1. 引言

随着石油资源的耗竭以及价格的不断攀升,煤制油技术成为缓解石油危机的重要措施之一 [1] [2] 。煤制油是以煤炭为原料,通过化学加工过程生产油品和石油化工产品的一项技术。我国对煤制油技术的研发较早,近10多年取得重大进展。在煤制油的煤粉制备工艺以及气化装置中,都存在粉煤仓。粉煤仓是研磨好的煤粉的临时储存设备,内部煤粉的粒度小,容量大。设备正常运行时其内部为惰性环境,处于安全状态;如果操作失误或设备故障,则仓内可能进入氧气,有发生超压的可能性。所以煤粉煤仓需要进行泄爆设计,安设泄爆装备。现需要对我公司煤粉制备和气化工艺中的2个粉煤仓进行泄压面积设计,降低可能出现的超压对设备本身及周边环境造成的危害。

2. 煤尘云最大爆炸压力及最大爆炸压力上升速率测试

依据GB/T15605-2008 [3] 的要求,设备泄压面积设计要根据粉尘云最大爆炸压力、爆炸指数等参数来确定,而爆炸指数可以由粉尘云最大爆炸压力上升速率来计算。根据GB/T16426-1996 [4] 中的测定标准,利用20 L粉尘爆炸特性测试系统(如图1所示)对我公司煤样的煤尘云最大爆炸压力与最大爆炸压力上升速率进行了实验测试。该装置由爆炸罐体、喷尘装置、点火装置、数据采集系统、真空配气装置以及除尘装置六大部分组成。

实验前,使用200目的筛子对我公司煤粉进行了筛分处理,达到了相关标准中“粒径 < 75 μm”的要求。

本实验是在常温常压条件下进行的,实验室环境温度在15℃~25℃之间,环境相对湿度在70%~90% rh之间。实验时,首先打开储尘罐将称量好的粉尘装入储尘罐并关紧;然后将储气室空气压力调节到2.0 MPa;打开真空泵,将爆炸罐抽真空到0.052 MPa;最后启动计算机应用程序并开始试验;

通过测试,煤尘云的最大爆炸压力为0.62 MPa,其对应的煤尘云浓度为300 g/m3;煤尘云的最大爆炸压力上升速率为54.14 MPa/s,其对应的煤尘云浓度为200 g/m3。由上述数据,可计算出煤粉的爆炸指数Kst为14.70。

3. 粉煤仓泄爆面积核算

3.1. 备煤系统粉煤仓泄爆面积

备煤系统是煤制油的准备环节,是利用磨煤机将原煤研磨至所需粒径并临时储存的工艺。粉煤仓就是煤粉临时存储的容器,备煤系统粉煤仓为圆柱体,其高度为18.5 m,直径Φ为6.0 m,包裹体容积约为100 m3。

根据GB/T15605-2008 [1] 的规定,对pred,max > 0.15 MPa按式(1)计算:

Figure 1. 20 L dust explosion characteristics test system

图1. 20 L粉尘爆炸特性测试系统

(1)

(1)

(2)

(2)

上述公式各符号的意义及有效范围为:

容器泄爆面积A;

容器体积V:0.1 m3 ≤ V ≤ 10,000 m3;

泄压装置的静开启压力Pstat:0.01 MPa ≤ Pstat ≤ 0.1 MPa;

最大泄爆压力Pred,:0.01 Mpa ≤ Pred,max ≤ 0.2 MPa,此处取最大值0.2 MPa;

最大爆炸压力Pmax。

由式(1)、(2)可知,备煤系统粉煤仓的泄爆面积为:

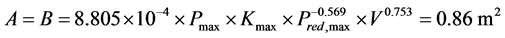

3.2. 气化装置粉煤仓泄爆面积

气化装置是以煤粉为原料,氧气和水蒸气作气化剂,生产以H2和CO为主的合成气。气化装置的粉煤仓也是临时存储煤粉的作用,粉煤仓尺寸L × W × H为10 m × 6.5 m × 4.8 m,包裹体容积约为150 m3。

由式(1)、(2)可知,气化装置粉煤仓的泄爆面积为:

4. 泄爆设计

根据前面的实验测试及计算,已经可以确定出粉煤仓所需的泄压面积。接下来需要选择合适的泄爆设备,并设计其安装位置。目前,市场上的泄爆设备种类型号繁多,如泄爆片、防爆门、防爆阀、弹簧泄压装置等。这些设备各有特点,原理不尽相同。目前应用较多的是泄爆片(如图2所示)和重力式防爆门(如图3所示)。

泄爆设备的选型应考虑安装设备的实际情况及环境特点。粉煤仓主体设备都处于室内,仓体四壁安设有氮气管路及附属设施,不适宜再增加其他设备。因此,考虑在粉煤仓的顶部安装泄爆设备,并采用水平布置,即泄爆面与粉煤仓顶部表面平行。

粉煤仓顶部安装有压力变送器及测尘仪等,是巡检人员经常检查的区域。由于泄爆片直接承压能力弱,如果巡检人员无意中立足上面可能会发生安全事故。因此,考虑在粉煤仓顶部安装重力式防爆门,防爆门的重力盖为钢结构,有较大的承压能力。当仓体内部压力超过预设的数值时,防爆门重力盖自动

打开,瞬间泄压,达到保护设备和管道的目的,泄压后能自动复位。最终,根据实际应用效果并考虑经济因素,选择泄爆面积为0.393 m2的重力式防爆门。

由计算得知备煤系统和气化装置粉煤仓所需的泄爆面积分别为0.635 m2和0.86 m2,考虑到安全因素,增加1.5倍的安全系数后泄爆面积为0.9525 m2和1.29 m2。所以,需要安装的重力式防爆门的个数分别是3个和4个。

5. 结论

本文通过实验测试以及计算分析,得到以下结论:

(1) 测试煤样的煤尘云最大爆炸压力为0.62 MPa,其对应的煤尘云浓度为300 g/m3;煤尘云最大爆炸压力上升速率为54.14 MPa/s,其对应的煤尘云浓度为200 g/m3。

(2) 通过计算,备煤系统粉煤仓的泄爆面积为0.635 m2,气化装置粉煤仓泄爆面积为0.86 m2。

(3) 根据实际应用效果并考虑经济因素,将粉煤仓选择泄爆面积为0.393 m2的重力式防爆门作为泄爆装备;考虑到安全效果,备煤系统粉煤仓的安装数量为3个,气化装置粉煤仓的安装数量为4个。

基金项目

神华集团公司科技创新项目(SHJT-14-13)。