Abstract:

The nano-sized La

2Ce

2O

7 powders were synthesized by sol-gel method. The structure, morphology and properties of the nano-powders were analysed by XRD, SEM and TEM. The results show that this method can obtain nano-La

2Ce

2O

7 powder with stable fluorite crystal structure at lower temperature (700˚C). The calcination temperature is increased to 1000˚C, and the grain size is about 30 nm. The grains of nano-La

2Ce

2O

7 are agglomerated together and the particle size distribution is uniform. The calculated activation energy of the crystal is 27.85 KJ∙mol−1. The La

2Ce

2O

7 ceramic disk has a good anti-sintering performance after incubation at 1400˚C for 6 hours.

1. 引言

热障涂层(TBCs)是指由金属缓冲层或称金属粘结层和陶瓷表面涂层组成的涂层系统。表面的陶瓷层是抵抗高温冲刷、腐蚀和隔热的最重要部分。由于热障涂层材料具有耐高温、耐腐蚀、耐磨损等优良特点,所以广泛应于航空发动机以及汽轮机的热端部件上,以达到隔热、防止高温腐蚀和延长使用寿命的作用 [1] [2] [3] 。

典型的热障涂层材料为氧化钇稳定化氧化锆(YSZ),它具有热膨胀系数大,热导率低,抗热冲击性好等优良特性,但是YSZ在高温下易腐蚀,1473 K以上容易烧结,1443 K发生相变,相变过程中的体积膨胀使涂层产生裂纹,导致涂层失效。这些缺点大大限制了YSZ的使用,所以,寻找能替代YSZ在更高温度下使用的陶瓷层材料成为当今热障涂层研究的急迫工作 [4] [5] [6] [7] 。

近年来研究发现稀土复合氧化物铈酸镧(La2Ce2O7, LC)可作为一种新型的热障涂层材料,它实际上是La2O3溶解进CeO2晶格中形成的固溶体,具有高的相稳定性、低的热导率(0.6 W/(m∙k))、高的热膨胀系数(13 × 10−6K−1),所以La2Ce2O7不仅在固体氧化物燃料电池、氧传感器、催化剂载体等领域备受关注,而且在热障涂层领域有广阔的应用前景 [8] [9] 。

合成热障涂层材料常用的方法是固相法 [10] ,但固相法得到的产物颗粒较大,为微米级别。而与非纳米材料相比,纳米材料的热膨胀系数大、热扩散系数低、硬度大、断裂韧性高,纳米材料制成的涂层晶粒堆积紧密、气孔率低且结合性能较好 [11] ,所以采用合适的方法制备纳米La2Ce2O7材料是本研究的重点。

曹学强等 [12] 采用水热法合成纳米铈酸镧(La2Ce2O7),Tinwala H采用了共沉淀法 [13] 制备。溶胶凝胶法 [14] 由于具有操作简单,配比精准,合成温度较低,产物均匀性好而被本研究用来合成纳米La2Ce2O7粉末。本研究探讨了不同条件下纳米粉末的结构与形貌,并将得到的纳米粉末在150 MPa下压成圆状的陶瓷片,在高温下保温6 h后测量样品的收缩率,研究抗烧结性能。

2. 实验方法

2.1. 制备过程

本研究是以La2O3、Ce(NO3)3∙6H2O、柠檬酸、乙二醇为主要原料。实验时首先将La2O3在1100℃下干燥2 h,立即称取一定量干燥后的La2O3溶解于浓硝酸,蒸发多余的硝酸,将得到的La(NO3)3溶解于去离子水中。称取Ce(NO3)3∙6H2O(Ce3+: La3+ = 1: 1)溶解于去离子水,两种溶液混合搅拌10 min后,加入与金属离子相同摩尔量的柠檬酸,持续搅拌1 h,加入适量乙二醇,继续搅拌溶液至凝胶状。将湿凝胶在烘箱中80℃下干燥24 h得到La2Ce2O7前驱体,得到的前驱体研磨后在高温下煅烧,得到La2Ce2O7纳米晶。

图1为实验流程图。

2.2. 实验的表征手段

产物的物相分析利用德国bruker d8advance型X射线衍射仪(XRD),采用CuKα靶辐射扫描,扫描范围为15˚~90˚,扫描速度为12˚/min。粉末的形貌观察采用JSM-7000F型扫描电子显微镜,使用日本生产JEM-2100型透射电子显微镜进一步观察样品的微观形貌及结构。

根据XRD的结果,由Scherrer公式:

(1)

(1)

分析粉末的粒径。其中,d为晶体直径,B 为衍射峰半高宽度,λ为X射线波长,q为衍射峰对应的角度,k为比例常数。

晶体的晶格常数由公式:

(2)

(2)

d为晶粒大小,a为晶体的晶格常数,h,k,l为晶面指数。

晶体生长的表观活化能由公式:

(3)

(3)

求得。式中Dt和D0分别表示某一温度和初始温度下La2Ce2O7的晶粒大小(nm); R表示摩尔气体常数(8.314 J/K∙mol),T表示煅烧温度(K),Q表示表观活化能。

3. 实验结果与分析

3.1. 物相分析

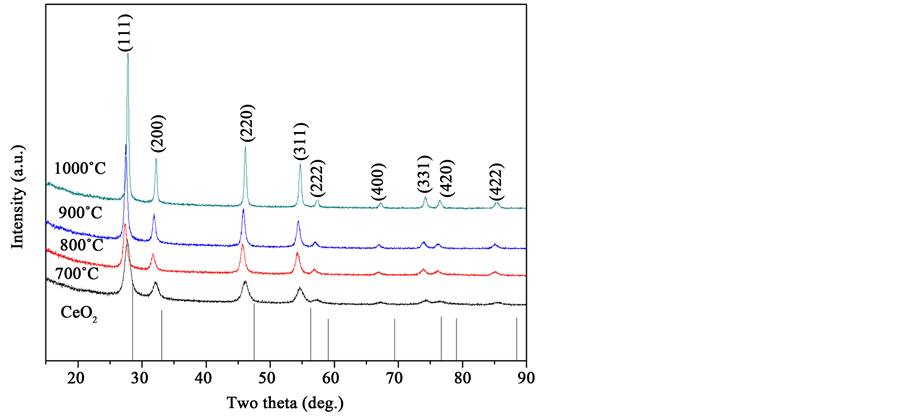

将得到的La2Ce2O7干凝胶前驱体分别在700℃~1000℃下煅烧5 h,以及在900℃下保温不同的时间。产物的XRD结果如图2,图3所示,从图中可以看出700℃下La2Ce2O7已基本成型,随着煅烧温度的

Figure 2. XRD patterns of La2Ce2O7 precursor sintered at different temperature for 5 h

图2. La2Ce2O7前驱体在不同温度下煅烧5 h的XRD谱图

Figure 3. XRD patterns of La2Ce2O7 precursor sintered for different time at 900˚C

图3. La2Ce2O7前驱体在900℃下煅烧不同时间的XRD谱图

升高,衍射峰越来越尖锐,半高宽越来越窄。在900℃下保温不同的时间,随着保温时间的延长,衍射峰也越来越尖锐。升高煅烧温度至1000℃时仍未见到标志着烧绿石结构的(331)和(511)峰的出现 [15] [16] ,说明La2Ce2O7为萤石结构。通过与CeO2的标准峰比较,可以发现La2Ce2O7的峰与其一致,只是峰整体往小角度偏移,这是因为La3+进入CeO2晶格,使得La2Ce2O7的晶格常数增大。通过公式(2)计算La2Ce2O7的晶格常数,结果如表1所示,从表中可以看出,不同温度下的La2Ce2O7的晶格常数均比CeO2的晶格常数大一点,证明La3+进入CeO2晶格中。

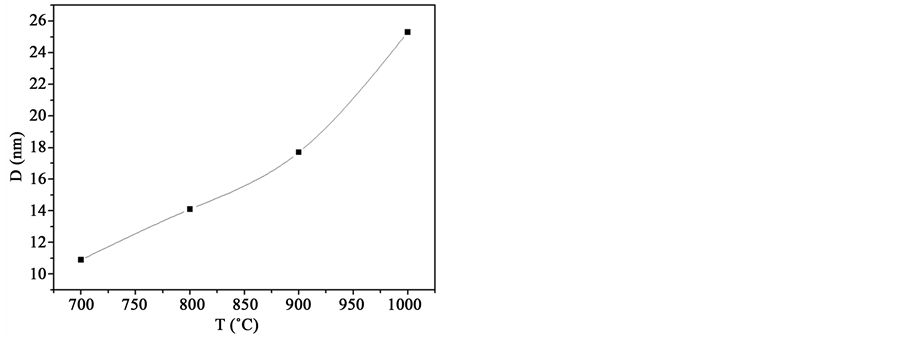

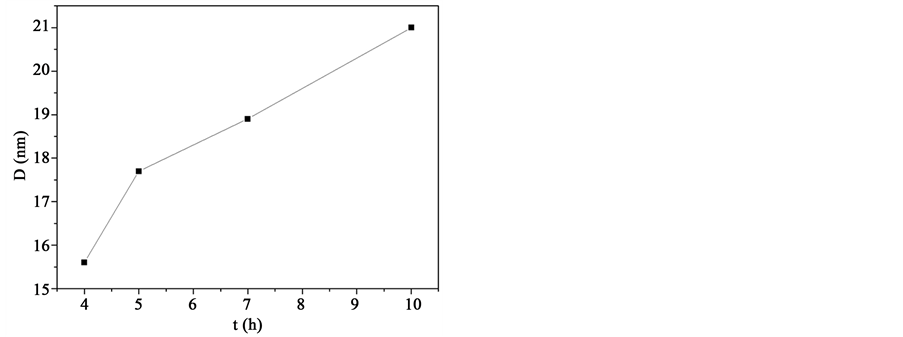

通过公式(1)计算出不同条件下的晶粒大小,结果如图4所示。随着煅烧温度的升高,晶粒逐渐长大,这是因为随着温度的升高,原子扩散能力增强,反应速率加快,晶界移动速率加大,所以导致晶粒长大。而保温时间越大,长大就越充分,故晶粒变大,但是直至温度升到1000℃,La2Ce2O7的晶粒大小仍在30nm以下。

(a) (b)

(a) (b)

Figure 4. Size of nanocrystalline La2Ce2O7 powder: (a) 5 h sintered at different temperature; (b) sintered different time at 900˚C

图4. 纳米La2Ce2O7粉末的晶粒大小:(a) 不同温度下煅烧5 h;(b) 900℃保温不同时间

Table 1. Lattice parameter of La2Ce2O7 in different temperature

表1. 不同温度下La2Ce2O7的晶格常数

CeO2的晶格常数:5.411 Å。

3.2. 形貌分析

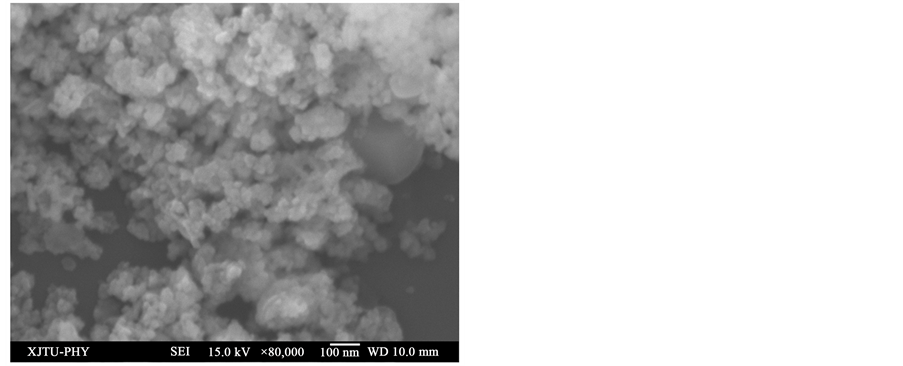

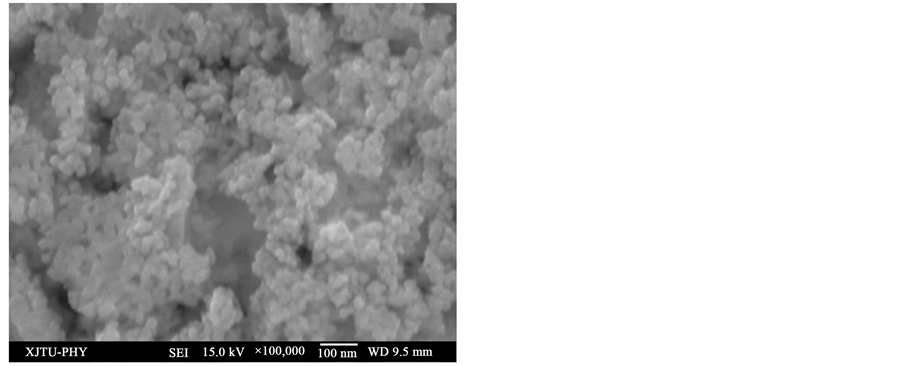

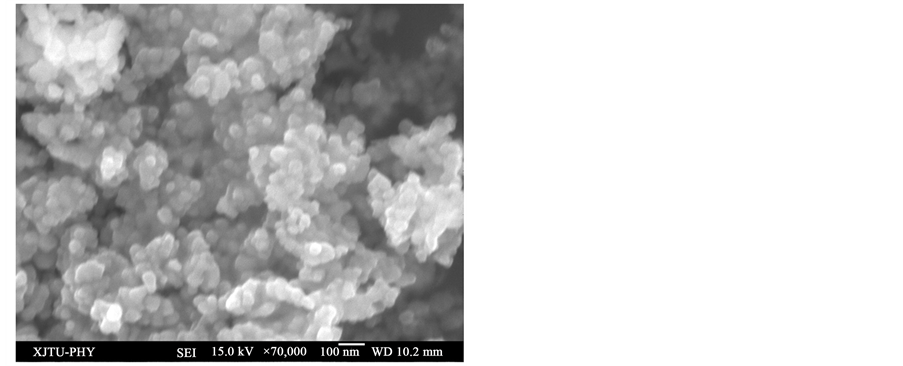

纳米La2Ce2O7的微观形貌如图5,图6所示,图5为700℃~1000℃下煅烧得到的La2Ce2O7粉末的微观形貌,图6为900℃下分别煅烧5 h和10 h的形貌图。从图中可以700℃下的粉末已基本成型,大量的球状颗粒团聚在一起,随着煅烧温度与保温时间的延长,粉末晶化程度提高,球状颗粒越来越明显;同时颗粒的尺寸也逐渐变大,但可以看出制备的La2Ce2O7粉体均为纳米尺寸,且颗粒分布均匀,而颗粒团聚是由于一次晶粒小表面活性较大所以易发生团聚。

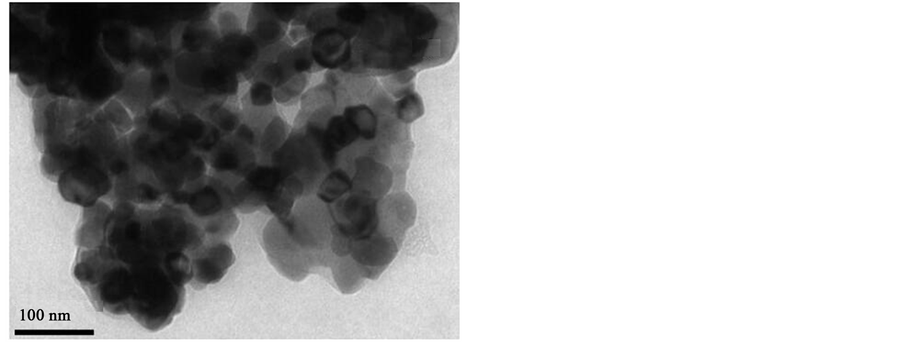

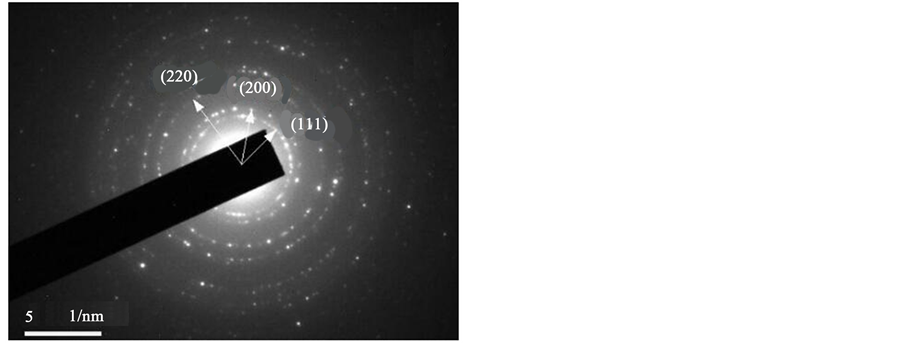

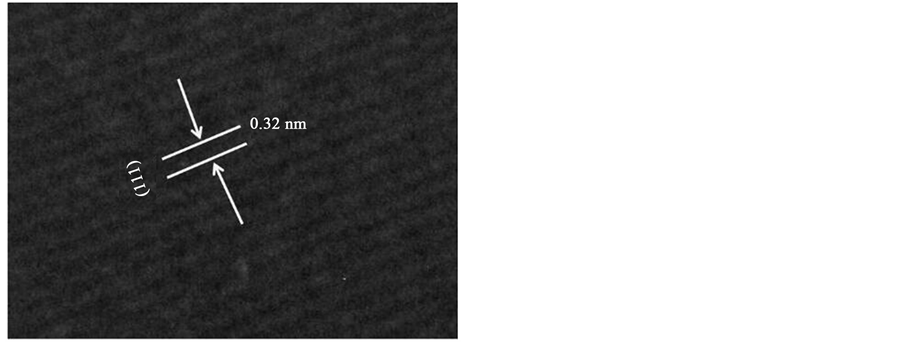

通过TEM进一步观察La2Ce2O7的微观形貌,从图7可以看出La2Ce2O7纳米晶是由许多团聚的立方晶粒组成,SAED中看到证明多晶结构的衍射环。通过HRTEM可清晰地看出La2Ce2O7晶体的晶格条纹,测得晶面间距0.32 nm与萤石相CeO2的(111)一致 [12] 。

3.3. 纳米La2Ce2O7晶体的生长活化能

利用公式(3)计算晶体生长的表观活化能 [17] ,将等式左右两边同时取对数,以−1000/T为横坐标,lnD为纵坐标作图,线性拟合后如图8所示。计算所得,纳米La2Ce2O7晶体的生长活化能为27.85 KJ·mol−1。

3.4. 纳米La2Ce2O7的抗烧结性能

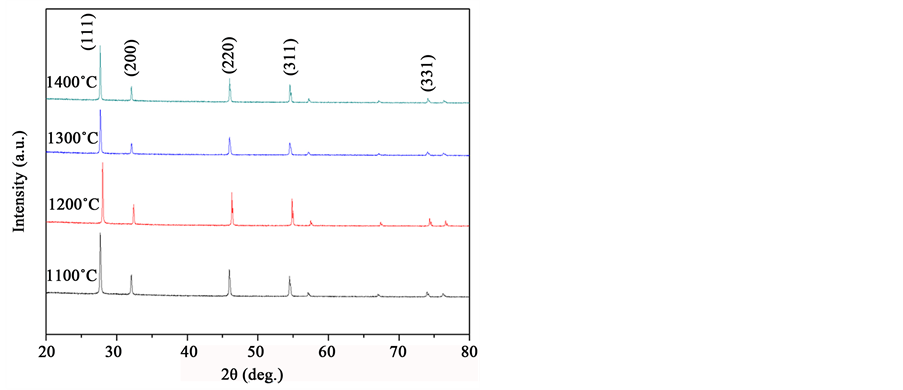

将纳米La2Ce2O7粉末在150 MPa下压成直径约为10 mm,厚度约为1 mm的圆状陶瓷片,在高温下保温6 h后通过XRD谱图观察样品的相稳定性以及测量样品的收缩率来研究烧结性能。图9为La2Ce2O7陶瓷片在1100℃~1400℃下煅烧6 h的XRD图,从图中可以看出直至升温至1400℃,La2Ce2O7陶瓷片仍未发生相变,说明La2Ce2O7保持良好的相稳定性。烧结体的密度通过称量陶瓷片的质量以及运用阿基米德方法测得体积求得,其相对密度如图9(b)所示,从1100℃的55%升至1400℃的90%,具有良好的抗烧结性能。

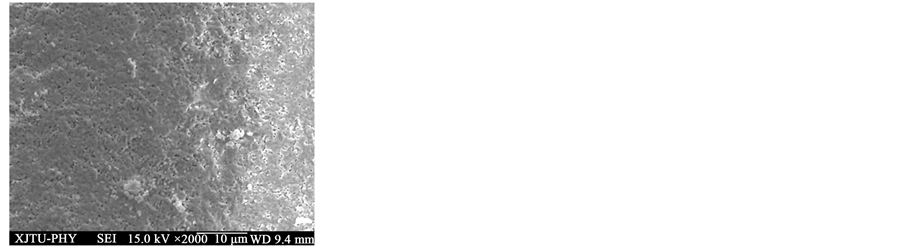

图10为不同烧结温度下煅烧6 h的La2Ce2O7陶瓷片的SEM。从图中可以看出,有许多孔洞不均匀

(a) (b)

(a) (b)

(c) (d)

(c) (d)

Figure 5. SEM images of La2Ce2O7 sintered at different temperature: (a) 700˚C; (b) 800˚C; (c) 900˚C; (d) 1000˚C

图5. 不同温度下的La2Ce2O7的SEM:(a) 700℃;(b) 800℃;(c) 900℃;(d) 1000℃

(a) (b)

(a) (b)

Figure 6. SEM images of La2Ce2O7 sintered for different time at 900˚C: (a) 5 h; (b) 10 h

图6. 900℃下煅烧不同时间的La2Ce2O7的SEM:(a) 5 h; (b) 10 h

(a) (b)

(a) (b)

(c) (d)

(c) (d)

Figure 7. TEM, SAED and HRTEM images ofLa2Ce2O7 sintered at 1000˚C

图7. 1000℃下的La2Ce2O7的TEM, SAED和HRTEM图

Figure 8. Activation energy plot of La2Ce2O7

图8. La2Ce2O7的生长活化能曲线

(a) (b)

(a) (b)

Figure 9. XRD patterns (a) and relative density (b) of La2Ce2O7 ceramic disk at different temperature

图9. 不同温度下的La2Ce2O7陶瓷片的XRD (a);相对密度 (b)

(a) (b) (c)

(a) (b) (c)

Figure 10. SEM images of La2Ce2O7 ceramic disk sintered for 6 h at different temperature (a) 1200˚C 2000×; (b) 1400˚C 2000×; (c) 1400˚C 5000×

图10. 不同烧结温度下煅烧6 h的La2Ce2O7陶瓷片的SEM (a) 1200℃ 2000×; (b) 1400℃ 2000×; (c) 1400℃ 5000×

地分布在陶瓷片的表面,这可能是由于压片的粉末粒径较小,为纳米级别,导致压片过程中存在许多气体难以排出。而随着烧结温度的增大,晶粒长大,颗粒之间的气体慢慢排除,孔洞减少,晶界也越来越明显。

4. 结论

1) 溶胶–凝胶法制备的La2Ce2O7前驱体在700℃下煅烧后即可得到晶型良好的纳米粉末,随着煅烧温度与时间的增大,粉末的晶型越来越好,晶粒越来越大。由于La2Ce2O7是La2O3溶解进CeO2的晶格中,所以为萤石结构。

2) SEM与TEM观察下的La2Ce2O7纳米粉末由于晶粒太小,均有一定程度的团聚。

3) 在700到1000℃温度范围内,纳米La2Ce2O7的晶体生长活化能为27.85 KJ·mol−1。

4) 150 MPa下压制的纳米陶瓷片在1100℃~1400℃下保温6 h,1400℃下相对密度达到90%,具有良好的抗烧结性能。从SEM中可以看出La2Ce2O7陶瓷片的表面存在许多孔洞。随着煅烧温度的增大,晶粒长大,晶界也更明显。

NOTES

*通讯作者。