摘要:

为了减小磁盘高速旋转所承受的气体阻力、降低硬盘内部结构所承受的气流冲击和振动、以及提高硬盘存储密度和工作稳定性,人们正考虑向硬盘内部填充低密度气体。充气硬盘还具有存储容量大、节能、散热性能好等优点。硬盘工作过程中,磁头滑块飞行特性(承载力W、压力中心Xc和Yc)对硬盘工作稳定性有着重要影响。本文研究了充气气体物理特性、表面粗糙度、磁盘转速、飞行高度和俯仰角对硬盘磁头滑块飞行特性的影响,研究结果发现:磁盘转速的增加、飞行高度的降低、俯仰角的减小和氦气在氦气–空气混合气体中的比重(不同气体物理特性)下降,都会导致磁头滑块承载力的增加;磁盘转速的增加、飞行高度的增加、俯仰角的减小,都会导致压力中心Xc的减小;对于不同的磁盘转速、飞行高度、俯仰角、氦气在氦气–空气混合气体中的比重,压力中心Yc都几乎保持不变;粗糙度高度(σ)对承载力、压力中心Xc和Yc的影响,在不同粗糙度方向(γ)时,呈现出不同的影响规律。

Abstract:

In order to reduce the gas resistance of the high speed rotating disk and the impact and vibration of internal structure in a hard disk drive (HDD), and improve the storage density and working stability of a HDD, some kinds of gases with a low density are considered to fill inside a sealed HDD. The filled-gas HDD has some advantages of a large capacity, energy saving and heat dissipation performance. In an operating HDD, the flying characteristics of the slider, including the bearing capacity W, the pressure center Xc and Yc, have an important effect on the working stability of the HDD. In present paper, the effects of the gas physical properties filled inside the HDD, surface roughness, disk rotational speed, flying height and pitch angle, on flying characteristics of the slider, are studied. The results show that the W of the slider increases with the increase of the disk rotational speed, the decrease of the flying height, the decrease of the pitch angle and the decrease of proportion of helium gas in a mixed gas. The Xc decreases with the increase of the disk rotational speed, the increase of flying height, the decrease of the pitch angle. For different disk rotational speed, flying height, pitch angle, and proportion of helium gas in a mixed gas, the Yc keeps almost unchanged. For different direction of roughness (γ), the roughness height (σ) has different effect on W, Xc and Yc.

1. 引言

当硬盘工作时,磁盘在电机驱动下作高速旋转,且转速越高,磁盘承受的气体阻力就越大。为了减小磁盘高速旋转所承受的气体阻力,人们正考虑向硬盘内部填充低密度气体(例如氦气或氦气/空气混合气体) [1] 。同时,填充的低密度气体能降低硬盘内部结构所承受的气流冲击振动,使得磁头滑块具有更好的飞行特性,从而把磁道设计得更细密,增加硬盘的存储密度。此外,充气硬盘还具有存储容量大、节能、散热性能好等优点 [2] 。Bouchard等 [3] 最先考虑向密封硬盘中填充气体,通过激光多普勒干涉仪研究了磁盘振颤幅度,并指出在氦气中磁盘的振颤幅度要比空气中小30%。受当时硬盘密封技术的影响 [4] ,文献 [3] 的研究工作没有引起人们足够重视。直到最近,Zhou等 [5] 研究了各种气体对硬盘磁头滑块飞行特性的影响,指出氦气硬盘在密封和非密封环境中,磁头滑块的飞行高度(磁头磁盘间隙)变化幅度都要小于其他气体。Liu等 [6] [7] 研究了氦气–空气混合气体对磁头滑块飞行高度的影响,随着氦气在混合气体中比例增加,磁头滑块飞行高度逐渐增加,达到最大值后,又逐渐减小,这说明了飞行高度与氦气在混合气体中的比例为非线性关系。Aruga等 [8] 研究了硬盘在氦气和空气环境下的机械振动,指出了高转速情况下气流诱导振动是导致硬盘振动的主要原因,并且氦气中硬盘的振动幅度要远小于空气中相同情况下硬盘的振动幅度,从而使得氦气硬盘的定位精度比空气硬盘提高了一倍。通过实验和数值模拟的方法,Kil等 [9] [10] 研究了在氦气和空气环境中磁头滑块周围的湍流强度,结果表明磁头滑块在氦气环境中湍流强度较小,从而由湍流引起的振动幅度也比较小。然而,在磁盘转速较高的情况下,氦气流过手臂圆孔结构周围会引起较大的湍流强度,但是,因为氦气密度较小,最终引起的振动幅度仍然小于空气引起的振动幅度 [11] 。从这些研究结果可以看出,填充气体会对硬盘磁头滑块飞行特性产生重要影响。

在硬盘设计过程中,磁头滑块飞行特性主要通过承载力和压力中心表示。除了填充气体外,承载力和压力中心还受到磁盘转速、表面粗糙度、磁头滑块飞行高度、俯仰角等因素的影响。王玉娟等 [12] 研究了磁头滑块飞行高度在25~30纳米之间粗糙度对双轨磁头滑块承载力和压力中心的影响。Ng等 [13] 研究了磁头滑块与磁盘接近接触情况下,粗糙度对磁头/磁盘界面承载力、粘附力和振动的影响。Yoon等 [14] 对磁头滑块表面进行了结构优化设计,使得硬盘在卸载过程中磁头滑块飞行高度、俯仰角和侧倾角的变化幅度在合理范围内,减小气膜承载力变化幅度和磁头滑块与磁盘接触碰撞的可能性。史宝军等 [15] [16] [17] 研究了磁盘转速、表面粗糙度、容纳系数等参数对磁头滑块压力分布、承载力和压力中心的影响。但是,这些研究对象都是普通的非充气硬盘,且磁头滑块形状简单,对真实硬盘磁头滑块进行了较大简化。

因此,在硬盘充气环境下,综合研究充气气体物理性质、磁盘转速、表面粗糙度、磁头滑块飞行高度、俯仰角等因素对硬盘磁头滑块飞行特性的影响,弄清这些因素对磁头滑块飞行特性的影响规律,为提高磁头滑块飞行稳定性,研发具有大存储容量、节能和高稳定性的充气硬盘,提供重要的理论基础。

2. Reynolds方程及数值求解

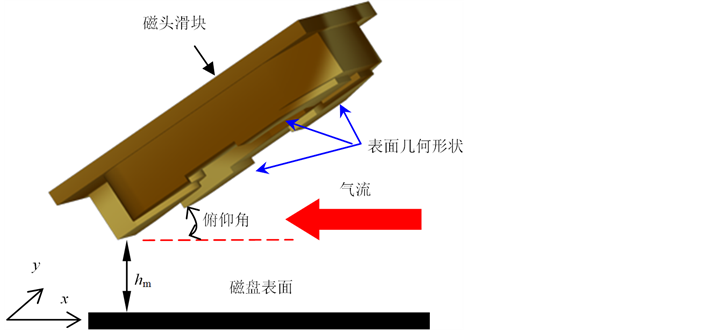

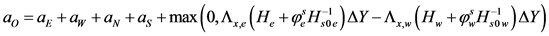

硬盘工作时,磁头滑块飞行在磁盘上方,磁头滑块与磁盘之间的主要参数如图1所示。其中,hm表示磁头滑块的最小飞行高度。磁头滑块与磁盘之间会形成一层气体润滑膜,在考虑气体稀薄效应和表面粗糙度情况下,该气体润滑膜的控制方程为修正Reynolds方程 [18] ,其表达式为

(1)

(1)

其中, 为无量纲压力,

为无量纲压力, 为周围环境压力,单位为Pa。X和Y分别为磁头滑块长和宽方向的无量纲坐标,

为周围环境压力,单位为Pa。X和Y分别为磁头滑块长和宽方向的无量纲坐标, 为磁头滑块与磁盘之间无量纲距离,hm为磁头滑块尾部与磁盘之间的最小距离(单位:m)。

为磁头滑块与磁盘之间无量纲距离,hm为磁头滑块尾部与磁盘之间的最小距离(单位:m)。 为气膜数,

为气膜数, 为气体的运动粘度(单位:μN×s/m2),

为气体的运动粘度(单位:μN×s/m2), 为磁盘转速在X方向的分量,

为磁盘转速在X方向的分量, 为磁头滑块长度(单位:m)。

为磁头滑块长度(单位:m)。 为膜厚比,其中

为膜厚比,其中 ,

, 和

和 分别为磁头滑块与磁盘的表面粗糙度,请参考文献 [15] 和 [16] 。

分别为磁头滑块与磁盘的表面粗糙度,请参考文献 [15] 和 [16] 。 为流量因子,其中

为流量因子,其中 和

和 分别为Poisson流和连续流因子,

分别为Poisson流和连续流因子, (R为气体常数,T为特征温度)。此外,

(R为气体常数,T为特征温度)。此外, 、

、 和

和 的表达式分别为

的表达式分别为

Figure 1. Interface of the slider and the disk in a hard disk drive

图1. 磁头滑块/磁盘界面

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

(6)

(6)

其中, ,

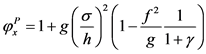

, 分别表示磁头滑块与磁盘剪切流因子,

分别表示磁头滑块与磁盘剪切流因子, 为无量纲的Peklenik数,且有

为无量纲的Peklenik数,且有

(7)

(7)

和

和 分别为磁头滑块与磁盘的Peklenik数。在式(5)和式(6)中,不同修正Reynolds方程的模型,

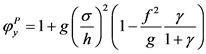

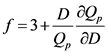

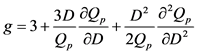

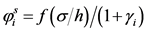

分别为磁头滑块与磁盘的Peklenik数。在式(5)和式(6)中,不同修正Reynolds方程的模型, 的表达式不一样,本文选取具有表达式简单、计算效率快等特点的线性流率(Linearized Flow Rate, LFR)模型[18],其表达式为

的表达式不一样,本文选取具有表达式简单、计算效率快等特点的线性流率(Linearized Flow Rate, LFR)模型[18],其表达式为

(8)

(8)

a和b为常数,其值可以根据表1进行选取。

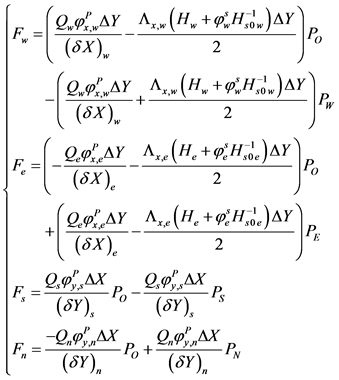

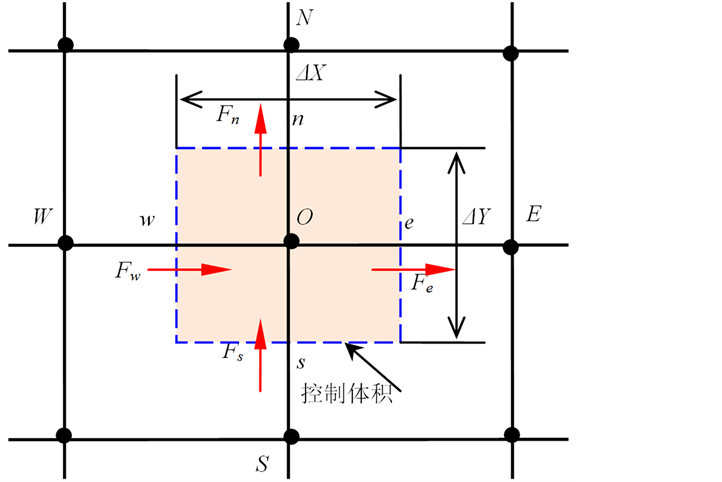

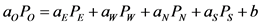

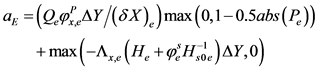

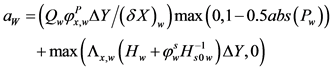

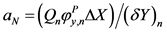

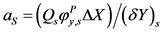

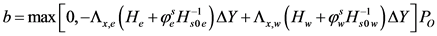

方程(1)是一个复杂偏微分方程,本文采用有限体积法进行求解 [18] [19] 。有限体积法的基本思想是在一个控制体积内,质量流要保持守恒(图2所示),有:

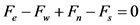

(9)

(9)

其中,

(10)

(10)

Table 1. Constant coefficients a and b in Eqnation (8)

表1. 常系数a和b

Figure 2. Illustration of the control volume

图2. 有限体积法

把式(10)代入方程(9),整理后得

(11)

(11)

、

、 、

、 、

、 、

、 和

和 的表达式为分别为

的表达式为分别为

(12)

(12)

(13)

(13)

(14)

(14)

(15)

(15)

(16)

(16)

(17)

(17)

(18)

(18)

系数 、

、 、

、 、

、 、

、 和

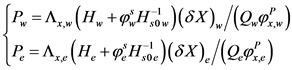

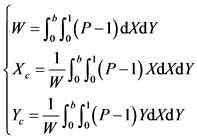

和 是压力P的函数,离散方程(9)是非线性的,本文通过Gauss-Seidel进行求解。计算出压力P后,磁头滑块的飞行特性参数(承载力和压力中心)可以通过下式进行计算

是压力P的函数,离散方程(9)是非线性的,本文通过Gauss-Seidel进行求解。计算出压力P后,磁头滑块的飞行特性参数(承载力和压力中心)可以通过下式进行计算

(19)

(19)

方程(1)中包含了填充气体的物理性质、磁盘转速、表面粗糙度、磁头滑块飞行高度、俯仰角等参数,当这些参数发生改变时,承载力W、压力中心Xc和Yc均会受到影响,从而影响到磁头滑块的飞行特性。

3. 影响因素的研究

3.1. 气体的物理性质

传统硬盘,其内部环境与外界相通,磁盘、磁头滑块等内部结构运动过程中受到空气的阻力。为了减小空气的阻力,可以向硬盘内部填充低密度的气体(例如氦气)。同时,气体的运动粘度、气体分子平均自由程(气体稀薄效应)也会对气体阻力产生影响,所以需要综合研究气体的这些物理特性(密度、运动粘度和气体分子平均自由程)对磁头滑块飞行特性的影响。在本文的研究过程中,以空气–氦气混合气体,得到不同密度、运动粘度和分子平均自由程的混合气体,来研究气体物理特性对磁头滑块飞行特性的影响。表2给出了氦气–空气混合气体对应的物理特性,百分比为氦气在混合气体中所占的比重。从表中可以看出,随着氦气在混合气体中比重的增加,气体密度逐渐减小、运动粘度和平均分子自由程逐渐增加。

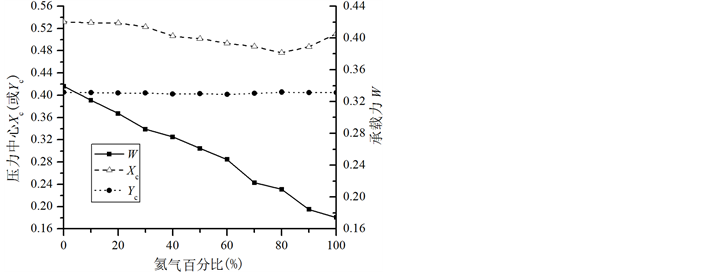

求解方程(1)后,就可以得到不同氦气百分比时磁头滑块对应的飞行特性参数如图3所示。从图中可以发现,随着混合气体氦气百分比的增加,磁头滑块的承载力W、压力中心Xc和压力中心Yc呈现出不同的变化趋势:① 磁头滑块的承载力不断减小;② 压力中心Xc先减小,后增加,并且在氦气百分比80%时达到最小值;③ 压力中心Yc始终在0.4附近,几乎不发生变化。

3.2. 粗糙度

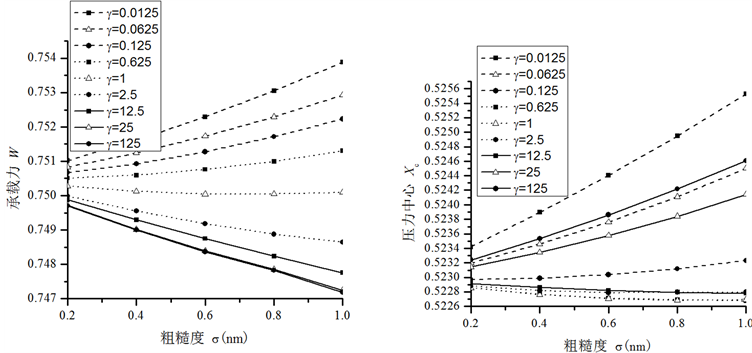

由于磁头滑块飞行高度已经低于10纳米,磁盘和磁头滑块表面粗糙度对磁头滑块飞行特性的影响不能忽略 [20] ,需要进行深入研究。粗糙度包括大小和方向两个方面,分别用 和

和 表示(如方程(7)所示)。图4给出了

表示(如方程(7)所示)。图4给出了 和

和 对承载力、压力中心Xc和Yc的影响。从图4(a)可以发现,对于不同的

对承载力、压力中心Xc和Yc的影响。从图4(a)可以发现,对于不同的 ,随着

,随着 的增

的增

加,承载力不断的减小。当粗糙度高度 从0.2纳米不断增加到1纳米时,如果

从0.2纳米不断增加到1纳米时,如果 ,承载力不断增加,如果

,承载力不断增加,如果 ,承载力却不断减小,如果

,承载力却不断减小,如果 ,承载力几乎保持不变。从图4(b)可以发现,当

,承载力几乎保持不变。从图4(b)可以发现,当 、125、0.0625和25时,随着

、125、0.0625和25时,随着 的增加,压力中心Xc不断增加;但是,当

的增加,压力中心Xc不断增加;但是,当 为其他值时,随着

为其他值时,随着 的增加,Xc却有较小幅度的变化。在图4(c)中,对于一定的

的增加,Xc却有较小幅度的变化。在图4(c)中,对于一定的 值,随着

值,随着 的增加,Yc不断增加。对于一定的

的增加,Yc不断增加。对于一定的 ,

,

Table 2. The physical characteristic parameters for the mixed gas with different percentages of Helium

表2. 不同氦气百分比时混合气体的物理特性参数

Figure 3. Effects of physical properties of the mixed gas on the flying characteristics of the slider

图3. 混合气体物理特性对磁头滑块飞行特性的影响

(a) 粗糙度对承载力的影响 (b) 粗糙度对压力中心Xc的影响

(a) 粗糙度对承载力的影响 (b) 粗糙度对压力中心Xc的影响

(c) 粗糙度对压力中心Yc的影响

(c) 粗糙度对压力中心Yc的影响

Figure 4. Effects of roughness on the flying characteristics of the slider

图4. 粗糙度对磁头滑块飞行特性的影响

随着 增大,Yc会不断减小。但是,随着

增大,Yc会不断减小。但是,随着 的增大,Yc随

的增大,Yc随 增大不断减小的速度会逐渐变慢;当

增大不断减小的速度会逐渐变慢;当 、25时,Yc就几乎不随

、25时,Yc就几乎不随 增大而发生变化了。

增大而发生变化了。

3.3. 磁盘转速

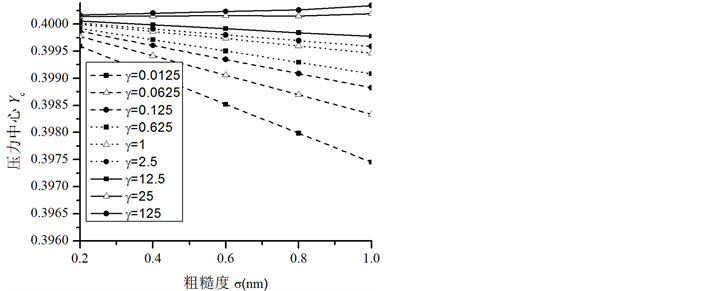

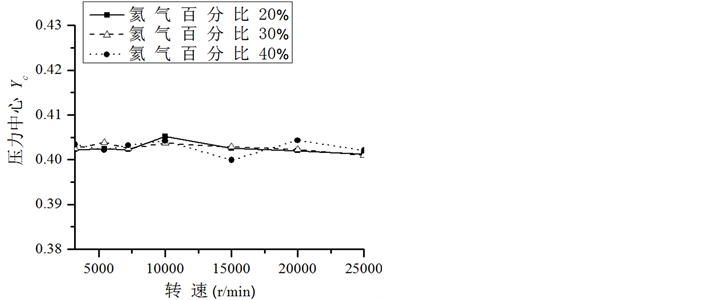

磁盘转速是影响硬盘读/写速度的重要性能指标,为了提高硬盘读/写速度,硬盘转速不断增加。不同的硬盘转速,会对磁头滑块的飞行特性产生重要影响。图5给出了不同氦气百分比情况下,磁盘转速对承载力、压力中心Xc和Yc的影响。从图5可以看出,对于不同氦气百分比的混合气体,随着磁盘转速的增加,磁头滑块的承载力、压力中心Xc和压力中心Yc呈现出不同的变化趋势:① 磁头滑块的承载力不断增大;② 压力中心Xc不断减小;③ 压力中心Yc始终在0.4附近,拥有很小的变化幅度。

3.4. 粗糙度

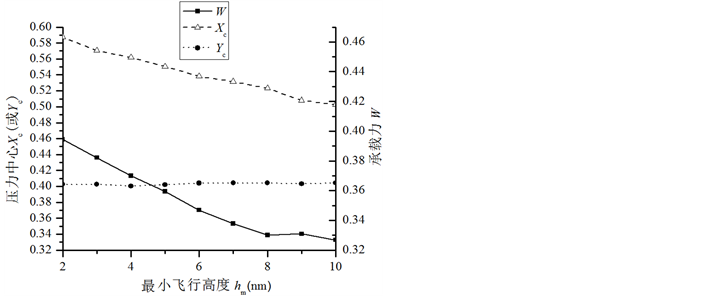

当硬盘受到外界冲击和振动时,磁头滑块的飞行高度会发生变化,从而影响到承载力W、压力中心Xc和Yc。在研究过程中,以磁头滑块尾部到磁盘之间的最小飞行高度(hm) (如图1所示)作为特征参数。

图6给出了最小飞行高度对磁头滑块承载力、压力中心Xc和Yc的影响规律。从图中可以看出,随着磁头滑块飞行高度的增加,承载力和压力中心Xc不断地减小,而压力中心Yc几乎保持不变。

3.5. 俯仰角

硬盘工作过程中,当遭受外界冲击和振动、或者进行数据读写时,磁头滑块的俯仰角(如图1所示)会发生改变,从而影响磁头滑块的飞行特性。

图7给出了俯仰角对磁头滑块承载力W、压力中心Xc和Yc的影响规律。从图中可以看出,随着俯仰角的增加,磁头滑块的承载力不断减小,压力中心Xc不断增加,而压力中心Yc几乎不随俯仰角的增加而发生变化。

4. 结论

为了减小磁盘高速旋转所承受的气体阻力、降低硬盘内部结构所承受的气流冲击、以及提高硬盘存储密度和工作稳定性,人们正考虑向硬盘内部填充低密度气体。气体的物理特性、粗糙度、磁盘转速、磁头滑块飞行高度、俯仰角等因素会对磁头滑块飞行特性(承载力W、压力中心Xc和Yc)产生不同的影响,

(a) 承载力 (b) 压力中心Xc

(a) 承载力 (b) 压力中心Xc (c) 压力中心Yc

(c) 压力中心Yc

Figure 5. Effects of disk rotating speeds on the flying characteristics of the slider

图5. 磁盘转速对磁头滑块飞行特性的影响

Figure 6. Effects of the minimum flying height on the flying characteristics of the slider

图6. 最小飞行高度对磁头滑块飞行特性的影响

Figure 7. Effects of different pitch angle on flying characteristics of the slider

图7. 俯仰角对磁头滑块飞行特性的影响

通过本文的研究,得出以下结论:

1) 承载力的影响因素。磁盘转速的增加、飞行高度的降低、俯仰角的减小和氦气在氦气–空气混合气体中的比重下降,都会导致磁头滑块承载力的增加。对于粗糙度,随着 的不断增加:① 当Peklenik数

的不断增加:① 当Peklenik数 时,承载力不断增加;② 当

时,承载力不断增加;② 当 时,承载力却不断减小;③ 当

时,承载力却不断减小;③ 当 时,承载力几乎保持不变。对于不同的

时,承载力几乎保持不变。对于不同的 ,随着

,随着 的增加,承载力不断的减小。

的增加,承载力不断的减小。

2) 压力中心Xc的影响因素。磁盘转速的增加、飞行高度的增加、俯仰角的减小,都会导致压力中心Xc的减小。随着氦气在氦气–空气混合气体中的增加,压力中心Xc先减小,后增加,并且在氦气百分比80%时达到最小值。对于粗糙度,当 、125、0.0625和25时,随着

、125、0.0625和25时,随着 的增加,压力中心Xc不断增加;当

的增加,压力中心Xc不断增加;当 为其他值时,随着

为其他值时,随着 的增加,Xc却有较小幅度的变化。

的增加,Xc却有较小幅度的变化。

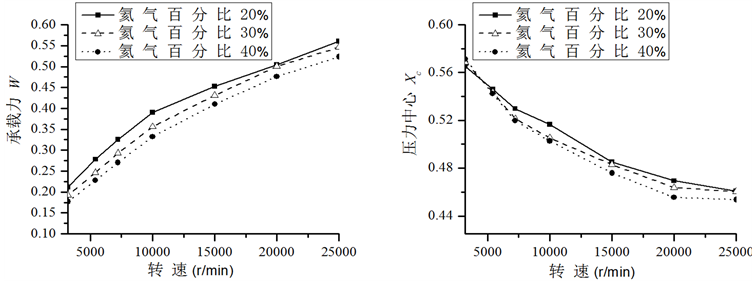

3) 压力中心Yc的影响因素。对于不同的磁盘转速、飞行高度、俯仰角、氦气在氦气–空气混合气体中的比重,Yc都几乎保持不变。粗糙度对Yc的影响表现为:① 对于一定的 值,随着

值,随着 的增加,Yc不断增加;② 对于一定的

的增加,Yc不断增加;② 对于一定的 ,随着

,随着 增大,Yc会不断减小,但随着

增大,Yc会不断减小,但随着 的增大,Yc随这种不断减小的速度会逐渐变慢。

的增大,Yc随这种不断减小的速度会逐渐变慢。

本文的研究结果,为减小磁盘高速旋转所承受的气体阻力、降低硬盘内部结构所承受的气流冲击和振动、以及提高硬盘存储密度和工作稳定性,提供了重要的理论基础。

基金项目

国家自然科学基金项目(51505262)资助。