1. 引言

Karamkas油田位于哈萨克斯坦的曼格什套(Mangistau)州,该油田储层埋深浅(平均油层深度864 m),储层物性好,供液能力强,采液指数变化范围大(最大可以达到1000 m3/(d∙MPa)),地层平均静压为9.2 MPa,平均饱和压力为6.5 MPa。目前以游梁式有杆泵为主要的举升方式,平均抽汲参数小,最大理论排液量为135 m3/d,无法充分发挥地层的供液能力。为了提高产液量,有必要对抽油机井系统进行挖潜设计。

有杆泵采油系统具有结构简单、适应性强、成本低等特点,目前是国内外应用最广泛的采油方式 [1] 。在以往的研究中,抽油机井系统设计大多以系统效率为目标,产液量为约束条件,以追求系统能耗最低 [2] [3] [4] [5] ;文献 [6] 综合考虑井下效率和地面系统合理性得到一个抽汲参数组合下的经济指标,并以此作为目标函数。有杆泵采油系统挖潜设计可以定义为通过调整工作制度,包括冲程、冲次、泵径、下泵深度等最大程度地提高抽油机井产量,同时要保证抽油机系统安全高效地运行。所以挖潜设计数学模型是一个以抽油机井产量最大为目标,以抽油机井的工作制度为设计参数的最优化模型。该模型是一个非线性优化模型,且产量方程无法用一个显式表达。对于这类方程一般采用智能算法求解,比如遗传算法 [7] 、群算法等。但由于模型解集是有限的、非连续的,采用枚举法求解速度更快,而且不会陷于局部最优。节点分析原理是抽油系统设计 [8] [9] 、参数敏感性分析 [10] 及优化 [11] 的重要理论基础。求解抽油机井挖潜数学模型同样要以生产系统的供排协调为基础,根据节点分析的原理进行求解。

2. 数学模型

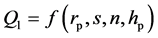

在抽油机系统中,对一口固定的井,其产液量可以看成是冲程、冲次、泵径和下泵深度的函数,即:

(1)

(1)

式中:Ql为产液量m3/d;rp为泵径,m;s为抽油机冲程,m;n为抽油机冲次,min−1;hp为下泵深度,m。

其中冲程、冲次和泵径主要影响泵的理论排量。高冲次下,杆柱的工作状况恶化,特别容易造成抽油杆的损坏,同时高冲次容易引起抽油机振动,所以冲次不能过高。另外,更换抽油机的工作量大,在现场一般不采取更换抽油机的方式进行挖潜。

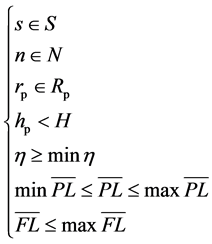

建立以产液量最大为目标的最优化模型,以目前现场设备所能提供的抽汲参数以及考虑安全经济生产作为约束条件:

(2)

(2)

式中:S为抽油机能提供的冲程集合;N为抽油机能提供的冲次集合;Rp为现场提供的泵径集合;H为油层中深,m; 为泵效,%;

为泵效,%; 是允许最小泵效,%;

是允许最小泵效,%; 为应力范围比,%;

为应力范围比,%; 、

、 分别是抽油杆允许最小和最大应力范围比,%;

分别是抽油杆允许最小和最大应力范围比,%; 为抽油机载荷利用率,%;

为抽油机载荷利用率,%; 为抽油机允许最大载荷利用率,%。

为抽油机允许最大载荷利用率,%。

3. 求解方法

求解该最优化模型,最主要的是求解在某种工作制度下的产量,二者的关系无法用一个显式方程表达。可以采用节点分析的原理求解。

图1所示为抽油机井生产系统,以泵吸入口为求解点进行分析。流入过程为从油层到泵吸入口,流出过程为从泵吸入口到泵筒内。泵排出口以上不能和泵以下作为一个系统进行分析,主要是因为在该过程中,泵对流体做功,系统不满足能量守恒。

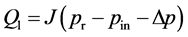

流入曲线函数可以用下式表示:

(3)

(3)

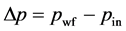

式中:J为采液指数,m3/(d∙MPa);pr为地层平均压力,MPa;pin为泵吸入口压力,MPa;Δp为泵挂深度到油层中深的油管流体压差(利用气液两相流压力降公式计算), ,MPa;pwf为井底流压,MPa。

,MPa;pwf为井底流压,MPa。

流出过程反映的是泵吸入口压力与进泵液量之间的关系,可以按下式计算:

Figure 1. The production system of a rod pumping well

图1. 抽油机井生产系统

(4)

(4)

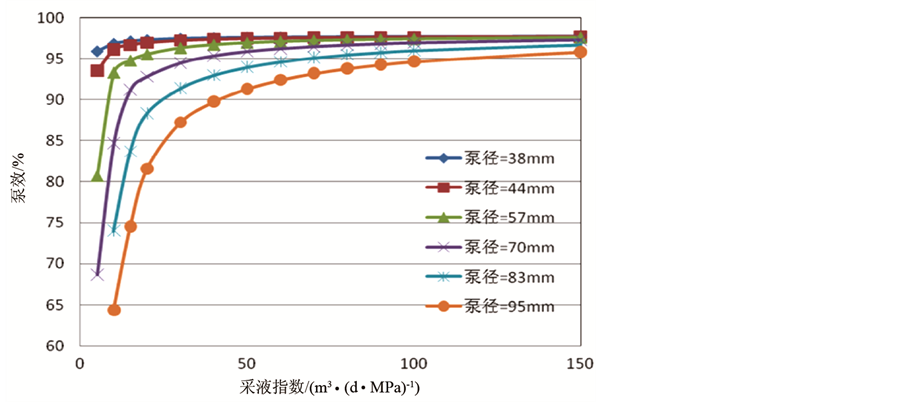

式中:Qt为泵的理论排量,m3/d;fp为柱塞截面积,m2。对于给定的工作制度,在同一坐标系里,根据上述计算方法绘制流入、流出曲线(图2),其交点即为协调产量和对应的泵吸入口压力。

在该基础上,计算泵效、抽油机载荷利用率和抽油杆的应力范围比,根据约束条件,判断该工作制度是否满足要求。

冲程集合S、冲次集合N以及泵径集合Rp都是有限的几个点且不连续,下泵深度hp也可以取有限的一系列非连续的点,因此模型的解集是有限的。对于该模型如果采用智能算法求解,不但工作量大,还会因为陷入局部最优而得不到最优解。笔者采用枚举法求解,即求出每一个解对应的产液量、载荷利用率、泵效以及抽油杆应力范围比,然后选择最优工作制度。

4. Karamkas油田挖潜设计

4.1. 挖潜选井原则

挖潜设计必须要选有潜力而且抽汲参数偏小的井。根据Karamkas油田实际情况,制定以下挖潜选井原则。

1) 选择供液能力强、目前抽汲参数偏小的油井。这类油井可以根据抽油机井动态控制图选择。

2) Karamkas油田普遍含水率高,当含水率大于95%时,则认为没有挖潜的必要。

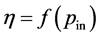

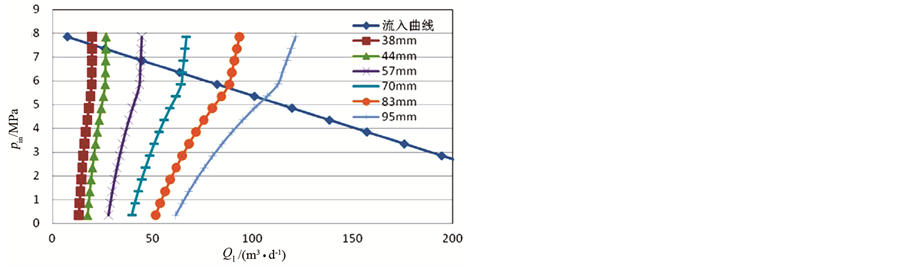

3) 采液指数对产液量、泵效和载荷都有很大影响。该油田采液指数范围较大,通过计算分析可以得到不同泵径下采液指数和悬点载荷、泵效之间的相互关系,如图3、图4所示。从图3和图4可以看出,随着采液指数增加,悬点载荷逐渐减小,泵效逐渐增加,且变化幅度逐渐变小。当采液指数大于80 m3/(d∙MPa)时,载荷小、泵效高,满足约束条件,可以采用大泵快速抽汲,不需要进行设计。

根据以上原则,对含水率小于95%、采液指数小于80 m3/(d∙MPa)的53口油井进行动态控制分析,结果如图5所示。其中潜力井有22口。由于该油田地层压力高,部分井属于连喷带抽状态,校核泵效大于100%。

Figure 3. The relation between fluid production index and polished rod load

图3. 采液指数与悬点载荷关系曲线

Figure 4. The relation between fluid production index and pump efficiency

图4. 采液指数与泵效关系曲线

Figure 5. The dynamic control chart of pumping wells

图5. 抽油机井动态控制图

4.2. 挖潜设计

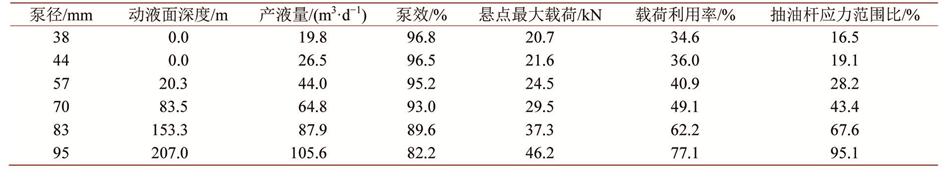

现场设备能提供的工作参数见表1。典型井基本参数见表2。假设一个工作制度,冲程为2.1 m,冲次为6 min−1,下泵深度为800 m,以泵吸入口为求解点,绘制不同泵径下的系统分析图,从而得到对应的产液量和泵吸入口压力,然后计算抽油机载荷和抽油杆应力范围比,结果见图6和表3。

采用上述方法,对不同的工作制度进行求解,然后根据约束条件优选产液量最高的几种方案。约束条件为:泵效大于80%,应力范围比上限取90%,不考虑下限;载荷利用率小于80%,同时考虑到冲次过大会影响抽油机的稳定性,在选择方案的时候,冲次最大不超过7 min−1。挖潜方案设计结果见表4。

Table 1. The list of operating parameters

表1. 工作参数列表

Table 2. The basic parameters of a typical well

表2. 典型井基本参数

Figure 6. The system analysis curve of a typical well (stroke, 2.1 m; rate of pump, 6 min−1; depth of plunger, 800 m)

图6. 典型井系统分析曲线(冲程2.1 m,冲次6 min−1,泵深800 m)

Table 3. The result of system analysis of a typical well (stroke, 2.1 m; rate of pump, 6 min−1; depth of plunger, 800 m)

表3. 典型井系统分析结果(冲程2.1 m,冲次6 min−1,泵深800 m)

Table 4. The results of designed potential tapping scheme

表4. 挖潜方案设计结果

5. 结论

1) Karamkas油田储层埋藏浅,采液指数大,地层压力高,很多油井泵效大于100%,挖潜空间大。所以在满足抽油设备安全的情况下,可以快速抽汲。

2) 因为抽油设备系列是有限的,且不连续,所以可以对每种工作制度进行计算,然后选择最优方案。这种方法相对智能算法不但计算量小,而且不会陷于局部最优。

3) 该方法简单实用,适合现场挖潜设计。对不同的油田,应根据实际情况调整约束条件,优选最优方案。