1. 引言

固体碱催化甲醇–油脂酯交换制备生物柴油反应体系,由于其操作过程绿色化以及生物柴油产率高等特点,一直以来是快速制备生物柴油及其连续化生产的研究重点 [1] [2] 。目前使用的固体碱主要有碱土金属氧化物以及负载型固体碱两大类。碱土金属氧化物中氧化钙具有良好的催化活性,反应3 h生物柴油产率就可达到90%以上 [3] [4] 。为了进一步提高催化剂活性,研究者还通过掺杂以及负载等方法对氧化钙进行改性 [5] [6] 。张家仁等 [7] 以KF/Al2O3作催化剂催化制备生物柴油,反应6 h产率达到90%以上;卞庆贵等 [8] 又以KF/γ-Al2O3催化乌桕籽油制备生物柴油,反应4 h产率也可达到90%以上。

纳米材料由于晶粒极小,比表面积特大,导致了纳米微粒在热、光、敏感性和表面稳定性等方面优于普通微粒,因此广泛的应用于化工生产、电子产业、医学和军事领域 [9] [10] 。尤其在催化化工行业,纳米催化剂由于具有比表面积大、表面活性位点多等特点,在一些化学反应中表现出高活性、高选择性等的优良催化性能 [11] [12] ,因此引起研究者的广泛关注。Wen等 [13] 采用纳米技术制备了纳米级钙基固体碱,该催化剂在室温下就可以实现对甲醇–油脂酯交换反应的催化,极大提高了氧化钙催化剂的催化活性。

本文采用共混法和浸渍法两种不同方法制备催化剂,以γ-Al2O3为载体制备大比表面积以及强碱性的KF/γ-Al2O3负载型固体碱,单就制备方法而言,共混法制备催化剂操作简单,反应时间大大缩短;并考察该固体碱催化甲醇–油脂酯交换制备生物柴油的性能,实现非均相反应体系快速高效制备生物柴油,为生物柴油连续化生产提供可靠依据。

2. 实验部分

2.1. 试剂和仪器

菜籽油,陕西建兴农业科技有限公司;γ-Al2O3,宣城晶瑞新材料有限公司;无水乙醇95%,天津市天力化学试剂有限公司;KF·2H2O,成都市科龙化工试剂厂;甲醇,天津市天力化学试剂有限公司;乳化剂OP,天津市科密欧化学试剂有限公司(均为分析纯)。

DF-101S恒温加热磁力搅拌器,巩义市予华仪器有限公司;SC-03低速离心机,安徽中科中佳科学仪器有限公司;RE-2000A旋转蒸发器,西安安泰仪器科技有限公司;气相色谱仪HP-GC2000,北京科普生分析科技有限公司。

2.2. 催化剂制备

共混法:称取一定量纳米γ-Al2O3溶于50 mL无水乙醇中,按一定物质的量之比加入KF·2H2O和1 mL乳化剂OP,均匀混合,在一定温度下充分搅拌反应2 h,烘箱内烘干后置于马弗炉内定温定时煅烧,最后研磨成粉,装袋备用。

等体积浸渍法:称取0.9 g KF·2H2O溶于蒸馏水,再加入6 g γ-Al2O3,均匀混合后常温下静置12 h,烘箱内烘干后置于马弗炉内定温定时煅烧,最后研磨成粉,装袋备用。

2.3. 酯交换反应

按一定比例将精制菜籽油、甲醇和催化剂混合于三口烧瓶,充分搅拌后在恒温下反应,每隔一定时间取一次样品,采用离心分离和减压蒸馏分别除去催化剂和未反应的甲醇,得到的亮黄色产物即为生物柴油。产物通过气相色谱仪(HP-GC2000)进行分析。采用内标法以十七酸甲酯做内标物定量分析生物柴油产率。色谱分析条件为:HP-INNOWAX型毛细管柱(30 m × 0.32 mm);N2为载气,流量30 mL/min,分流比20:1;进样口温度300℃,检测器温度300℃,进样量1 uL。

3. 结果与讨论

3.1. KF用量

在反应温度

65 ℃

,醇/油比8:1,催化剂用量为5% (油质量百分数)的条件下,考察氟化钾不同用量对催化剂性能的影响。考察结果如图1所示。从图1可知,随着KF·2H2O/γ-Al2O3(物质的量)比例的增大,生物柴油的产率呈现先增后减的趋势,当KF·2H2O/Al2O3比为1.30:1时生物柴油产率高达96.47%。KF的增加能够提高催化剂表面活性位点数量,从而提高催化剂活性;但KF·2H2O用量过多,使得催化剂表面活性位点分散性降低,造成活性位点被覆盖,从而降低其催化活性 [11] 。

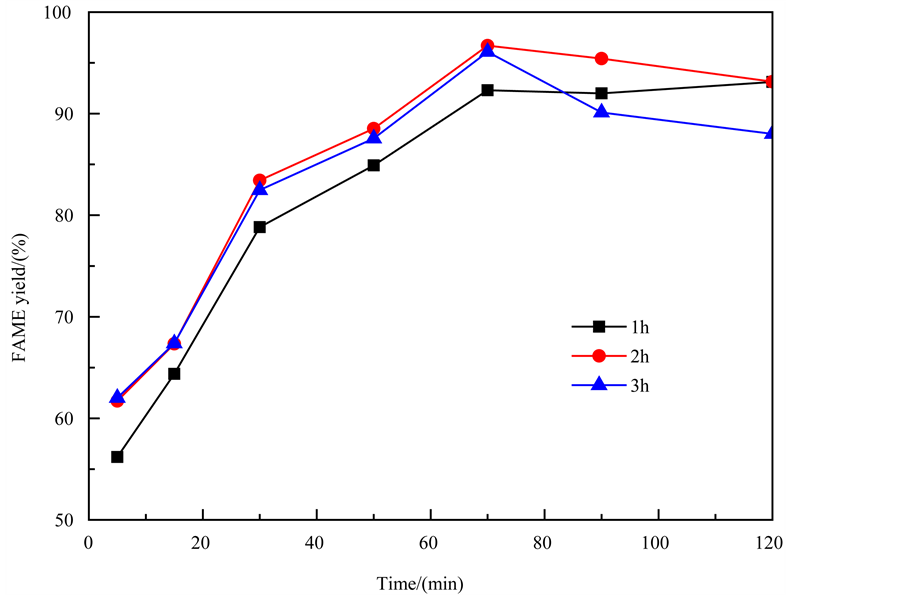

3.2. 共混反应时间

在

65 ℃

反应温度,醇/油比8:1,催化剂用量为5%的条件下,考察共混反应时间对催化剂性能的影响。从图2可知,随着共混反应时间延长,生物柴油产率升高,继续延长共混反应时间,产率下降,共混反应2 h所得到的催化剂制备生物柴油产率达96.47%。因为共混反应时间太短,活性组分在载体上的分散不充分,共混时间过长活性组分团聚,降低催化剂活性,因此实验确定最佳共混反应时间为2 h。

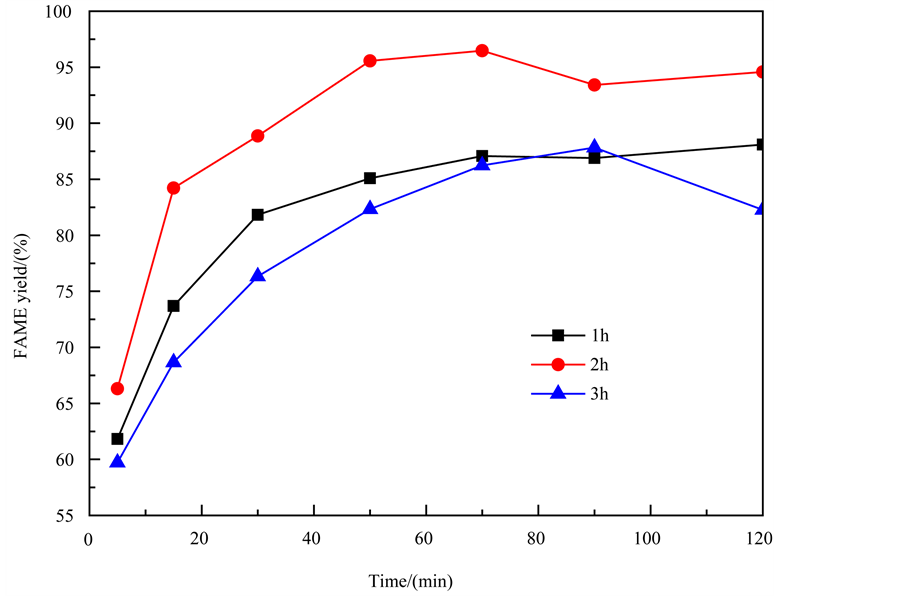

3.3. 煅烧温度

在反应温度

65 ℃

,醇/油比8:1,催化剂用量为5% (基于油质量百分数)的条件下,考察了不同温度焙烧的KF/γ-Al2O3催化酯交换反应制备生物柴油的性能,结果如图3所示。从图3可知,随着煅烧温度的升高,生物柴油产率增加,继续升高煅烧温度,产率反而降低。因为焙烧温度过低时催化剂表面活性位点没有完全暴露;而煅烧温度太高又会导致催化剂表面烧结,降低催化剂活性,因此实验确定最佳煅烧温度为

300 ℃

。

Figure 1. Effect of KF amounts on catalytic properties

图1. 氟化钾用量对催化剂性能的影响

Figure 2. Effect of blending time on catalytic properties

图2. 共混反应时间对催化剂性能的影响

Figure 3. Effect of calcination temperature on catalytic properties

图3. 煅烧温度对催化剂性能的影响

3.4. 煅烧时间

在反应温度65℃,醇/油比8:1,催化剂用量为5% (基于油质量百分数)的条件下,考察不同的煅烧时间对催化剂性能的影响。由图4可知,煅烧时间在2 h,催化剂催化效果最好,延长煅烧时间会造成催化剂的表面烧结,从而使得生物柴油产率降低。因此实验确定催化剂最佳煅烧时间为2 h。

3.5. 甲醇用量

反应温度65℃、催化剂用量5%条件下考察甲醇用量对生物柴油产率的影响。实验结果如图5所示。从图5可知,随着醇/油比的增大,生物柴油的产率增加,当醇/油比由5:1增加到8:1时生物柴油产率增长幅度较大,当醇/油比为8:1时,反应50 min,生物柴油产率就达到95.56%,反应70 min,产率达到最高96.47%。继续增大醇/油比,产率又下降,这主要是由于增加甲醇用量可以促进酯交换反应向生成生物柴油方向进行,但过多甲醇会产生稀释效应 [14] ,造成产物浓度降低,从而导致产率先升后降。因此确定该反应的最佳醇/油比为8:1。

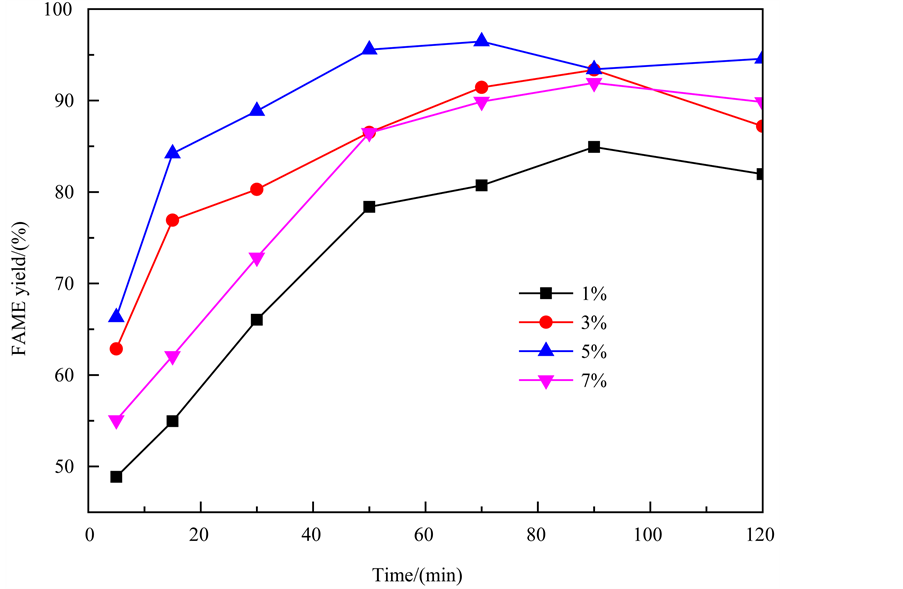

3.6. 催化剂用量

在反应温度

65 ℃

、醇/油比8:1条件下考察了催化剂用量对生物柴油产率的影响,实验结果如图6所示。从图可知,催化剂用量由1%增加到7%,生物柴油的产率呈先增后减趋势。当催化剂用量为5%时,反应70 min,产率达到最高96.47%。这是由于催化剂用量增加,能使反应物与催化剂接触面积增大,促进酯交换反应的进行,提高生物柴油产率,但催化剂用量过多,也会导致皂化反应的发生 [15] ,产率降低。

Figure 4. Effect of calcination time on catalytic properties

图4. 煅烧时间对催化剂性能的影响

Figure 5. Effect of methanol ratio on yield of FAME

图5. 甲醇用量对生物柴油产率的影响

Figure 6. Effect of catalyst amounts on yield of FAME

图6. 催化剂用量对生物柴油产率的影响

Figure 7. Catalytic performance comparison of different KF/γ-Al2O3

图7. 不同方法制备KF/γ-Al2O3催化性能比较

3.7. 不同方法制备催化剂性能比较

本研究还采用常规浸渍法,以γ-Al2O3为载体制备了KF/γ-Al2O3催化剂。将不同方法制备的两种KF/γ-Al2O3催化剂,在反应温度

65 ℃

、醇/油比8:1、催化剂用量5%条件下进行性能比较,结果如图7所示。由图可见,共混法制备的KF/γ-Al2O3催化性能远优于普通等体积浸渍法,产率提高60%以上。

4. 结论

以γ-Al2O3作载体负载活性组分KF制备纳米固体碱催化剂催化油脂–甲醇酯交换体系制备生物柴油,并考察不同方法制备的催化剂性能,对催化剂进行表征。优化得到催化剂最佳制备条件:KF/γ-Al2O3摩尔比1.30:1、65℃反应2 h、300℃煅烧2 h。在反应温度65℃、醇/油为8:1、催化剂5%条件下催化制备生物柴油,反应70 min产率达96.47%,高于等体积浸渍法制备KF/γ-Al2O3催化剂60%,说明共混法制备的纳米催化剂在酯交换制备生物柴油体系中表现出更好的活性。

基金项目

国家自然科学基金项目(21306149)、2016年地方高校国家级大学生创新创业训练计划项目(201610705002)和陕西省大学生创新创业训练计划项目“纳米固体碱催化三组分耦合反应制备生物柴油”。