1. 引言

混凝土预制构件具有生产效率高,成本低,质量稳定,环境污染小等诸多优点,已被广泛应用于现代建筑结构中 [1] [2] 。在生产混凝土预制构件的过程中,通常采用高温蒸汽养护工艺 [3] 。高温蒸养能够加速胶凝材料的早期水化,提高混凝土的早期强度 [4] [5] 。但早期高温蒸养会导致硬化浆体后期的孔结构较疏松,使混凝土具有较低的强度增长速率和较差的耐久性 [6] [7] 。

磷渣是工业上生产黄磷时的废渣,排放量为黄磷产量的8~10倍 [8] 。磷渣的矿物组成以玻璃体为主,化学组成主要为CaO,SiO2,Al2O3,P2O5等 [9] 。研究表明,磷渣是一种具有火山灰活性的物质,作为矿物掺合料应用于混凝土中时,具有提高新拌混凝土工作性,减少水泥早期的水化放热,改善硬化浆体后期的孔结构,提高混凝土后期的强度和耐久性等优点;但磷渣会延缓水泥的水化反应,导致其早期强度发展缓慢 [10] [11] [12] [13] 。磷渣应用于蒸养混凝土中时,高温养护可以显著提高水泥和磷渣早期的水化速率,进而改善早期磷渣对水泥水化速率的不利影响 [13] 。

较高的拆模强度是保障蒸养混凝土高效生产并安全使用的前提。同时,蒸养混凝土后期的抗压强度发展和耐久性对其服役寿命也至关重要。本文的研究中,在不改变蒸养制度的前提下,通过降低水胶比,以提高掺磷渣的混凝土的拆模强度,并探究其后期强度发展规律及抗氯离子渗透性。

2. 原材料与试验方法

2.1. 原材料

试验所用水泥为金隅P·O 42.5水泥。磷渣为水淬磷渣。水泥和磷渣的化学成分如表1所示。采用激光粒度分析仪测试水泥和磷渣的粒度分布,结果如图1所示。粗骨料为粒径5~20 mm的石灰石碎石,细骨料为粒径<5 mm的天然河砂。

2.2. 试验方法

纯水泥混凝土的水胶比为0.4和0.32,分别对应普通混凝土与高强混凝土,并作为对照组。普通混凝土和高强混凝土的配合比分别如表2、表3所示。混凝土成型10 cm × 10 cm × 10 cm的立方体试块后,

Table 1. The chemical compositions of the cement and phosphorus slag /%

表1. 水泥和磷渣的化学组成 /%

Na2Oeq = Na2O + 0.685 K2O

Table 2. Mix proportions of the ordinary concrete /kg·m−3

表2. 普通混凝土的配合比

Table 3. Mix proportions of the high strength concrete /kg·m−3

表3. 高强混凝土的配合比

Figure 1. Particle size distributions of cement and phosphorus slag

图1. 水泥和磷渣的粒度分布

在20℃环境下静置3 h,之后放入蒸养箱中进行60℃恒温蒸养;升温速率为20℃/h,恒温蒸养时间为8 h;蒸养结束后冷却至室温并测试拆模强度,冷却速率为20℃/h。

混凝土抗压强度按照GB/T 50081-2002《普通混凝土力学性能试验方法标准》进行测试。抗氯离子渗透性测试前,将混凝土块切割成10 cm × 10 cm × 5 cm尺寸,并根据ASTM C1202-2012《混凝土抗氯离子渗透性能的电动指示》进行测试。

3. 结果与讨论

3.1. 拆模强度

水胶比0.4时,普通混凝土的拆模强度如图2所示。从图中可以看出,掺磷渣的混凝土的拆模强度明显低于对照组。随着磷渣掺量的增加,混凝土的拆模强度逐渐降低。尤其是当磷渣掺量为30%时,混凝土的拆模强度仅有10 MPa左右。水胶比为0.32时,高强混凝土的拆模强度如图3所示。从图中可以看出,对于高强混凝土,其拆模强度的变化规律与普通混凝土基本一致。掺磷渣的混凝土的拆模强度明显低于纯水泥混凝土,且随着磷渣掺量增加,高强混凝土的拆模强度逐渐降低。这主要是由于,一方面,磷渣对水泥具有缓凝作用,掺入磷渣后使水泥早期的水化程度降低;另一方面,磷渣早期的水化活性较弱,产生的水化产物较少。综上可知,无论是对于普通混凝土还是高强混凝土,掺入磷渣后,蒸养混凝土的拆模强度均明显低于对照组。

Figure 2. The demolding strength of ordinary concretes with W/B of 0.4

图2. 水胶比0.4时,普通混凝土的拆模强度

Figure 3. The demolding strength of high strength concretes with W/B of 0.32

图3. 水胶比0.32时,高强混凝土的拆模强度

降低水胶比后,普通混凝土的拆模强度如图4所示。对于掺15%磷渣的混凝土,当水胶比降低至0.37时,其拆模强度已非常接近对照组;当水胶比降低至0.34时,其拆模强度明显高于纯水泥混凝土。对于掺30%磷渣的混凝土,当水胶比降低至0.33时,其拆模强度略高于对照组;当水胶比降低至0.29时,其拆模强度明显高于对照组。降低水胶比后,高强混凝土的拆模强度如图5所示。对于掺15%磷渣的混凝土,当水胶比降低至0.29时,其拆模强度已非常接近对照组;当水灰比降低至0.26时,其拆模强度明显高于对照组。对于掺30%磷渣的混凝土,当水胶比降低至0.25时,其拆模强度仍低于对照组;但当水胶比降低至0.21时,其拆模强度已明显高于对照组。综上可知,无论是对于普通混凝土还是高强混凝土,降低水胶比均能显著提高掺磷渣的混凝土的拆模强度,使其接近甚至超过对照组。

3.2. 强度发展

降低水胶比后,普通混凝土的抗压强度发展规律如图6所示。从图中可以看出,纯水泥混凝土的抗压强度增长速率相对较低,尤其在28 d龄期后,强度增长非常缓慢,这可能是由于早期高温蒸养使硬化浆体后期的孔结构变得相对疏松。而掺磷渣的混凝土具有较高的抗压强度增长速率,尤其是当磷渣掺量为30%时,混凝土即使在28 d后也具有一定的抗压强度增长速率。28 d时,掺磷渣的混凝土的抗压强度已明显高于对照组;90 d时,试样N1-0.34和N2-0.29的抗压强度已超过对照组25%以上。降低水胶比后,

Figure 4. The demolding strength of ordinary concretes with different W/C

图4. 不同水胶比下,普通混凝土的拆模强度

Figure 5. The demolding strength of high strength concretes with different W/C

图5. 不同水胶比下,高强混凝土的拆模强度

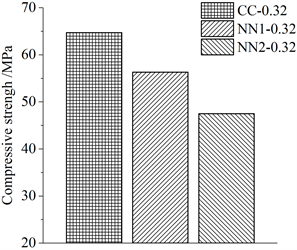

高强混凝土的抗压强度发展规律如图7所示。对于高强混凝土,其强度增长规律与普通混凝土基本一致。90d时,试样NN1-0.26和NN2-0.21的抗压强度已超过对照组20%以上。综上可知,无论是对于普通混凝土还是高强混凝土,掺磷渣的混凝土后期都具有较高的抗压强度增长速率。这主要是由于,一方面,随着水灰比降低,硬化浆体的孔结构和混凝土的界面过渡区逐渐改善;另一方面,随着龄期的增长,水泥水化产生的Ca(OH)2逐渐增多,磷渣的火山灰反应得到激发,火山灰反应过程中消耗Ca(OH)2晶体,产生C-S-H凝胶,改善了混凝土的界面过渡区和硬化浆体的孔结构 [13] [14] 。

3.3. 抗氯离子渗透性

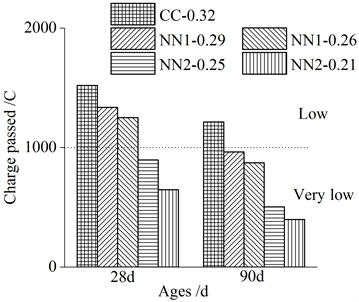

抗氯离子渗透性通常作为评价混凝土耐久性的指标之一 [15] 。根据ASTM C1202-2012中的相关规定,当混凝土的氯离子电通量为2000~4000 C时,混凝土的氯离子渗透性等级为“中”;当混凝土的氯离子电通量为1000~2000 C时,混凝土的氯离子渗透性等级为“低”;当混凝土的氯离子电通量低于1000 C时,混凝土的氯离子渗透性等级为“很低”。

降低水胶比后,普通混凝土的氯离子渗透性如图8所示。从图中可以看出,无论是28 d还是90 d龄期,掺磷渣的混凝土的氯离子电通量均明显低于纯水泥混凝土。纯水泥混凝土28 d和90 d龄期的氯离子渗透性等级均为“中”。对于掺15%磷渣的混凝土,其28 d和90 d龄期的氯离子渗透性等级均为“低”,

Figure 6. The compressive strength of ordinary concretes with different W/C

图6. 不同水胶比下,普通混凝土的抗压强度

Figure 7. The compressive strength of high strength concretes with different W/C

图7. 不同水胶比下,高强混凝土的抗压强度

比对照组降低了一个等级。对于掺30%磷渣的混凝土,其28 d龄期的氯离子渗透性等级为“低”,比对照组降低了一个等级;其90 d龄期的氯离子渗透性等级为“很低”,比对照组降低了两个等级。综上可知,对于普通混凝土,掺入磷渣能够明显改善混凝土的抗氯离子渗透性,且随着磷渣掺量的增加,改善效果逐渐增强。

降低水胶比后,高强混凝土的氯离子渗透性如图9所示。从图中可以看出,对于高强混凝土,掺磷渣的混凝土的氯离子电通量同样明显低于纯水泥混凝土。但由于高强混凝土的水胶比较低,28 d时孔结构已经比较密实。因此,掺入15%磷渣后,与对照组相比,混凝土28d龄期的抗氯离子渗透性等级并没有降低;但90 d时,掺15%磷渣的混凝土的抗氯离子渗透性比对照组低一个等级。对于掺30%磷渣的混凝土,其28 d和90 d龄期的抗氯离子渗透性均比对照组低了一个等级。综上可知,对于高强混凝土,当磷渣掺量为15%时,只有到了90 d龄期,掺入磷渣才能显著改善混凝土的抗氯离子渗透性;但当掺量增加到30%后,无论是28 d龄期还是90 d龄期,掺入磷渣均能显著改善混凝土的抗氯离子渗透性。

Figure 8. Chloride ion permeability of ordinary concretes with different W/C

图8. 不同水胶比下,普通混凝土的氯离子渗透性

Figure 9. Chloride ion permeability of high strength concretes with different W/C

图9. 不同水胶比下,高强混凝土的氯离子渗透性

4. 结论

(1) 在相同水胶比条件下,无论是对于普通混凝土还是高强混凝土,掺入磷渣均会降低蒸养混凝土的拆模强度。

(2) 降低水胶比后,无论是对于普通混凝土还是高强混凝土,掺15%和30%磷渣的蒸养混凝土的拆模强度均能接近甚至超过对照组。

(3) 降低水胶比后,掺磷渣的混凝土后期具有较高的抗压强度增长速率抗氯离子渗透性能。