1. 引言

钛及钛合金由于其高的比强度、极好的耐腐蚀性能和良好的生物相容性广泛地应用于航空航天、航海、生物医疗以及其他领域[1] -[3] 。但较差的耐磨制约了钛及钛合金在很多地方的应用,改善钛及钛合金耐磨性的主要方法为:表面碳化、氮化、热氧化等[4] -[6] 。

热氧化法(Thermal Oxidation)是在大气环境中,将钛及钛合金放在电阻炉中,在一定温度、保温一段时间,使其表面形成一层致密的氧化膜,从而改善钛及钛合金表面性能的热处理方法。热氧化通过在钛材表面形成钛的氧化物来提高钛表面性能,该方法绿色环保、操作简单,且显著提高其耐磨性,国内外已有很多相关研究[6] -[9] 。

本文选用TA18钛合金和TA2纯钛为材料,在箱式电阻炉中进行热氧化处理。对比研究TA18钛合金和TA2纯钛热氧化,探讨合金元素对热氧化特性的影响。

2. 实验材料与方法

实验材料为TA18钛合金和TA2纯钛棒材,TA18 名义化学成分(重量百分比)为Ti-3Al-2.5V,也称半TC4钛合金。TA2化学成分(重量百分比)为:Fe ≤ 0.30,C ≤ 0.10,N ≤ 0.05,H ≤ 0.01,O ≤ 0.25,Ti余量。

采用真空自耗电弧炉(VAR)熔炼、锻造获得直径为90 mm的TA18钛合金和TA2纯钛棒材,经线切割成规格为10 mm × 10 mm × 5 mm的小块。首先用150目和400目的Al2O3砂纸及1~5#的SiC砂纸打磨、再用Cr2O3抛光后用蒸馏水和无水乙醇超声波清洗,吹干,待用。

采用日产JSM-6360LA型扫描电镜(SEM)分析热氧化后氧化层表面形貌,采用日本理学D/max-2500衍射仪(XRD)对表面渗层进行相组成分析,使用Cu-Kα射线辐射(0.154 nm),扫描速度0.2˚/min,步宽0.02˚,2θ范围为20˚~90˚。

采用静态增重法研究TA18钛合金和TA2纯钛在不同温度下的热氧化动力学。氧化初期,每隔0.5 h称重一次,以后逐渐增加,后期每隔2 h称重一次,总氧化时间为16 h。所用称重电子天平为FA2004N型,测量精度为0.1 mg。

样品原始重量记为Wo,将试样分别置于箱式电阻炉中依次进行600℃、700℃和850℃的热氧化,每隔半小时取出空冷,称量,重量记为Wt,如此反复,根据式(1)计算试样热氧化导致的单位面积增重,并作出TA18钛合金和TA2纯钛在不同温度下的氧化动力学曲线。

(1)

(1)

式中Wo为原始重量,Wt为热氧化t时间后样品的重量,单位是g,S为样品表面积。v为热氧化t时间后样品单位面积增重,单位为g/m2。

3. 结果与讨论

3.1. 表面氧化层形貌观察

图1为TA18钛合金和TA2纯钛试样经700℃热氧化210 min后的表面氧化层形貌。可以看出,热氧化后,TA18钛合金和TA2纯钛试样表面都形成了氧化层,且相同热氧化温度和时间条件下,TA18钛合金比TA2纯钛表面形成的氧化物颗粒尺寸细小些,氧化程度轻些,即TA18抗热氧化性优于TA2。

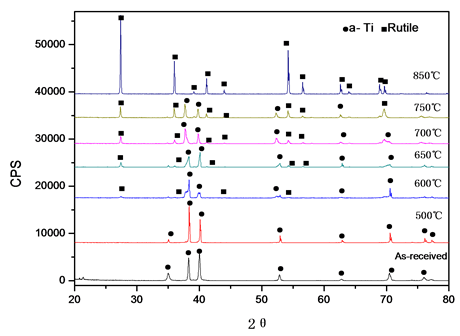

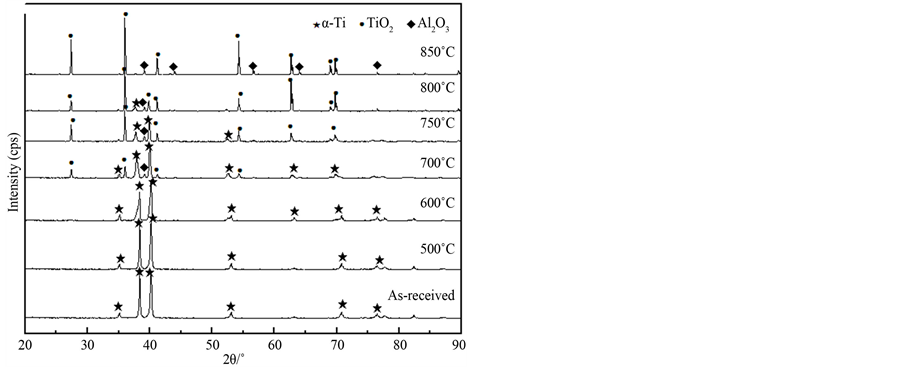

3.2. XRD物相分析

图2为TA18钛合金和TA2纯钛试样经700℃热氧化210 min后的XRD衍射谱。可以看出,热氧化后,TA18钛合金表面形成的氧化膜以金红石型TiO2为主,并有少量Al2O3。而TA2纯钛热氧化后表面形成的氧化膜全部为金红石型TiO2。

3.3. 热氧化动力学分析

图3为TA18钛合金和TA2纯钛在600℃、700℃和850℃的热氧化动力学曲线。可以看出,TA18钛合金和TA2纯钛氧化程度都随热氧化温度升高而加剧,其中600℃和700℃时氧化增速缓慢,氧化增重与氧化时间呈抛物线规律,850℃出现快速氧化,氧化增重与氧化时间呈直线规律。同时,任一相同热氧化温度下,TA18钛合金的氧化速度比TA2纯钛平缓,增重比TA2慢。氧化温度为600℃时,随着热氧化时间的增长,TA18钛合金氧化增重十分缓慢;而TA2纯钛样品则在刚开始氧化210 min内增重较快,随后增重较慢。

氧化速率由氧和金属的扩散控制,根据抛物线规律,可表示为:

(2)

(2)

式中 为单位面积氧化增重,mg2·cm−4;

为单位面积氧化增重,mg2·cm−4; 为抛物线速率常数,mg2·cm−4·h−1;

为抛物线速率常数,mg2·cm−4·h−1; 为氧化时间,h。

为氧化时间,h。

从图3获得单位面积氧化增重平方 与氧化时间的关系,经拟合得出TA18钛合金和TA2纯钛在600℃和700℃温度下氧化的抛物线速率常数分别为:

与氧化时间的关系,经拟合得出TA18钛合金和TA2纯钛在600℃和700℃温度下氧化的抛物线速率常数分别为:

TA2纯钛的抛物线速率常数分别为:

Figure 1. SEM images of surface morphology samples thermally oxidized at 700˚C for 210 min: (a) TA18; (b) TA2

图1. 试样经700℃热氧化210 min后表面形貌(SEM):(a) TA18;(b) TA2

(a) TA18 (b) TA2

(a) TA18 (b) TA2

Figure 2. XRD pattern of thermally oxidized samples at 700˚C for 210 min

图2. 试样经700℃热氧化210 min热氧化后XRD衍射谱

Figure 3. Oxidizing dynamic curves of TA18 and TA2 at various temperatures

图3. TA18和TA2在不同温度下的氧化动力学曲线

可见,随着氧化温度的增加抛物线速率常数随之也增加。且600℃和700℃时TA18的抛物线速率常数都比TA2小。

3.4. 分析与讨论

如上所述,TA18钛合金热氧化抛物线速率常数比TA2小,原因是TA18钛合金和TA2纯钛在热氧化温度为600℃和700℃时,在样品表面形成的氧化膜阻止了氧的进一步渗入。特别是在700℃热氧化时,TA18钛合金的氧化层由TiO2和其外表的一薄层Al2O3所组成。在热氧化初期,TA18钛合金表面形成TiO2薄膜,造成氧化膜与基体界面处贫钛,同时该处的铝浓度相对提高,从而促进内层铝向外扩散,在氧化膜的外表面形成一薄层氧化铝,它具有阻挡氧化物内层渗透的作用,从而减少合金的氧化速度。因此,TA18钛合金的热氧化动力曲线比TA2纯钛的平缓,增重比TA2慢。

TA18钛合金和TA2纯钛样品在850℃增重的氧化动力曲线几乎呈直线规律,这是因为随着热氧化时间的延长,热氧化温度在800℃以上时氧化膜分解,导致此时氧化物膜对基体没有保护作用。随氧化的进行,样品表面氧化皮不断形成和脱落,在脱落之后又被再氧化,再脱落,随着热氧化时间的延长不断循环。

4. 结论

1) 热氧化后,TA18钛合金和TA2纯钛试样表面都形成了氧化层,但TA18抗热氧化性优于TA2。

2) 热氧化后,TA18钛合金表面形成的氧化膜以金红石型TiO2为主,并有少量Al2O3。而TA2纯钛热氧化后表面形成的氧化膜全部为金红石型TiO2。

3) TA18钛合金和TA2纯钛样品在850℃增重的曲线呈直线规律;当氧化温度为600℃和700℃时,两者氧化动力学曲线是遵循抛物线规律;

4) 在相同的热氧化温度和时间下,TA18钛合金的热氧化动力学曲线比TA2纯钛的平缓,增重比TA2慢;TA18的抛物线速率常数比TA2小。

基金项目

江苏省科技成果转化项目(项目编号:BA2013078)。