1. 引言

随着科学技术的高速发展,其对各种材料的使用性能提出了更高的要求,钢铁材料因其资源、性能、价格以及回收利用等特点,更受到了人们的青睐。尽管世界钢铁工业已经过了它的鼎盛时期,但人们对高性能结构材料的研发热情却日益高涨,同时,也对钢铁材料的开发人员提出了更高的要求。汽车工业一直是工业发达国家中的支柱产业,也是钢铁企业最大的用户之一,在节能、环保、安全及可持续发展的要求下,高强和超高强度钢成为了汽车车身用钢的主流,从而达到汽车的轻量化、安全性、节能、减排等目的,为了发展汽车用高强度钢板,促使汽车轻量化,近年来在世界范围内开始了大量的相关汽车轻量化项目的研究,其研究的共同点是将汽车质量降低20%~40% [1] 。

先进高强钢是近年来出现的新型钢铁材料,其与普通高强钢的主要区别是它们的微观组织不同。普通高强钢是单相铁素体组织,而先进高强钢基本上是多相组织,包括铁素体F (Ferrite),马氏体M (Martensite),贝氏体B (Bainite)和残余奥氏体(Retained Austenite)。其强化方式除了固溶强化、沉淀强化、细晶强化外,还有相变强化,其中相变强化是先进高强钢的主要强化方式。与普通高强钢相比,先进高强钢成形性好,能量吸收率高,抗凹性好,烘烤硬化性能、屈服强度、加工硬化率高,好的疲劳性能等优点,在汽车工业显示了良好的应用前景 [2] 。

按照强塑化的组织特征,先进高强度钢可划分为三代:第一代是以铁素体为基体的复相钢,包括低合金相变诱导塑性TRIP钢、具有少量残余奥氏体的铁素体–马氏体DP钢以及复相CP钢等;第二代是以奥氏体为基体的复相钢,即高锰合金(W(Mn) = 15%~25%)孪晶诱导塑性TWIP钢;第三代是以奥氏体 + 马氏体为基体的复相钢,主要是淬火配分钢Q-P系列高强塑性钢 [3] 。本文结合相变强化的三代复相钢的开发与应用现状,讨论了相变强化类复相钢的主要技术特征,包括使用性能对塑性指标的要求,复相组织与残余奥氏体的强塑化关系、焊接裂纹敏感性等。

2. 以铁素体为基体复相钢的研发

2.1. 相变诱导塑性钢(TRIP钢)

2.1.1. TRIP效应原理

相变诱发塑性钢(TRIP)之所以具有优异的性能,是因为其具有相变诱发塑性效应这一独特的强韧化手段。首先将钢加热到两相区(α + γ)进行退火,退火后微观组织包括低碳的铁素体和高碳的奥氏体,在这个阶段奥氏体含碳量约为0.30%,这个碳含量对于要在室温下使奥氏体稳定是较困难的。然后就有进行中温贝氏体转变,这样会使奥氏体进一步富碳,从而使钢中有大量稳定性好的奥氏体在室温保留下来,称作残余奥氏体 [4] 。当钢板发生变形时,就会使钢中的残余奥氏体发生应变诱发马氏体相变,其不仅能提高钢的强度,尤其是能使塑性显著提高,故称之为“相变诱发塑性效应”,简称“TRIP效应”。钢在发生TRIP效应时,即使外加载荷远低于材料的屈服强度,其仍能发生显著塑性流动 [5] ,该效应使TRIP钢具备了维持大塑性变形的条件。

以拉伸试验为例,拉伸变形时变形最大的部位首先诱发马氏体相变,使局部强度升高,变形难以继续进行,导致变形向未发生马氏体相变的其它部位转移,推迟了缩颈的形成;同时拉伸变形引起的局部应力集中因马氏体相变而松弛,推迟了裂纹的产生;另外,残余奥氏体与外加应力呈共格关系,高能界面不利于裂纹的扩展,因此宏观效应表现为伸长率的提高,特别是均匀伸长率的提高。

2.1.2. TRIP钢的实验研究进展

冷轧TRIP钢采用连续退火工艺,形成铁素体、贝氏体和少量残余奥氏体(一般5%~15%)的混合组织。其中的残余奥氏体由于含碳量高,稳定性差,在一定的塑性变形量下,就会向较为稳定的马氏体转变,生成的马氏体的硬化性能比相变前的奥氏体有较大的提高,增加了材料的均匀变形能力,由此带来了材料塑性的提高。如图1所示为TRIP钢多相结构的示意图。1967年Zackey等首次发表了利用相变诱发塑性效应改善奥氏体不锈钢塑性的研究成果 [6] 。1975年,在双相钢研究中,Hayami等也发现了具有TRIP效应的残余奥氏体 [7] 。几年后,具有高强度和较好均匀伸长率的双相钢开始在汽车行业得到了广泛应用。但在应用过程中仍存在强度高,塑性差的问题。为解决这一问题,具有TRIP效应的双相钢开发又引起了人们的重视。进入20世纪90年代,汽车工业对高强度、高塑性和高成形性钢板的需求进一步增加,日本、德国等国家先后采用热连轧或冷轧连续退火生产线批量生产出了TRIP钢 [8] 。张梅等 [9] 对低碳硅锰TRIP1000钢进行了一系列的两相区退火和贝氏体区等温处理实验研究,结果表明,两相区退火温度为820℃,贝氏体区等温温度为420℃,等温240 s时,TRIP1000钢呈现出铁素体、贝氏体和残余奥氏体三相组织,晶粒大小为2~4 μm,残余奥氏体及其碳含量较高,TRIP1000钢具有较好的力学性能,其强塑积达到23088 MPa∙%。

2.2. 双相钢(DP钢)

2.2.1. 合金元素对双相钢组织和性能的影响

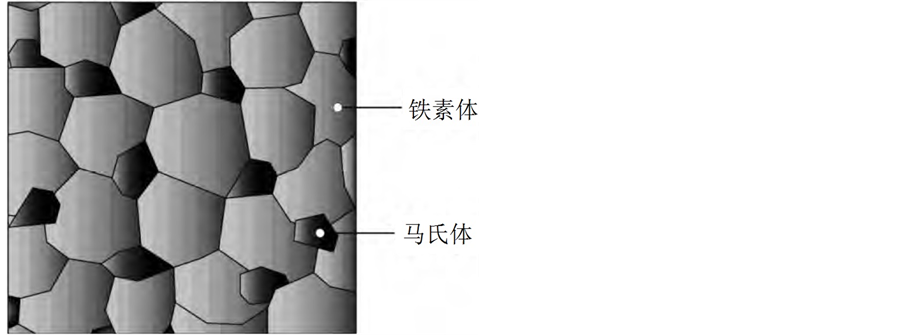

双相钢自70年代发明以来,由于其铁素体 + 马氏体两相组织(如图2)的特征使其具有了优异的综合力学性能,其主要表现为低的屈强比,高的加工硬化速率以及高的伸长率等。张增良等 [10] 研究了微合金元素Nb和V对双相钢性能的影响。结果表明,双相钢中加入V可提高临界区加热下所形成的奥氏体岛的淬透性,同时V是强碳化物形成元素,对于消除铁素体间隙固溶强化,细化晶粒,产生高延展性的铁素体,消除屈服点伸长均有好处。在相同的实验条件下,含V钢与不含V钢相比,其总伸长率较大。添加Nb的双相钢由于在固溶态的Nb延迟热变形过程中静态和动态再结晶和奥氏体向铁素体的相变,因此含Nb双相钢的铁素体基体较其它双相钢不够纯净,伸长率较低。另外,Nb的碳氮化物析出阻止了晶粒长大,并有明显的弥散强化效果,其抗拉强度较大。

Jewoong Lee等 [11] 通过组织结构分析和扩孔试验,研究了微合金元素对双相钢拉伸凸缘性能的影响规律。结果表明,临界退火温度对退火后的双相钢在缓慢冷却过程中生成的新取向铁素体的形成数量有较大影响。由于临界温度下得到的奥氏体中有较低的碳含量,其在高温退火时大量的新取向铁素体形成。高温退火的试样具有高的总伸长率和扩孔率,但是强度较低。少量Nb的添加对双相钢的拉伸凸缘性能有利,即当加入200 ppm的Nb时,双相钢的扩孔率较高,当Nb的添加量达到400 ppm时,双相钢的扩孔率变差。

Figure 1. Schematic diagram of microstructure of TRIP steel

图1. TRIP钢金相组织示意图

Figure 2. Schematic diagram of microstructure of DP steel

图2. 双相钢的金相组织示意图

2.2.2. 工艺对双相钢组织和性能的影响

双相钢以其良好的强度和延性匹配、高的初始加工硬化率、高的碰撞能量吸收能力和屈强比等优点逐渐成为汽车制造的重要材料 [12] 。在成分一定的情况下,生产工艺对双相钢优异的性能获得起到了关键作用。冯太国等 [13] 研究了冷轧连续退火温度和缓冷温度对热镀锌双相钢DP780组织和性能的影响规律。结果表明,通过调整退火工艺,可以得到强韧性能匹配较好的铁素体–马氏体双相钢组织;在一定的温度范围内,随着退火温度和缓冷温度的升高,双相钢DP780的抗拉强度有不同程度的下降,而伸长率有所上升,缓冷温度在600℃左右可以获得较理想的综合力学性能。

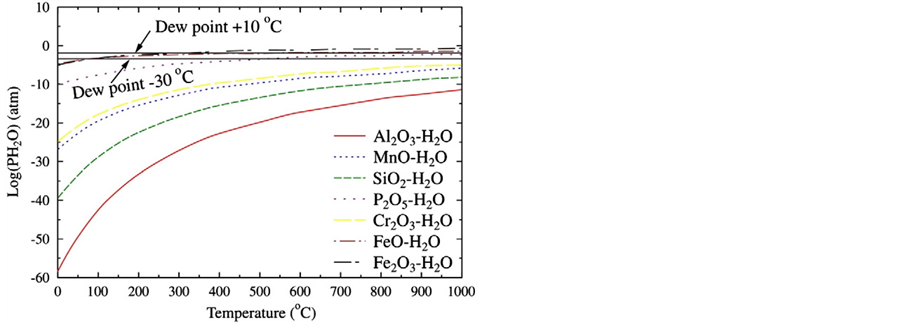

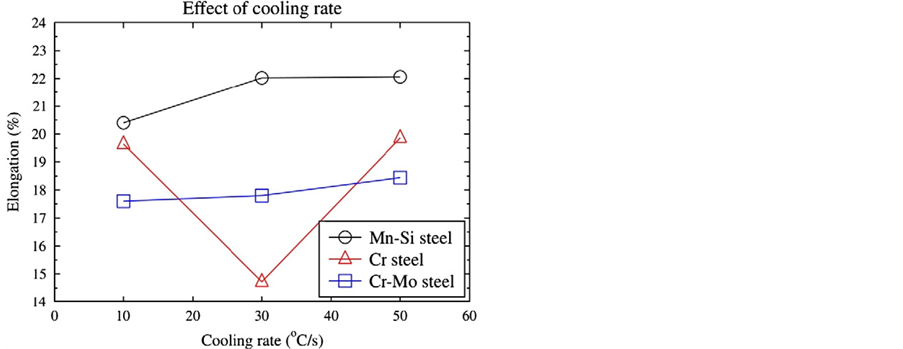

对于热镀锌双相钢的研发和生产过程中存在两个人们比较关注的问题,一个是双相钢在临界退火过程中合金元素在钢表面的选择性氧化问题;如图3显示了合金元素如Al、Si、Mn和Cr与氧有较强的亲合力,当钢在带有H2 + N2保护气氛的退火炉中高温退火时,这些元素倾向于在钢板表面发生选择性氧化,从而造成热镀锌板表面漏镀或其它表面缺陷 [14] 。Huachu Liu等开展了两个不同露点下热镀锌双相钢板退火过程中的选择性氧化实验,同时研究了热镀锌工艺参数对双相钢性能的影响。结果显示,退火气氛的露点和钢的成分对双相钢表面选择性氧化有影响;在−30℃低的露点下退火,钢板表面全部被氧化物覆盖,外部氧化较为严重。当露点增加到10℃时,钢板表面覆盖的氧化物减少,但是内部氧化消耗了大量的合金元素,并且在表面下存在大量的堆积。另外,冷却速度和带钢在460℃等温时间对双相钢的性能有一定的影响,且钢中添加Cr和Mo元素可提高热镀锌双相钢的性能稳定性,如图4和图5分别显示了冷却

Figure 3. Thermodynamic stability of elements during annealing under H2 + N2 atmosphere with trace amount of water vapor

图3. 在H2 + N2气氛下退火期间各元素的热力学稳定性趋势图

Figure 4. Effect of cooling rate on the ultimate tensile strength of dual phase steels with different components

图4. 冷却速率对不同成分体系双相钢抗拉强度的影响

Figure 5. Effect of cooling rate on the elongation of dual phase steels with different components

图5. 冷却速率对不同成分体系双相钢断裂伸长率的影响

速率对不同成分体系双相钢强度和伸长率的影响规律 [14] 。

2.3. 复相钢(CP钢)

复相钢的组织与TRIP钢类似,其主要组织为细小的铁素体和高比例的硬相(马氏体、贝氏体)。通过马氏体和贝氏体以及析出强化的复合作用,CP钢的强度可达到800~1000 MPa,该系列钢具有较高的吸收能和扩孔性能,特别适合于制作汽车的车门防撞杆、保险杠和B立柱等安全件。依靠合金成分优化设计以及工艺控制,热轧和冷轧复相钢可得到不同的组织,从而获得从500 MPa到1000 MPa以上级别的高强度钢。如蒂森克虏伯公司开发的热轧复相钢CP800和CP1000的抗拉强度分别为800 MPa和1000 MPa级,厚度最薄可达到1.8 mm。韩国浦项的热轧CP980钢和冷轧CP1180和CP1470钢已经商业化。宝钢利用钒钛微合金化开发出了抗拉强度1150 MPa级热轧复相钢,其3.0 mm厚度热轧板的典型性能值为:屈服强度为825 MPa,抗拉强度为1165 MPa,伸长率为14% [15] 。

F. Silva等 [16] 通过模拟连续退火实验及不同温度的水淬实验,分析了化学成分为0.08% C-1.91% Mn-0.04% Si冷轧复相钢的微观组织特征。结果显示,所实验复相钢的再结晶开始温度约为650℃,且在700℃保温5 min后再结晶完成。在750℃临界退火温度下,通过加速冷却,对冷轧复相钢的MA岛的形态和分布、碳化物和铁素体晶粒尺寸都有影响。但是其力学性能变化不大,最大冷却速度下形成的MA岛的体积分数最大,铁素体晶粒尺寸最小。

Jongpan Kong等 [17] 研究了硼含量对复相钢强度的影响。结果表明,随着硼含量的增加复相钢的硬度随之增加(如图6);复相钢组织中的各相随硼含量的增加而变化的情况如图7所示,由图中可以看出,随着硼含量的增加,马氏体和贝氏体的体积分数呈线性增加,而铁素体的体积分数呈线性减少。其硬度随硼含量的增加而增加的原因主要是因为软相铁素体的分数减少,而硬相马氏体和贝氏体的体积分数增加造成的。并且为了了解B含量对复相钢微观组织的影响结果,Jong Pan Kong等通过试验分析了B含量对复相钢CCT曲线的影响规律(如图8)。

3. 以奥氏体为基体复相钢的研发

以奥氏体为基体复相钢的代表钢种为高锰TWIP钢,即高锰孪生诱发塑性(Twinning Induced Plasticity)钢,因其具有极高的强塑积(大于40 GPa∙%)且延伸率高达90%以上而受到汽车制造企业的广泛关注。TWIP钢是第二代先进高强度钢的一种,因其形变过程中产生大量形变孪晶、推迟缩颈的形成,故具有高

Figure 6. Hardness of base metal as a function of B contents

图6. 硬度随硼含量的变化趋势图

Figure 7. Change of the volume fraction of each phases as a function of B contents

图7. 各相的体积分数随硼含量的变化

Figure 8. Effect of boron content on the CCT curve of complex phase steel

图8. 硼含量对复相钢CCT曲线的影响

的应变硬化性、高能量吸收能力,是一种理想的汽车用抗冲击结构材料。

3.1. 成分对TWIP钢组织性能的影响

TWIP钢经典成分(Fe-25Mn-3Si-3Al)中的主要合金元素为锰、铝、硅。锰是钢中的最重要的组成元素之一,具有很强的促进奥氏体化的作用,使TWIP钢在室温下仍能获得稳定的奥氏体相,同时又是增加合金层错能的最有效元素,强烈促进TWIP效应,抑制TRIP效应。研究表明 [18] ,随着锰含量的增加,TWIP钢的塑性迅速提高,强度明显下降。铝也可增加合金的层错能,抑制奥氏体向马氏体的转变,但铝易氧化,在连铸浇铸过程中易堵水口,其不利于工业化生产。硅可以降低Ms点,对室温下得到稳定的奥氏体组织有利,且硅溶于奥氏体,有利于强度的提高,但硅会降低合金的层错能。

3.2. TWIP钢的组织结构特征

形变孪生是TWIP钢主要的增塑机制,即TWIP钢的性能是由形变孪生控制的,而织构或晶粒取向又影响形变孪生。房秀慧等 [19] 研究了室温下锰的质量分数分别为26%和30%的两种TWIP钢拉断过程中织构的演变规律和孪生弱化〈111〉织构的作用。结果表明,TWIP钢拉伸时形成较强的〈111〉织构,也形成由〈111〉取向晶粒的不同孪晶产生的接近〈100〉的弱织构,从而孪生弱化了〈111〉拉伸织构。另外,粗的奥氏体晶粒促进孪生,从而加速〈111〉织构的弱化。拉伸过程中〈111〉取向的晶粒有利于形变孪生,〈100〉取向的晶粒不利于孪生。锰含量较低的钢出现少量的形变诱发ε-M,由于ε-M主要从〈111〉取向的形变孪晶内形成,因此也出现了择优取向,弱化了〈111〉织构。严玲等 [20] 研究了中碳-高锰TWIP钢在700℃~1150℃不同温度固溶处理后微观组织的演变规律。结果显示,固溶处理后的TWIP钢由具有孪晶结构的奥氏体晶粒构成,晶粒间取向差约为60˚的晶粒占大多数。并且随着固溶处理温度的提高,奥氏体晶粒增大,由700℃时的5~10 μm增大到1100℃时的90 μm,此后即使温度继续升高,晶粒尺寸也不再增大。另外,TWIP钢在单向拉伸过程中,随着变形量的增加,位错密度和形变孪晶的密度增大,孪晶间距和片层厚度减小,在奥氏体晶内出现多组孪晶集束并相互交截。

4. 以奥氏体+马氏体为基体复相钢的研发

随着汽车用钢的发展,为减轻车体重量,大量采用高强度、高塑性钢板以成为必然趋势。国外的Speer J G等 [21] 人开发出了一种新型的具有TRIP效应的钢,并将其命名为Q & P钢(Quenching and Partitioning)。Q & P钢是一种新的含有富碳残留奥氏体的钢种,其热处理过程的机理是碳从过饱和的马氏体扩散到残留奥氏体中。是一种新型的高强度和高塑性的马氏体钢,其室温组织是贫碳的板条马氏体和富碳残余奥氏体,硬相马氏体保证了钢板的强度,残余奥氏体由于在形变过程中发生相变诱发塑性而提高了钢的塑性 [22] 。因此,该钢成为了现阶段和将来一段时间冶金行业和汽车工业重点研究的产品之一。

Q & P钢中的合金元素主要是置换型合金元素Si和Mn。Si在钢中主要是抑制形成渗碳体,另外,它能增加碳在奥氏体中的活度,阻碍渗碳体形核和长大,使碳在奥氏体中富集。Mn主要通过固溶强化降低γ→α的相变温度,从而促使晶粒细化,并降低Ms点。赵才等 [23] 研究了淬火和碳再分配热处理工艺对化学成分为0.17% C-1.41% Si-1.48% Mn-0.016% P-0.25% Al的Q&P钢的显微组织及精细结构的影响。结果显示,实验钢经910℃完全奥氏体化,淬火至240℃等温得到可控量的残余奥氏体,之后经350℃等温段的碳再分配处理,提供了间隙原子碳由马氏体向奥氏体扩散的动力,碳原子活动能力增加,能进行较长距离扩散。最终得到了板条马氏体和条间膜状残余奥氏体,较高的含碳量使得条间膜状残余奥氏体在室温状态下具有较高的稳定性。控冷后试验钢组织中的奥氏体量可以达到6%~12%。

Q & P钢之所以既能获得高的强度又具有良好的塑性,除从成分设计上得以保证外,其Q & P处理工艺显得尤为重要。Jing Sun等 [24] 研究了化学成分为0.20% C-1.5% Si-1.9% Mn的Q & P钢热处理工艺对其组织和性能的影响规律。结果显示,在350℃保温100 s后,以50℃/s分别冷却到不同温度,残留奥氏体中碳含量随淬火温度的变化情况如图9所示,由图中可以看出随着淬火温度的升高,残留奥氏体中的碳含量降低,但是实验测得的残留奥氏体中的碳含量均高于计算值。造成这一现象的主要原因是在模拟计算过程中没有很好的结合配分动力学和奥氏体内碳的浓度梯度。Q & P处理工艺是获得残留奥氏体的最有效的方法。其能获得的最大的残留奥氏体的分数约为10%。

5. 结语

随着国内汽车工业的飞速发展,以及能源短缺问题的日益突出,汽车行业一直致力于追求更安全、更节能、更环保的汽车生产新工艺。因此,高强钢和先进高强度钢铁材料的应用具有广阔的前景,尤其是相变强化类先进高强钢的应用越来越受到人们的关注。与铝镁合金相比也具有较强的竞争能力。国外钢铁企业十分注重先进高强度复相钢的研究开发工作,近年来成功开发出了DP钢、TRIP钢、CP钢,并

Figure 9. Change of C contents of retained austenite as a function of quenching temperature

图9. 残留奥氏体中的碳含量随淬火温度的变化曲线图

形成了商业化规模,在汽车车身上得到了广泛应用。第二代和第三代先进高强钢的代表钢种TWIP钢和Q & P钢目前已完成开发,正在积极探索商业化批量生产和应用。国内冶金行业和汽车工业,以及一些研究机构和高等院校也正在进行先进高强钢的开发和研制工作,并实现了第一代先进高强钢的商业化,希望在第二代和第三代先进高强钢的研制开发工作上取得更大的突破,以促进我国汽车用钢达到国际先进水平。