1. 引言

随着汽车工业及家电业的快速发展,普通冷轧带钢已经无法满足上述领域对于冷轧薄板高质量的要求,市场对高质量表面毛化冷轧板的需求越来越大。表面毛化冷轧板是由表面经毛化处理的轧辊轧制而成,具有表面糙度均匀、无划伤、无条纹等优点,其板面光亮整洁且板形良好[1] [2] 。轧辊毛化技术就是对磨光轧辊进行毛化,使其表面具有特殊形貌的技术。轧制过程中毛化辊表面所形成的半球形结构形貌的大小和复合镀层的形状特性,是轧辊表面毛化技术的关键所在,毛化轧辊表面特性主要是由毛化球的形貌特性决定的,毛化表面的应力状况在轧辊的磨损性能、使用寿命,保证轧辊质量方面都有重要影响 [3] 。然而对毛化的研究主要通过试验的方法来获得具有微凸体结构的毛化点 [4] - [6] ,对毛化过程中加工工艺对毛化表面应力的研究还很少。因此对轧制过程进行数值模拟研究,有助于对轧辊表面的半球形结构与复合镀层中材料的变形情况进行评估。

文中应用ANSYS有限元软件对带钢轧制过程进行了有限元模拟,分析了带钢牵引速度对带钢表面形貌形成及成形质量的影响规律,轧辊过渡层厚度、轧辊表面形貌对毛化球应力的影响规律。研究结果对轧辊表面毛化技术有一定的指导意义。

2. 有限元建模方法

2.1. 几何模型的建立

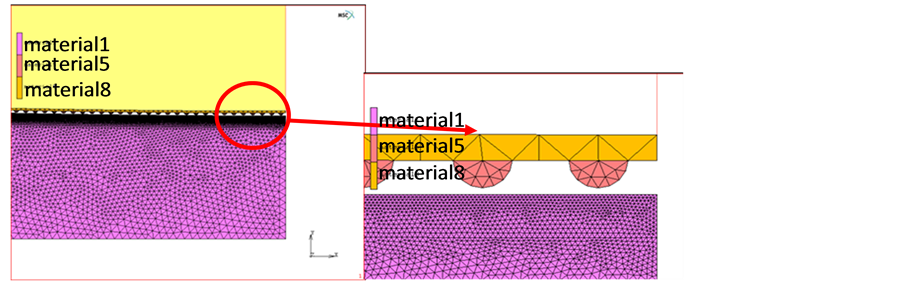

由于轧辊表面的半球形毛化结构的尺寸在微米量级,而轧辊和带钢的尺寸单位为米,使得毛化球结构的局部网格划分尺寸过小,整体单元数目庞大,为了提高计算精度与效率,本项目对带钢的轧制过程采用二维数值模拟分析。同时考虑轧制过程中带钢的对称性,在模拟过程中仅分析带钢咬入阶段与轧制变形区域的1/2模型。毛化辊轧制带钢的有限元模型如图1所示。

轧辊直径为750 mm,带钢厚度为2 mm,其中轧辊主体采用刚性材料模型;带钢、毛化球与复合镀层采用变形材料模型。复合镀层弹性模量为45 GPa;毛化球弹性模量为230 GPa。带钢选取常用汽车钢板,其材料弹性模量为210 GPa,,屈服强度为210 Mpa。变形材料选取三节点平面应变单元,整体单元数量为256,598个。

2.2. 边界条件的确定

图2为模型所受的位移边界条件,其中边界条件(apply2)为带钢牵引速度约束,边界条件(apply3)为带钢的对称约束。轧辊转动速度为0.2弧度/s。

3. 有限元仿真结果与分析

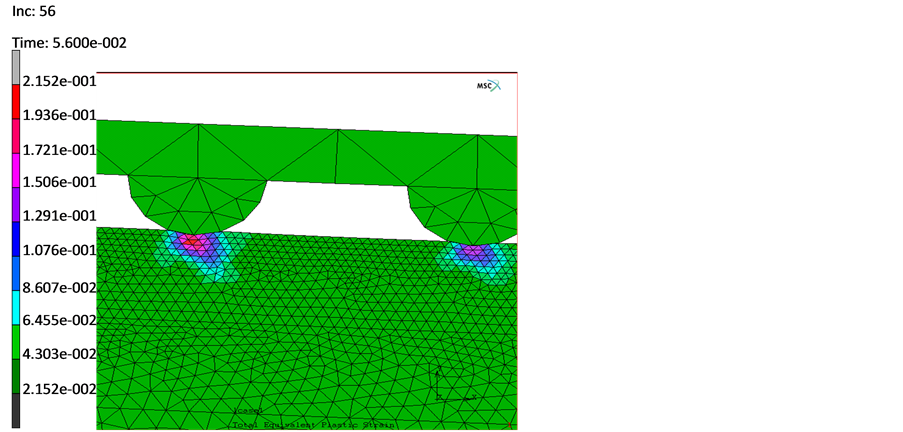

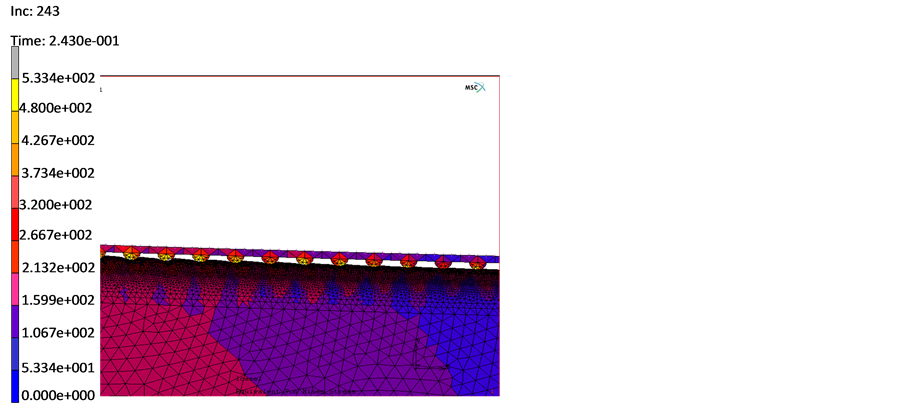

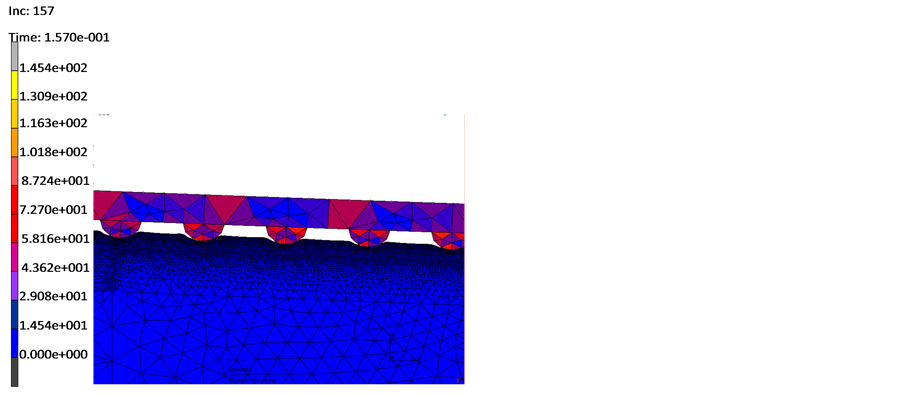

图3为带钢轧制后几何构形与塑性应变分布。在变形过程中,带钢表面在毛化球的压缩作用下,形成向下的微坑。带钢表面微坑变形部分承担了主要的塑性变形,轧制变形后带钢厚度方向上最大压下率设定为2%;图4为带钢轧制过程中的等效应力分布图,由图可知带钢表面及毛化球所受的应力较大。带

Figure 1. FEA model of band steel rolling

图1. 带钢轧制过程的有限元模型

Figure 2. Displacement boundary conditions of band steel

图2. 带钢位移边界条件

Figure 3. Plastic strain distribution of band steel rolling

图3. 带钢轧制变形过程中塑性应变分布图

Figure 4. The equivalent stress distribution in the process of rolling

图4. 轧制过程中的等效应力分布图

钢在毛化球作用下,产生塑性应变,材料在变形屈服抗力作用下,具有较大的等效应力。而毛化球直接作用于带钢,在带钢反力作用下,毛化球与带钢接触部位受到较高的应力水平。而复合镀层由于弹性模量较低,起到对带钢反力的缓冲作用,其承受的应力水平急剧下降,由500多兆帕下降到100多兆帕。

3.1. 带钢牵引速度对带钢表面形貌形成、成形质量的影响

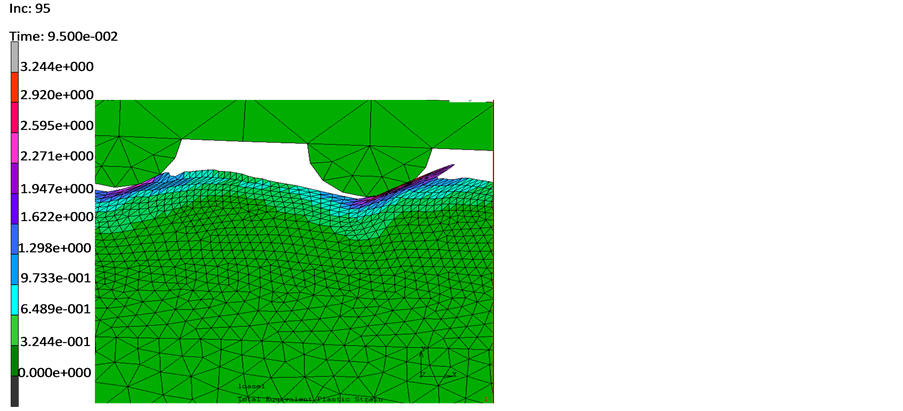

图5为带钢牵引速度与轧辊转速一致时的带钢变形构形,即轧辊整体转速相对于带钢没有形成速度差。但由于带钢表面在毛化球作用下形成了半圆形的微坑,使得带钢表面在同时间内需要经历的变形曲线弧长比轧辊刚体旋转所经历的弧长要大,因此在毛化球与带钢接触表面形成了速度差,其中轧辊转速相对带钢运行速度较快。因此,在变形过程中带钢表面材料的变形流动速度相对毛化球移动速度较慢,在毛化球侧向的压力作用下,形成带钢材料的聚集,进而造成应力集中,不利于带钢表面微坑形貌的形成。同理,若轧辊转速相对带钢牵引速度过慢,带钢表面材料在毛化球侧向阻力作用下,材料难以流动,同样形成带钢材料的剧集。因此,与在变形过程中,轧辊转速带钢牵引速度的设定将影响到带钢表面形貌的形成与成形质量。

图6为合适的轧辊转速下,带钢变形后的几何构形与表面形貌。带钢在轧辊压缩应力作用下,带钢的厚度逐渐变薄,并在表面形成半圆形的微坑形貌。微坑间距分布均匀,且圆弧过渡平缓,表面质量相对较好,应变分布相对均匀,有利于带钢的后续加工。

3.2. 轧辊过渡层厚度对毛化球应力的影响

基于以上分析可知,轧辊表面的毛化球承受了大部分的带钢反力,而过渡层则有效缓冲了带钢反力。因此,毛化球的剪切应力大小对其在变形过程中与轧辊复合镀层的结合状态至关重要。本文通过改变复合镀层的厚度,研究镀层对毛化球剪切应力分布的影响。其中,毛化球直径为30 um,镀层厚度分别为15 um、30 um、45 um。

表1为不同镀层厚度条件下,毛化球所承受应力情况。当镀层厚度为15 um时,即为毛化球直径的一半时,带钢轧制变形后毛化球的最大剪切应力为204 Mpa,毛化球在带钢作用反力下,由于接触面积很小,形成应力集中现象,其等效应力达到500 Mpa以上;当镀层厚度为30 um时,即与毛化球直径相

Figure 5. The deformation configuration when the drawing speed is consistent with the rolling speed

图5. 带钢牵引速度与轧辊转速一致时的带钢变形构形

Figure 6. The surface appearance after band steel rolling

图6. 带钢轧制后表面形貌

Table 1. The influence of different coating thickness on texturing ball stress

表1. 不同镀层厚度对毛化球应力的影响

当时,毛化球上所承受的等效应力值仍然在500 Mpa以上,而其最大剪切应力仅为165 Mpa;复合镀层对轧辊所受剪切应力的缓冲作用明显,仅与毛化球相连的单元承受带钢的作用反力,其余部分所受应力均很小,所有镀层单元均参与缓冲剪切应力分布;当镀层厚度为45 um时,即镀层厚度大于毛化球直径时,由于镀层相对毛化球材料较软,应力主要集中在毛化球上,毛化球最大剪切应力值相应增加为253 MPa,剪切应力主要分布在毛化球与带钢接触单元与镀层边部。

3.3. 轧辊表面形貌对毛化球应力的影响

图7是毛化球直径为50 um、镀层厚度50 um时,带钢的几何构形。由于毛化球尺寸增加,在带钢表面形成的半圆微坑弧长增加,需要增加轧辊的转动速度,否则带钢表面材料在毛化球侧向压应力下,形成材料聚集,进而影响带钢表面质量。同样的变形条件下,带钢未能形成明显的微坑,其剪切应力值相对较小,最大值仅为145 Mpa,最大等效应力值为403 Mpa。

图8为毛化球尺寸非均匀分布,在直径50 um的大球之间夹杂着小尺寸毛化球。在同样的变形条件下,毛化球的最大等效应力值增加到500 Mpa以上,最大剪切应力也增加到160 Mpa以上,且最大应力主要由大尺寸毛化球承担。表明,毛化球分布不均匀也造成毛化球所受应力增加。

(a) (b)

(a) (b)

Figure 7. The stress distribution when the diameter of texturing ball is 50 um. (a) Shear stress; (b) Equivalent stress

图7. 毛化球直径50 um时带钢几何构形与应力分布。(a) 剪切应力;(b) 等效应力

(a) (b)

(a) (b)

Figure 8. The stress distribution when the dimension of texturing ball is non-uniform distributed. (a) Equivalent stress; (b) Shear stress

图8. 为毛化球尺寸非均匀分布时应力分布。(a)等效应力;(b)剪切应力

4. 结语

1) 轧辊转速相对带钢牵引速度过快或过慢,在毛化球侧向压力和阻力的作用下,均会形成带钢材料的聚集,进而造成应力集中。合适的轧辊转速下,带钢表面质量相对较好,应变分布相对均匀,有利于带钢的后续加工。

2) 当镀层厚度与毛化球直径尺寸相当时,其受到的等效应力与剪切应力值最低;而镀层厚度相对薄或厚时,毛化球上的剪切应力值均增加,进而影响到毛化球与镀层的结合程度。若剪切应力过大,将导致在变形过程中毛化球有从镀层表面脱落的危险。

3) 毛化球尺寸分布均匀时,毛化球剪切应力值相对较小,带钢表面质量较好;毛化球分布不均匀时,造成毛化球所受应力增加。

基金项目

863项目(2013AA031604)。