1. 引言

从18世纪末期到20世纪中期出现的三次工业革命将人类带入了蒸汽时代、电力时代和数字时代,它们成功地改变了人类生产作业的方式,导致了生产力的提升。德国人工智能研究中心(DFKI) 2011年研究报告指出第一次工业革命对应于工业1.0,第二次工业革命对应于工业2.0,第三次工业革命对应于工业3.0,并提出工业4.0概念。2013年4月德国汉诺威工业博览会上正式推出了工业4.0,世界各国分别将其上升为各自的国家战略。例如:德国政府启动的《德国2020高技术战略》,中国政府《中国制造2025》中的十年规划工业战略,美国政府在2012年启动了国家战略《先进制造伙伴(AMP)》等 [1] [2] 。

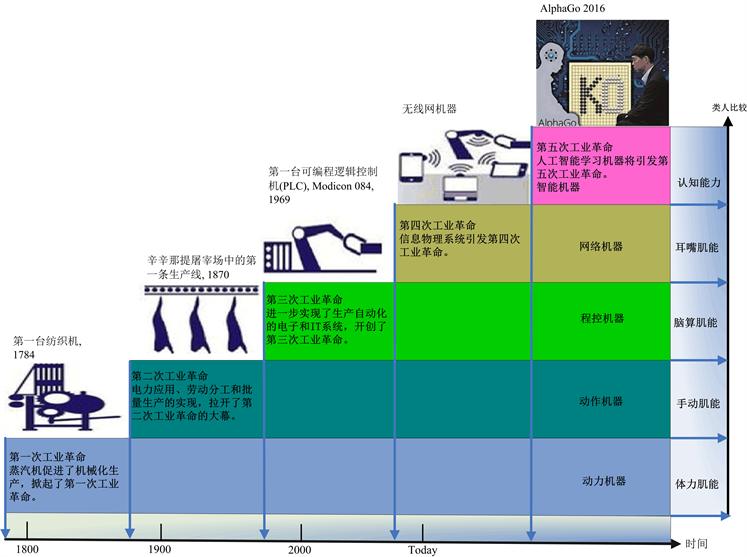

在本文中,我们对前四次工业革命的发展进行了深入分析,将每一次工业革命涉及的机器(广义机器)类人比较进行机器机能衍生的划分 [3] ,分析工业革命的发生发展的规律,进而预测下一次工业革命的实质和内涵,这为未来工业发展重点乃至科学研究方向提供了战略性的理论依据。

2. 工业革命类人比较分析

近几年中,各种学术会议和期刊发表了关于工业4.0的讨论 [4] [5] [6] [7] 。本文主要通过对工业革命中机器进行类人比较分析工业革命的发展模式。

2.1. 第一次工业革命类人比较分析

第一次工业革命是蒸汽机促进了机械化生产,掀起了第一次工业革命,其标志性的第一台机器就是1784年哈格里夫斯发明的珍妮纺织机。类人比较意味着第一次工业革命使纺织机器(广义机器)衍生出了类人体力肌能的动力机能,由此各种类型动力机能机器不断诞生和广泛应用,即为工业1.0。

2.2. 第二次工业革命类人比较分析

随着电力应用,劳动分工和批量生产的实现,拉开了第二次工业革命,第二次工业革命代表性的诞生机器系统就是1870年辛辛拉提宰杀场建设的第一条肉鸡宰杀生产线。类人比较意味着第二次工业革命使得机器(宰杀生产线的一个工位)衍生出了类人手工宰杀动作肌能的动作机能,由此各种类型动作机能机器不断诞生和广泛应用,即为工业2.0。

2.3. 第三次工业革命类人比较分析

随着1969年第一台莫迪康084可编程逻辑控制器(PLC)的诞生,以及生产自动化的电子和IT系统的实现,开创了第三次工业革命的大幕。类人比较意味着第三次工业革命使机器衍生出了类人脑算肌能的计算机能,由此各种类型计算机能机器的诞生和广泛应用,即为工业3.0。

2.4. 第四次工业革命类人比较分析

信息物理系统引发了第四次工业革命,各种机器都以信息发送和接收为重要标志,也即机器与机器之间采用信息进行交流通信。类人比较意味着第四次工业革命使机器衍生出了类人耳嘴肌能的机器听讲机能,由此各种类型听讲机能机器诞生和广泛应用,即为工业4.0。

通过前四次工业革命发展的类人比较分析发现,每一次工业革命都是以机器衍生出类人某种重要器官肌能(即体力、手足、大脑、耳朵、嘴巴)的机器机能(即动力、动作、计算、听、讲)为标志,诞生各种类型的机能机器和广泛应用,即为工业X.0的发展规律。以此类推很容易想到,引发第五次工业革命应是机器衍生出类人眼睛肌能的视觉机能,诞生各种类型的视觉机器和广泛使用,即为工业5.0。但引发第四次工业革命的信息物理系统中,可以认为信息物理系统涉及的信息包含视觉信息,因此,可以把类人眼睛肌能的视觉机能归并于第四次工业革命之中。那么要问,第五次工业革命机器会衍生出类人什么重要器官肌能的机器机能?诞生什么样的机能机器?

3. 什么是工业5.0

3.1. 工业5.0

通过机器类人深入比较分析,已经很难再找到机器还会衍生出类人哪种重要器官肌能的机器机能。于是联想人在成长过程中,若要成长为一个有智慧的人只有通过上学读书,而上学读书的必须条件是要人的各重要器官肌能发育成熟,包括体力够、手能写、脑能算、耳能听、嘴能讲、眼能看等,可以增长智慧。因此借助类人成长过程这一现象类比机器,设想机器要发展成为智能机器,在各重要机器机能(即动力够、会动作、会计算、能会听、能会讲、能会看)发展齐备后,机器只有通过学习可以实现智能。由此可以认为,引发第五次工业革命一定与机器学习有关,即机器衍生出类人认知学习能力的机器学习机能将引发第五次工业革命,由此具有各种类型学习机能的智能机器(人工智能)机器诞生和广泛应用,即为工业5.0。

由于工业发展越来越快,很多机器机能并发出现,如听、讲、看的机器机能,因此将其归为第四次工业革命的核心内容。通过进一步深入分析,给出了工业革命类人比较的详细结果,如表1所示。

3.2. 第五次工业革命标志性机器

从机器学习和智能机器角度考虑,可以认为与李世石PK的围棋高手阿尔法狗称得上是引发第五次工业革命的标志性机器——人工智能机器。由此可以将工业革命发展历程图扩展为从工业1.0到工业5.0,如图1所示。

Table 1. Comparison between human organ abilities and machine functions emerged in industrial revolutions

表1. 工业革命出现的机器功能与人类器官功能的比较

Figure 1. From industry 1.0 to industry 5.0

图1. 从工业1.0到工业5.0

为进一步说明每一次工业革命机器衍生的机器机能和诞生该机能机器的区别,给出了工业X.0机器的基本定义,如表2所示。从表中工业X.0机能机器定义看出,每次工业革命对机器发展都是对机器机能的续增,并非是对机器机能的革命或淘汰,即是工业1.0机器与工业2.0机器的动力由蒸汽变为电力,但并没有影响工业2.0机器的机能续增,仅仅是机器动力形式的改变。而工业2.0机器相当于在工业1.0机器动力机能基础上续增了动作机能。

4. 工业5.0智动化系统模型研究

在研究提出工业5.0概念基础上,依据工业5.0机器机能的定义,研制开发了群机器人柔性智动化教学实验系统平台,如图2所示,作为工业5.0机器机能与智能系统模型案例简介如下。

群机器柔性智动化教学实验系统平台由四台视觉机器人、一台移动视觉机器人和物料输送线等单元组成。该实验系统平台中的所有机器(机械臂和AGV小车)都具备电驱动的动力机能、机械手末端夹抓的动作机能、控制计算机的计算机能、Wifi通信的听讲机能、双目或单目CCD的视觉机能等工业4.0机器定义的全部机器机能。为了达到具有工业5.0的机器自主智能机能,通过软件集图像采集、图像处理、模式识别、以及机器学习等算法软件实现了所有视觉机器人的自主学习机能和多视觉机器人智动化系统协同作业的群体智能。目前通过了基于场景感知的四种工件智动化拆装试验,基于场景感知和规则分析决策的象棋人机对决智动化试验,基于场景感知与规则分析决策的麻将人机博弈群体智动化试验等。在

Figure 2. A flexible intelligent swarm robotic assembly system

图2. 群机器柔性智能装配系统

Table 2. Basic definition of iconic machines for industry revolution

表2. 工业革命中标志性机器的基本定义

智能组态软件XAVIS的支持下,可利用该实验系统平台同时进行两种不同任务的作业实验,如同时进行工件装配与象棋对决、工件装配与虚拟制造等智动化教学实验,这些都为小批量、多品种、高效个性化现代服务的柔性智动化系统关键技术研究奠定了试验基础。

5. 结论与展望

通过类人比较对工业革命的研究分析,发现工业革命有着仿人重要器官肌能而发展机器机能的很强的规律性,以工业发展的这种规律性,前瞻性的预测未来机器机能和工业智能化系统的发展走向。在此基础上,研究得到了工业X.0的机器机能定义,依据工业4.0机器机能定义设计了具备工业4.0机器机能的无线网络机器,通过增加机器视觉与机器学习机能,使得工业4.0机器具备工业5.0机器的自主智能特性,进而结合生产线产品装配与未来智能化生产发展需要,研制了一种群机器人柔性智动化系统试验模型,实现了多台视觉机器人协同的群体智能,用该系统实现了群机器人工件协同拆装、象棋人机或机器协同对决、麻将人机或机器博弈等智能化系统教学实验。

工业革命和发展是无止境的,以工业自身的发展规律,有待读者提出第五次工业革命的新见解和新观点,或预测第六次工业革命的机器机能发展的新展望!

致谢

非常感谢西安交通大学电子与信息工程学院提供的专业严谨的科研环境,非常感谢西安交通大学电子与信息工程学院科研团队辅助完成群机器人柔性智动化系统的建立。

基金项目

本研究得到了广东省科技计划项目(No. 2015B010104002)的资助。