1. 前言

蒸发式冷凝器是一种高效节能节水设备,目前,已被广泛用于发电、制冷、化工、纺织等诸多行业 [1] [2] 。蒸发式冷凝制冷系统中,在蒸发式冷凝器的换热盘管外侧,水膜首先通过管壁的热传导,吸收管内制冷剂的冷凝热,再通过显热和潜热交换与管外的空气进行对流换热。深入研究换热盘管外侧的换热对强化蒸发式冷凝器的传热传质以及提高蒸发式冷凝制冷系统的性能有着重大的意义。

由于在蒸发式冷凝器的换热盘管外,气–液两相界面处同时存在质量、动量和热量的传递,使蒸发式冷凝器的模拟计算十分复杂,因此早期的研究方法主要数学分析和实验 [3] [4] ,随着计算机和计算方法的发展,采用数值模拟方法对两相流传热传质现象进行研究成为可能 [5] [6] 。近年来,一些学者采用数值模拟的方法,对空气和水的传热传质进行了相关研究。Feddaoui等 [7] - [10] 发表了一系列文章,对竖直圆管内降液膜蒸发过程进行了数值研究,考察了液膜温度、流量及气流雷诺数对蒸发冷却效果的影响,研究结果表明,液膜内部及界面的微对流过程决定了传热速率。Maria Fiorentino等 [11] 建立了水平管外的降膜蒸发模型,分别研究了稳态和滴状水膜对其性能的影响,并研究管型排布方式对水膜的影响。以上文献表明,运用数值模拟方法研究蒸发式冷凝和传热传质是可行的。

本文利用FLUENT商业软件,将采用VOF (Volume of Fluid)法建立二维流动的计算模型,对管外水膜的传热传质进行研究,以期得到水与空气顺流和逆流过程中,管壁外水膜流动状况、管壁外速度场、水蒸气的浓度分布及空气–水相界面处潜热换热量和显热换热量的比例关系等。

2. 数值模型

2.1. 计算模型

由于对蒸发式冷凝器的换热盘管进行整体模拟极其复杂,需耗费大量的时间,且对计算机的配置要求很高。为了模拟水膜的传热传质现象,本文采用简化计算方法,以一个单元管型切面为例,将喷淋水与空气之间的传热物理模型简化为二维非稳态气–液流动模型,其逆流模型如图1所示。在顺流模型中,

Figure 1. Air and water film two phase counter flow physical model of heat transfer

图1. 空气与水膜两相逆流物理模型

水膜和空气的方向相同,除此以外,其他同逆流模型。

水平管外水膜与空气两相逆流过程属于非稳态气–液分层流动过程。为了确定流动液膜的自由表面位置,本文选用VOF界面追踪技术 [12] [13] 进行数值模拟,VOF模型适用于分层或自由表面流。水平管外的液膜流动属于近壁流,在气相吹扫下,液膜表面发生湍动,这种湍动过程属于低雷诺数下的湍流过程,相界面产生的湍动可采用RNG (Renormalization group) 湍流模型 [14] 。

湍流模型 [14] 。

2.2. 控制方程

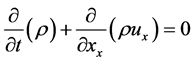

1) 质量守恒方程:

(1)

(1)

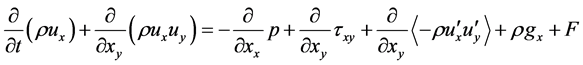

2) 动量守恒方程:

(2)

(2)

式中, 是层流剪应力张量,Pa;

是层流剪应力张量,Pa; 是湍流雷诺应力张量,可由Boussinesq假设来表示;

是湍流雷诺应力张量,可由Boussinesq假设来表示; 是表面张力,本文的表面张力模型采用Brackbill等提出的CSF模型 [15] 中的连续表面力模型。

是表面张力,本文的表面张力模型采用Brackbill等提出的CSF模型 [15] 中的连续表面力模型。

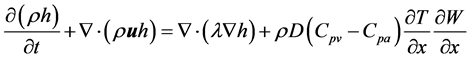

3) 能量守恒方程:

对液膜和空气流,能量方程分别用下式表示:

(3)

(3)

(4)

(4)

式(3)、(4)中,h为流体比焓,kJ·kg−1; 为导热系数,W·m−1·K−1;D为水蒸气在空气中的扩散系数,m2·s−1;Cpv为水蒸气的定压比热,kJ·kg−1·℃−1;CPa为空气的定压比热,kJ·kg−1·℃−1;W为水蒸气在空气中的质量含量,kg·m−3。

为导热系数,W·m−1·K−1;D为水蒸气在空气中的扩散系数,m2·s−1;Cpv为水蒸气的定压比热,kJ·kg−1·℃−1;CPa为空气的定压比热,kJ·kg−1·℃−1;W为水蒸气在空气中的质量含量,kg·m−3。

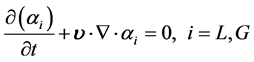

4) 体积分率方程:

设 为计算单元内第

为计算单元内第 相的体积分率,气–液两相界面可用体积分率

相的体积分率,气–液两相界面可用体积分率 的连续方程(5)式求得:

的连续方程(5)式求得:

(5)

(5)

5) 水蒸气组分扩散方程:

空气中水蒸气组分的扩散方程如下式所示:

(6)

(6)

2.3. 模型可靠性验证

本文的计算求解器选用FLUENT6.3流体力学软件包。离散时,时间项采用隐格式;对流项采用一阶迎风格式;压力项采用PRESTO!算法;压力–速度偶合方程的求解采用PISO方法;时间步长为10~6 s。对气–液相界面的追踪采用精度较高的Geo-Reconstruct界面重构技术。

为了验证数值模拟的可靠性,首先在不考虑能量方程和分子扩散方程情况下,按照文献 [16] 的实验条件,对气–液两相的流动情况进行模拟计算。图2反映了液膜厚度随液相Re数的变化,通过对比模拟结果与文献 [16] 及Nusselt理论值可知,三者吻合很好,证明该模型是可靠的。从图2中可知,平均液膜厚度随Re的增加而增加,模拟值比实验测量值 [16] 和Nusselt理论的预测值都要大,模型值比实验测量值大3.03%~6.90%,比Nusselt理论的预测值大8.33%~10.34%,在合理的误差范围内。由此可见,本文建立的数学模型可用于模拟气–液两相流的流动及传热传质分析。

3. 气–液两相顺流和逆流模拟分析

在气–液两相顺流中,水膜和空气的流动方向相同,而气–液两相逆流中,水膜和空气的流动方向相反。由于水膜和空气流向的变化,势必引起气、液界面处剪应力的不同,从而导致不同的结果。为了比较气–液两相流中由于水流方向和空气流方向的变化,对水膜和空气流动状态、水膜和空气流速度场以及空气中水蒸气质量分数的影响,本文分别对顺流和逆流进行了模拟。

气相的流动是影响液膜流动的主要因素之一,气相的流动方向将对液相的流动造成很大的影响。由于气相的吹扫使得水膜自由表面波动加剧,水膜难以维持稳定的膜状。当气相和液相同向流动(顺流)时,由于气–液界面的同向切应力,加快了液相的流动,同时,也削薄了液相的厚度。图3和图4分别为水的流量 ,空气进口流速为

,空气进口流速为 时,顺、逆流不同时刻的液相流动情况以及气相中水蒸气质量分数浓度分布图。从图3可以看出,空气与水达到稳定流动的时间约为0.2秒,出口水膜的厚度约为入口水膜厚度的二分之一左右。气–液两相顺流有利减少水膜厚度,从而减小水膜与管外壁之间的热阻,有利于向热量从管壁水膜的传递(显热传递)。

时,顺、逆流不同时刻的液相流动情况以及气相中水蒸气质量分数浓度分布图。从图3可以看出,空气与水达到稳定流动的时间约为0.2秒,出口水膜的厚度约为入口水膜厚度的二分之一左右。气–液两相顺流有利减少水膜厚度,从而减小水膜与管外壁之间的热阻,有利于向热量从管壁水膜的传递(显热传递)。

从图4可以看出,空气与水达到稳定流动的时间约为0.6秒,约为顺流时间的3倍。出口水膜的厚度约为入口水膜厚度的三分之二左右。当气相和液相反向流动(逆流)时,由于气相的反向切应力,阻止了液相的流动。在气流速较大时,水膜易被吹散成液滴,形成雾末夹带,甚至产生液泛现象。气–液两相逆流不利于减少水膜厚度,从而增加水膜与管外壁间的热阻,不利于热量从管壁向水膜的传递。但是,由于空气的反吹,增大了水膜的扰动,且部分水膜形成水滴扩散到空气中,从而大大增加了水膜和空气的

Figure 2. Liquid film thickness changes with the number of Re

图2. 液膜厚度随液相Re数的变化

接触面积,有利于热量从水膜向空气的传递。

从图3中可以看出,在气–液两相的界面处,存在一个明显的水蒸气质量分数浓度边界层。由于气相和液相中的水蒸气压力不同,因此,当气相和液相接触时,必定在气–液界面存在水蒸气分子的扩散运动。由于液相中的水蒸气分压力高于气相中的水蒸气分压力,因此,液相中的水蒸气分子将向气相中扩散;由于高水蒸气含量的湿空气不断被带走,低水蒸气含量的干空气不断被吸入,因此,气–液两相间持续存在较大的水蒸气分子压力差,液相中的水蒸气分子不断向气相中扩散。由分子运动论可知,液相中的水蒸气分子只有获得足够的能量,才能摆脱液相对它的束缚后脱离。由于液相中的水蒸气分子的扩散、脱离运动,带走了水膜中的大量热能,从而使得水膜的温度下降。这种现象即为水蒸气的传热传质。

图3显示了气–液相顺流时,空气与水从开始流动到达到稳定流动过程中,空气中水蒸气质量分数浓度分布。从图中可以看出,在流动达到稳定前,随着水的流动,水膜从热壁面吸收热量,使得水膜的温度升高,空气与水界面的水分子获得的能量增加,从而使更多的水分子从水膜的逸出,扩散到空气中去,因此,气–液界面处水蒸气质量分数浓度增大;但随着水膜的进一步流动,扩散到空气中的水分子吸收了水膜中的能量,使得水膜的温度降低,从而使气–液界面处的水蒸气质量分数浓度降低。当水膜流动和空气流动达到稳定时,由于气–液顺流,气相对液相的扰动作用不大,空气与水膜的接触面较少,气–液界面处的水蒸气质量分数浓度也达到相对稳定。同样,图4显示了气–液相逆流时,空气与水从开始流动到达到稳定流动过程中,由于在气–液逆流中,气相对液相的扰动作用比在气–液顺流中大,空气与水界面的水分子获得的能量更大,从而使更多的水分子从水膜的逸出,扩散到空气中去,因此,气–液界面处的水蒸气质量分数浓度比气–液顺流时大。而且,空气与水膜的接触面比顺流时大很多,因此,水膜中水蒸气的蒸发相对多,现象更明显。

4. 模拟结果讨论

在蒸发式冷凝器的工作过程中,换热盘管内的制冷剂冷凝热通过壁面传递给管外水膜,再由管外水膜穿过气–液相界面传递给空气。在界面处同时存在着传热和传质现象,其显热和潜热传热量的相对关系是非常重要的,也是评价蒸发式冷凝器性能优劣的一个重要指标。

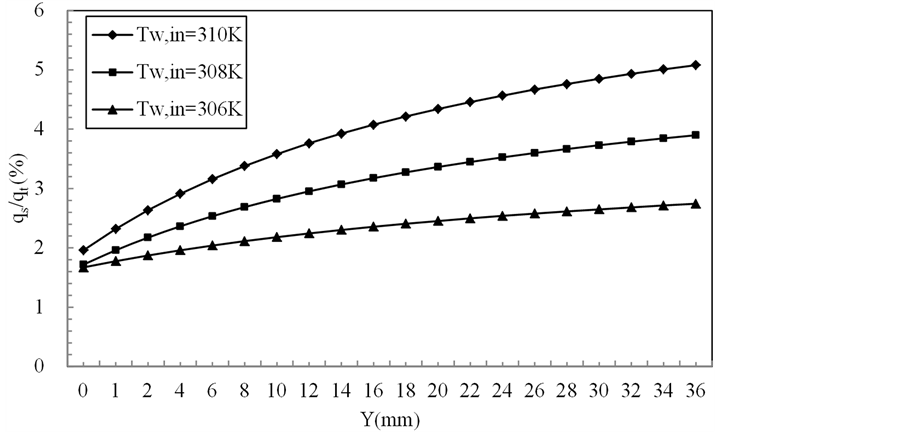

4.1. 喷淋水入口温度对显热和潜热量的影响

蒸发式冷凝器的换热盘管壁面传递的热量,除极少部分直接传递给空气外(壁面湿润率小于1时),主要部分直接传递给管外水膜,而这部分热量中一部分促使水膜蒸发为水蒸气,并扩散至空气中使得空气湿度增大;剩余部分热量则通过水–空气对流传热方式传递给空气,使空气温度升高,最后所有水蒸气和热量都被空气带走,排到蒸发式冷凝器外,可见水膜在整个传热传质过程中起着重要作用,不仅是热、质传递的主要介质,而且也是热量移动的主要载体。如图5和图6所示,在壁面热量密度为3000 w,入口空气温度为303 K,相对湿度为50%,空气流速3 m·s−1,喷淋水流量为1 kg·s−1的条件下,喷淋水的入口温度分别为306 K、308 K、310 K时,气–液界面处显热和潜热与总传热的比值沿喷淋水流动方向的分布。

从图5中可以看出,由于喷淋水入口温度大于空气入口温度,一部分热量以显热的方式由水膜传递给空气,随着喷淋水与空气温差的增大,显热所占气–液界面总传热量的比值也相应增大。沿水膜的流动方向,由于水膜吸收壁面的热量,水膜温度不断增大,而由于空气与水膜的流动方向相反,在同一喷淋水入口温度的条件下,水膜与空气之间的温差越来越大,因此,显热所占总传热量的比值也相应增大。相应地,从图6中可以看出,在沿水膜的流动方向上,在气–液分界处,潜热与总传热的比值和显热与总传热的比值的变化趋势相反。

Figure 5. Ratio of sensible heat rate and total heat rate with different inlet water temperature

图5. 不同入口喷淋水温条件下气–液界面显热与总传热量的比值沿流动方向的分布

Figure 6. Ratio of latent heat rate and total heat rate with different inlet water temperature

图6. 不同入口喷淋水温条件下气–液界面潜热与总传热量的比值沿流动方向的分布

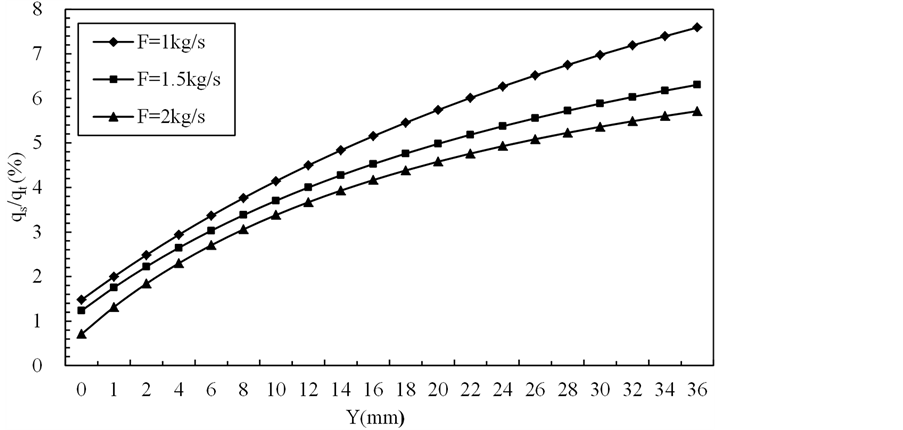

4.2. 喷淋水量对显热和潜热量的影响

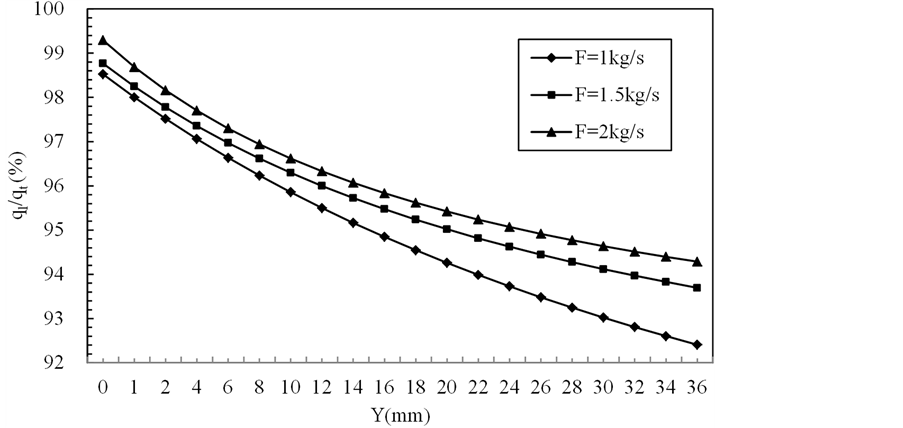

如图7和图8所示,保持其他条件不变,喷淋密度为1 kg·s−1、1.5 kg·s−1、2 kg·s−1时,气–液界面处显热和潜热与总传热的比值沿喷淋水流动方向的分布。

从图7中可以看出,喷淋水量越大,气–液界面显热量所占总热量的比值越小。这是由于喷淋水量的增大,壁面的水膜厚度增大,水的热阻增加,使得壁面传递的热量在穿过水膜的过程中被水膜吸收的部分也较大,而传递到气–液界面处的热量相对较小,导致界面处温度和水蒸气质量分数相应变小,因此显热和潜热传热均减小,其中,对显热的影响更大。相应地,从图8中可以看出,随着喷淋水量的增大,潜热所占全热的比例增大。实验研究表明 [17] ,液膜的流量不能太小,否则,会出现板面液流分布不完全和不均匀,局部的干壁和降膜流动的死区,使这一部分的传热由“蒸发冷”变成了“风冷”,传热效果恶化。

Figure 7. Ratio of sensible heat rate and total heat rate with different water flow rate

图7. 不同水流量条件下气–液界面显热与总传热量的比值沿流动方向的分布

Figure 8. Distribution of ratio of latent heat rate and total heat rate with different water flow rate

图8. 不同水流量条件下气–液界面潜热与总传热量的比值沿流动方向的分布

从气–液两相流的液相分析,综合考虑水膜入口温度和喷淋水量的影响可知,这两个因素都是通过气–液相界面的温度影响传热传质性能,在其他条件相同的情况下,入口水膜温度越高,喷淋水量越小(保证壁面完全湿润前提下),水膜厚度越小,相应气–液界面温度也越大;使得空气与水膜之间的温差增大,界面饱和蒸汽压差也越大,有利于气–液两相之间的传热传质。

5. 结论

由上述分析可知,传热传质引起的传热主要是由水膜与空气之间的水蒸气压力差,导致水分子不断从水膜中向空气中扩散,从而引起热量的传递(潜热换热),同时,由于水膜与空气之间的温差,由此引起的水与空气之间的对流换热(显热换热)。要实现水向空气的蒸发,在气–液界面处必须具有传质的推动力,即水膜表面饱和蒸汽压大于空气中水蒸气压力,且压差越大越有利于传质。总结喷淋水温度、喷淋水量、空气相对湿度、空气干球温度等主要参数的变化对气–液两相流中显热和潜热传热量的影响可以得到如下结论:

1) 就换热盘管管外水膜而言,在相同的操作条件下,水膜入口温度越大,喷淋密度越低(保证壁面完全润湿的前提下),则气–液界面处温度越大,界面饱和蒸汽压也越大,相应增大了气–液两相之间的水蒸气压力差,提高了传质推动力,有利于气–液两相之间的传热传质。

2) 就换热盘管管外空气侧而言,在相同的操作条件下,同一相对湿度下空气的温度越高,或同一空气温度下相对湿度越小,即空气干、湿球温度之差越大,空气主体内的水蒸气分压越小,水膜与空气间的蒸发就越剧烈,传质带动的传热量就越大。

3) 在气–液两相逆流过程的气–液界面的总传热量中,潜热传热量所占比值在90%以上,比气–液两相顺流时高,在气–液相界面处是以水蒸发传质引起的潜热换热为主、温差引起的显热传热为辅的换热形式,逆流比顺流更有利于传热。

致谢

本文由广东美的制冷设备有限公司院市合作项目(科技创新项目) (2014HK100283)和中国南方智谷引进创新团队(顺府办函[2014]365号)资助,在此表示诚挚而又衷心的感谢。

基金项目

广东美的制冷设备有限公司院市合作项目(科技创新项目) (2014HK100283);中国南方智谷引进创新团队(顺府办函[2014]365号)。