1. 引言

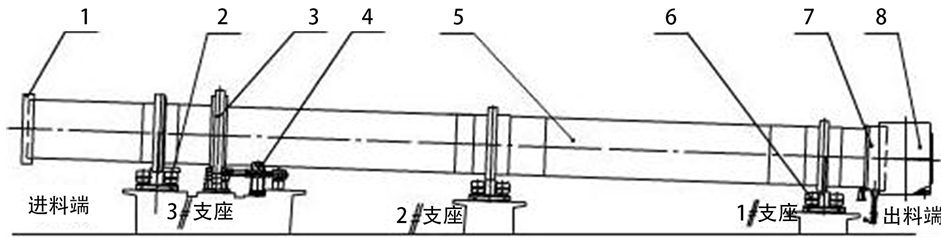

目前,冶金含锌含铁固体废弃物,如干法灰、电炉灰、含锌污泥等,主要采用回转窑工艺处理。该处理工艺处理量大,效率高。但是,该工艺也存在自身的缺点,即炉窑结圈严重,结圈会造成料层不均匀、回转窑系统阻力增大、回转窑内有效截面积缩小,严重影响回转窑的产能,同时缩短了窑衬的使用寿命。文献 [1] 研究认为固体颗粒越小、表面曲率越大,熔化温度越低,因此,小颗粒可以在较低的温度下产生软熔,引起粘结。文献 [2] 中进行脱锌还原试验结果表明:瓦斯泥锌挥发率和铁金属化率均随反应温度升高和反应时间增加而增大,但温度的影响是决定性的。文献 [3] 认为钾钠的存在有利于低熔点物质的形成,尤其是通过电子探针微区能谱分析发现结圈物的玻璃质中K2O含量高。然而,关于回转窑结圈形成机制目前鲜有报道。鉴于上述,本文针对回转窑结圈现象严重的问题,通过物相分析研究回转窑结圈机理,在此基础上,提出相应的抑制措施,为回转窑处理含锌固废结圈问题的预防与处理提供理论指导和技术支持。图1是回转窑的结构简图。

2. 实验

现场的调研结果显示:窑头和窑尾不易结圈,窑中结圈程度最严重。该结果表明结圈主要在高温区发生。因此,对高温区结圈进行了现场采样。另外回转窑处理的物料也进行了采样。

将取回的结圈物自上向下用切割机切开,观察结圈物的截面形貌;将回转窑处理的物料和结圈的不同区域的样品研磨到300目以下,采用XRF进行了成分分析;结圈块状样进行磨平并抛光,采用SEM&EDS分析。

3. 实验结果与分析

3.1. 形貌分析

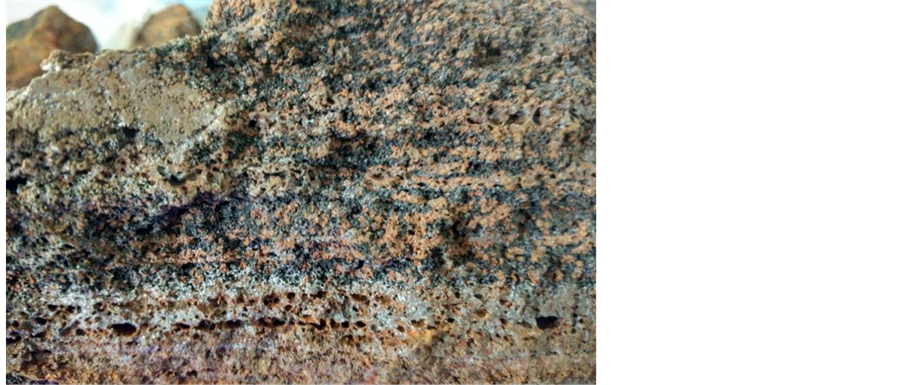

取南钢盛昌公司回转窑内一整块窑中结圈物观察,图2是现场窑中结圈物断面照片。明显可见结圈

1.窑尾密封装置 2.带挡轮支承装置 3.大齿圈装置 4.传动装置 5.窑筒体部分 6.支承装置 7.窑头密封装置 8.窑头罩

1.窑尾密封装置 2.带挡轮支承装置 3.大齿圈装置 4.传动装置 5.窑筒体部分 6.支承装置 7.窑头密封装置 8.窑头罩

Figure 1. Rotary kiln structure diagram

图1. 回转窑的结构简图

Figure 2. Photograph of ring sample in Rotary kiln

图2. 回转窑结圈物试样图片

物断面具有明显的层状结构。粘附在窑壁上的结圈物称为内层结圈物,它是由很多细小的粉末粘接在一起形成的。中层结圈物结构较为致密,很多的黑色粉状物料粘结在一起,这可能是原料中粒状物料和煤粉颗粒被生成的液相粘结在一起造成的。断面上能看到明显的金属光泽且呈金属光泽的物质连成一块,说明有金属铁相产生并且金属铁在回转窑内熔化了。产生结圈物的形状不规则,呈暗红黑色,表面呈金属光泽,有许多熔融状结圈物,据此可推测结圈物中含有铁氧化物,并且铁氧化物与粉末物料熔融粘结在一起。

3.2. 化学成分分析

对混合原料和窑中不同位置处结圈物进行化学成分分析,由安徽工业大学分析测试中心按照国家标准进行检测,分析结果见表1。

由表1可以看出,回转窑内结圈物的最主要的化学成分的铁和铁的氧化物,其他各种化合物的总量约在40%左右。氧化锌基本被还原成金属锌随烟气从窑尾进入沉降室、空气冷却管,再进入布袋除尘室打包成为ZnO成品。结圈物中CaO、SiO2和Al2O3含量都高于原料中的的含量,主要是因为煤灰粘结在结圈物中造成的。回转窑结圈物中的全铁含量自内层至外层不断升高,是因为结圈形成初期,原料中铁氧化物还原后的产物随回转窑转动从窑尾排出,主要是粉末状物料或者煤灰粘结在窑壁上。而随着结圈物的增厚,阻碍了窑内的物料运动以及煤气流的运动,造成回转窑内温度分布不均匀,许多铁氧化物被还原后去其它物质形成了低熔点的多组分化合物在局部高温的作用下形成液相而粘附在

Table 1. The main chemical composition of raw materials and ring samples (w/%)

表1. 入窑原料和结圈试样主要化学成分(w/%)

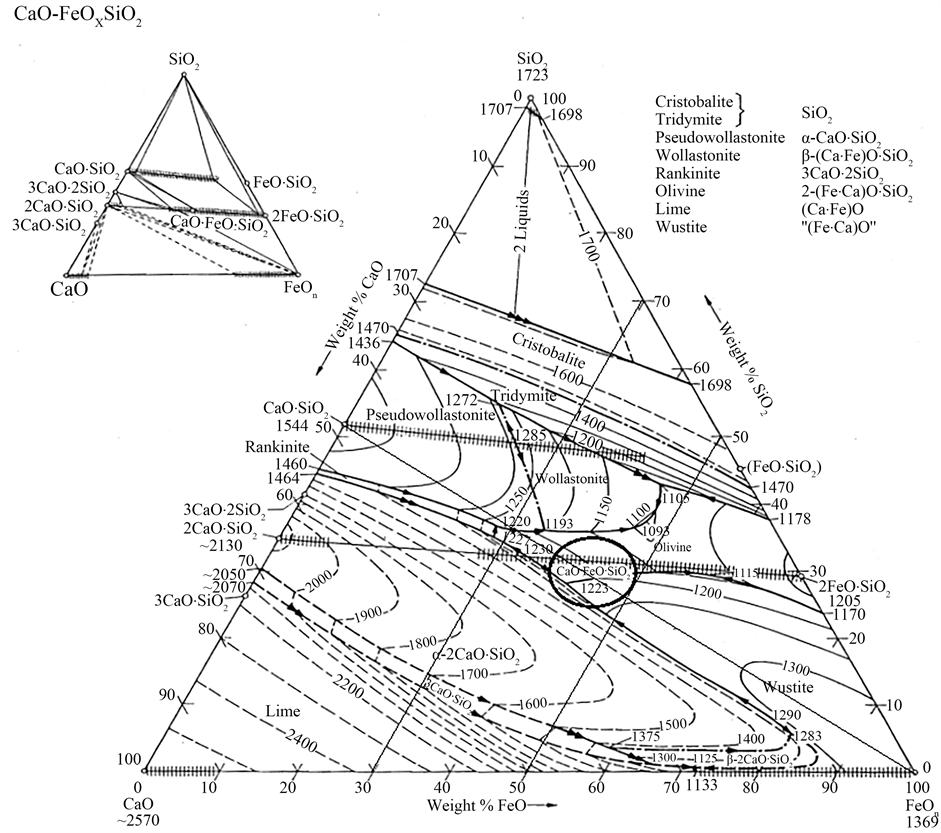

结圈物上 [4] 。图3是CaO-FeO-SiO2三元系相图。由表1可知,结圈物中CaO与SiO2的比值接近1,根据相图可知,当1160℃左右,回转窑中部的焙烧温度在1180℃~1250℃,最高温度可达1300℃,故钙铁橄榄石很大可能是结圈物的液相粘结相。

3.3. 物相分析

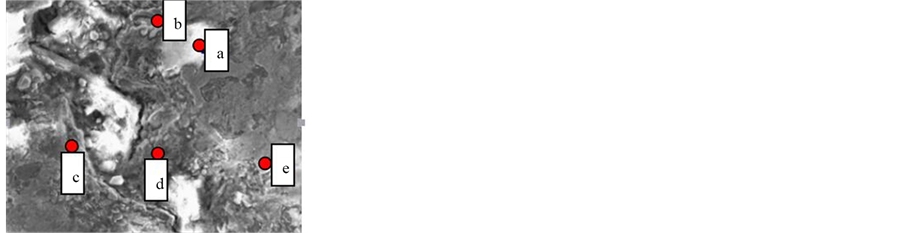

对窑中不同位置处试样进行扫描电镜观察和能谱打点分析。图4是结圈物的扫描电镜照片,表2~4为结圈物不同区域的成分。

回转窑内层结圈物由其显微结构和EDS能谱分析可知:内层结圈物中铁的浮氏体、钙长石的含量较高,有少量的液相、磁铁矿和金属铁。a点为钙长石,是由煤灰长期堆积矿化而成。b点是金属铁颗粒,铁中碳含量较高。c点是铁的浮氏体,和煤粉固结在一起呈板块状连接成片 [5] 。d点是液相,是原料中未被还原的SiO2、CaO、Al2O3类氧化物与煤灰混合在一起形成了低熔点的多组分化合物,主要是硅酸盐类。e点是磁铁矿。

由内层结圈物的矿相组成和大致分布情况可得出,回转窑结圈的初期,由于煤灰和少量粉末物料的表面能大,很容易粘附在不光滑的窑壁上,粘附的细小微粒在回转窑转动过程中在重力和上部物料的压力的作用下机械沉积且不断被加固,煤灰慢慢矿化为钙长石类矿物 [6] 。该类矿物熔点高(1500℃以上)、硬度大,且呈突出结构,一旦形成,很容易成为物料粘附的核心。碳粉和铁的浮氏体之间主要是固相粘结在一起。因此可认为,回转窑内层结圈主要是粉末与粉末和粉末与颗粒物料间的固相固结作用为主,液相粘结为辅。

回转窑中层结圈物由其显微结构和EDS能谱分析可知:中层结圈物中液相的含量最高,铁的浮氏体和黄长石、尖晶石类物质次之,有少量游离的Al2O3。a点主要是黄长石类矿物。一方面是煤灰聚集矿化形成的,一部分是原料中带入的。b点是铁的浮氏体,铁的浮氏体与煤粉固结在一起。c点是镁铁尖晶石和游离的Al2O3形成的高熔点化合物。d点是硫化亚铁,是硫和铁在高温下共熔而得,在1200℃左右,

熔化成液态熔化成液态。e点是液相,主要是硅铝酸盐和铁铝酸盐类物质,是物料中Al2O3、FeO、SiO2和CaO这些氧化物形成的低熔点的多组分化合物。f点是橄榄石液相,是CaO、SiO2、MgO和FeO形成的钙铁橄榄石和钙镁橄榄石类化合物。

由中层结圈物的矿相组成和大致分布情况可得出,高熔点高硬度的黄长石、尖晶石类物质的形成,这些物质呈突出形态,成为粉末和粒状物料依附和液相结晶的坚硬核心。液相明显增多,一方面是由于初期固相反应生成的一些低熔点化合物或共熔体在高温下下熔化,另一方面是结圈物的形成影响了窑中温度的分布,造成了窑中局部温度过高。液相的增多,加剧了固体物料之间的相互粘结以及固体物料与液相之间的粘结,结圈物滚雪球式地不断形成再长大,如此恶性循环,导致结圈物不断增厚 [7] 。因此,窑中结圈的主要原因液相粘结造成的。形成的液相中,铁主要是以FeO的形式与其他物质形成低熔点的化合物。如果降低窑中FeO的生成,则窑中的液相将明显减少,从而很好的抑制窑内结圈的发生 [8] 。

Figure 3. CaO-FeO-SiO2 ternary facies phase diagram

图3. CaO-FeO-SiO2三元系相图

(内层) (中层) (外层)

(内层) (中层) (外层)

Figure 4. SEM photograph of Rotary kiln (magnified 250 times)

图4. 结圈物的扫描电镜照片(放大250倍)

回转窑外层结圈物由其显微结构和EDS能谱分析并可知:a点是硅灰石和氟化钙形成的化合物,结合CaO-FeO-SiO2三元系相图可知,它们以固态存在于结圈物中。图5是CaO-FeO-SiO2三元系相图。B

Table 2. Component of different areas of inner circles (w/%)

表2. 内层结圈物不同区域的成分(w/%)

Table 3. Component of different areas of middle circles (w/%)

表3. 中层结圈物不同区域的成分(w/%)

Table 4. Component of different areas of outer circles (w/%)

表4. 外层结圈物不同区域的成分(w/%)

点是金属铁液相。在窑中靠近煤气流中心的位置,铁氧化物被充分还原形成大量金属铁,它们活性很高,当与气相中有氧接触将发生铁的剧烈燃烧,产生局部高温而使金属铁熔化 [9] 。c点是铁的浮氏体,与煤粉固结在一起。d点是煤灰和少量FeS熔融包裹碳粉和固相反应产物FeO·Al2O3。e点主要是正硅酸钙和氟化钙,结合相图可知,它们之间形成了稳定化合物(C2S)2F,并且熔点在1170℃左右,因此属于液相。f点主要是游离的三氧化二铝和尖晶石固溶在一起形成的复杂化合物。

由外层结圈物的矿相组成和大致分布情况可得出,硅酸钙和尖晶石类物质成为物料依附和液相结晶的坚硬核心,大量金属铁、(C2S)2F化合物和少量的煤灰熔化形成的液相加剧了窑内物料之间的相互粘结,最后就形成了严重的结圈现象。因此,外层结圈主要是液相粘结造成的,粘结相主要是金属铁液相和少量的硅酸盐液相。局部高温和料层氧化气氛是外层结圈物液相形成的主要原因,因此,可以从这两方面着手来抑制外层的结圈。

3.4. 液固相粘度对结圈的影响

结圈物是由固液相组成的体系。体系粘度与固相和液相的体积分数的关系可用Einstein粘度公式表示 [10] :

Figure 5. CaO-FeO-SiO2 ternary facies phase diagram

图5. CaO-FeO-SiO2三元系相图

式中,η为固液体系粘度;η0为液相的粘度;Φ为固相所占的体积分数。

由上式可以看出,固相所占的体积分数对整个体系的粘度影响很大。低熔点物质在窑中形成的液相粘度并不大,但是由于颗粒状物料如碳粉、CaO等固相成分的存在,使得固液间形成的粘结相体系粘度很大,很容易粘附,导致了严重的结圈现象。

综上分析,窑中结圈物的结圈机制如下:初期,煤灰和粉末物料黏附在不光滑的窑壁上,粘附的细小微粒在回转窑转动过程中在重力和上部物料的压力的作用下机械沉积且不断被加固,煤灰慢慢矿化为钙长石类矿物,成为物料粘附的核心。初期固相反应生成的一些低熔点化合物或共熔体,为液相的生成的提供了条件。黄长石、尖晶石脉石类物质的形成,成为物料依附和液相结晶的新的核心。液相的增多,加剧物料间的相互粘结,结圈物滚雪球式地不断形成再长大,如此恶性循环,导致结圈物不断增厚,最后形成了严重的结圈现象。

3.5. 抑制回转窑结圈的措施

通过上述分析可知,煤灰和粉末状物料是结圈的基础物质,长石、尖晶石类矿物是窑中物料粘附和液相结晶的核心,局部高温和大量低熔点物质是大量液相形成的条件。由此,可以针对性提出以上抑制措施:

1) 尽量选用灰分少,脉石含量低,灰分软熔温度在1300℃以上(该公司窑内最高温度可达1300℃)的煤粉作为喷吹剂。

2) 换用长火焰烧嘴以增加火焰长度,避免了窑内高温区集中,降低了高温带的温度 [11] 。热工确定合理的热工制度,选择合理的热工参数并严格控制可以有效地减缓结圈现象的发生。

3) 降低窑中FeO的生成,则窑中的液相将明显减少,从而很好的抑制窑内结圈的发生。提高烧结原料的碱度以及降低配碳量都能有效降低FeO的含量。

4. 结论

1) 窑中结圈的主要原因是煤灰沉积引起了初期的结圈,大量液相的生成引起物料间的液相粘结则使结圈物不断增厚。内层结圈是固相固结为主,液相粘结为辅。中层和外层结圈主要是液相粘结造成的。

2) 采取增长火焰烧嘴的长度、提高入窑原料的碱度和提高喷吹煤粉的质量等措施,回转窑结圈基本得到了有效控制,生产逐步实现了温度顺行。