1. 前言

GCr15轴承钢是一种合金含量较少、具有良好性能、应用广泛的高碳铬轴承钢。经过淬火+回火后具有高而均匀的硬度、良好的耐磨性、高的接触疲劳性能 [1] 。研究轴承钢在不同冷却速度下的组织转变规律对于提高轴承钢的综合性能具有重要意义。本文借助于先进的Gleeble3800热模拟试验机测定不同冷却速度下的静态CCT曲线,并对其组织转变进行了研究,为后续优化生产工艺提供参考。

2. 实验材料和方案

2.1. 实验材料

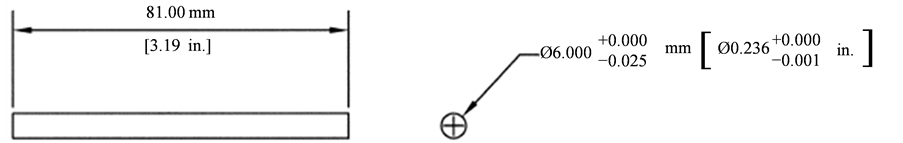

实验采用某钢厂的Φ50 mm规格热轧GCr15圆钢作为材料,将其机加工成如图1所示的热模拟试验样,其原材料的化学成分如表1所示。

2.2. 实验方案

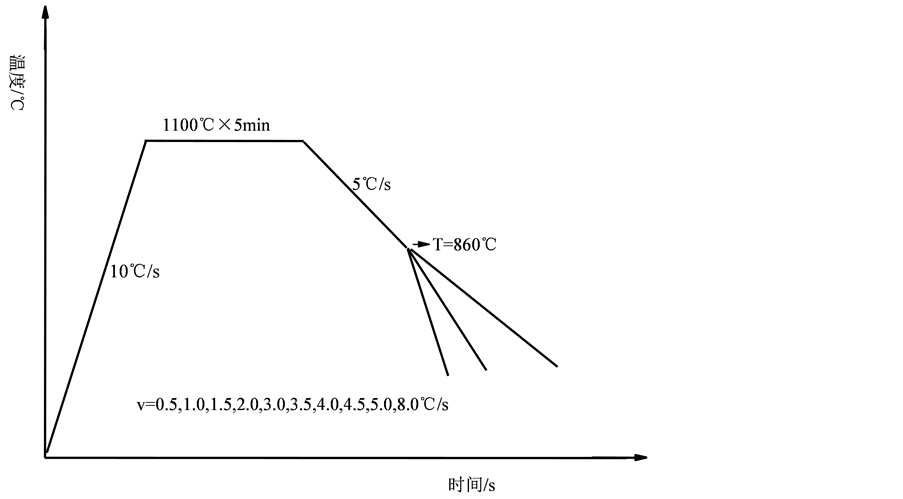

实验方案如图2所示,先将试样以10℃/s的升温速率加热到1100℃,保温5 min,使碳化物充分溶解到奥氏体中,以5℃/s的冷却速率将试样冷却至860℃,然后按照不同冷却速度(V = 0.5, 1.0, 1.5, 2.0, 3.0, 3.5, 4.0, 4.5, 5.0, 8.0℃/s)冷至室温。

使用IsoMet 4000砂轮切割机将试样在热电偶焊点处横向剖开,用SimpliMet1000镶样机进行镶嵌,依次进行粗磨、细磨、抛光处理后用4%的硝酸酒精溶液进行浸蚀,用酒精清洗,将试样吹干,置于DMILM型 LEICA倒置数字显微镜下观察试样的微观组织,并用型号为Zwick ZHμ-A型显微硬度计对试样进行硬度测量,设定试验载荷为500 gf,试验力保持时间为15 s,试验温度为21℃,每个试样测量3次,然后取平均值,观察试样硬度的变化。

在采集的膨胀量曲线上,利用切线法确定相变的开始温度和结束温度,通过金相组织确认发生的相变类型,将不同冷速下的相变开始温度和相变结束温度绘制在温度–时间图上,连接同种类型的相变点,得到静态CCT曲线。

3. 实验结果与分析

3.1. GCr15静态CCT相变温度

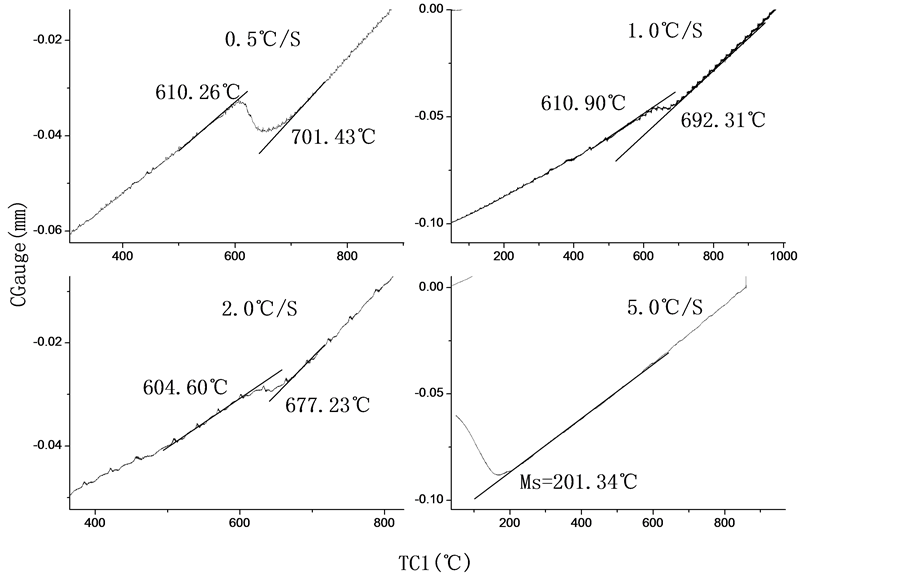

通过膨胀曲线得出了GCr15轴承钢在不同冷速下的相变温度,见表2。在随后的冷却过程中,由于过冷奥氏体绝大部分转变为珠光体,此过程中伴随着体积膨胀,故在膨胀曲线上可以发现较明显的拐点,

Table 1. Chemical constitution of GCr15 smaple (Mass, %)

表1. GCr15试样化学成分(质量分数,%)

Table 2. The temperature of Pearlite phase transformation under static test

表2. 静态实验测定的珠光体相变温度

Figure 1. Schematic illustration of thermal simulation sample size

图1. 热模拟试样规格示意图

Figure 2. Schematic illustration of static CCT test

图2. 静态CCT实验示意图

不同冷却速度下的膨胀曲线如图3所示,其中Ms点为过冷奥氏体向马氏体转变开始温度。

在膨胀曲线的拐点附近作切线,以切线与曲线部分的分离点作为相变开始或结束点,将开始点和结束点分别连接起来,得到静态CCT曲线。

3.2. GCr15静态CCT相变组织

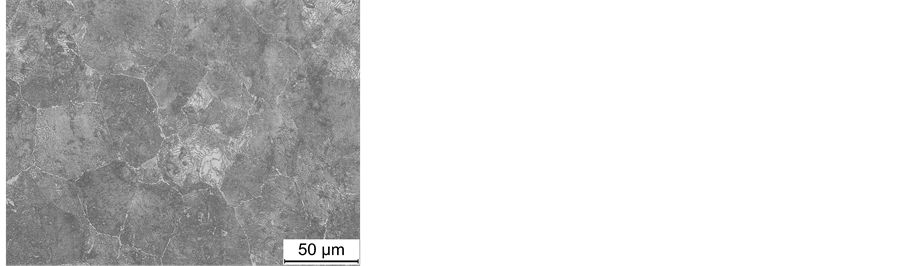

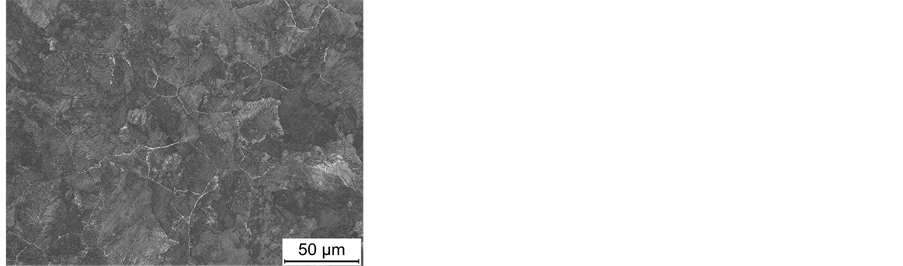

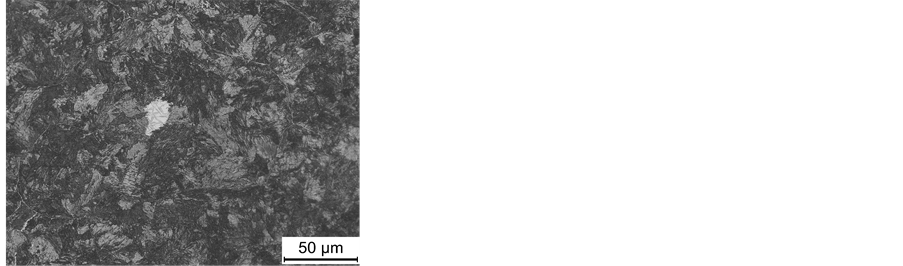

图4及图5为不同连续冷却速度下的金相组织和静态CCT曲线,从金相组织中可以看出,以0.5℃/s的冷却速度冷却至室温时,其组织主要为粗大的珠光体球团,珠光体片层在500倍下清晰可见,呈一

簇一簇的平行排列,珠光体晶界处有紧密围绕的先共析二次碳化物,这些清晰可见的二次碳化物彼此相连呈网状。随着冷却速度的增加,珠光体球团直径有所减小,分布在晶界处的网状碳化物局部连接处发生断裂,呈网状及半网状分布。当冷却速度达到3℃/s时,珠光体呈团絮状分布,二次碳化物厚度变细,呈隐约可见的半网状,二次碳化物的网状趋势逐渐减弱,同时在组织中发现有马氏体生成,这与静态CCT曲线测定的马氏体转变的临界冷却速度为3℃/s相符合。当冷却速度增大到5℃/s时,其组织主要为灰白色针状马氏体 + 黑色珠光体 + 部分亮白色残余奥氏体,没有发现呈网状或半网状的二次碳化物。

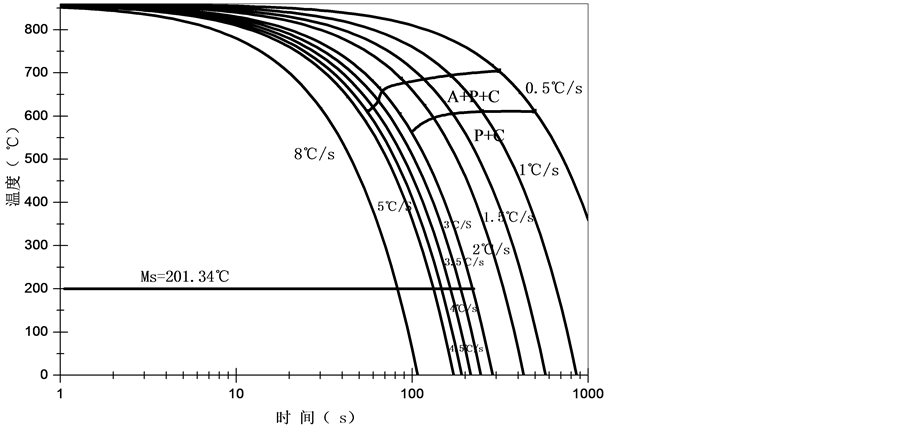

由CCT曲线可以看出,珠光体相变的析出温度主要处于567℃~701℃之间,随着冷却速度不断增大,奥氏体的过冷度逐渐增大,发生珠光体转变的温度也随之降低。当冷却速度处在0.5℃/s~3℃/s区间时,珠光体转变的开始温度变化较平缓,当冷却速度增大到3℃/s及以上时,珠光体转变终止线消失,这是由于珠光体转变不完全,只有一部分过冷奥氏体转变为珠光体,剩余的过冷奥氏体发生了马氏体转变。同时,由静态CCT曲线可知:过冷奥氏体发生马氏体转变的临界冷却速度约为3℃/s,转变开始温度约为201℃。

Figure 3. Static dilatation curves of GCr15 bearing steel

图3. GCr15轴承钢静态膨胀曲线图

(a) (b)

(a) (b)

(c)(d)

(c)(d)

Figure 4. Microstructure of static in different cooling rates at 500 times. (a) 0.5˚C/s; (b) 1.0˚C /s; (c) 3.0˚C /s; (d) 5.0˚C /s

图4. 静态不同冷速下的金相组织照片500×。(a) 0.5℃/s;(b) 1.0℃/s;(c) 3.0℃/s;(d) 5.0℃/s

(V = 0.5, 1.0, 1.5, 2.0, 3.0, 3.5, 4.0, 4.5, 5.0, 8.0℃/s)

(V = 0.5, 1.0, 1.5, 2.0, 3.0, 3.5, 4.0, 4.5, 5.0, 8.0℃/s)

Figure 5. Static CCT curve of GCr15 bearing steel

图5. GCr15轴承钢静态CCT曲线图

3.3. GCr15轴承钢静态CCT显微硬度

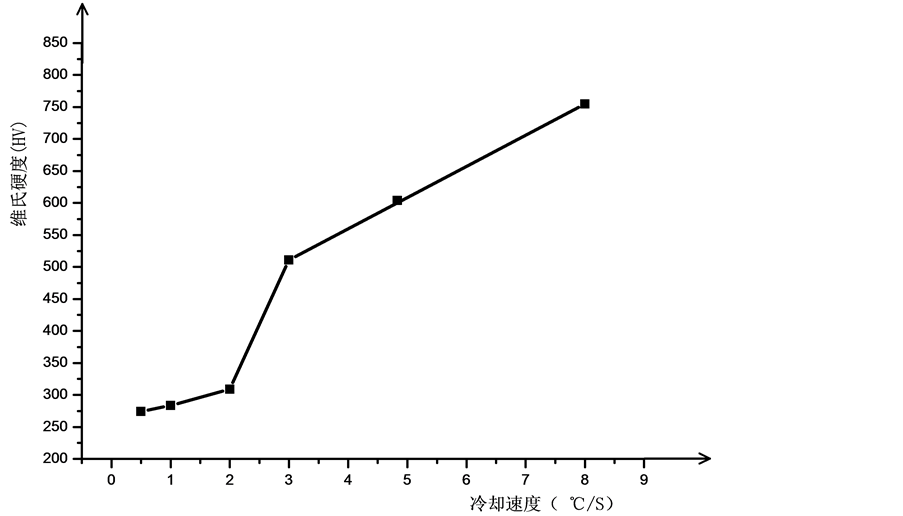

表3列出了静态条件下不同冷却速度对应的显微硬度值,可见随着冷却速度的提高,维氏硬度值逐

Table 3. The hardness of static in different cooling rates

表3. 静态不同冷却速度的硬度值

Figure 6. Vickers hardness in different continuous cooling rates

图6. 连续冷却速度下的维氏硬度图

渐增大,其显微硬度变化趋势如图6所示,可以看出,当冷却速度处在0.5℃/s~2℃/s区间时,随着冷却速度的增加,硬度值增加较为平缓;当冷却速度处在3℃/s以上区间时,硬度值增加较为明显。结合前面的金相组织分析,可以发现,当冷却速度较低时,得到的室温组织为珠光体及网状碳化物,其硬度值较低,随着冷却速度的增大,珠光体球团明显细化,片层间距减小,相界面显著增加,并且部分奥氏体转变为硬而脆的马氏体,使材料抵抗变形的能力大大提高,在硬度上的直观表现就是硬度值逐渐增大。此外,轴承钢GCr15中C、Cr等元素的扩散受温度的影响也很大,随着冷却速度的增加,奥氏体的过冷度逐渐增大,奥氏体中C、Cr等元素的扩散系数显著减小,再加上可扩散的时间减短,C、Cr元素向晶界处的聚集将会减弱,这将导致珠光体中C、Cr含量增加,起到强化珠光体的作用 [2] ,同时晶界处二次碳

化物形态变化构成第二相颗粒,起到强化作用,其强化机制主要为Orowan机制:位错绕过粒子,在粒子周围留下一个位错环使材料得到强化的机制,第二相质点越弥散,数量越多,间距越小,位错运动阻力越大,其强度硬度也会越高 [3] 。综上可以看出,冷却速度较低时,随着冷速的增加,硬度值上升较为平缓;冷速再继续增加时,组织逐渐转变为马氏体,硬度值大幅度提高。当冷却速度达到3℃/s后硬度值迅速升高,结合前面的CCT曲线和组织分析可知,此时金相组织中已经有马氏体产生,马氏体硬度极高,一旦有马氏体生成就会使其硬度大幅度增加。

4. 结论

1) 静态CCT曲线图得到的珠光体相变温度为567℃~701℃。冷却速度控制在0℃/s~3℃/s之间时,室温组织为粗大的珠光体团和网状碳化物组织,冷却速度增加到3℃/s及以上时,珠光体转变终止线消失,在201℃左右将发生过冷奥氏体向马氏体的转变,以大于5℃/s的冷却速度冷却时,网状碳化物明显减少,可有效抑制网状碳化物的析出。

2) 维氏硬度随着冷却速度的增加而增加,在较低冷却速度下随着冷速的增加,珠光体片层间距减小,球团直径明显细化,高冷速下组织以马氏体为主,还有少量残余奥氏体,由于马氏体的硬度极高,形成马氏体使显微硬度明显升高。