摘要:

采用含有较高Al-Mg含量的锌液(7.2%Al~1.6%Mg-Zn),改变钢板入锅温度、露点和H

2含量,研究该3种热镀工艺参数对汽车用深冲钢镀层质量和形貌的影响。结果表明,试验钢冷轧薄板在高Al含量的镀液中具有良好的浸润性,厚度均在10~20 µm左右。镀层由三种不同形貌组织的组成:亮白色Zn颗粒、粗大富Al相、细小密布富Mg相。随着热镀工艺的钢板,镀层形貌有明显的差异:入锅温度为460、475、490˚C时,镀层形貌变化不大;露点从−50增加到30˚C,粗大富Al相大大减少,亮白色Zn颗粒更为细小;H

2含量从5增加到15%时,粗大的富Al相破碎,贯穿整个视场的枝晶状组织消失。

Abstract:

The effect of three hot dipping parameters on coating quality and morphology of deep drawing auto steel by high Al-Mg content zinc pot was studied, including diving temperature, dew point and H2 content. The results display that, the cold rolled thin sheet has a good wettability in the high Al-Mg content zinc pot, with average coating thickness from 10 to 20 µm. The coating morphology consists of three phases: bright Zn particle, coarse Al rich phase and fine Mg rich phase. The coating morphology changes a lot with different dipping parameters: as diving temperatures increase from 460˚C to 490˚C, the morphology has little difference with each other; as dew points increase from −50˚C to 30˚C, the amount of coarse Al rich phase decreases significantly, and Zn particles became finer; as H2 content increases from 5% to 15%, the coarse Al phase is broken and the dendrite structure disappear.

1. 引言

纵观世界汽车工业的发展历程和现状,汽车行业越来越重视材料的使用寿命。镀层钢板的最大优点是优良的抗腐蚀性、涂装性以及良好的可成形性 [1] 。在过去的几十年中,锌铝镁合金镀层以其优异的耐蚀、加工、焊接性能吸引了全世界研究者的注意 [2] [3] 。日本的川崎钢铁公司、新日铁、神户制钢所和德国蒂森克虏伯都对钢板锌镁合金镀层的制造工艺及其耐蚀性能做过报道 [4] [5] 。Nippon Steel的Dyma Zinc [6] 、Super Dyma [7] 以及Nisshin Steel的ZAM [8] 等多种Zn-Al-Mg镀层产品被开发应用并进行商业化生产。

本文对上述商业化生产的锌铝镁合金镀层成分进行相关改进,研究包括带钢入锅温度、露点、H2含量在内的热镀工艺对镀层形貌的影响。

2. 实验材料和方法

试验钢为冷硬态(酸轧后未退火)超低碳深冲钢(0.06C~0.35 Mn),板厚0.7 mm。在生产现场经过连铸、热轧和酸轧。剪切成220 × 110 mm标准试样,擦拭表面油污后经超声波清洗,在热浸镀工艺模拟试验机上进行连续热镀工艺模拟。设计主要热镀工艺如下:以5℃/s加热到800℃保温60 s,快冷到460℃~490℃保温30 s,冷却速度为25℃/s,在不同镀液成分的锌锅中浸润4 s,露点为−50℃~30℃,H2含量为5%~25%H2-N2,气刀流量和速度分别设定为500 l/min和500 mm/s,镀液成分为7.2%Al~1.6%Mg-Zn,由于Al含量高于市场现有的镀层成分,本文定义为HAMZ。具体热镀工艺参数如表1所示。利用SEM (HITACHI-S-4300)对镀层相结构及形貌进行分析。

3. 结果与讨论

3.1. HAMZ的镀层质量

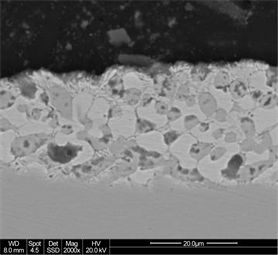

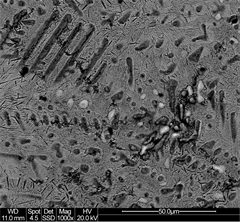

与市场上现有的Zn-Al-Mg镀层产品对比,由于Al、Mg含量均有提高,而目前镀锌工艺参数对锌铝镁镀层质量影响的研究较少,本文对相关热镀工艺参数进行了研究。HAMZ镀层宏观及微观形貌如图1所示,图1(a)显示肉眼观察HAMZ镀层较为灰暗,无可视漏镀点。图1(b)、图1(c)显示镀层包括三种不同形貌组织:亮白色颗粒、粗大枝晶和细小密布相。

粗大的枝晶相所占体积分数最大,是镀层的主要组成部分,镀层与钢基之间存在极薄的合金层。根据文献 [4] [5] [6] [7] [9] 所述,亮白色颗粒对应纯锌,粗大枝晶相对应锌铝共晶相,细小密布相对应锌铝镁三元共晶相。而锌铝共晶、纯锌、锌铝镁三元共晶的凝固点从高到低的顺序为锌铝共晶、纯锌、锌铝镁三元共晶,但其差异较小,且纯锌、锌铝共晶的过冷度较大,因此在快速凝固条件下,锌铝共晶、纯锌、锌铝镁三元共晶完全可以同时凝固,从而出现如图1的镀层结构。

3.2. 钢板入锅温度对镀层质量的影响

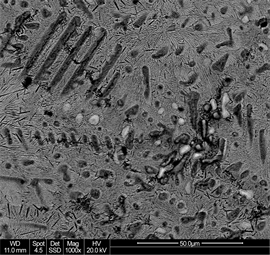

当钢板入锅温度分别为460℃、475℃、490℃时,图2显示,HAMZ镀层截面和表面微观形貌变化不大,有贯穿于整个视场的枝晶状组织存在。由表1和图2可知,在其它热镀工艺相同的条件下,在露点和氢气含量分别固定为−30℃和5%时,钢板入锅温度在460℃~490℃区间变化,镀层的微观结构变化不大,枝晶状组织均较为粗大,有的枝晶长度超过100 μm。亮白色的纯锌颗粒较多,大都分布在枝晶周围。

Table 1. Main hot dipping parameters

表1. 热镀工艺参数

(a)

(a)  (b)

(b)  (c)

(c)

Figure 1. Macro and micro morphology of HAMZ: (a) macro, (b) cross-section, (c) surface

图1. 试验钢HAMZ热镀宏观及微观形貌:(a) 宏观,(b) 截面,(c) 表面

实际生产时一般将钢板温度控制在高于镀液温度,本轮实验的镀液温度稳定在455℃,略低于热镀纯锌的锌液温度5℃~10℃。钢板的温度在30℃范围内变化对镀层质量的影响不大。

3.3. 露点对镀层质量的影响

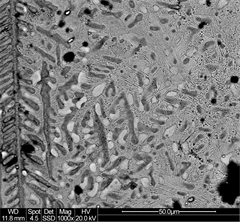

由表1和图3可知,在其它热镀工艺相同的条件下,将钢板入锅温度和氢气含量分别固定为475℃和5%时,露点在−50℃~−30℃区间变化,镀层的微观结构变化较大。其中,露点在−50℃~−10℃时,有较多的粗大富Al相,但当露点为10℃和30℃时,粗大富Al相大大减少,亮白色Zn颗粒更为细小。

(a)

(a)  (b)

(b)  (c)

(c)

Figure 2. Surface morphology of HAMZ by different diving temperatures (a) 460˚C, (b) 475˚C, (c) 490˚C

图2. 不同入锅温度条件下HAMZ镀层表面微观形貌(a) 460℃,(b) 475℃,(c) 490℃

众所周知,带钢的热镀锌生产过程中,露点是影响带钢表面合金元素的选择性氧化和带钢镀锌性能的重要因素之一。在相同的退火气氛和热处理条件下,随着露点的变化,带钢表面合金元素的选择性氧化物形态和成分也随之变化,并影响镀层和钢基之间的过渡层结构 [10] 。图3所示的HAMZ镀层微观形貌随露点变化明显,枝晶状组织破碎,纯锌颗粒减少。可以认为高露点时,气氛中氧含量少,枝晶组织生长速度快;而低露点时,气氛中氧含量增加,镀层中的Al、Mg、Zn与O2发生反应,形成更为细小的组织。具体的组织成分需要进一步的检测分析。

3.4. H2含量对镀层质量的影响

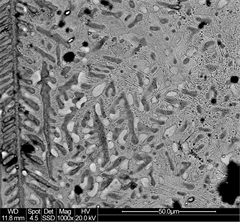

由表1和图4可知,在其它热镀工艺相同的条件下,将钢板入锅温度和露点分别固定为475℃和−30℃时,H2含量从5%增加到25%,镀层组织形貌有较大变化。随着氢气含量增加,三种组织均有所细化,尤其粗大的富Al相更为破碎,没有贯穿整个视场的枝晶状组织出现。与图3相比,组织的细化程度较小。因为在N2 + H2的混合气氛中的H2只能还原带钢表面铁的氧化物,并不能阻止带钢内部合金元素的表面氧化,氢气含量对镀层的结构有影响,但没有露点的影响大。

3.5. 镀层能谱和面扫描分析

对HAMZ镀层组织进行能谱分析,该镀层中有三种明显不同组织,一种为粗大灰暗组织,一种为细小密布组织,还有一种为较为明亮的圆形组织。对于前两种组织随机取三点进行化学成分能谱分析,结果如表2所示。镀层中富Al相(粗大组织)平均含17.53%的Al未检测到Mg,可认为是含ZnAl的化合物;富Mg相(细小组织)平均含3.2%的Mg和4.09%的Al,可认为是含ZnAlMg的化合物。

(a)

(a)  (b)

(b)  (c)

(c)

Figure 4. Surface morphology of HAMZ by different H2 contents (a) 5%, (b) 15%, (c) 25%

图4. 不同保护气氛条件下HAMZ镀层截面和表面微观形貌(a) 5%,(b) 15%,(c) 25%

Table 2. Spectrum analysis of HAMZ coating elements (wt, %)

表2. HAMZ镀层合金元素的能谱分析结果(wt, %)

结合图1~4与表2可知,锌液中添加Mg使得镀层形成富Mg层,且组织变得细小、弥散、分布均匀。而由于镀液中Al含量较多,粗大组织的枝晶状明显,在常规的热镀工艺下尺寸较大,贯穿整个视场,这样的组织对镀层的均匀性不利。未避免该粗大组织的出现,需要将露点控制在10℃、氢气含量25%以上。在该热镀工艺下,粗大枝晶状组织消失,同时Zn颗粒尺寸较小、数量降低。

4. 结论

1) 冷轧薄板在高Al含量的镀液中均具有良好的浸润性。镀层截面形貌显示镀层与基板结合处平滑,并有较好的附着性,厚度均在10~20 µm左右。

2) 镀液添加Mg后,镀层相组成发生改变:镀层表面由四种不同的相构成的复杂微观组织,主要的物相为富锌相,Zn和硬的金属间化合物MgZn2组成的二元共晶相,同时包含前两项以及富铝相的三元共晶相和富铝相枝晶结构。

3) 热镀工艺参数对HAMZ镀层形貌影响较大,其中露点为10℃和30℃时,粗大富Al相大大减少,亮白色Zn颗粒更为细小;随着H2含量的增加,粗大的富Al相破碎,贯穿整个视场的枝晶状组织消失。

NOTES

*通讯作者。