1. 引言

自电路领域开发出熔断器、敏感电阻器、碳膜电阻器等一系列元件以来,人们不断研制和设计新的元件以提高仪器设备的精密性和可靠性,随后出现的具备熔断器和电阻器功能的双功能元件的熔断电阻器 [1] 由于其特殊性深受研究者们的青睐。它在同一电路中可以取代熔断器和电阻器,在额定功率下就相当于普通的电阻器,当电路发生短路或其它故障时电流会突然超出额定电流,其熔体的温度会迅速升温直至达到熔体的熔点便熔化断开,起到熔断器对电路的保护功能 [2] 。但通过研究表明,熔断电阻器只能在一些低要求保护或只需作短路保护的场合起到熔断器的功能,相对在安全性和专业性方面还差一些,其熔断性能还需要进一步的改善 [3] [4] ,所以熔断电阻器并不能真正代替熔断器。随着当今电子产品逐渐走向微型化和轻量化,作为电子设备的保护元件,对熔断器的性能要求越来越高 [5] [6] [7] ,一种精度高、安全可靠性好的熔断器已成为研究设计的主要方向。正是因为对熔断性能更高的需求,不管是从仪器设备的精度性、安全可靠性还是从元件的微型化、轻量化考虑,研究者们对熔断器的探究都已追溯到其熔体的选择上 [8] [9] 。

熔体是控制熔断器熔断特性的关键元件,其形状、尺寸和材料决定了熔断特性。近些年来,熔体的材料从普通材料转换为贵金属或复合材料 [5] [9] ,主要分为高熔点和低熔点两类。熔点低的材料虽然容易熔断,但只适用于低分断能力的熔断器,而用于高分断能力的熔断器因熔体材料熔点高不易熔断对其精度性会造成一定的影响 [10] [11] 。熔体形状一般分为带状和丝状,一般情况下这两种熔体的温度需要达到熔点才熔断,所以为了保证高分断能力熔断器的精度性,须从形状和尺寸上做进一步的探索。在材料界中,纳米线的电学性能相对于块体材料变化明显,导电性将远远小于块体材料 [12] [13] 。但随着科技的进步,人们发现一维贵金属纳米线体现出良好的导电性、高机械强度和比表面积大等独特性能 [14] [15] ,其中Au纳米线 [16] 因能够在医学界被制成一种心脏补丁而受到广泛关注,这不仅大大提高其导电性,而且有望帮助修复病人因心脏病发作造成的心肌组织坏死。那么将这种Au纳米线应用到熔断器中作为熔体材料能否既保证熔断器的高分断能力又保证熔断器的高精度性亟需我们探究。

为了研究Au纳米线的熔断特性,采用计算机模拟技术研究这一变化过程,解决了实验过程中需要耗费大量资源和人力的问题。模拟这类热、电等复杂物理场的问题常常用到的是有限元模拟法 [17] [18] 。然而有限元分析法是基于熔体材料、形状确定的前提下进行的,当熔体达到熔点后会熔化,并没有考虑这一过程对研究结果造成的干扰。所以这种方法难以精确描述熔体材料熔断过程中的变化情况。而熔断过程是熔断器发挥作用的关键过程 [19] ,并且熔体的升温速率是影响熔断特性和熔断时间的主要因素之一 [1] 。因此本研究采用分子动力学模拟方法,从微观结构的角度对新型熔体材料进行较为精确的模拟。建立稳定的结构模型,模拟不同升温速率下Au纳米线的熔断过程,研究其在不同升温速率下的熔断特性和熔断时间变化,探索升温速率对Au纳米线熔断特性的影响机制。利用该方法可以有效地弥补有限元分析法对材料相态变化模拟的不足,为熔断器的设计和生产提供方法和理论依据。

2. 模拟条件与方法

采用LAMMPS分子动力学模拟软件,建立分子动力学模拟的模型,将Au原子放入三维方向上具有周期性边界条件(PPP)的盒子中,模拟中使用EAM势 [20] 研究升温速率对Au纳米线熔断特性的影响,势函数具体形式为:

其中,Ei表示的是某个原子i受周围粒子势能影响的总能量,公式由两个主体部分组成,F()函数代表了嵌入势能,其受到所有原子中第i、j个原子的原子密度(ρ)的集合影响,Φ()函数是当第i、j原子的元素类型不同时产生的新势能,元素类型使用α、β下标进行表示。i、j的含义为i附近截断区间(cutoff)内的j原子。

将等温运行得到的稳定FCC构型的Au纳米线(长为14.09 nm,总共包含3418个原子)作为本模拟的初始结构。模拟设计分成三个阶段:第一个阶段为低温等温模拟,在300 K等温运行100,000步,以获得该温度下稳定的初始结构;第二阶段为升温过程模拟,根据Au的熔点(1063℃)、沸点(2807℃)以及熔断器工作的实际情况,以2300 K作为升温模拟的最高温度,设置五个升温速率R1: 1.0 × 1012 K/s, R2: 2.5 × 1012 K/s, R3: 5.0 × 1012 K/s, R4: 1.0 × 1013 K/s, R5: 2.0 × 1013 K/s,分别使得系统以这五个不同的速率从300 K升温至2300 K;第三阶段的模拟为高温等温模拟,当温度达到2300 K后,等温运行100,000步。这三个阶段的模拟过程均在NVT系综下,时间步长为2 fs,每隔1 ps输出一次坐标信息,以研究其熔断时间和熔断过程状态变化。结合可视化技术探索Au纳米线熔断过程中的微观结构变化情况,分析升温速率对熔断特性的影响机制。

3. 分析与讨论

在熔体熔断时,根据Q = I2Rt能量公式,电流会直接影响熔体内部的升温,同一材料在相同时间内,电流越大,升温速率越大,产生热量越多,所以升温速率对熔断起着重要作用。本研究模拟了在同样的升温区间内,不同升温速率对Au纳米线的熔断特性和时间的影响。

实验中最重要的对比项为升温速率,这里需要将最高温度的影响排除掉,所以将最高温度统一设定为2300 K,并以300 K为初始温度,分别按照升温速率R1、R2、R3、R4、R5进行模拟。不同升温速率对应着不同的升温时间,这是由模拟中升温阶段的运行步数控制,由此得到不同升温速率所引起的Au纳米线的对应熔化温度、熔化时平均原子势能和熔断时间、熔断温度以及熔断时平均原子势能等模拟结果如下表1所示。

以上五组温度曲线:R1、R2、R3、R4、R5速率依次从小到大,选择最高温度为2300 K一方面是该温度介于Au的熔点和沸点之间,另一方面在这温度区间不同升温速率所引起的模拟结果有很好的对比性。其中R1、R2、R3三组中Au纳米线的熔断温度是在升温区间内,而在R4、R5两组中Au纳米线的熔断温度已达到最高温度2300 K。对于表1中不同升温速率的模拟结果,从总体上来看,在升温区间内随着升温速率的增加,Au纳米线的熔化温度逐渐递增,熔断温度在较低升温速率的R1、R2、R3三组中逐渐递增,在后面较快升温速率的R4、R5两组中熔断时已达到模拟最高温度2300 K。在一定升温区间内升温速率越快,Au纳米线的熔断时间越短,这是由于升温速率增加,达到熔点的时间越短,原子能够更快地吸收热量而脱离晶格位置,并随着运动的加剧进一步熔断,相应的熔断过程也随之加快。

从原子势能的角度考虑,表1中显示的是熔化时平均原子势能和熔断时平均原子势能在该温度区间内变化情况。平均原子势能随着升温速率的增加波动变小,其中熔化时平均原子势能在−3.51 eV左右波动,这反映熔断器中的原子脱离晶体晶格位置而使得整体呈现熔化状态所需达到的平均原子势能。而熔断时平均原子势能随升温速率的升高而呈增大趋势,由于原子从熔化状态到熔断状态需要一定的时间,升温速率较快时,到熔断时的平均原子能量较高。

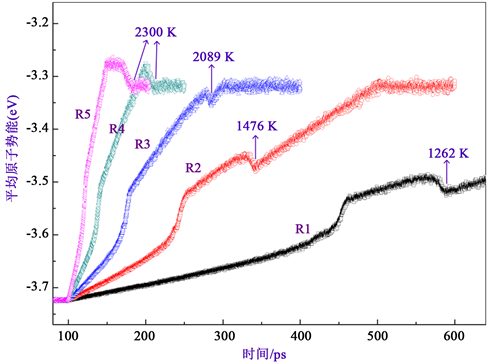

为了更准确地了解Au纳米线的平均原子势能在不同升温速率下熔断过程中的变化情况,图1显示了平均原子势能随时间的变化关系。可以看出,五组模拟在升温过程中,每组Au纳米线的平均原子势能总体趋势都是增长的,升温速率越快,对应的Au纳米线平均原子势能的增长速率越快。但平均原子势能在熔断温度附近均有小范围的减小。从图1中还可以发现,对于R4和R5两组中熔断点出现在升温到最高温度2300 K之后,而对于R1、R2、R3三组中熔断点出现在升温过程中。

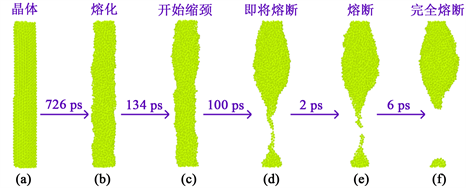

在升温速率为R1的这一组中,将Au纳米线从晶体至完全熔断的全过程可视化如图2。我们可以看出Au纳米线从最初的300 K下的晶体状态经历了熔化、开始缩颈、即将熔断、熔断、最终在1268 K温度下完全熔断。其中在升温初始的时候,原子需要吸收大量的能量才能实现结构的改变,即从晶体到熔化这一阶段需要较长时间去吸收能量。从可视化图中可以看出Au纳米线的熔化温度为1026 K,远低于Au的熔点1336 K,这是因为本模拟中的Au纳米线半径较小,对于同一材料其纳米线的物理性质和化学性质相对于块体材料有差异,熔点会低于块体材料 [21] [22] 。当Au纳米线熔化后,随着持续的升温,经历了134 ps后开始出现缩颈现象,从可视化图中可以看出Au纳米线上半部分的原子开始积聚、靠拢,

Table 1. The simulation results of different heating rates

表1. 不同升温速率模拟结果

Figure 1. The influences of different heating rate on the average atomic potential energy and fusing time of nanowire Au

图1. 不同升温速率对Au纳米线的平均原子势能和熔断时间的影响

Figure 2. Evolution of the Au nanowire from the crystal to the fully fused at the heating rate of R1. (a) 300 K; (b) 1026 K; (c) 1160 K; (d) 1260 K; (e) 1262 K; (f) 1268 K

图2. 升温速率R1下Au纳米线从晶体至完全熔断的演变过程。(a) 300 K; (b) 1026 K; (c) 1160 K; (d) 1260 K; (e) 1262 K; (f) 1268 K

以至于Au纳米线下半部分的原子越来越少,再经历100 ps后Au纳米线即将熔断,在中间保留了细细的液桥连接熔断器的两端,最后断点出现在液桥的中部。由于该模拟设置为三维周期性边界条件,这整个熔断过程是Au纳米线由圆柱形结构到非标准球形结构的转化过程。所以随着模型上半部分原子越来越多、能量越来越大,模型下半部分的原子会变得更少,在温度为1268 K时完全熔断,也就是说Au纳米线在升温速率较低时,温度不需达到Au块熔体材料的熔点也可完全熔断。

在将不同升温速率下Au纳米线熔断模拟的可视化过程中,除了以上分析的升温速率对其熔断温度的影响外,还发现升温速率对熔断后的断面结构有重大影响。如图3显示了不同升温速率下Au纳米线由相同程度的缩颈到熔断的变化情况。从图3(a)~(e)中,可以发现Au纳米线从缩颈状态到熔断状态所需的时间逐渐递减。并且Au纳米线熔断过程中的液桥长度总体上逐渐变短,从前两组(a)、(b)即升温速率较慢的R1、R2两组的4 mm到后两组(d)、(e)即升温速率较快的R4、R5两组时只有1.9 mm。在升温速率为R1、R2和R3时,熔断后的断面呈现链状结构,而在升温速率为R4和R5时,熔断后的断面呈现锥形结构。

Figure 3. Evolution of the Au nanowires at different heating rates, (a) R1; (b) R2; (c) R3; (d) R4; (e) R5

图3. 不同升温速率下Au纳米线由缩颈到熔断的结构变化示意图,(a) R1; (b) R2; (c) R3; (d) R4; (e) R5

4. 结论

升温速率越快,Au纳米线的熔化温度逐渐递增。在一定范围内,熔断温度随升温速率变快而越高,对应熔断时间越短。不同升温速率对熔断位置没有明显影响,但对熔断过程中的缩颈长短有显著影响。升温速率较低时,缩颈部分较长,使得熔断后的断面呈链状,升温速率较高时,缩颈部分较短,使得熔断后的断面呈锥形。这对设计不同应用场景的Au纳米线高精度熔断器具有非常好的参考价值。

基金项目

本文获得基金项目支持:国家自然科学基金(No. 60766002),贵州省科学技术基金项目(No. J[2015] 2050),贵州省科技合作计划项目(No. LH[2016] 7430)。

NOTES

*通讯作者。