1. 引言

高质量的半固态合金浆料的制备是半固态流变成形技术应用的基础和关键 [1] [2] [3] [4] 。为了适应现代化工业生产的需要,新型的半固态流变成形工艺要求在获得高质量浆料的同时,尽可能地通过合理的热处理工艺使流变成形制件获得更高的力学性能 [5] [6] [7] [8] 。

作为航空、航天广泛应用的高强度铝合金,7系超高强度铝合金是现代化生产中以铸代锻、轻量化目标的理想材料 [9] [10] [11] [12] 。近年来,越来越多的学者开始研究将半固态流变成形工艺应用于7系铝合金,并开发出了很多新型的流变成形工艺。然而由于7系铝合金的多元合金性质,导致在固溶处理及时效析出过程中的强化相复杂多变,目前关于7075铝合金的热处理强化机制的研究多集中于轧制态合金,对于铸态及半固态7075铝合金的热处理强化机理研究较少,铸态条件下7075铝合金的热处理强化机制以及强化相的构成目前并无较为统一的认识。这对半固态流变成型7系铝合金的推广和应用带来了阻碍。针对这一问题,本文初步探讨了不同的固溶温度及固溶时间对半固态7075合金浆料组织的影响规律,研究结果可为优化半固态7系铝合金的热处理工艺,揭示铸态7系铝合金的热处理强化机制提供参考。

2. 试验方法

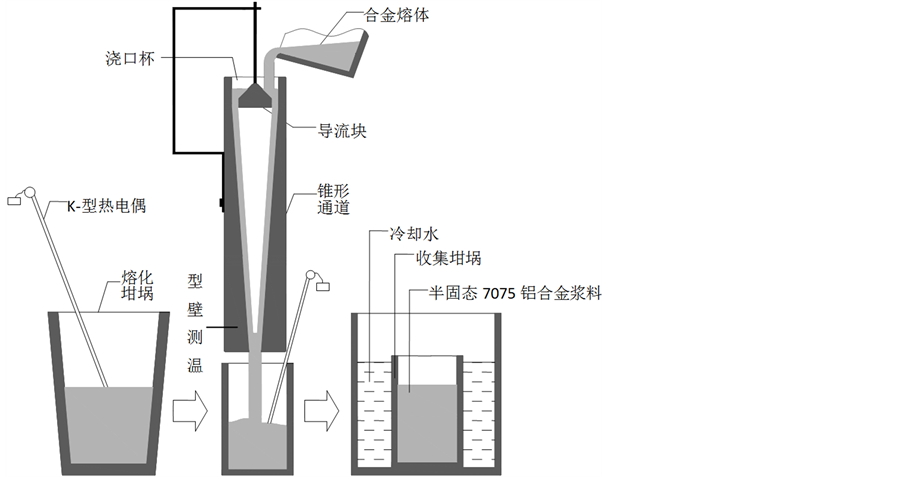

试验合金为商用7075铝合金,其化学成分(质量分数)为:5.9%的Zn,2.2%的Mg,1.7%的Cu,0.35%的Fe,0.1%的Si,余量为Al。该铝合金的理论液相线温度为635℃,固相线温度为477℃。试验所用制备半固态铝合金浆料的锥形管长度为400 mm,内壁锥度4˚,出口内径20 mm。半固态7075铝合金浆料的制备装置如图1所示。浆料收集装置采用不锈钢坩埚,其尺寸为Φ80 mm × 150 mm。在浇注之前,锥形管和收集坩埚均为室温。7075铝合金浇注温度为660℃,合金浇注完毕后立即坩埚连同浆料一起淬火,以保存高温浆料组织。之后采用电火花切割机从锭坯上取若干10 × 10 × 10 mm的样品进行固溶处理,固溶处理在箱式电阻炉内进行,固溶温度分别为460℃、475℃、490℃、500℃,固溶时间分别为1 h、2 h、4 h、6 h。固溶处理前后的试样经过机械抛光之后,用体积分数为0.5%的HF水溶液进行浸蚀,在Neuphoto光学显微镜下观察组织形貌,在Neuphoto光学显微镜下观察组织形貌,初生α-Al晶粒直径用显微镜直

Figure 1. Semi-solid slurry of 7075 Al alloy prepared by schematic diagram of funnel-shaped channel process

图1. 半固态7075铝合金浆料的锥形管浇注制备示意图

接测量。用Image-proPlus金相分析软件来分析金相图片,并对初生α-Al晶粒的面积和周长进行测量,初生α-Al晶粒形状因子利用公式F = 4πA/P2来计算,公式中A和P分别代表初生α-Al晶粒的面积和周长。F值在0和1之间变化,F值越接近1,表明初生α-Al晶粒相形态越圆整。利用公式D = 2(A/π)1/2和F = 4πA/P2来分别计算初生α-Al晶粒的当量直径D和形状因子F,式中A和P分别代表晶粒的面积和周长。

3. 试验结果与讨论

3.1. 半固态7075铝合金浆料的显微组织

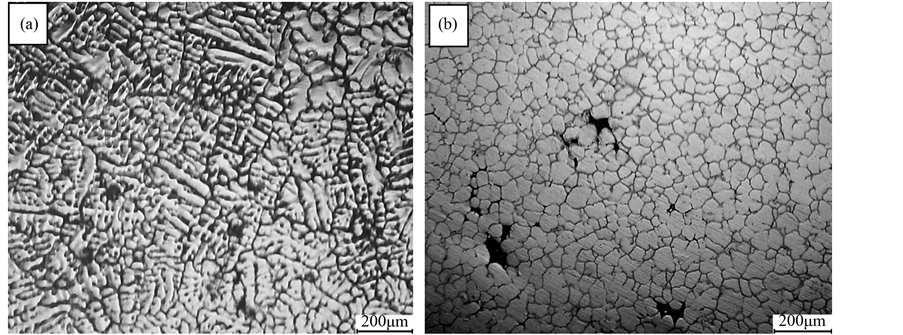

7075铝合金为高强度变形铝合金,极少采用铸造方式对其加工成形,因而需要对其传统凝固组织进行观察和分析。本论文首先研究了一定过热度下液态7075铝合金的传统凝固组织。图2(a)为浇注温度为660℃时,过热的7075铝合金熔体不经过锥形管直接浇入收集坩埚并立即淬火后的组织。可以看到,在常规7075凝固组织中,无论是试样的心部还是边部,初生α-Al晶粒几乎全部都是发达的枝晶,平均晶粒直径为200 μm以上。初生α-Al的形状因子仅为0.28左右。图2(b)所示为采用锥形管浇注流变成形工艺在浇注温度660℃时获得的半固态7075铝合金浆料组织。从图中可以看出,通过锥形管浇注流变成形工艺制备得到的半固态7075铝合金浆料与常规凝固凝固组织相比有了很大的变化,组织中的初生α-Al晶粒均为球状或近球状颗粒,平均晶粒直径约也降低到42 μm左右,初生α-Al的形状因子为0.82,组织相对细小均匀,半固态浆料的质量较高。

3.2. 固溶温度对浆料组织的影响

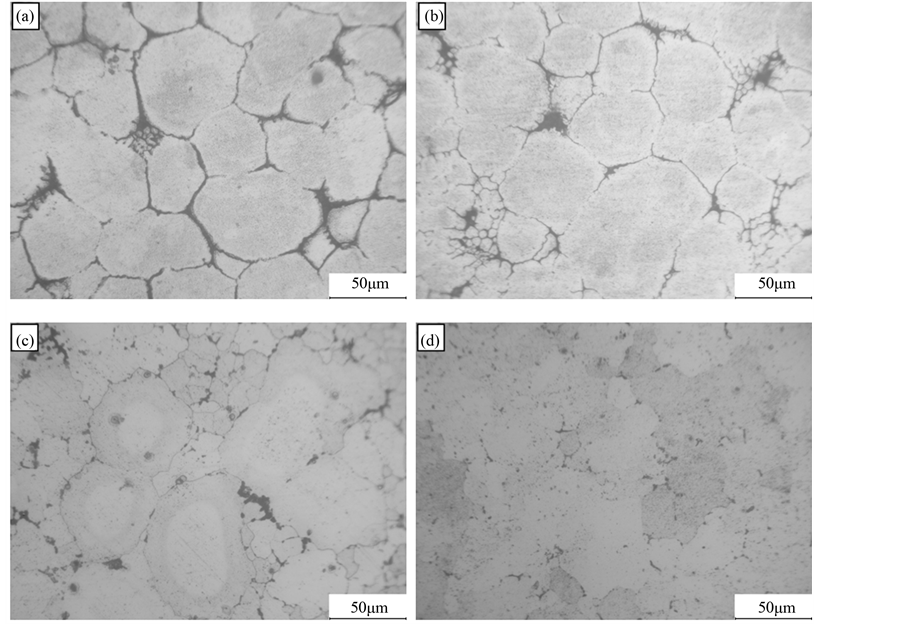

7075铝合金的理论固相线温度为477℃,过低的固溶温度会使合金的固溶效果明显减弱,而过高的固溶温度则会使合金中的初生相出现重熔和过烧现象,本文参考轧制态7075铝合金的处理方式制定了半固态7075铝合金浆料的固溶处理温度范围,并研究了合金分别在460℃、475℃、490℃、500℃时,固溶时间为4 h条件下固溶温度对浆料微观组织的影响趋势。不同的固溶处理温度下半固态7075铝合金浆料的微观组织如图3所示。由图可知,当固溶温度为460℃,固溶时间为4 h时,组织中的初生晶粒形态

Figure 2. Typical microstructures of original cast 7075 Al alloy vs. water quenched semi-solid slurry of 7075 Al alloy: (a) original cast 7075 Al alloy at pouring temperature of 660˚C, (b) semi-solid slurry of 7075 Al alloy at pouring temperature of 660˚C

图2. 半固态7075铝合金浆料与常规凝固组织对比:(a) 660℃时的常规凝固组织,(b) 660℃通过锥形管浇注工艺制备的半固态浆料组织

Figure 3. Microstructures of semi-solid 7075 Al alloy slurry after solution treatment (solution time 4 h): (a) 460˚C, (b) 475˚C, (a) 490˚C, (a) 500˚C

图3. 不同固溶温度下半固态7075铝合金浆料的显微组织(固溶时间4 h),(a)固溶温度460℃,(b) 固溶温度475℃,(c) 固溶温度490℃,(d) 固溶温度500℃

相较固溶处理前变得更加圆整,初生α-Al的形状因子为0.84,有一定的晶粒熟化效果,晶粒尺寸变化并不明显,平均晶粒尺寸约为44 μm,第二相粒子在晶界处的富集现象仍十分明显,固溶处理效果较弱。当固溶温度升高至475℃时,初生晶粒的平均尺寸变为52 μm,初生α-Al的形状因子为0.87,同时可看到晶界处第二相粒子的数量显著减少,晶界变得纤细且模糊,少部分晶界出现断裂和晶粒融合现象。随着温度进一步升高至490℃时,初生初生晶粒的平均尺寸变为68 μm,初生α-Al的形状因子为0.86,组织中的第二相粒子大部分已溶入基体中,部分晶界处残留有一定数量的硬质难熔相,面分布扫描显示为富铜相,如图4所示。当固溶温度提高至500℃时,可以看到组织中已基本看不到第二相粒子,晶粒的异常长大和合并现象明显增多,初生α-Al的形状因子降至0.68,晶界变得难以区分,且出现了部分区域晶界重熔现象,说明固溶处理温度过高。综合上述分析可以看出,适合半固态7075铝合金浆料的固溶处理温度为475℃附近。

Figure 4. Surface scanning image of the microstructures of semi-solid 7075 Al alloy slurry after solution treatment: 490˚C, 4 h

图4. 固溶处理后7075铝合金组织的面分布扫描:固溶温度490℃,固溶时间4 h

3.3. 固溶时间对浆料组织的影响

本文研究了固溶时间分别为1 h、2 h、4 h、6 h时,固溶温度为475℃条件下固溶处理过程中半固态7075铝合金浆料的微观组织演变趋势。不同固溶时间时浆料的微观组织变化情况如图5所示。可以看到,与未经固溶处理的半固态7075铝合金浆料组织相比,当固溶时间为1 h时,组织中的第二相粒子仍大部分聚集在晶界附近,溶入基体的趋势并不明显,晶粒也无明显长大现象,与处理前组织并无太大差别。当固溶时间为2 h时,组织中的晶界变得纤细,第二相粒子已部分溶于基体中,平均晶粒尺寸约为45 μm左右,初生α-Al的形状因子为0.86。随着固溶时间的进一步延长,合金组织中的第二相粒子更多的溶入基体中,晶界进一步模糊,晶粒尺寸增长趋势逐渐加快,部分晶界处仍残留有难熔得富铜相质点。当固溶温度为6 h时,可以看到合金组织中的第二相粒子大部分都已溶解进入基体中,大部分晶界消失,同时难熔质点在合金组织中的分布也更加均匀,晶粒的异常长大和合并现象并不明显。因此,当固溶温度为475℃时,适宜的固溶处理时间应为4~6小时左右。

由于经过锥形管流变工艺制备所得的半固态7075浆料主要以球晶或近球晶为主,因而在固溶处理时合金第二相的溶解与后续强化相的析出机理与轧制态7075铝合金并不一致 [13] [14] [15] 。在本试验中,制备半固态7075铝合金浆料时在晶界处聚集析出的第二相粒子对固溶过程中晶界的迁移有显著的阻碍作用。当固溶温度较低时,晶界上的第二相粒子溶入基体的速度较慢,固溶效果较弱,但由于第二相粒子的钉扎作用,合金组中的初生相长大并不明显。随着固溶温度的升高,第二相粒子的溶解速度加快,晶界逐渐变得纤细和模糊,晶界迁移效果增强,但初生相的尺寸也逐渐变大。当固溶温度过高时,合金

Figure 5. Microstructures of semi-solid 7075 Al alloy slurry after solution treatment (solution temperature 475˚C): (a) 1 h, (b) 2 h, (c) 4 h, (d) 6 h

图5. 不同固溶时间下半固态7075铝合金浆料的显微组织(固溶温度为475℃):(a) 固溶时间1 h,(b) 固溶时间2 h,(c) 固溶时间4 h,(d) 固溶时间6 h

组织中的晶界重熔及合金过烧现象显著增加,浆料质量显著恶化。同样,当固溶温度一定时,随着 固溶时间的延长,合金中第二相粒子的溶解现象进一步增强,晶界迁移显著增加,固溶效果逐渐增强。

4. 结论

1) 经锥形管浇注流变工艺制备所得的半固态7075铝合金浆料组织普遍为球状或近球状初生晶,晶粒细小均匀,浆料质量较高。

2) 当固溶温度为460℃~500℃时,随着固溶温度的升高,合金中第二相粒子的溶解速度加快,晶界迁移效果明显。当固溶温度低于475℃时,初生晶粒的长大效应不明显,当固溶温度高于475℃时,浆料中的晶粒异常长大和合并现象显著增加,浆料质量下降。

3) 当固溶温度为475℃不变时,随着固溶时间的延长,第二相粒子的溶解现象更加明显,固溶效果显著提高,初生晶粒的长大趋势并不明显。

基金项目

本课题获河南科技大学大学生研究训练计划项目(2015020)支持。