1. 引言

温室气体二氧化碳的排放造成了温室效应 [1] 。二氧化碳气体造成温室效的贡献率达到55% [2] 。世界能源结构以化石燃料为主,目前80%的能源来自化石燃料,燃烧的化石燃料产生的二氧化碳正在以每年4%的速率增长,大气中二氧化碳含量大概在7000~9000亿吨 [3] 。据统计我国在当今世界二氧化碳排放量位居第二位,主要是因为我国的能源结构问题,主要以煤炭、石油、天然气为主,而且能源利用效率低下 [4] 。二氧化碳的利用具有很高的价值 [5] ,可以利用二氧化碳合成多种有机原料,不仅减少了对不可再生的化石能源的消耗,而且增加了多种有机原料的供应。

甲醇作为一种重要的化工基础原料 [6] ,是C1反应的原料,且广泛运用于生产橡胶塑料等。甲醇全球年需求量在3000万吨左右 [7] ,甲醇是继乙烯、丙烯和苯之后,消耗量较大的一种工业化工原料。目前据统计我国甲醇的消耗量在900万吨左右,而且以每年8%~10%的速率持续增长 [8] 。由于二氧化碳在自然界的广泛存在 [9] ,使甲醇的合成具有稳定的碳源,二氧化碳加氢合成甲醇技术的研究和发展,既解决了经济效益问题,也解决了环境气候问题,因此二氧化碳合成甲醇技术广泛发展,应用催化剂合成甲醇是当前合成的主要技术手段。而铜基催化剂催化能力在众多催化剂中表现较为优秀 [10] ,铜基催化剂研究最为广泛的CO2加氢合成甲醇催化剂,其具有比表面积大、分散度高、选择性较好、副反应少等优点。但是也具有易中毒失活、热稳定性差、机械性能差等缺点。

本实验采用并流沉淀法,制备了一系列不同铜、锌比例的CuO-ZnO-Al2O3型催化剂。通过BET分析出,制备条件的不同对于组成催化剂的物质的比表面积、孔径等影响。用XRD分析出铜、锌组分的分布情况,和铜、锌之间的相互作用。通过SEM电子扫描显微镜观察样品的微观结构分析其对催化剂结构和催化性能的影响。

2. 实验部分

2.1. 催化剂制备

2.1.1. 实验药品

所用实验药品如表1。

2.1.2. 实验仪器

所用实验仪器如表2。

表1. 试剂药品

Table 2. Instruments and equipments

表2. 仪器设备

2.1.3. 样品制备

本实验制备CuO-ZnO-Al2O3型催化剂。用并流沉淀法,在搅拌条件下,将配置的1 mol/L碳酸钠溶液和1 mol/L硝酸盐混合液分别放入分液漏斗中,然后滴加进恒温水浴锅中的三颈烧瓶中,沉淀过程中将控制沉淀温度在70˚C和pH在7~8左右。滴加完毕继续搅拌20 min,然后将沉淀物倒入烧杯中,在室温条件下陈化10 h。陈化完毕,用循环水多用真空泵将沉淀物抽滤洗涤直至滤液呈中性然后将抽滤得到的沉淀物放入电热恒温干燥箱,设置干燥温度为110˚C,干燥8 h后。最后,放入马弗炉中,从室温20˚C程序升温到400˚C,并在400˚C焙烧4 h后。降温到室温后,取出样品,压片,用粉末粉碎机粉碎后,筛选出40~60目的颗粒。

2.2. 催化剂表征

2.2.1. X射线衍射仪(XRD)

XRD能进行结构分析。其原理是用X射线照射试样,利用在不同角度上出现一系列的衍射峰,通过分析峰的位置,强度和结构等,可以得出试样的组成实验运用岛津XRD-6000型衍射仪,管电压40 kv,CuKa射源,电流30 mA,衍射角2θ为10˚到80˚,扫描速度为2˚/min,扫描步幅为0.02˚。对催化剂进行表征,通过已知晶体的标准X射线衍射谱图分析结果。

2.2.2. BET比表面积及孔结构的测定

利用BET比表面积及孔径分析仪,催化剂的比表面积和孔径测定用氮气在样品表面进行吸附。测定时,首先用蒸馏水清洗承装样品的试管,然后将试管进行烘干,称量空试管后,称量0.1~0.5 g的样品,最后将样品加入到试管中。把装有样品的试管在300˚C下真空脱气4 h,脱气压力小于0.1333 Pa。向杜瓦瓶中加注液氮,用氮气做为吸附质,在−196˚C的温度下进行吸附,以氦气做载气,脱气条件:300˚C,6.67 Pa,真空脱气8 h。测定样品的比表面积、孔结构,分析组成及制备条件对样品的影响。

2.2.3. SEM电子扫描显微镜

本实验运用德国蔡司电子扫描显微镜(SEM)通过扫描电子显微镜观察样品的微观结构,通过微观结构的结果,分析出样品中的物质尺寸大小,及物质的分布情况。

3. 结果分析与讨论

3.1. XRD表征结果

XRD对于晶体物质的物相分析。晶态物质组成元素或基团如不相同或其结构有差异,它们的衍射谱图在衍射峰数目、角度位置、相对强度次序以至衍射峰的形状上就显现出差异。因此,通过样品的X射线衍射图与已知的晶态物质的X射线衍射谱图的对比分析便可以完成样品物相组成和结构的定性鉴定。

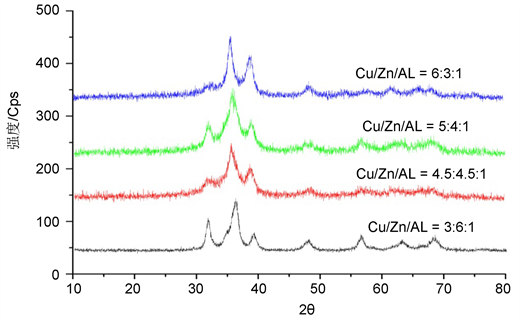

通过图1可知四种不同比例Cu/Zn/Al的催化剂样品,其主要的特征衍射峰出现在衍射角2θ在30˚和40˚之间。与已知晶体标准衍射图谱的比对,可得出Cu/Zn/Al = 3:6:1 的催化剂中主要以ZnO特征衍射峰(31.7˚, 36.3˚)为主;Cu/Zn/Al = 6/3/1的催化剂主要以CuO特衍射峰(35.6˚, 38.7˚)为主,而且CuO和ZnO的特征衍射峰比较尖锐。随着Cu/Zn比的增加,Cu/Zn/Al比为4.5:4.5:1、5:4:1与6:3:1的催化剂,均出现CuO和ZnO的特征衍射峰。随着催化剂中锌含量逐渐减少,31.7˚和36.3˚处ZnO特征衍射峰减弱趋势明显,ZnO以高度分散在于催化剂中。随着催化剂中铜含量逐渐增加,35.6˚和38.7˚处CuO特征衍射峰呈现出增强的趋势,说明氧化铜分散度逐在体系中不断下降。Cu/Zn/Al = 4.5:4.5:1时,在2θ为35.9˚处是CuO与ZnO的宽化程度相同的且发生弥散的特征衍射峰。从XRD谱图中并没有发现Al2O3的特征衍射峰,说明Al2O3晶粒比较细小,而且高度分散。在催化剂中并未出现Al2O3的特征衍射峰,其特征衍射峰不明显,可能是Al2O3以其它形式分散于催化剂中。

3.2. BET比表面积及孔径表征结果

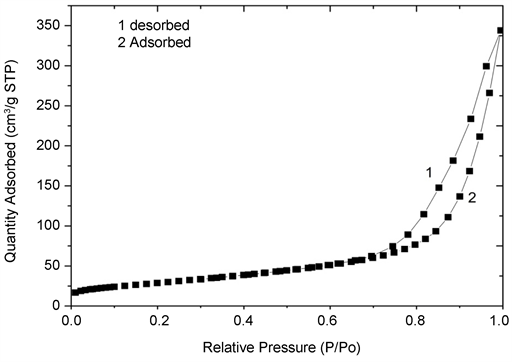

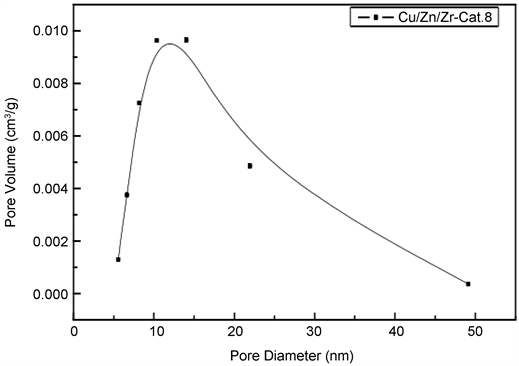

BET实验结果分别由图2、图3和表3所示。

可以看出,当Cu/Zn/Al = 6:3:1其比表面积、孔径、孔容最小是因为这个体系中氧化铜较多且分

Figure 1. XRD of catalysts with different ratios of Cu/Zn/Al

图1. 不同比例Cu/Zn/Al的催化剂XRD图谱

散不均,其平均晶体颗粒较大,故导致其比表面积减小孔径减小。Cu/Zn/Al = 4.5:4.5:1 时,因为Cu/Zn比为1时,铜、锌组分间分散较为均匀,铜锌间作用增强并且相互促进。分散度高,从而使铜、锌晶粒平均粒径减少,使比表面积增大,单个晶体的孔径也增大。当Cu/Zn/Al = 5:4:1其比表面积、孔径等介于两者之间。而且,较为细小的Al2O3晶粒高度均匀的分散在催化剂中,因为有结构较为充分的Al2O3晶粒微孔,所以在催化剂中比表面积、孔容大于氧化铜和氧化锌,从而是二者能负载在Al2O3晶粒上对于提高催化剂的活性有较大作用。从Cu/Zn/Al = 4.5:4.5:1的等温脱吸附曲线可以看出属于IV型吸附回线,滞后环为H4型,故可以说明其为介孔结构。

3.3. SEM电子扫描显微镜表征结果

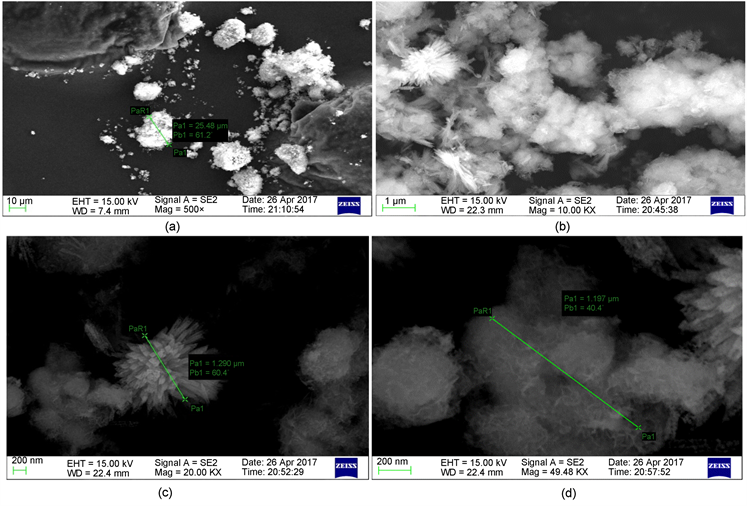

从图4(a)我们可以看出CuO-ZnO-Al2O3型铜基催化剂,催化剂中三种成分在聚集成球状形态分布,分散比较明显,没有发生大规模的聚集。证明这种催化剂的分散性较好。这样对催化剂的性能影响较大,分散度越好,催化剂的催化性能越好。

分析图4(b)可知对单个球状聚集物,放大观察后看出物质有两种形态,一种为柱状,另一种为球状。在球状物质周围聚集这大量的球状物质。对比氧化铜,氧化锌和三氧化二铝的单独的电镜扫描图。可知柱状物质为氧化铜,而氧化锌和三氧化二铝两者均为球状。图4(d)上可以看出氧化锌和三氧化二铝具有较大的孔径,且氧化铜被两者分布包围,而且在三者之间的孔隙较大。图4(c)上看出柱状的氧化铜没有

表3. 催化剂性能

Figure 2. Adsorption and desorption isotherms

图2. Cu/Zn/Al催化剂的等温吸脱附曲线

Figure 3. Distribution curve of pore size

图3. Cu/Zn/Al催化剂的孔径分布曲线

Figure 4. SEM image of catalysts with Cu/Zn/Al = 4.5:4.5:1

图4. Cu/Zn/Al = 4.5:4.5:1 SEM扫描电镜显微图

出现聚集的现象。可以说明氧化锌的分散作用明显,使得氧化铜没有聚集,而催化剂中起催化作用的是氧化铜被还原后的铜离子,所以氧化铜分布情况决定了这个催化剂的催化效能的高低,可以证明了此催化剂性能是比较高的。并且可以看出此体系的铜锌的颗粒较小,比表面积较大,铜锌之间的协同做用较好可推断出催化剂的活性较好,催化剂的使用时间也较长。

4. 结论

1) 氮气吸附性研究结果对于探究催化剂的结构有重要的参考价值。通过测定出来催化剂的比表面积、孔径等数据。可以分析出制备条件的不同对于催化剂的结构影响。实验结果表明,制备条件中铜锌比例的不同改变了催化剂的结构实验数据,分析可得在Cu/Zn/Al = 4.5:4.5:1时催化剂的比表面积为59.21 S/(m2/g),孔径大小为0.42 cm3/g。对比发现其比表面积,孔结构均最大。可以推断出比表面积和孔结构较大时,使催化剂的性能变得更好,活性较好。

2) XRD特征图谱说明出不同物质在同一个催化剂体系中的含量和其分散程度。实验结果显示当Cu/Zn/Al = 4.5:4.5:1时,在35.9˚处铜、锌具有共同宽化且弥散的特征衍射峰。说明其在催化剂中分散程度较高,分散的均匀。而其他铜锌比例的催化剂,其氧化铜和氧化锌的分散不均匀,出现氧化锌和氧化铜聚集的现象。铜系催化剂中起催化作用的主要以氧化铜为主,其分散度的大小影响着催化剂的催化效果和催化剂的活。

3) SEM电子扫描显微镜的结果证明了XRD和BET的结果,分散度的大小,物质的孔径和比表面积的大小对于催化剂有着重要的影响。当Cu/Zn/Al = 4.5:4.5:1时催化剂分散度均匀,故催化剂的性能好。比表面积和孔径越大,催化剂的活性越好。

基金项目

陕西省军民融合项目(17JMR22)。