1. 引言

5083铝合金属Al-Mg系合金,具有轻质、耐蚀、易成型等特征 [1] [2] ,5083铝合金板带材在汽车板、船舶板、运煤敞车、压力罐、易拉罐、花纹板、铝塑复合板等领域应用广泛 [3] [4] 。随着我国工装水平的提高,热连轧高效制备技术广泛应用于5083铝合金产品的制备,而在热连轧生产过程中,合金组织将随着工艺的变化发生动态回复、动态再结晶、静态回复、静态再结晶等多种变化,合金再结晶行为直接影响材料性能,尤其是材料卷取后的静态再结晶行为甚至将影响中厚板成品性能。因此,铝合金静态再结晶行为的研究具有重要意义。为此,作者以已完全再结晶5083铝合金热粗轧板为材料,在Gleeble-3800热模拟机上对试样进行高温压缩,对高温压缩试样进行了盐浴退火,分析了热变形条件及后续热处理条件对5083铝合金静态再结晶行为的影响,并建立了静态再结晶动力学方程,为生产过程中热连轧工艺参数设置与产品性能预测提供依据。

2. 实验方法

实验材料为已完全再结晶退火的5083铝合金热粗轧板,其化学成分如表1所示。

将试样制备成直径为10 mm、高度为15 mm、两端带有深度为0.2 mm凹坑的热压缩标准样品 [5] 。在Gleeble 3800热模拟机上进行等温压缩试验,压缩前在试样两端的凹槽内填充75%石墨 + 20%机油 + 5%硝酸三甲苯脂,减少摩擦对应力状态的影响,压缩后立即水淬以保留高温变形组织。根据热压缩试验数据计算出不同压缩条件下样品所对应的Zener-Hollomon参数值 [6] ,将水淬后的圆柱试样沿纵向剖开进行盐浴退火,并对退火后的试样剖分面进行光学金相观察与维氏硬度检测。本文试样的热压缩变形条件、Z参数值、试样退火条件如表2所示。

3. 实验结果与分析

3.1. 热变形与热处理条件对显微组织的影响

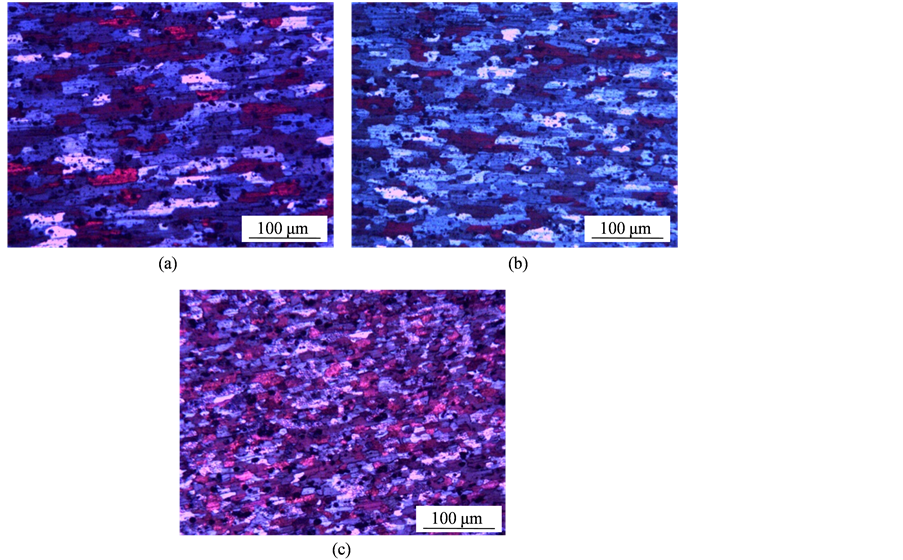

图1为8#、3#、6#试样完全再结晶退火后的金相组织照片,如表2所示,3组试样变形量及后续退

Table 1. Chemical composition of the investigated 5083-type alloy (wt.%)

表1. 实验所用5083铝合金化学成分(wt.%)

Table 2. Sample number and test conditions

表2. 试样编号及试验条件

Figure 1. Optical micrographs of different Z parameters of 5083 aluminum. (a) lnZ = 30.2; (b) lnZ = 32.5; (c) lnZ = 34.8

图1. 不同Z参数下的5083铝合金光学显微组织。lnZ = 30.2; (b) lnZ = 32.5; (c) lnZ = 34.8

火温度都保持一致,而变形过程中的lnZ分别为30.2、32.5、34.8,通过Image-Pro Plus 软件统计得到其再结晶后的平均晶粒尺寸分别为38.6 μm、28.5 μm、19.3 μm,这说明在一定范围内随着试样变形过程中Z参数值的增大,试样退火后的平均再结晶晶粒尺寸减小。

Z值越小,说明热压缩过程中应变速率较低或变形温度较高,原子热运动加剧,试样有足够的时间进行位错运动和空位扩散,因而动态回复程度大,形成大量的亚晶结构,在后续热处理过程中,小的亚晶粒通过相互合并粗化长大形成大的亚晶粒,粗大的亚晶无需孕育期直接形核长大,且已形核的动态再结晶晶粒将成为静态再结晶晶粒的核心优先长大,因此图1中8#试样平均再结晶晶粒尺寸相对较大。

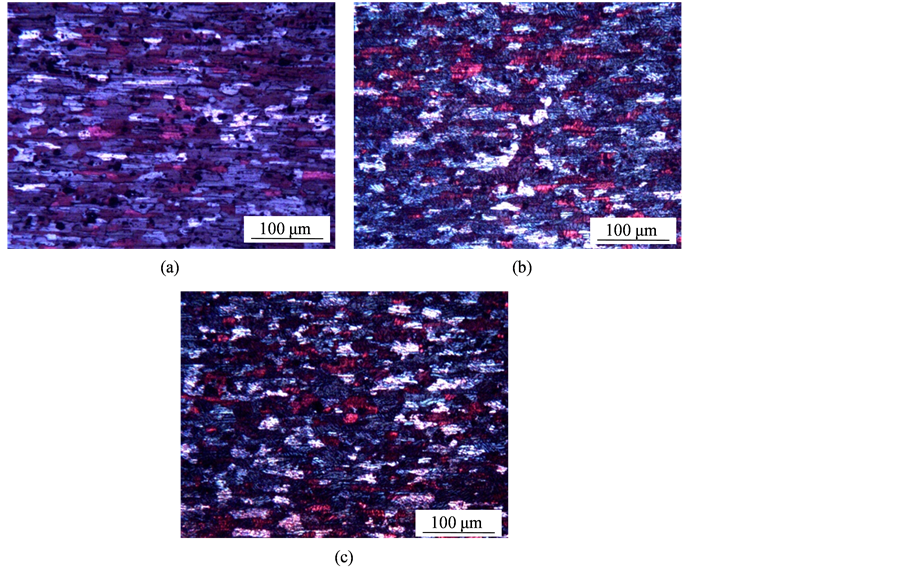

图2为5#、6#、7#试样完全再结晶退火后的金相组织照片,其热变形温度均为350℃,应变速率均为10 s−1,退火温度均为400℃,变形量分别为30%、50%、70%,再结晶平均晶粒尺寸分别为46.2 μm、19.3 μm、16.8 μm,这说明变形量越大,试样的再结晶平均晶粒尺寸越小。

对于5#、6#、7#试样,变形量越大,变形过程中形成的位错密度越高,形变储能也越多,在后续退火过程中,试样晶界在形变储能的驱动下向高密度位错晶粒移动时,晶界所扫过的区域位错密度降低,能量释放,所形成的无应变小区域尺寸达到一定值时成为了再结晶核心 [6] 。形变储能较高的试样将获得较大的形核率,这些晶粒还未充分长大之前晶界就相遇,阻碍了各自的长大,因此也降低了晶粒的长大速率。变形量越大,长大速率/形核率比值越小,因此7#试样平均再结晶晶粒尺寸相对较小。

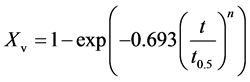

图3为2#、3#、4#试样再结晶退火后的金相组织照片,其热变形温度均为350℃,应变速率均为1 s−1,变形量均为50%,退火温度分别为350℃、400℃、450℃,退火后的试样平均晶粒尺寸分别为26.0 μm、28.5 μm、29.1 μm,这说明退火温度对再结晶晶粒的尺寸的影响较小。

对于2#、3#、4#试样,其热变形条件一致,因此退火初期试样的位错密度及畸变储能一致,3组试样的形核率相近。当退火温度高于再结晶温度时,完全再结晶能够在较短的时间内完成 [7] ,2#、3#、4#试样的退火温度分别为350℃、400℃、450℃,均高于5083铝合金再结晶温度,因此3组试样完成完全再结晶的时间相近,并且晶粒周围临晶生长过程也相似,因此3组试样的再结晶晶粒尺寸相差不大。

图4为6#试样经过不同时间再结晶退火后的金相组织照片,退火时间分别为0 s、8 s、45 s、45 min,随着退火时间的延长,晶粒发生了显著的变化。热粗轧板变形完成后,纤维组织是其主要的组织特征,随着退火过程的进行,纤维组织开始粗化,当退火进行到8 s时纤维组织中开始出现细小的再结晶晶核,随着退火时间的延长,再结晶组织所占比例逐渐增大,经过45 s退火之后,整个组织基本都被再结晶晶粒所代替。当退火时间达到45 min时,晶粒发生明显长大的现象。

图1~4表明变形过程中随着Zener-Hollomon参数值的增大、变形量的增加,再结晶晶粒尺寸越细小,而退火温度对再结晶后的晶粒尺寸影响不明显。随着退火时间的延长,纤维组织逐渐演变为等轴的晶粒,并且随着时间的增加,晶粒发生明显长大的现象。

3.2. 热变形与热处理条件对再结晶速率的影响

试样经过盐浴退火后的再结晶百分数可以通过硬度值的降低来表征,根据文献 [8] 可知计算公式如下:

(1)

(1)

其中,hque为热压缩试样淬火后的硬度值,hp-rec为试样完全再结晶后的硬度值,h为试样经过不同时间盐浴退火后的硬度值。

试样按照表2所示的温度进行盐浴退火,退火时间由0 s逐渐增大至试样完全再结晶,将试样在不同退火时间下测得的硬度值带入公式(1),可得到热变形条件及热处理条件与材料再结晶速率的关系,其曲线关系如图5所示。

由图5(a)可知,Z参数越大,再结晶速率越快,再结晶是一个热激活的过程,涉及到位错运动、晶界迁移,Z参数越大表明试样应变速率越大或变形温度越低,因而变形过程中发生回复或者再结晶软化等

Figure 2. Optical micrographs of different deformation of 5083 aluminum. (a) 0.3; (b) 0.5; (c) 0.7

图2. 不同变形量下的5083铝合金光学显微组织。(a) 0.3; (b) 0.5; (c) 0.7

Figure 3. Optical micrographs of different annealing temperature of 5083 aluminum. (a) 350˚C; (b) 400˚C; (c) 450˚C

图3. 不同退火温度下的5083铝合金光学显微组织。(a) 350˚C; (b) 400˚C; (c) 450˚C

Figure 4. Optical micrographs of different annealing time of 5083 aluminum, deformation conditions: Tdef = 350˚C,  , Trec = 400˚C,

, Trec = 400˚C,  , (a) 0 s; (b) 8 s; (c) 45 s; (d) 45 min

, (a) 0 s; (b) 8 s; (c) 45 s; (d) 45 min

图4. 5083铝合金经不同时间退火后的光学显微组织

过程的时间越短,软化过程进行的程度越低,这些都能导致变形完成之后试样有更大的畸变储能,使得再结晶的驱动力增大,因此再结晶速率也越大。由图5(b)可知,随着应变量增大,再结晶速率增大,应变量越大,变形后位错密度越高,再结晶的驱动力也越大,从而导致再结晶速率增大。图5(c)表明随着退火温度的升高,再结晶速率加快。退火温度越高,原子之间的相互作用力越小,位错越容易运动,因此运动速率越快,再结晶速率越快。

3.3. 再结晶动力学方程

再结晶是一个热激活过程,可采用Avrami方程 [9] 描述不同条件下样品的再结晶速率,方程如公式(2)、(3)所示:

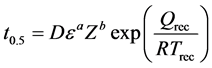

(2)

(2)

(3)

(3)

Xv为再结晶百分数,t为退火时间,k、n为材料常数。t0.5为再结晶百分数达到50%所需的退火时间,因热压缩实验所选取样品的初始晶粒度一致,因此将公式中 作为常数D,即公式(3)简化为公式(4):

作为常数D,即公式(3)简化为公式(4):

(4)

(4)

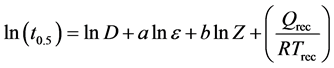

对公式(4)两边取对数可得:

(5)

(5)

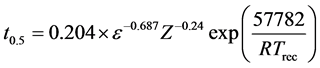

根据图5中的数据进行线性拟合与计算,可求得a = −0.687,b = −0.24,Qrec = 57.782 kJ/mol,D = 0.204。将计算所得的各参数值代入公式(5)可得到5083铝合金静态再结晶的动力学方程:

(6)

(6)

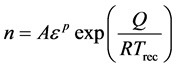

n值为材料常数,与合金再结晶速率及晶粒生长维度有关。根据公式(4)及公式(8)可计算得到不同变形及退火条件下的t0.5及n值。

根据文献 [9] 可知,n值与变形及退火条件的关系可以用如下公式来表示:

(7)

(7)

对所求得到n值进行数值拟合可求得公式(7)中各参数值,最终可确定n可表示为:

(8)

(8)

4. 结论

1) 5083铝合金热变形过程中Z参数值越大或变形程度越大,则合金在后续退火过程中的再结晶速率越大,再结晶后的晶粒尺寸越细小;热变形后的退火温度越高,则合金在退火过程中的再结晶速率越大,但退火温度对合金再结晶后的晶粒尺寸影响不明显;随着退火时间的延长,合金金相组织从纤维状转变为等轴状,进一步延长退火时间后晶粒将发生长大现象。

2) 建立了5083铝合金静态再结晶动力学方程,静态再结晶激活能为57.782 kJ/mol,再结晶方程可表示为:

基金项目

广西“八桂学者”计划课题、广西科学研究与技术开发计划课题(桂科重1598001-2)。