1. 前言

在压水堆核电厂严重安全事故中,如采用堆内注水方式冷却,可能导致低温冷却剂刺入熔融堆芯中,此时高温熔融物和低温冷却剂互相接触,在一定触发条件下,低温射流发生进一步碎化,传热面积急剧增大,引发蒸汽爆炸,造成重大核安全事故 [1] 。冷却剂刺入熔融物过程涉及到复杂高速多相传热、相变等物理过程,相比于熔融金属落入水中模式,研究不足,缺乏统一的理论模型。

对冷却剂射流刺入熔融金属的射流碎化过程研究,研究者们通过实验获得射流碎化行为和不同参数影响效应 [2] [3] [4] [5] 。在冷却剂射流刺入熔融金属实验中,因熔融金属的不透明性,多数研究者采用透明替代材料进行绝热条件下实验研究 [2] [3] 。STBAMOTO [2] 采用中子照相技术捕捉射流形态变化,获得了射流形态的图像及触发蒸汽爆炸的温度条件的成果,但因现有射线照相技术限制,难以捕捉射流表面具体微观细节。很多研究者尝试采用数值计算方法研究冷却剂射流碎化机理 [6] [7] [8] 。Sachin Thakre [6] 等人基于FLUENT软件模拟研究了射流的水力学现象,分析了射流碎化长度的参数影响效应。日本Hirokazu [7] 等人采用MPS数值方法,对射流水刺入高密度液态氟化液的Park实验进行了模拟研究,基于实验结果将射流现象分为两个阶段(线性下落后不稳定碎化阶段和碎化射流稳定于一定深度阶段)。数值模拟成功模拟了第一阶段,但未能模拟射流在第二阶段的形态变化规律(如图6所示)。

本文基于FLUENT15.0软件,采用流体体积法(VOF)模拟了射流穿透深度水力学的两个阶段现象,模拟结果与日本Park实验吻合。通过数值模拟,分析了射流速度、密度比、张力和粘性系数对第二阶段的射流最终深度的影响效应,为深入研究冷却剂刺入熔融金属过程奠定基础。

2. 数值分析方法

2.1. 数值方法

本文基于FLUENT15.0软件,采用基于压力的瞬态求解器,通过多相流模型中的VOF法对射流水刺入熔融金属过程进行界面追踪。VOF法 [9] ,即流体体积法,可通过计算每个控制体内某种流体的体积份额来实现界面追踪。公式(1)为VOF法中体积标量函数F的变化方程 [4] ,F指一个网格单元内,特定物理相的体积份额。

(1)

(1)

本文共设空气、水、液态金属三相,其中空气为第一相,水为第二相,熔融金属为第三相。若F = 0,则该控制体全部为初相空气;若F = 1,则该控制体全部为第二相水;若F = 2,则该控制体全部为第三相熔融金属;若0 < F < 1,则该控制体为空气–水交界面单元;若1 < F < 2,则该控制体为水–熔融金属交界面单元。VOF法中引入Body Force公式用于加入体积力影响,Co数设置为0.25。

本文只模拟射流水刺入熔融金属的水力学现象,在运算公式中没有加入能量方程。采用PISO法用于压力–速度耦合计算;采用Geo-Reconstruct法进行界面重建;表明张力采用连续张力模型(CSF model)。

2.2. 数值模型

冷却剂刺入金属的过程中伴随着射流表面的失稳碎化现象,为研究射流碎化机理,日本原子能研究所Park等人以氟化液为熔融物,水为冷却剂开展了关于FCI基本过程的可视化实验。本文以Park实验为基本工况 [7] ,进行3D轴对称数值模拟计算。Park实验物性参数如下表1所示。

采用3D对称模型,两个对称面使得实际数值计算区域为真实模型的1/4 (如图1)。其中水池上部中心区域为进口边界条件,水池上部非中心区域为出口边界条件,其余部分为墙壁边界条件。水和熔融物相互作用数值模拟实验真实模型几何结构尺寸如下表2所示。

计算区域网格采用局部加密,总体均匀划分的网格方案,网格单元共250000个。具体来说,将计算区域按y轴平均分成4份(如图1所示),因射流形态变化主要发生于中间两个部分,故中间段0.2 m区域y轴节点170个,上下0.2 m区域节点共80个。底部为20 × 50的均匀矩形网格,射流区域共有5 × 5个正方形网格。最小网格位于中段区域,体积为1.191173 mm3,最大网格位于上下区域,体积为2.468741 mm3。最大纵横比为7.13529e+00,最小矩形质量为4.63386e−01 (数值越接近0网格质量越差)。初始化时,定义了液态金属的区域(X轴为0到0.05 m,Y轴为−0.4到−0.2 m,Z轴为0到0.02 m),速度为0 m/s、熔融物体积份额为1;初始化射流水定义于熔融物表面正上方(X轴为0到0.005 m,Y轴为−0.2到0 m,Z轴为0到0.005 m),速度设为Y轴方向−3.8 m/s、水体积份额为1。

表1. 物性参数表

Table 2. Geometrical parameters of real model

表2. 真实模型几何尺寸结构参数

Figure 1. 3D calculation model and mesh number scheme

图1. 3D模型计算区域及网格节点示意图

3. 数值计算结果及分析

3.1. Park实验数值模拟

熔融物与冷却剂互相作用过程的形态结果如图2所示。通过对比文献中实验结果(见图3),可以看到形态模拟图2和实验图3可以较好吻合。具体可分为三个阶段,在第一阶段(0 s~0.1 s),形成了空气口袋,空气口袋在0.1 s左右封口;第二阶段(0.1 s~0.133 s),空气口袋出现塌缩,空气被向下挤压,空气封口变细;第三阶段(0.133 s~0.167 s),射流出现流动不稳定性,熔融物、水和空气互相混合形成混流区域。

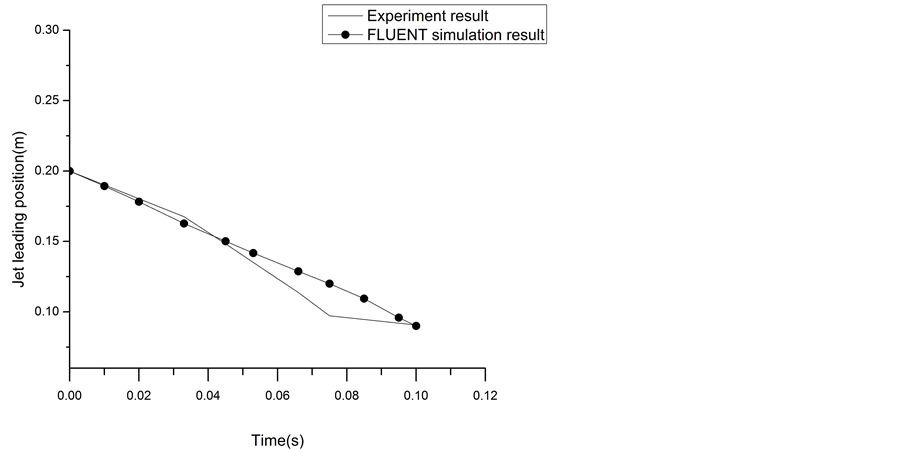

为定量比较计算结果和实验结果 [7] ,分别选取水刺入深度变化和液态金属液位变化进行比较,见图4和图5。由图4和图5所示,实验结果都近似线性变换,模拟结果在趋势上与实验结果一致。实验数据出现了转折情况,说明射流速度在不断减小,这是因为射流在刺入高密度液体后,因为浮力作用而不断减速。

3.2. Park模拟结果分析

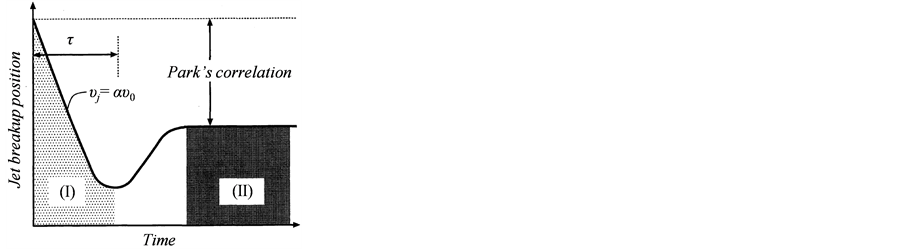

在理论模型上,Hirokazu等人 [7] 提出射流碎化过程可以分成两个重要阶段(如下图6所示):1) 射流匀速穿透熔融物,并在射流周围形成空隙;2) 熔融物表面向射流靠拢,空隙变成闭合口袋状,随后“空气口袋”破裂,流动不稳定性占主导,射流表面和前端不断剥离碎化,最后稳定于某一深度位置。

Hirokazu等人采用MPS方法完成了第一阶段模拟,但并未成功对第二阶段进行模拟。本文通过数值模拟,得到了第二阶段的模拟结果(如下图7所示)。第一阶段结束后,射流达到最大深度,之后由于水在向上浮力和不断下落的熔融物重力作用下,最终达到稳定位置,称为最终深度。通过定性和定量分析,验证了本模型的可行性。本文进一步对最终深度的参数效应进行探究。

Figure 2. Numerical results of jet behaviors

图2. FLUENT数值计算结果

Figure 4. Comparison of melt surface level

图4. 熔融物液面高度对比

Figure 5. Comparison of coolant penetration depth

图5. 射流透射深度对比

Figure 6. The sketch map of the histories of jet leading position [7]

图6. 射流水穿透深度随时间变化示意图 [7]

Figure 7. Histories of jet leading position

图7. 射流深度随时间变化

3.3. 参数影响

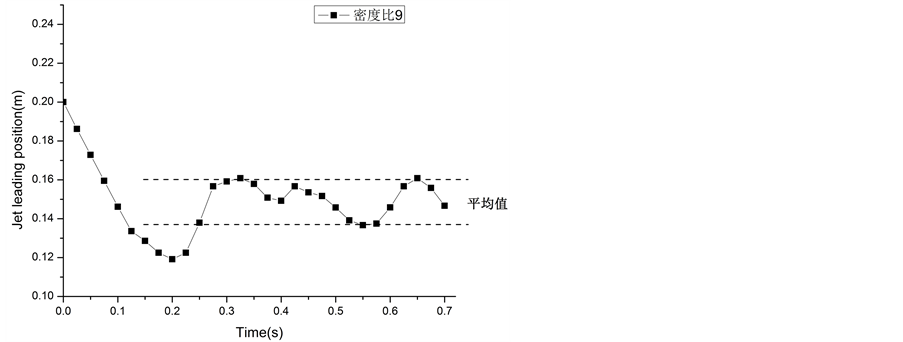

数值结果表明最终深度存在不同程度的波动现象,以密度比为9的工况为例,图8为波动现象较明显的密度比为9的射流深度变化模拟结果。按照公式2确定最终结果,即

(2)

(2)

其中LMax为射流深度波动的最大值,LMin为最小值。

通过对射流形态的分析,发现出现波动的原因是射流前端在碎化过程中,经历大块颗粒到小颗粒的变化,在碎化为小颗粒后,浮力作用占主导,小颗粒开始回升,待与继续向下的未完全碎化射流前端相遇后,会因重力作用重新开始下降,如此周而复始,导致射流最终深度出现波动现象。基于此现象,以下所有最终深度结果,都按照公式2取为最终结果。

对于碎裂长度,Park和Saito基于实验提出了第二阶段下碎裂长度的表达式 [7]

(3)

(3)

其中在Park模型中,Cbr = 1.45,Saito模型中,Cbr = 2.1。

3.3.1. 密度比影响

熔融物密度和射流密度之比ρp/ρj是射流最终深度重要影响因素。本文共设置了5组不同密度比的工况,分别为1.88、3、6、9、11。其中射流水密度始终为1000 kg/m3。最终深度结果如图9所示,结果表明最终深度随密度比增大而减小,且下降趋势与关系式趋势基本一致。在熔融物密度增大时,射流水更难将熔融物向上挤压,导致射流在熔融物池内减速得更快。

3.3.2. 射流速度影响

为研究射流入射速度对其最终深度的影响,设置了4组不同入射速度工况,其分别为2 m/s、3.8 m/s、6 m/s、8 m/s。通过模拟结果(见图10),射流最终深度随速度增大而增大,且与关系式一致基本满足线性增长关系。这是因为在其他参数保持不变前提下,射流速度增大时,需要更长距离使得射流速度下降,并最终出现碎化及达到最终深度。

3.3.3. 表面张力影响

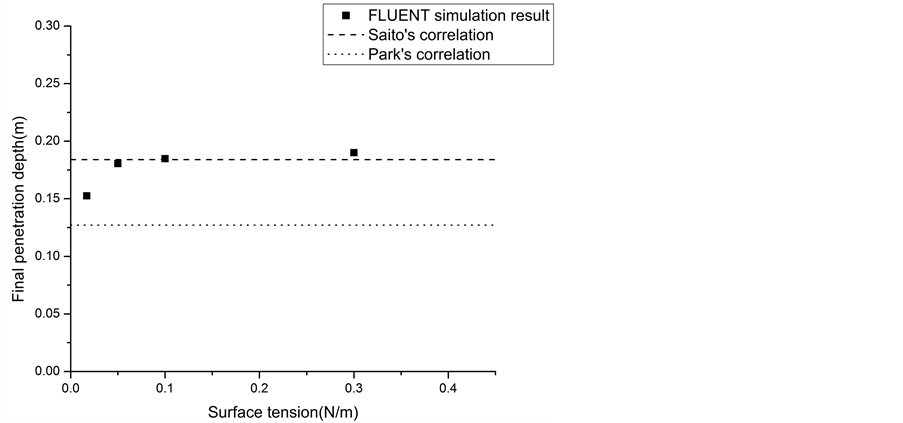

为研究熔融物表面张力对射流最终深度的影响,设置了4组不同张力工况,其分别为0.017 N/m、0.05 N/m、0.1 N/m和0.3 N/m,通过模拟结果(见图11),在本节公式3中,碎化长度表达式认为张力对最终深度(即LII)无影响,数值模拟结果显示表明表面张力对最终深度影响不明显。

3.3.4. 粘性系数影响

为研究熔融物粘性系数对射流最终深度的影响,设置了4组不同粘性系数工况,其分别为0.00109 kg/(m*s)、0.002 kg/(m*s)、0.003 kg/(m*s)和0.004 kg/(m*s)。通过数值模拟结果(见图12),发现与粘性系数增大会导致最终深度轻微提高,粘性系数参数的变化对最终深度的影响不大。

4. 结论

本文基于FLUENT软件,采用VOF方法对Park实验射流水的碎化过程及射流碎化最终深度进行了数值模拟,模拟结果与实验结果吻合很好,能够合理模拟射流形态变化和最终深度。主要结论有:

1) 射流水进入液态金属现象可分为两个阶段:① 射流向下挤压熔融金属,使其周围形成空腔;②

Figure 8. The fluctuation phenomenon of final depth

图8. 最终深度波动现象

Figure 9. Parameter effect of density ratio on jet final depth

图9. 密度比对最终深度影响

Figure 10. Parameter effect of velocity on jet final depth

图10. 射流速度对最终深度影响

Figure 11. Parameter effect of surface tension on jet final depth

图11. 张力对最终深度影响

Figure 12. Parameter effect of melt viscosity on jet final depth

图12. 粘性系数对最终深度影响

空腔闭合并破裂,射流水表面受不稳定性影响出现碎化过程,大块液滴剥离射流表面,并在重力,浮力和摩擦力共同作用下不断向下运动,并碎化为小颗粒。小颗粒在浮力主导下回升,与向下运动的大块颗粒接触结合,最后随射流水颗粒不断聚集和碎化,射流穿透深度呈现一定波动现象。

2) 公式3和模拟结果表明密度比和射流速度对最终深度有规律性影响,其中密度比越大,射流最终深度越小,且近似正比于1/(ρp/ρj)0.5。而对于射流速度,射流速度越大,最终深度越大,且近似正比于射流速度。

3) 液态金属粘性系数对射流最终深度影响不明显。

基金项目

本论文的研究得到国家自然科学基金(No.51506134)资助。