随着不锈钢产量的不断增加、不锈钢产品、汽车用钢等对钛铁质量越来越高的要求,市场需求也越来越大。目前,高钛铁合金主要用在特种不锈钢、管线钢、船板钢等钢种精炼中,不完全统计目前实际消耗量应该在30,000吨以上,我国已成为高钛铁卖方市场,严重的供不应求,但由于我国高钛铁存在氧含量高、铝杂质残留高等缺陷,实际定价权却在下游的买方(钢铁企业)手里[22] [23] 。

按照发达国家的水平保守估算,要满足中国当前不锈钢、管线钢、船板钢、汽车板钢需求,目前我国每年将有35~40万吨左右的高钛铁缺口。随着高性能管线钢、船板钢、汽车钢及海洋工程用钢用量的急剧增加,高品质高钛铁需求量将会急剧增加。

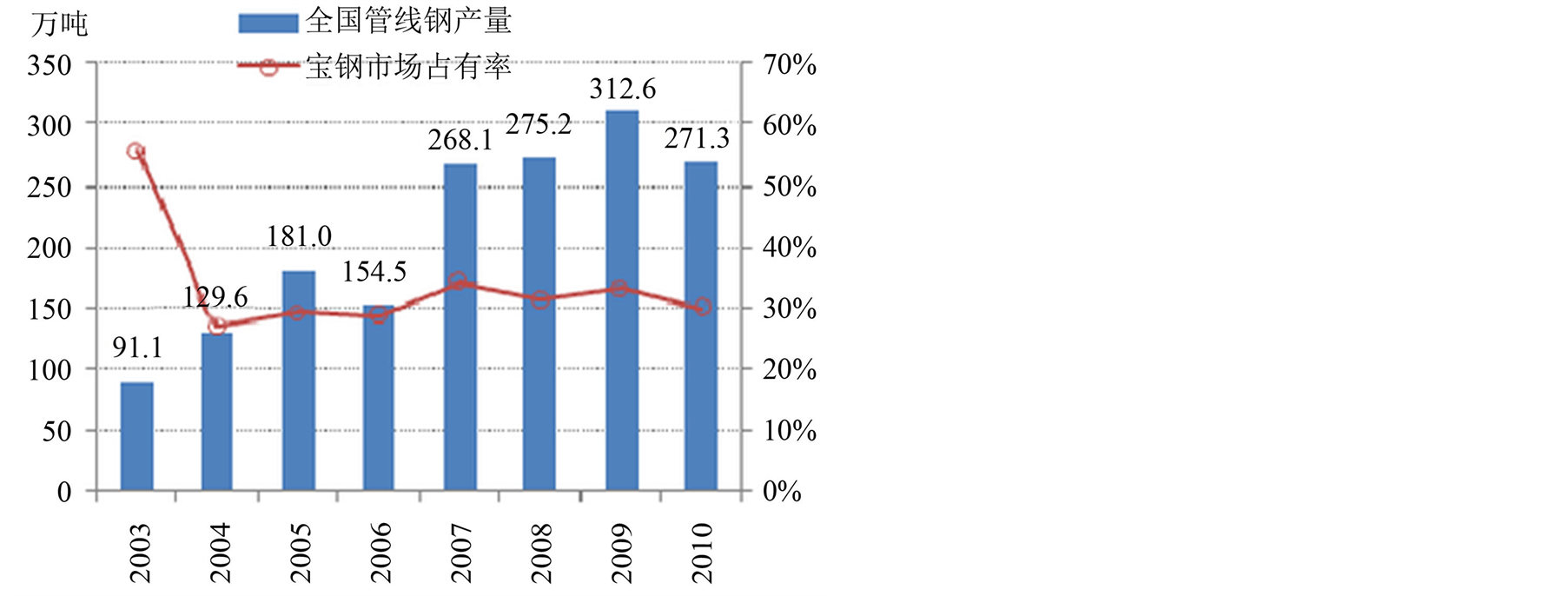

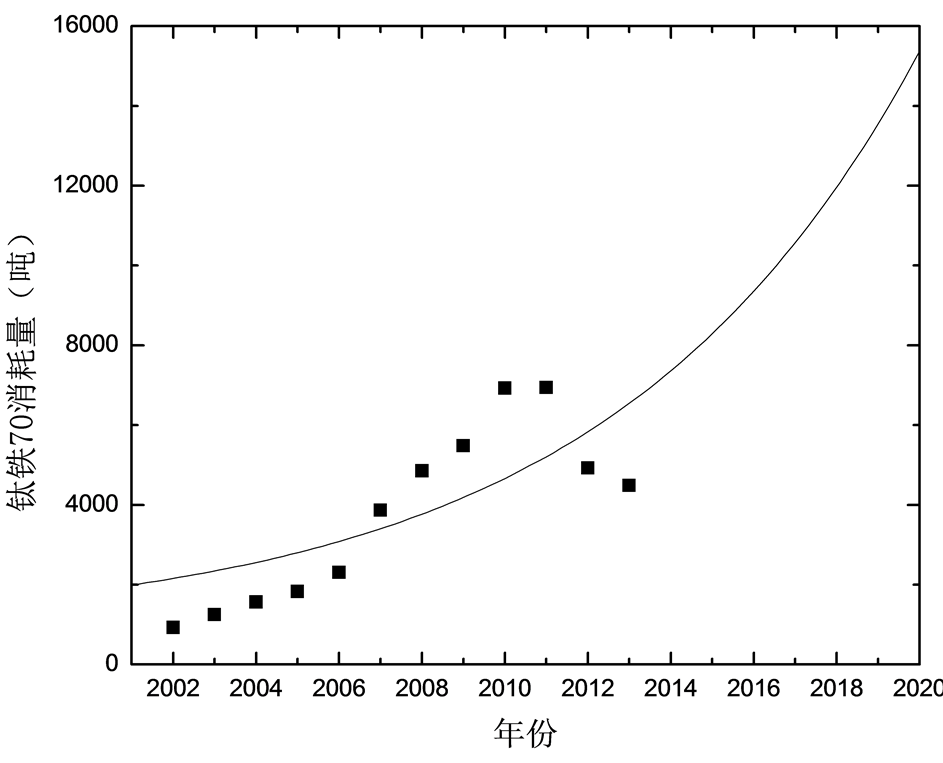

我国管线钢2003~2010年产量如图10所示。根据我国管线钢产量发展趋势,预计2016年仅管线钢精炼用高钛铁钢钛铁需求量(以FeTi70计)可达3500吨(如图11所示),2020年高钛铁需求量将达到8500吨。

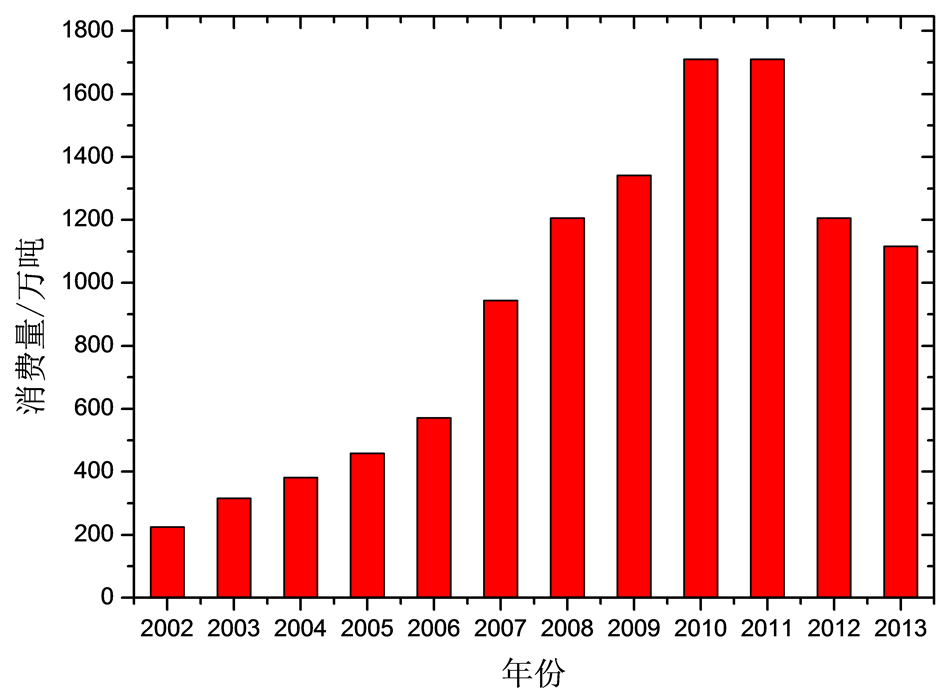

进入二十一世纪以来,中国的造船业得到了迅猛的发展,年造船量已经占到世界造船总量的9%以上,出口量占到70%以上。2002年以来,我国船板钢经历了先升高后回落的过程,消费量见图12。根据我国船板钢产量发展趋势,预计2016年仅船钢精炼用高钛铁钢钛铁需求量(以FeTi70计)可达9000吨左右(如图13所示),2020年高钛铁需求量将达到15000吨。

2000年中国汽车产量130万辆,汽车板钢用量为218万吨;2010年中国汽车产量400万辆,汽车板钢用量为410万吨;2015年前五个月汽车产量已达560万量,预计2015年仅汽车板钢需要高钛铁12,000吨。预计未来五到八年内,中国的汽车年产量将从2200万台提升到3000万至3500万台,目前国内由于高档汽车板材无法满足汽车需求的快速发展,每年需进口汽车板150万~200万吨,这都为高钛铁提供了巨大的市场空间。保守估计2020年汽车板钢精炼用高钛铁需求量可达30,000吨以上,管线钢、船板钢、汽车板钢精炼用高钛铁需求量可达53,500吨。按照国外汽车板钢占钢产量的15%(中国汽车协会公布的数据)比例估算的话,2020年仅汽车板钢高钛铁预期需求就达60,000吨以上。按照目前世界废钛材量增长

Figure 9. SEM and EDS of high titanium ferro powders prepared by the thermite reduction in K2TiF

图9. 氟盐铝热还原制备的高钛铁粉体SEM及EDS

Figure 10. Pipeline steel yield of China from 2003 to 2010

图10. 2003~2010年中国管线钢产量

Figure 11. Demands of high titanium ferro predicted based on Pipeline steel yield

图11. 由管线钢产量预测的2016年高钛铁需求量

Figure 12. Shipbuilding steel yield of China from 2002 to 2013

图12. 2002~2013年中国船板钢产量

Figure 13. Demands of high titanium ferro predicted based on shipbuilding steel yield

图13. 由船板钢产量预测的2016年高钛铁需求量

速度来看,国内高钛铁工业根本无法钢铁行业急剧增长的需求量。

废钛料主要来之于海绵钛生产到钛材加工,其中海绵钛环节产生的废钛约5%~7%,钛铸锭产生的废钛约5%,加工成材产生的残钛约40%~60%,由钛材加工成钛制品产生的残钛约为50%~75%。目前,世界上真空法生产高钛铁所需的废钛料主要来之于俄罗斯和乌克兰,而且乌克兰某些废钛料还实行限制出口。美国钛锭产量为40,000 t/a~45,000 t/a,钛废料供需基本持平。如果钛锭产量在45,000 t/a以上,美国钛废料就会短缺。2014年中国海绵钛的产量仅6万吨,但钛材加工量不足40,000万吨,将近40%~50%的海绵钛是出口国外,因此国内废钛料的产量有限,假设产生的废钛料全部用于生产高钛铁,国内高钛铁实际产能也不会超过15,000吨,实际钛工业产生的废钛料60%以上是行业内循环利用。可预测2016年国内高钛铁缺口将达15,000吨以上,2020年国内高钛铁缺口将达45,000吨~50,000吨以上。

近年来钢包喂线技术已成为炼钢精炼的首选技术,合金包芯线通过喂线速度的调整,可以平稳地在包内一定深度反应,不致引起剧烈反应而产生喷溅,钢包降温幅度也显著地小于喷粉。国外资料统计表明:喂线比喷粉处理费用吨钢节约3美元,而且喂丝法收得率可提高50%以上。目前,各大钢厂越来越多地采用合金包芯线。各类合金原料的消耗占钢产量比重不断上升,仅由各类合金组成的包芯线产品需求已达到钢产量的1.3~1.5%。按照目前8亿吨钢产量估算,目前包芯线的产量的可达1.0~1.2亿吨。但目前国内达到年产万吨包芯线且多品种厂家寥寥无几。炼钢脱氧精炼如铝、钙脱氧等基本都已完全采用喂丝法,如钙铁线、硅钙线、铝钙线,未来钛铁精炼剂的加入方式也将会全部采用抚顺特钢的钛铁包芯线加入方式,目前,国内还没有直接生产针对钛铁包芯线用的高钛铁超细粉的方法,现有的钛铁包芯线用钛铁都还是采用钛铁铸锭破碎成颗粒,再生产包芯线。因此,开发生产高钛铁包芯线用低氧高钛铁超细粉体新技术也是未来高钛铁工业可持续发展的必然选择[24] 。

再加上国内真空重熔法生产的高钛铁精炼剂存在的氧含量高,铝残留高等缺陷,国内高端管线钢、汽车钢等依赖进口。如果国内未来五年内没用低氧、低残留高钛铁生产方法的突破话,将会严重威胁到中国管线钢、船板钢、汽车钢以及快速发展的海洋用钢的发展,严重时会威胁到国家安全和国民经济建设发展。因此,未来高钛铁及高钛铁包芯线市场发展空间巨大。

5. 建议

高钛铁合金主要用于特种不锈钢、汽车用钢、管线钢、船板钢等高附加值钢种精炼上,我国已成为高钛铁卖方市场,严重的供不应求。尤其是“西气东输”工程和海洋工程的实施,以及造船业、汽车工业的快速发展,未来5年我国特种不锈钢、管线钢、汽车板钢、船板钢精炼用高钛铁将处于一个严重的供不应求的状态。

如按照发达国家的高钛铁占钛铁合金70%比例(未来钢铁精炼的必然选择)估算,如果要满足中国当前不锈钢、管线钢、船板钢、汽车钢需求,保守估计目前我国每年将会超过35万吨的高钛铁巨大缺口,因此我国的高钛铁市场空间巨大。随着对钢品质要求越来高,对高钛铁精炼剂的质量要求也越来越苛刻,低氧低碳低硅低铝等低残留指标逐渐被越来越多的下游厂家提出。因此开发低氧低残留高品质高钛铁大规模化制备新方法及关键装备,是钛铁工业可持续发展的必然选择,也是为我国国家安全和国际民生建设提供物质保障的战略需求。

新型铝热还原法作为一种短流程低能耗制备新方法,是未来最有前景的大规模化工业化生产低氧低残留优质高钛铁的新方法,我国在该领域研究一直处于世界领先水平。目前,我国已在氟盐铝热还原法工业化生产方面取得了突破性研究进展,成功制备出氧含量<2.0%,铝含量<4.0%的低氧低残留优质高钛铁超细粉体,并在筹备万吨级规模的生产线建设。根据当前炼钢精炼工艺优化发展趋势,使用包芯线喂丝法添加精炼剂是未来的必然选择,因此氟盐铝热还原法制备低氧低残留优质高钛铁超细粉体新方法是一种极具发展前景的新方法,应加快其工业化推广应用。另外,分步深度热还原法在高钛铁合金及钛基合金直接制备方面具有极大的优势,应加快其工业化应用研究的力度,尽快实现其工业化推广应用。从而形成具有我国特色的新型铝热还原法制备低氧低残留高品质高钛铁及钛基合金制备新方法及核心装备,从而引领世界金属热还原制备钛基合金的发展潮流。

基金项目

国家自然科学基金项目(51422403, 51274064)、973计划项目(2013CB632606)、教育部中央高校基本业务费项目(N140204013, N130102002, N130702001)、辽宁省教育厅高校重点实验室项目(LZ2014021)。