1. 引言

电磁铆接作为一种新型的铆接技术,具有加载速度快,冲击力大,铆钉变形稳定等优点,已引起研究者的广泛关注。采用该技术可克服铆接时复合材料易被挤压破坏,以及难变形钛合金铆钉铆接力不足等技术瓶颈,并且可以实现稳定可靠的干涉配合。在铆接质量、连接件的疲劳寿命和力学性能等方面较普通铆接方式优势明显 [1] [2] [3] 。

高速冲击过程中,铆钉的变形主要集中在镦头区域,这一区域的变形类似于自由镦粗工艺。但在很高加载速率下进行,因此呈现出许多不同与普通加载情况的现象,而普通加载时的变形机理也无法适用于电磁铆接过程。铆钉镦头的变形通常以高应变速率(高达103 s−1)下的大塑性变形形式完成,可以视为动态塑性变形的一种。与准静态变形相同,动态塑性变形中滑移和孪晶仍然是主要变形机制。但是当应变速率高于一定值时材料内部的变形近似绝热状态完成,变形组织中将会出现绝热剪切带现象。无论是铝合金铆钉还是钛合金铆钉,电磁铆接时绝热剪切带 [4] [5] 都是很常见的现象。滑移机制研究中,很多学者发现动态塑性变形时,位错迅速增值并以位错胞形式存在。卢秋虹 [6] 在研究纯铜液氮条件下动态塑性变形时,观察到当真实应变增加到2.0时位错密度急剧增加,由于低温阻碍了动态回复的进行导致位错以位错胞形式存在。Liu等 [7] 研究表明随着应变速率的增加材料屈服时的位错密度不断增加,而且位错组态由非均一型变成均一型并位于同一个滑移面上。Xiao等 [8] 研究Cu-Zn合金的动态塑性变形时发现,由于该合金具有较低的层错能变形后试样中存在平面型的滑移带,低的层错能既抑制了位错的交滑移也促进孪晶的形成,Deng等 [9] 人研究钛合金铆钉电磁铆接时,发现铆钉镦头绝热剪切带中同样存在动态再结晶想象。

本文针对2A10铝合金铆钉电磁铆接,绝热变形组织演化进行研究,研究铆钉高速成形性能,促进电磁铆接技术工程应用。

2. 实验

2.1. 试验材料

铆钉材料为2A10铝合金,属于Al-Cu合金经过时效强化处理,具有较高的强度和良好的塑性,是航空航天紧固件首选材料。本文采用直径6 mm的半圆头铆钉进行电磁铆接试验。被连接板材为5083铝合金,是铝镁合金,在不可热处理合金中强度良好,耐蚀性、可切削性良好,板材厚度为3 mm。两种材料化学成分见表1所示。

2.2. 电磁铆接原理

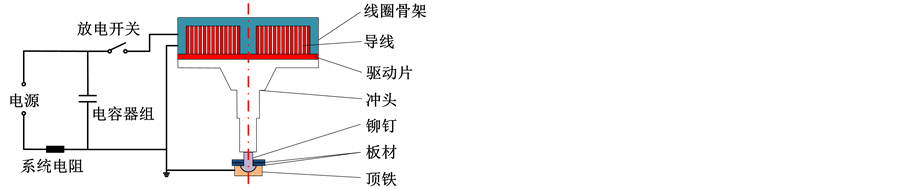

电磁铆接是基于电磁成形理论和常规铆接技术发展起来的一种新型连接工艺,其原理如图1所示,主要包括电磁成形设备(为铆接过程提供冲击能量)和铆接动力头两个部分。通常情况下,常规电压通过变压器得到实际所需电压,之后经过整流桥电路将其转变成直流形式对电容器组进行充电,当电容器充满之后,闭合放电开关立即通过置于铆接动力头中的平板线圈进行放电,在高强度交变冲击电流作用下,在其周围产生交变强磁场。该磁场会使与线圈接触的驱动片中感生涡流,进而产生涡流磁场。两磁场之间的斥力推动冲头高速作用于铆钉使其成形,锁紧被连接板材。本文采用双层板结构,采用单个铆钉进行连接。板材厚度为3 mm,为了保证铆接前预留铆钉直径1.2倍左右的外伸量,铆钉钉杆尺寸选为Φ6 × 13 mm。此外,被连接板材预制孔直径为6.15 ± 0.15 mm。

3. 结果与讨论

3.1. 铆钉镦头变形分析

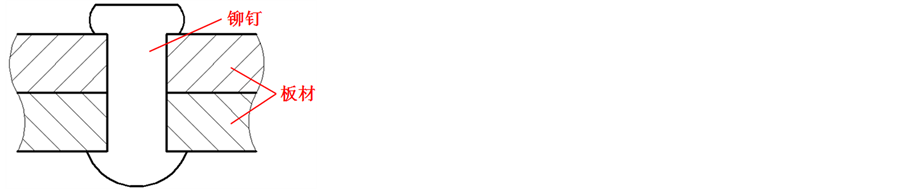

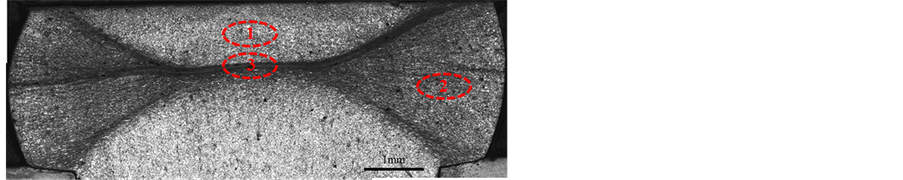

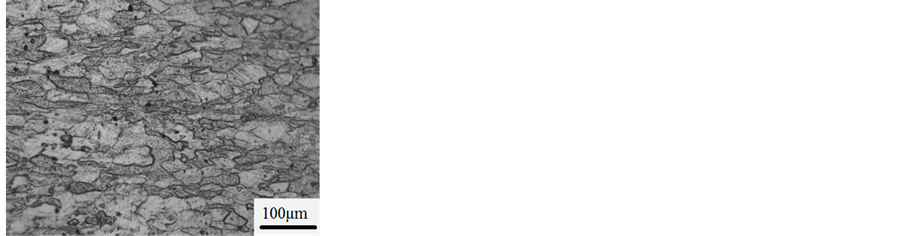

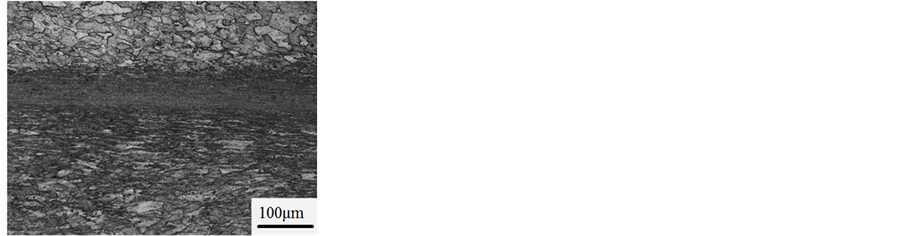

电磁铆接后沿铆钉轴线剖切,镦头变形组织分布如图2所示,局部放大金相组织见图3。铆钉镦头在高速冲击下镦粗成形,由于镦头上表面受冲头摩擦力作用,而下端受钉孔约束,只有圆柱面可自由径向流动,因此,变形后形成明显的“鼓型效应”。并且变形组织分区明显,大致可以分成4个区域,上下两端塑性流动受限,几乎保证静止的塑性流动状态,形成了小变形镦粗“死区”,变形组织如图3(b)所示,变形组织仍保持着原始的等轴晶粒形貌,只有少量晶粒受压缩破坏,并且已形成一定的晶粒取向。圆柱面附近金属自由径向流动,形成了扇形的自由变形区域,如图3(c)所示晶粒发生了明显变形破碎,而且径向塑性流动同时受轴线压缩晶粒出现了明显的折叠现象。此外,在镦头对角线方向以及中心位置发生了明显的变形集中,产生了高速冲击作用下的绝热剪切带现象,高速变形时铆钉镦头热量很难短时间扩散到周围环境,而集中在热源区域。圆柱镦粗变形对角线方向为剧烈剪切变形区域,塑性功转化成的热量主要集中在该区域,热量集中促进了塑性变形的持续,进而又生产了大量热量,这样变形-热量循环互动作用促进了绝热剪切带的形成。

3.2. 绝热剪切带内微观演化

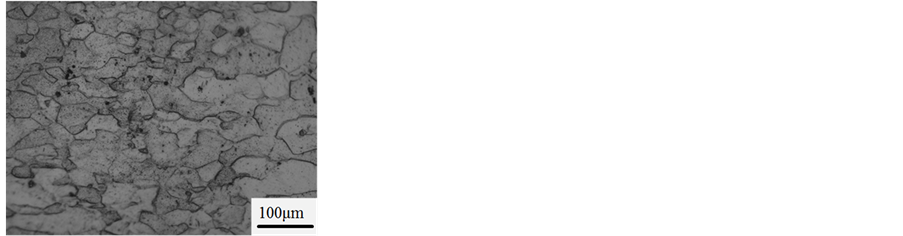

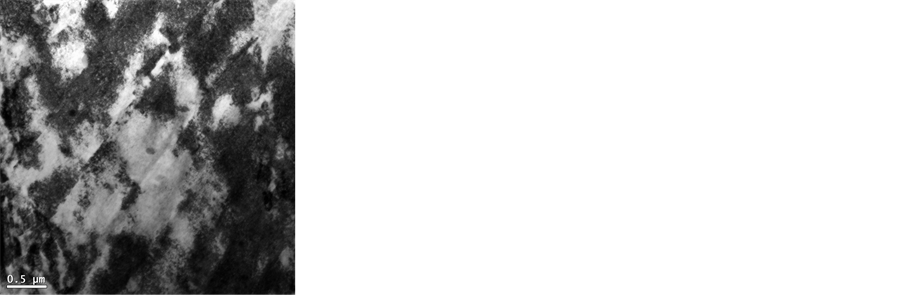

绝热剪切带是剧烈剪切变形集中区域,变形较大金相组织已无法辨认其内部微观组织演化。图4为绝热剪切带内透射电镜(TEM)组织,可以看出在剧烈剪切变形作用下,以形成沿着剪切方向分布的层片状亚结构,层片厚度大约在0.5 μm。原始晶粒尺寸在80 μm左右,可说明高速冲击作用下,绝热剪切带区域晶粒被显著拉长破碎。此外,在亚晶内部存在大量位错,而且如图4(b)所示,位错以相互缠结的方式分布在亚晶内部。

3.3. 铆钉镦头成形性能

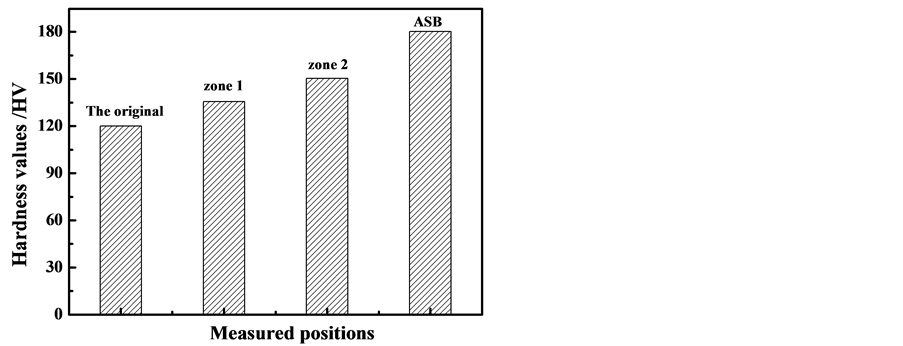

组织演化决定了材料变形后的性能,图5为电磁铆接后铆钉镦头显微硬度分布。未变形铆钉硬度为120 HV,可以看出变形后,加工硬化非常明显,尤其是变形高度集中的绝热剪切带区域(ASB),变形后硬度高达180 HV,较原始硬度升高了50%。对于小变形区域(zone 1),虽然从图3(b)可以看出微观组织变化较小,但是其硬度也略有升高,说明高速冲击过程中也经历了一定的强化。自由变形区硬度介于二

表1. 2A10铝合金铆钉和5083铝合金板材化学成分(wt. %)

(a) 电磁铆接原理 (b) 铆接试样

(a) 电磁铆接原理 (b) 铆接试样

Figure 1. The schematic of electromagnetic riveting

图1. 电磁铆接原理图

Figure 2. The microstructure distribution of a rivet tail

图2. 铆钉镦头微观组织分布

(a) 铆钉原始组织 (b) 变形区1 (zone 1)组织

(a) 铆钉原始组织 (b) 变形区1 (zone 1)组织

(c) 变形区2 (zone 2)组织 (d) 绝剪切带(ASB)

(c) 变形区2 (zone 2)组织 (d) 绝剪切带(ASB)

Figure 3. The partially enlarged view of a rivet tail

图3. 铆钉镦头局部放大视图

(a) 层片亚结构 (b) 位错缠结

(a) 层片亚结构 (b) 位错缠结

Figure 4. TEM microstructures in adiabatic shear band

图4. 绝热剪切带内TEM组织

Figure 5. Hardness distributions in rivet tail

图5. 铆钉镦头硬度分布

者之间,形变相对明显。由于形变过程中的加工硬化,所以总体硬度分布结果与镦头微观组织分布结果一致。

4. 结论

1) 高速冲击作用导致塑性变形主要集中于铆钉镦头的绝热剪切带区域,绝热剪切带宽度约为100 μm。

2) TEM组织表面绝热剪切带内部产生宽度0.5 μm层片状亚晶,并且亚晶内部存在大量相互缠结的位错。

3) 加工硬化导致铆钉镦头硬度分布与变形分布一致,剧烈塑性变形的绝热剪切带显微硬度明显高于其他区域。