1. 引言

锯齿形切屑是高速切削加工的典型特征,也是高速切削加工机理研究的一个主要方向。随着有限元和计算机技术的发展,有限元仿真已经成为高速切削锯齿形切屑研究的主要手段之一。近年来,国内外学者在高速切削锯齿形切屑的有限元模拟方面做了大量的研究工作。在国外,德国的Martin bäher [1] 采用ABAQUS结合c++开发的具有网格划分功能的前处理程序来进行锯齿形切屑的有限元模拟,并讨论了弹性特性和切削速度对锯齿形切屑的影响。后来又进一步讨论了材料参数(应变硬化、应变率硬化和热软化)对切削力和切屑变形的影响,结果表明锯齿形切屑的锯齿化程度可以用绝热应力曲线来定量解释 [2] 。Madalina等人 [3] 通过加入应变软化对流动应力的影响建立了Ti6Al4V新的本构方程,进而建立有限元模型分析了锯齿形切屑的形成和剪切局部化的过程。Lorentzona等人 [4] 考察了不同断裂准则对锯齿形切屑模拟的影响,认为不论热软化准则还是材料破坏准则,都能引起材料从连续带状切屑向锯齿形切屑的转化,并且采用静水压力相关的断裂准则能够更精确的对锯齿形切屑进行模拟。Yiğit等人 [5] 将温度相关流动软化行为集成到材料本构模型中来模拟绝热剪切带和锯齿形切屑,考察了流动软化条件对模拟结果的影响。在国内,赵军等人 [6] 分析了锯齿状切屑形成过程中应力、应变及温度场的分布规律,探讨了锯齿状切屑的形成机理及影响因素。鲁世红等人 [7] 应用有限元软件ABAQUS建立了Ti6Al4V钛合金高速正交切削有限元模型,模拟了锯齿形切屑的产生及其随切削条件的变化。陈涛等人 [8] 采用热力耦合有限元研究了淬硬轴承钢GCr15锯齿形切屑的形成过程中,分析了倒棱角度对切削力和切削温度分布的影响规律。

从现有的研究可以看出,目前虽然采用ABAQUS软件对高速切削锯齿形切屑进行了较多的仿真分析,但主要集中在切屑形态及其应力、应变和温度分布等切屑形成机理方面,而缺乏对有限元建模关键技术的研究,这在一定程度上限制了锯齿形切屑有限元模拟技术的进一步发展和应用。本文基于ABAQUS通用有限元软件,以45钢高速切削锯齿形切屑有限元模拟为例,开展几何模型、材料模型、摩擦模型和质量放大四个有限元模拟关键技术的研究,为锯齿形切屑有限元模拟技术的研究提供参考。

2. 有限元建模

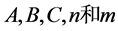

针对二维直角切削过程(如图1所示)建立高速切削有限元模型,忽略刀尖圆弧半径的影响,建立的几何模型如图2所示。为了避免在模拟过程中工件网格畸变导致计算终止,工件设计成向左倾斜的平行四边形。工件材料设为弹塑性体。为实现切屑分离,在切屑层和基本层之间加入了分离层。刀具设为刚体。采用热力耦合单元CPE4RT划分四边形网格。

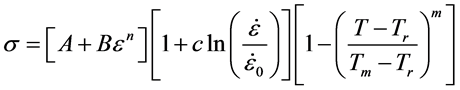

采用当前应用最为广泛的Johnson-Cook模型表征材料在切削条件下的动态力学性能,表达式为:

(1)

(1)

式中, 为流动应力;

为流动应力; 为塑性应变;

为塑性应变; 为塑性应变率;

为塑性应变率; 为参考应变率,取为10-3s-1;

为参考应变率,取为10-3s-1; 为室温,

为室温, 为材料的熔点,

为材料的熔点, 为本构参数,具体数值列于表1中 [9] 。材料密度为ρ = 7800 Kg/m3,弹性模量E = 200 Gpa,泊松比为0.3,比热为474 J/Kg.K,热传导率为146 W/m.K,熔点为

为本构参数,具体数值列于表1中 [9] 。材料密度为ρ = 7800 Kg/m3,弹性模量E = 200 Gpa,泊松比为0.3,比热为474 J/Kg.K,热传导率为146 W/m.K,熔点为 ,室温取为

,室温取为 。刀具材料的密度ρ = 14,400 Kg/m3,弹性模量为E = 800 Gpa,泊松比为0.3。

。刀具材料的密度ρ = 14,400 Kg/m3,弹性模量为E = 800 Gpa,泊松比为0.3。

将刀具前刀面和切屑之间的摩擦简化为经典库伦摩擦,用等效摩擦系数来表征其摩擦行为。采用失效应变准则实现切屑与工件的分离,根据文献 [6] 取失效应变为0.95。采用绝热分析来考虑切削温度的影响。

完成参数设置和网格划分后,对刀具/工件进行约束和加载。工件采用位移/旋转边界条件,约束住工件的左侧面(包括未变形切屑、分离线、工件基体三部分)、右侧工件基体的侧面以及工件的底面。刀具则采用速度/角速度边界条件,给定刀具沿x负方向的速度,并约束住刀具的其余5个自由度,防止刀具在切削中出现偏移和旋转,从而影响正常切削。边界条件及加载结果如图3所示。采用dynamic-temp-disp Explicit

Table 1. Johnson-Cook model parameters of 45 steel

表1. 45钢的Johnson-Cook模型参数

Figure 3. Results of loads and boundary conditions

图3. 边界条件及加载结果

求解器进行求解。

3. 关键技术分析

3.1. 工件几何模型倾斜角度的选择

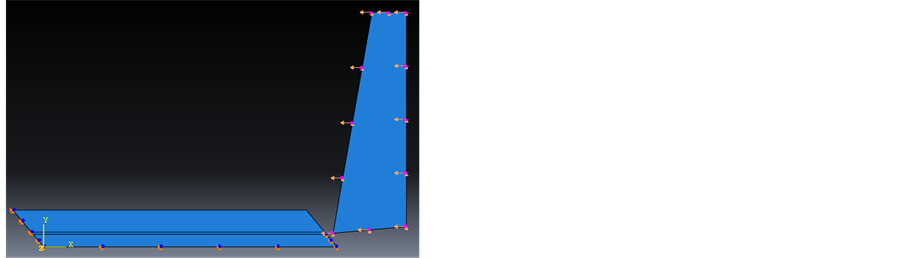

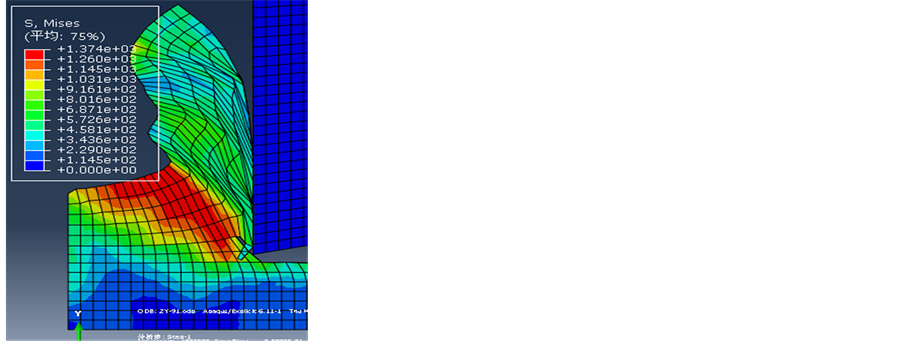

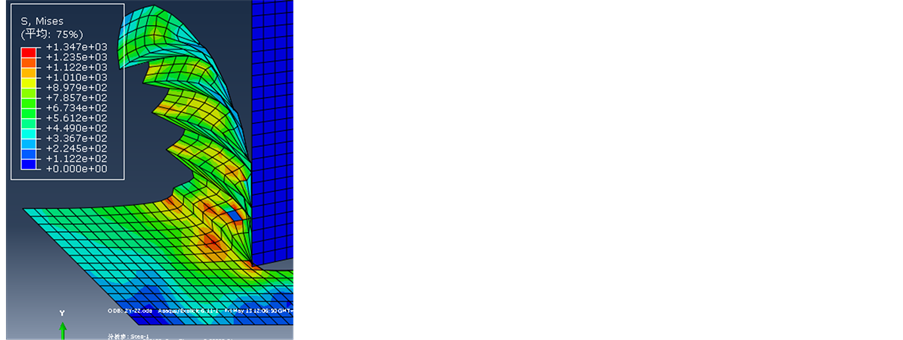

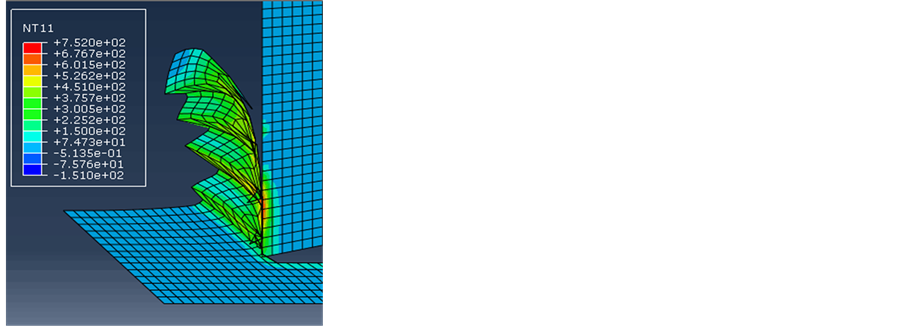

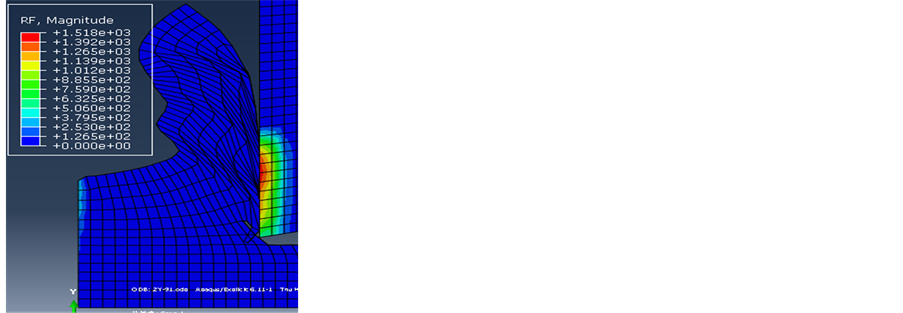

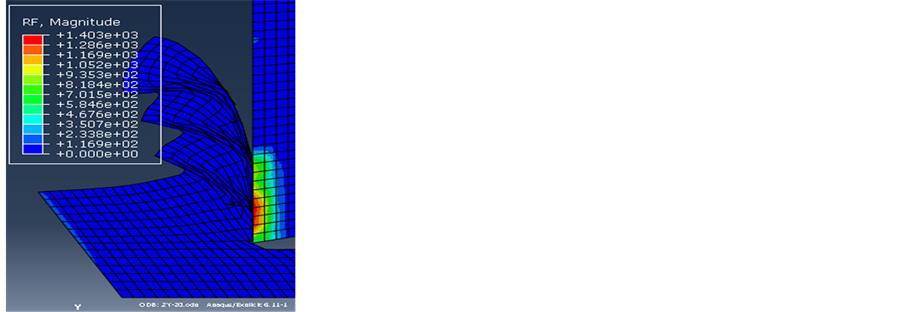

在锯齿形切屑的有限元模拟中,为了避免网格的畸变影响,通常需要将工件设计成向左倾斜的平行四边形,侧面与水平面形成一定的夹角,但该角度对模拟结果的影响及其选择还未见文献报导,因此本文通过对45˚、60˚和90˚三种典型角度工件模型的模拟结果(如图4所示)进行分析。从图中可以看出,虽然三种角度工件模型能够得到基本一致的等效应力,但切屑形态明显不同,45˚角时切屑形态更接近实际情况,60˚角时切屑底面产生一定的网格畸变,而90˚角时网格畸变更严重,从而影响了切屑形态。不同角度工件模型得到的切削力和温度模拟结果也相差不大,如图5和图6所示。因此可以认为在进行锯齿形切屑有限元模拟几何建模时,具有45˚角的工件几何模型能够较好的克服网格畸变的影响,获得更好的模拟结果。

3.2. 材料模型的影响

为了考察材料模型对模拟结果的影响,将前面给出的45钢的材料模型记为材料参数1,采用另外一组45钢的材料模型参数记为材料参数2,列于表2中 [10] 。

表3给出了采用不同本构参数时模拟得到的有效应力和切削力的对比。从表中可以看出,尽管采用不同的本构参数可以获得近似一致的有效应力分布,但是切削力模拟结果有很大差别,材料模型参数对模拟结果影响很大,说明采用不同实验方法和实验条件获得的本构关系时模拟结果差别很大。因此在进行锯齿形切屑有限元建模时,必须通过模拟切削力和实验切削力的对比来选取合适的材料模型,必要时还要对模型参数进行进一步的反求校准。

3.3. 摩擦系数的影响

由刀-屑摩擦将在切屑、刀具和工件中引起温度、应力及应变等物理量的重新分布,这些物理量之间的相互耦合作用使工件产生塑性变形。因此,正确理解前刀面的接触摩擦问题、建立刀具与工件之间合理的摩擦模型是切削加工模拟成功实现的关键因素之一。摩擦系数直接反映了刀具和切屑之间的摩擦情

(a) 45˚ (b) 60˚ (c) 90˚

(a) 45˚ (b) 60˚ (c) 90˚

Figure 4. Simulation results of effective stress under different angle of workpiece

图4. 不同工件几何模型角度时等效应力的模拟结果

(a) 45˚ (b) 60˚ (c) 90˚

(a) 45˚ (b) 60˚ (c) 90˚

Figure 5. Simulation results of cutting temperature under different angle of workpiece

图5. 不同工件几何模型角度时温度的模拟结果

(a) 45˚ (b) 60˚ (c) 90˚

(a) 45˚ (b) 60˚ (c) 90˚

Figure 6. Simulation results of cutting force under different angle of workpiece

图6. 不同工件几何模型角度时切削力的模拟结果

况,因此这里采用不同的摩擦系数来分析摩擦系数对模拟结果的影响,结果如表4所示。可以看出当摩

Table 2. Second group Johnson-Cook constitutive parameters of 45 steel

表2. 45钢的第二组Johnson-Cook本构参数

Table 3. Effective stress and cutting forces when using different constitutive parameter

表3. 采用不同本构参数时的等效应力和切削力

Table 4. Cutting force and cutting temperature when using different friction coefficient

表4. 不同摩擦系数切削力与切削温度模拟结果

Table 5. Simulation results under different mass scaling coefficient

表5. 不同质量放大系数的模拟结果

擦系数从0.15增大到0.45时,切削力从771 N增大到1208 N,相应的切削温度从537˚C升高到892˚C,表明摩擦系数对模拟结果影响很大。另外从实验结果相符的程度来看 [11] ,摩擦系数为0.3时的模拟结果相对较好。

3.4. 质量放大的影响

在有限元模拟中,为了缩短模拟过程,降低时间成本,通常会采用质量放大技术。但随着质量放大而产生的惯性力效应有时会影响模拟结果,甚至使模型无法收敛。因此本文通过对几组不同质量缩放因子的模拟结果来分析采用质量放大的可行性。表5给出了采用不同质量放大系数时切削力和计算时间的对比。可以看出,随着质量放大系数的增大,计算时间大大缩短,但切削力的变化不大,说明质量放大对锯齿形切屑的有限元模拟是有效的,合适的质量放大系数可以在保证模拟结果准确性的条件下大量节省时间成本。

4. 结论

本文在基于ABAQUS通用有限元软件建立的45钢高速切削锯齿形切屑有限元模型基础上,开展几何模型等锯形切屑有限元模拟关键技术的研究,主要结论如下:

(1) 在进行锯齿形切屑有限元模拟几何建模时,具有45˚锐角的平行四边形工件几何模型能够较好的克服网格畸变的影响,获得更好的模拟结果。

(2) 材料模型参数对模拟结果的影响很大,采用不同实验方法和实验条件获得的本构关系时模拟结果的差别很大。

(3) 摩擦系数对模拟结果有很大影响,对45钢来说,摩擦系数取0.3时模拟结果较好。

(4) 质量放大对锯齿形切屑的有限元模拟是有效的,合适的质量放大系数可以在确保模拟结果准确的条件下大量节省时间成本。

基金项目

感谢天津高等学校创新团队培养计划 (TD12-5043)和天津职业技术师范大学科技发展基金( KJY11-02)的资助。