1. 引言

现在,空调制冷行业飞速发展,但由此带来的环境问题也越来越引起人们的关注。制冷空调设备中使用的氟利昂制冷剂加剧了臭氧层的破坏和全球变暖。氯氟烃(CFCs)和氢氯氟烃(HCFCs)由于臭氧层消耗潜值(ODP)和全球变暖潜值(GWP)较高,是破坏臭氧层,产生温室效应的重要物质,已被《蒙特利尔议定书》列入淘汰目录中,各个国家正在加速淘汰;而作为它们的替代物-氢氟烃(HFCs)虽然ODP为零,但GWP值较高,大量使用仍能产生温室效应,已被《京都议定书》列为温室气体,现在也逐渐被淘汰 [1] 。2014年欧盟对F-gas法规进行了修订 [2] ,从2020年起,禁止GWP大于2500的HFCs用于商用制冷机组中;到2022年,禁止GWP大于150的HFCs用于商用制冷机和冷冻机中。多项法规明令控制高GWP工质的使用,这势必会成为一种寻找新型替代制冷剂的动力。

霍尼韦尔和杜邦公司联合开发的氢氟烃(HFOs)制冷剂包括R1234yf和R1234ze(E)等被认为是替代HFCs的新一代制冷剂 [3] [4] [5] [6] [7] 。HFOs的ODP为零,GWP < 1,大气寿命非常短暂(0.029年),ASHRAE将其化为A2L,属弱可燃制冷剂。但同时HFOs具有一些缺点,单位容积制冷量小,COP较低,换热系数小,价格昂贵,而且HFOs的使用存在专利缺陷,目前围绕HFOs系列制冷剂均被国外大公司申请了专利保护 [8] 。另外,HFOs及其混合工质一般不能直接充注在HFCs的制冷系统中,若要达到与原有制冷剂COP和制冷量相同的要求,就需要对原先的制冷系统进行改进和优化 [9] [10] [11] [12] 。因此,国内若以HFOs作为替代制冷剂来替代HFCs,那么必定会成本高,难度大。

碳氢制冷剂(HCs)的ODP为零,GWP极低,无毒,单位制冷量大,热物理性质良好而且来源广、价格便宜,但易燃易爆。由于其具有良好的环保性能和物理性质,因此HCs及其混合物仍具有极大的作为替代制冷剂的潜力 [13] [14] [15] 。一些常用的HCs制冷剂与R134a的临界状态点和常压沸点如表1所示。

Table 1. The normal pressure boiling point and critical state point of HCs and R134a [16]

表1. 常用的HCs与R134a的常压沸点和临界状态点 [16]

从表1中可以看出,没有单工质的HCs (如R290、R600a、R600等)与R134a的热物理性质相似,但一些学者研究发现R290/R600a (质量比为50/50, 40/60, 55/45)能表现出与R134a热物性相似的性质,其中R290/R600a (质量比为55/45)与R134a的相似性最好 [16] ,具有替代R134a的潜力。本文就R290/R600a混合制冷剂的各种性能及国内外研究进展进行介绍,为新型环保制冷剂的替代提供新思路。

2. R290/R600a的热物性研究

2.1. 可燃性研究

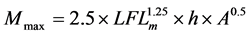

众所周知,HCs作为制冷剂使用的一个很大缺陷就是易燃易爆,这使得HCs的充注量不能过多,只能用于小型制冷系统如冰箱、冷柜中。若要将R290/R600a充注在制冷系统中,就必须要对它进行可燃性研究,确保它的充注量在安全范围内。R290与R600a的燃烧特性如表2所示。根据EN-378标准,应用方程(1)进行可燃制冷剂最大充注量的计算 [17] 进行计算:

(1)

(1)

式中,Mmax为房间内所允许的最大充注量,kg;LFLm为燃烧下限,kg/m3;A为房间面积,m2; h为装置的高度,m。假定设备中R290/R600a (质量比为50/50)充注量为150 g,设备高度1.8 m,R290/R600a的最低燃烧下限为0.041 kg/m3,则房间的最小面积为3.26 m2。

从表2可以看出,R290、R600a及其混合物的燃烧上下限差别不大,燃烧范围较广。对于可燃制冷剂来说,使用过程中的安全性是最需要关注的,所以为了保证使用HCs作为冰箱空调制冷剂的安全性,就必须要计算出它们的最大充注量,根据方程(1)可以实现可燃制冷剂最大充注量的求解。

2.2. 二元相互作用系数的研究

为了能得到R290/R600a混合后的性质,把它作为新型替代制冷剂应用于制冷空调系统中,则需要建立R290/R600a的热力学状态方程,而若要根据状态方程求得状态数据,还需得到R290/R600a的二元相互作用系数。对于二元混合物质,常用的状态方程是PR方程以及vdW混合法则。PR状态方程式的具体形式如下:

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

Table 2. The combustion characteristicsof R290 and R600a [18]

表2. R290与R600a的燃烧特性 [18]

(6)

(6)

(7)

(7)

其中,Tc为临界温度,K;Pc为临界压力,kPa;ω为偏心因子。

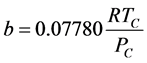

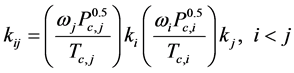

为了使PR方程适用于二元混合物质,应用vdW混合法则,如下:

(8)

(8)

(9)

(9)

(10)

(10)

其中,kij为二元相互作用系数, ,

, 。

。

对于这种立方型状态方程中的混合法则而言,二元相互作用系数kij针对不同的物质有不同的取值,得到kij的方法主要由实验法和解析法。国内外许多学者对R290/R600a二元相互作用系数进行了深入研究。国外学者Akasaka等 [19] 建立R290/R600a混合工质的PR + vdW方程模型,运用最小二乘法和目标函数对kij进行优化,得到R290/R600a的二元相互作用系数kij = −0.01116,通过解析法将kij代回原式可以得到一系列热物性数据,并与实验值作比较,绝对误差为0.83%,具有很好的重合度。

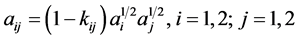

胡鹏等 [20] 运用解析法提出了HC/HC二元混合工质的相互作用系数kij的计算公式,如下:

(11)

(11)

他们运用解析法将上述公式与实验测出的kij相比较,相对误差较小,精度比较高。这为后续研究R290/R600a二元混合工质的热力学性质提供了可靠的依据。

以上学者通过实验法或解析法得到R290/R600a的二元相互作用系数,根据二元相互作用系数运用PR状态方程和vdW混合法则可以得到R290/R600a的PVT性质,这样就可以通过理论方法得到R290/R600a的基本热物性,为R290/R600a作为新型替代制冷剂提供了理论基础和依据。

3. R290/R600a制冷系统试验研究

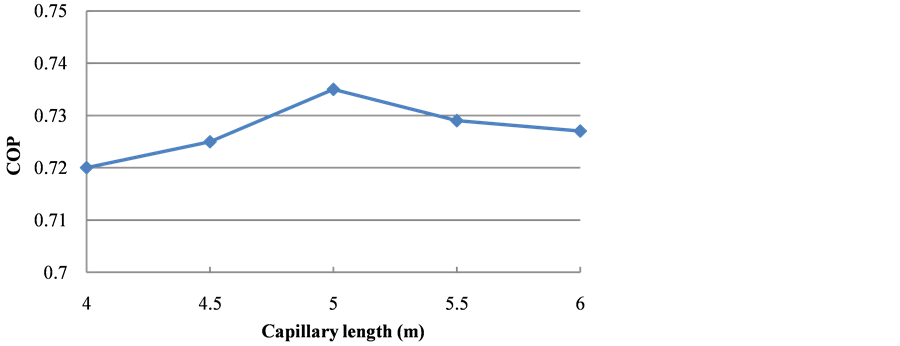

目前,国内制冷空调市场上许多冷柜、冰箱中依然采用R134a作为制冷剂,但由于R134a的GWP较高,不符合环保的要求,针对R290/R600a混合制冷剂替代冷柜、冰箱中的R134a,国内外众多学者进行了大量的实验研究。何茂刚等 [21] 对R290/R600a (质量比为90/10)混合制冷剂应用于大容量冷柜以替代R134a进行了实验研究和理论分析。结果表明,R290/R600a的单位容积制冷量和COP值比R134a分别高48.3%和2.4%;R290/R600a的最佳充注比为93.75%/6.25%,此时的功耗比R134a低27.5%。Mohanraj等 [22] 对R290/R600a应用在家用冰箱中替代R134a进行了实验研究。实验中,他们以HCM (R290/R600a质量比为45.2/54.8)不同的充注量作为研究对象与R134a作比较并进行性能分析。通过实验得到了以下结论:1) 充注HCM的冰箱比充注R134a的能耗低,排气温度低8.5~13.4 K,COP值高3.25%~3.6%,不同充注量的HCM与R134a的COP关系如图1所示;2) 当毛细管长为5 m时COP达到最大值,毛细管长度与COP之间的关系如图2所示;3) 蒸发器中的温度滑移为3K; 4) HCM与润滑油的相容性很好。

与此同时,Lee等 [16] 将R290/R600a (质量比为55/45)和R134a分别充入不同的冰箱中,实验研究发现,R290/R600a的充注量是R134a的一半,但毛细管的长度要比充有R134a的长约500 mm。另外,由

Figure 1. The relationship diagram of R134a for HCM and COP

图1. HCM与R134a的COP关系图

Figure 2. Relationship between capillary length and COP

图2. 毛细管长度与COP之间的关系图

于R290/R600a的工作压力比R134a高,换热能力也比R134a强,使得充有R134a的冰箱的能耗比充有R290/R600a的高12.3%,冷却速度低28.8%。Yu等 [15] 将三种不同质量比的HCs制冷剂,HC1 (R290/R600a质量比为65/35)、HC2 (R290/R600a质量比为50/50)、HC3 (R290/R600a质量比为0/100)分别充注在R134a类型的冰箱中,在最佳充注量的情况下,使用HC类制冷剂比R134a的冰箱的温度和能耗高;调整R134a、HC1、HC2、HC3的毛细管的长度分别为2.77 m、5.05 m、5.34 m和5.6 m,改变毛细管的长度后,所有的HC类制冷剂都能用在R134a的冰箱中。以上学者的研究表明,R290/R600a的各种热力性能都优于R134a,用R290/R600a替代R134a不仅环保而且效率高,耗能少;另外,不同质量比的R290/R600a完全可以充注于R134a的冰箱中来替代R134a,但需要相应的改变毛细管的长度。

R436A是由R290/R600a按照质量比为54/46混合而成的新型天然制冷剂,R436A比R134a节能20%,而且它的热工性能与R134a相近,所以对R134a制冷系统无须变更,目前R436A已经商业化。Mehdi等 [23] 对R436A作为R134a的替代制冷剂应用在家用冰箱中进行了能效分析。他们分别将R436A充注在HFC类压缩机和HC类压缩机中,研究结果表明,在HFC类压缩机中,R436A的最佳充注量为60 g,而且相对于R134a而言,它的充注量减少了14%;在HC类压缩机中,R436A的最佳充注量为50 g,充注量减少了14.6%。另外,Mehdi等 [24] 还将R436A充注于238 L的家用冰箱中,实验结果表明,与R134a相比,冰箱的开启时间比减小13%,每天的能耗相应降低5.3%,蒸发器的吸气温度降低3.5℃,TEWI值降低11.8%,这从不同角度说明了R436A应用在家用冰箱中比R134a性能优越。

液化石油气LPG是R290/R600/R600a按照质量比为30/55/15组成的,可以看出LPG也是由HCs混合而成,它天然环保的特点引起了人们的注意,近年来有许多人提出用LPG作为替代制冷剂应用于家用冰箱中,也有许多学者将LPG充注于家用冰箱中进行性能测试实验。Mohamed 等 [25] 对LPG作为替代R134a应用在家用冰箱中进行了能量和火用分析。分析结果表明,LPG的COP值比R134a低约10%,火用效率低5%,而且具有较大的不可逆性。Fatouh等 [26] 将LPG充注于283 L的冰箱中,并与R134a作性能比较结果发现,当LPG充注量为60 g,毛细管长为5 m时,表现出最优性能,与R134a相比较,充注60 g LPG的排气温度、压缩比、质量流量、耗电量和开启时间分别降低3.8%、5.5%、51%、4.3%和14.3%。从以上实验分析可以看出,适当调整LPG的充注量,改变毛细管道的长度,就使得LPG的性能比R134a优越,而且LPG来源广,价格便宜,使用成本低,因此依然具有作为新型替代制冷剂的潜力。

4. 其他制冷系统中的应用

R290/R600a除了应用在冷柜、冰箱等蒸汽压缩式制冷系统中,有些学者还将其充注在其他制冷系统中,并进行比较。Jose等 [27] 将R290/R600a混合制冷剂应用于蒸汽喷射式制冷系统中,并进行了性能评价。实验表明,当R290占30%~50%时,R290/R600a的表现出的性能最为理想,带有闪蒸罐的蒸汽喷射式制冷比普通的蒸汽压缩式制冷的COP值高,而且当膨胀阀的膨胀比为50%时,系统的COP值最高,同时温度滑移也较大。晏刚等 [28] 以R290/R600a (质量比50/50)做制冷剂应用在喷射式制冷循环系统中,经理论分析表明,该系统的COP值、容积制冷量和火用效率分别比传统的蒸气压缩式制冷循环高56%,4.5%和77.7%。此外,他还将R290/R600a充注在自复叠式制冷循环中,分析表明,R290/R600a应用在复叠式制冷循环中的COP与容积制冷量比传统的制冷系统分别高7.8%~13.3%和10.2%~17.1%,压缩机的压缩比减小7.4%~12.3% [29] 。可以看出,近几年许多学者也逐渐将R290/R600a应用在其他制冷系统如喷射式制冷系统和复叠式制冷系统中进行研究,这从另一个角度说明R290/R600a作为替代制冷剂应用的广泛性,从而扩大其使用范围,这也是作为替代制冷剂的必要趋势。

近期还有许多关于R290/R600a混合制冷剂性能及替代实验的研究 [30] [31] [32] [33] 。从这些研究中可以看出,R290/R600a作为制冷剂具有很好的热物性,在管道中的压降大,传热系数高,与矿物油互溶性较好等,这些都为R290/R600a作为新型替代制冷剂提供依据。

5. 总结与展望

目前,全球变暖形势日趋严重,HFCs作为高GWP制冷剂,被替代的呼声也越来越高。R290/R600a 是一种新型环保混合制冷剂,从近期研究可以发现,R290/R600a具有优良的性能,不管是制冷能力还是环保效果都优于R134a,而且只需对毛细管长度做相应的改变,R290/R600a就可以直接充灌在R134a的家用冰箱系统中。因此R290/R600a具有很大的作为R134a替代制冷剂的潜力。

热物性研究是替代制冷剂推广和应用的关键所在,目前对于R290、R600a单工质热物性的研究已经相当成熟,但对于R290/R600a混合制冷剂的热物性仍然缺乏必要的数据,R290/R600a若要作为新型替代制冷剂,就必须对它的气液相平衡、PVTx数据、以及二元相互作用系数等进一步展开研究,这样才能为其成为替代制冷剂提供可靠的依据。

易燃易爆是R290/R600a作为制冷剂的一大缺陷,这决定着R290/R600a只能充注在小型制冷系统中。在R290/R600a中加入一定的阻燃剂以及在制冷系统中充注量的计算也是接下来要研究的重点。

致谢

我历时近一个月时间将这篇论文写完了,在这段充满奋斗的历程中,带给我的学生生涯无限的激情和收获。在论文的写作过程中遇到了无数的困难和障碍,都在同学和老师的帮助下渡过了。在校图书馆查找资料的时候,图书馆的老师给我提供了很多方面的支持与帮助,尤其要强烈感谢我的论文指导老师—祁影霞老师,没有她对我进行了不厌其烦的指导和帮助,无私的为我进行论文的修改和改进就没有我这篇论文的最终完成。在此,我向指导和帮助过我的老师们表示最衷心的感谢!

同时,我也要感谢本论文所引用的各位学者的专著,如果没有这些学者的研究成果的启发和帮助,我将无法完成本篇论文的最终写作。至此,我也要感谢我的朋友和同学,他们在我写论文的过程中给予我了很多有用的素材,也在论文的排版和撰写过程中提供热情的帮助!

金无足赤,人无完人。由于我的学术水平有限,所写论文难免有不足之处,恳请各位老师和同学批评和指正!