摘要: 目前MEMS系统在航空航天、电子电力以及生物医学中的广泛应用及发展,导致Ti基合金的力学性能无法适应当前的应用环境。非晶合金因没有晶界、位错等晶体缺陷,因而表现出优异的机械性能。基于此,本文通过磁控共溅射技术,通过控制靶材参数实现调控Zr、V、Nb元素在Ti基薄膜中的成分变化,并成功制出具有完全非晶态结构的Ti80.6Zr6.0V6.9Nb6.5非晶合金薄膜。该非晶合金薄膜与晶态薄膜相比表现出优异的综合性能,包括:1) 优异的力学性能:高的硬度和弹性模量:7.01 GPa,162 GPa;2) 良好的薄膜质量:高的致密性以及低的粗糙度。此外,还解释了该非晶薄膜具有优异力学性能的原因:1) 结构因素:非晶态结构不具备晶界、位错等结构缺陷;2) 变形机制:对于非晶态材料而言,变形机制是以剪切带机制为主,而剪切带的形成是一个复杂过程,需要消耗大量的势能,因此能承受更高的外加载荷。本次研究为Ti基非晶薄膜家族体系研究提供了新的研究思路,也为MEMS系统提供了有希望的候选材料。

Abstract:

The current widespread use and development of MEMS systems in aerospace, electronics and power, and biomedicine has resulted in the mechanical properties of Ti-based alloys not being able to adapt to the current application environment. Amorphous alloys exhibit excellent mechanical properties due to the lack of crystal defects such as grain boundary and dislocation. Based on this, in this paper, the compositional changes of Zr, V, and Nb elements in Ti-based thin films are regulated by magnetron cosputtering technique through controlling the target parameters, and Ti80.6Zr6.0V6.9Nb6.5 amorphous alloy thin films with a completely amorphous structure are successfully produced. The amorphous alloy film exhibits an excellent combination of properties compared to crystalline films, including: 1) excellent mechanical properties: high hardness and modulus of elasticity: 7.01 GPa, 162 GPa; and 2) good film quality: high densities as well as low roughness. In addition, the reasons for the excellent mechanical properties of this amorphous thin film are explained: 1) structural factors: the amorphous structure does not possess structural defects such as grain boundaries and dislocations; 2) deformation mechanism: for amorphous materials, the deformation mechanism is dominated by the shear banding mechanism, and the formation of the shear banding is a complex process that consumes a large amount of potential energy, and thus can withstand higher applied loads. The present study provides new research ideas for the study of Ti-based amorphous thin film family systems and promising candidates for MEMS systems.

1. 引言

非晶合金(又称金属玻璃)拥有无序原子堆积使它们与传统的晶体合金截然不同,如:没有晶界、位错等缺陷,因而表现出优异的物理、化学和机械性能 [1] 。众所周知,Ti元素具有高比强度、耐腐蚀性和生物相容性,且早期过渡金属(Ti)和晚期过渡金属(Cu, Ni)在原子尺寸上存在巨大差异,因此Ti基合金薄膜拥有优异力学性能而被广泛应用于对基体材料的保护、生物医学、航空航天等各类尖端领域 [2] 。例如:Ti-Al-N [3] 合金薄膜具有优异力学性能(硬度约为 33 GPa)、热定性和热疲劳性等特点,常应用于刀具、模具制造、汽车零部件等领域。但是,随着微机电系统(MEMS) [4] [5] 的广泛应用,所使用的材料需要在多种复杂耦合环境中工作,这就导致对材料的力学性能需求不断提升。而传统的Ti基合金由于存在晶体缺陷,导致材料的力学性能明显低于非晶合金,已经不能满足目前的应用需求。因此,迫切需要具有新型的Ti基合金材料来克服这一问题。

目前,市面上应用较为广泛的非晶合金材料有三大类:块体、条带以及非晶薄膜。然而,由于非晶形成能力有限,导致块体、条带非晶材料的应用受到极大的限制。例如,Ti基非晶合金Ti-Zr-Cu、Ti-Zr-Si等,都具有有限的非晶形成能力;又或是具有优异非晶形成能力的Ti-Zr-Be非晶合金,由于具有有毒元素Be,因此也大大降低了其应用前景 [6] [7] [8] 。然而,非晶合金薄膜由于在沉积过程中冷却速率可达到约10−8 K/s,从本质上解决了形成能力有限的问题。此外,非晶合金薄膜的机械性能方面也完美继承了块体非晶合金,如:Ti-Ni-Cu [9] [10] 非晶薄膜,表现出较窄的应力滞后和超弹性,具有优异的力学性能、Ti-Ni-Zr [11] 非晶合金薄膜表现出较高的玻璃化转变温度,具有良好的热稳定性能。此外,Ti-Ta [12] 系列非晶合金由于其优异的力学性能和热稳定性能,因此被应用于在高温下的形状记忆材料。

基于此,本文主要通过磁控共溅射技术,来实现Ti基非晶合金薄膜的制备。有研究表明,在Ti基合金中添加V或Nb元素有助于提升Ti基体系的力学性能。此外,微量Nb添加也能提升Ti基体系的非晶形成能力及热稳定性能 [13] - [18] 。但是,在Ti基非晶薄膜中同时添加V、Nb的研究却很少。因此,为了增强Ti基体系的力学性能以及非晶形成能力,以及避免有毒元素的添加,选取适量等比例Zr、V、Nb元素添加至Ti基薄膜中。该方式可以获得具有优异力学性能的完全非晶态的Ti基非晶薄膜,这为Ti基非晶合金薄膜发展提供新的成分库,同时也是微机电系统(MEMS)良好的候选材料。

2. 实验设计及测试方法

具体来说,我们通过固定溅射靶相对于衬底的取向角(~20˚),通过磁控共溅射Ti和Ti-Zr-V-Nb (1:1:1:1)合金靶,在直径为1 × 1 cm的Si(100)晶正方形衬底上制备了Ti-Zr-V-Nb非晶薄膜。溅射靶材Ti和Ti-Zr-V-Nb (1:1:1:1)合金靶的纯度为99.99% (质量百分比)。由于Ti属于亲氧元素,溅射沉积室的真空度应低于1 × 10−4 Pa,并通过Ar气流量计来控制器将溅射室内的高纯度Ar (99.9995%)背景气体流量,并且调节到30 sccm,在沉积过程中调节溅射压力为1 Pa。此外,通过调节溅射时间来控制膜厚,薄膜生长速率约为12.5 nm/min。磁控溅射过程中为了保证薄膜的均匀性,需要调节阳极衬底旋转速度调节为5 r/min。通过控制靶材实际功率来控制所制备薄膜中的Zr、V、Nb元素含量,本文中所制备的Ti基薄膜体系功率为:Ti 150 W、Ti-Zr-V-Nb 15,30,45,60 W。为了方便起见,在本文中标记为Ti-Tialloy 15,30,45,60。所制备薄膜厚度均为1 μm。

Ti基薄膜体系结构性能测试所使用的XRD粉末衍射仪(XRD, MiniFlex 600)的X-ray为Cu-Kα射线,对非晶薄膜结构进行了检测。薄膜形貌及成分分析,利用的是能谱仪(EDS, JEOL)和扫描电镜(SEM, JSM-6700F)对Ti-Zr-V-Nb非晶薄膜进行了成分以及形貌表征。Ti基薄膜体系力学性能测试,通过在纳米压头(Bruker TI980)和金刚石Berkovich压头上进行纳米压痕测试。硬度测试所选取的参数标准为:最大载荷:10 mN,加载–保载–卸载时间为:5-2-5 s。

3. 结果与讨论

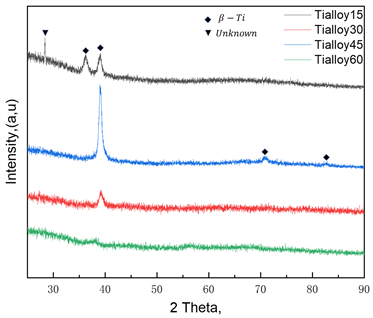

图1所展示的是Ti基体系Ti-Tialloy 15,30,45,60的XRD图谱,结果表明具有明显差异,即:薄膜Ti-Tialloy 15是由两个明显尖锐的中心峰组成,且峰位:2θ ≈ 37.5˚,39.5˚。随着Tialloy含量由15 W增加到30 W,薄膜Ti-Tialloy 30的中心峰逐渐转变为单一中心峰以及两个高角峰,峰位分别为2θ ≈ 39.5˚,72˚,84˚。随着Tialloy含量进一步增加到45 W,Ti-Tialloy45的中心峰逐渐转变为单一中心峰,2θ ≈ 39.5˚。此外,从峰的强度可知,薄膜的结晶度随着Tialloy含量的升高逐渐降低,同时也进一步确定了薄膜Ti-Tialloy 15,30,45为晶态合金薄膜,且中心峰所对应的相都为β-Ti相。然而,随着Ti-alloy含量增加到60 W,其衍射峰逐渐转变为馒头峰,同时也证明薄膜为非晶态,这也意味着Ti-Tialloy 60为非晶合金薄膜。

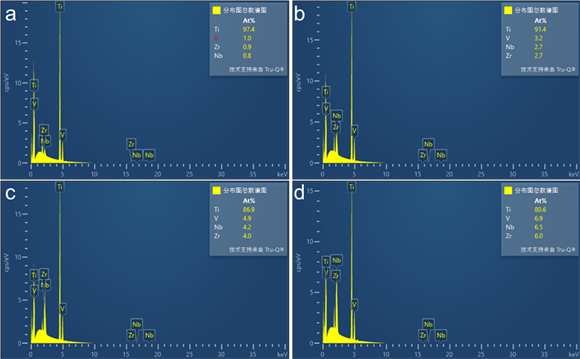

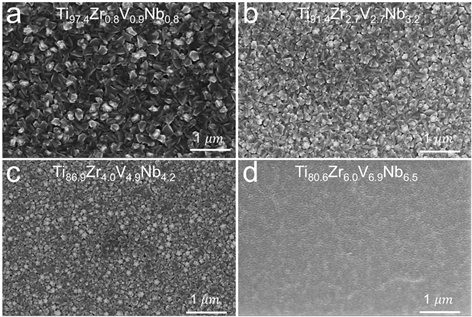

为了进一步确定薄膜的成分以及形貌变化,对Ti基薄膜体系分别进行EDS能谱测试以及扫面电子衍射(SEM),如图2、图3所示;图2(a)~(d)分别对应与Ti基薄膜体系Ti-Tialloy 15,30,45,60中各元素所对应的原子百分比(at .%),即:Ti97.4Zr0.8V0.9Nb0.8、Ti91.4Zr2.7V2.7Nb3.2、Ti86.9Zr4.0V4.9Nb4.2、Ti80.6Zr6.0V6.9Nb6.5。结果表明,随着Zr、V、Nb元素含量的升高,薄膜的结构由晶态逐渐转变为非晶态,这与以上结论一致。图3所表示的为薄膜的SEM图像,图3(a)~(d)为别对应于薄膜Ti97.4Zr0.8V0.9Nb0.8、Ti91.4Zr2.7V2.7Nb3.2、Ti86.9Zr4.0V4.9Nb4.2、Ti80.6Zr6.0V6.9Nb6.5。对于晶态薄膜而言,随着Zr、V、Nb元素含量的升高,晶粒尺寸明显由~200 nm减小到~100 nm,这与XRD结果基本吻合。此外,对于Ti86.9Zr4.0V4.9Nb4.2薄膜而言,薄膜的致密性以及粗糙度高于其它晶态薄膜,但是,仍然可以清晰的看见薄膜中晶粒的缺陷结构,如:晶界。有趣的是,当Zr、V、Nb元素含量达到19.4 at.%时(如图3(d)所示),所形成的Ti80.6Zr6.0V6.9Nb6.5非晶薄膜形貌明显不同与晶态薄膜,主要表现为高的致密性、低的粗糙度。这主要归因于非晶态结构不存在晶体缺陷,因此,薄膜生长过程中更加致密,这为非晶薄膜能获得良好的力学性能奠定了基础。

Figure 1. XRD patterns of thin films of Ti-Ti alloy 15, 30, 45, 60 show that the structure of the films changes from a crystalline alloy to an amorphous alloy with the increase of the content of Zr, V and Nb elements. The XRD patterns show that with the increase of Zr, V, and Nb elements, the film structure changes from a crystalline alloy to amorphous alloy

图1. 薄膜Ti-Tialloy 15,30,45,60的XRD图谱,表明随着Zr、V、Nb元素含量的增加薄膜结构由晶态合金变为非晶态合金

Figure 2. (a)~(d) correspond to the atomic percentage (at.%) of each element in the Ti-based thin film systems Ti-Ti alloy 15, 30, 45, 60, respectively. i.e., Ti97.4Zr0.8V0.9Nb0.8, Ti91.4Zr2.7V2.7Nb3.2, Ti86.9Zr4.0V4.9Nb4.2, Ti80.6Zr6.0V6.9Nb6.5

图2. (a)~(d)分别对应与Ti基薄膜体系Ti-Ti alloy 15,30,45,60中各元素所对应的原子百分比(at.%),即:Ti97.4Zr0.8V0.9Nb0.8、Ti91.4Zr2.7V2.7Nb3.2、Ti86.9Zr4.0V4.9Nb4.2、Ti80.6Zr6.0V6.9Nb6.5

Figure 3. (a)~(d) correspond toTi97.4Zr0.8V0.9Nb0.8, Ti91.4Zr2.7V2.7Nb3.2, Ti86.9Zr4.0V4.9Nb4.2 and Ti80.6Zr6.0V6.9Nb6.5 films SEM images , respectively

图3. (a)~(d)分别对应Ti97.4Zr0.8V0.9Nb0.8、Ti91.4Zr2.7V2.7Nb3.2、Ti86.9Zr4.0V4.9Nb4.2、Ti80.6Zr6.0V6.9Nb6.5薄膜的SEM图像

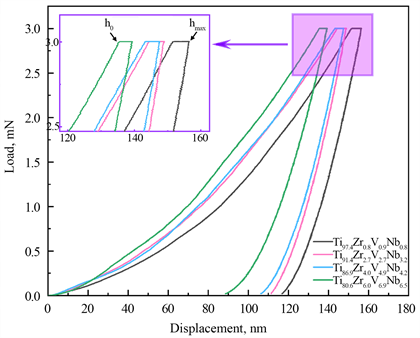

为了进一步验证薄膜的力学性能,对Ti基薄膜体系Ti97.4Zr0.8V0.9Nb0.8、Ti91.4Zr2.7V2.7Nb3.2、Ti86.9Zr4.0V4.9Nb4.2、Ti80.6Zr6.0V6.9Nb6.5分别进行纳米压痕测试,如图4所示;为了清晰起见,将图4粉色阴影矩形区域进一步放大,如图二插图所示。其中hmax和hmax分别表示蠕变初始位移和最大位移。对于薄膜Ti97.4Zr0.8V0.9Nb0.8而言,h0、hmax约为149.3 nm、155.9 nm,蠕变位移(Δh = hmax − h0)约为6.6 nm。随着Zr、V、Nb含量的进一步增加到13.1 at. %,h0、hmax分别降低到142.2 nm、145.6 nm,蠕变位移约为3.4 nm。这就意味着,随着Zr、V、Nb含量的逐渐升高,晶态薄膜的抗蠕变性能逐渐增强。令人惊讶的是,当Zr、V、Nb含量进一步增加,其h0、hmax明显降低到:134.6 nm、136.8 nm,蠕变位移约为2.2 nm。该结果表明,随着薄膜结构的由晶态转变为非晶态,其抗蠕变性能大大提升。

Figure 4. Displacement-load curve spectra of thin films Ti97.4Zr0.8V0.9Nb0.8, Ti91.4Zr2.7V2.7Nb3.2, Ti86.9Zr4.0V4.9Nb4.2, Ti80.6Zr6.0V6.9Nb6.5, show that with the increase of Zr, V, Nb element content of the film creep resistance gradually increases

图4. 薄膜Ti97.4Zr0.8V0.9Nb0.8、Ti91.4Zr2.7V2.7Nb3.2、Ti86.9Zr4.0V4.9Nb4.2、Ti80.6Zr6.0V6.9Nb6.5的位移–载荷曲线图谱,表明随着Zr、V、Nb元素含量的增加薄膜的抗蠕变性能逐渐增加

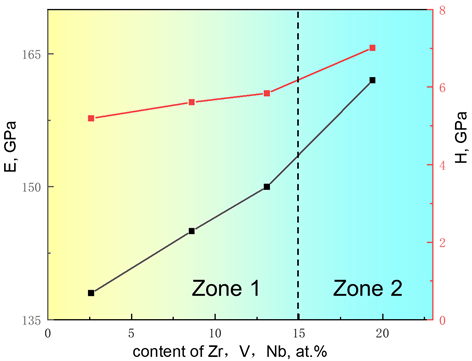

为了更加清晰的分析其力学性能,绘制了弹性模量及硬度随Zr、V、Nb元素含量变化折线图,如图5所示。其中,Zone 1所表示的为晶态薄膜区域,随着Zr、V、Nb元素的添加,薄膜的硬度H(GPa)和弹性模量E(GPa)由5.19 GPa,138.2 GPa逐渐增加到5.84 GPa,150.1 GPa。这可能主要归因于晶粒尺寸的减小,由谢乐公式可知,晶粒尺寸与结晶峰半高宽成反比,结合XRD图谱发现晶态薄膜Ti86.9Zr4.0V4.9Nb4.2的半高宽大于薄膜Ti97.4Zr0.8V0.9Nb0.8、Ti91.4Zr2.7V2.7Nb3.2。此外,图3(a)~(c)也能提供晶粒尺寸减小的直接证据。晶粒尺寸的减小有助与减少晶粒在受到外加载荷时在晶界处所产生的缺陷堆积应力,如:位错堆积应力。当缺陷堆积应力足够大时,这些缺陷的流动会导致材料产生灾难性的软化机制,如:全位错、滑移及晶界迁移等,从而使得材料失效。然而,随着Zr、V、Nb元素进一步增加,薄膜逐渐转变为完全非晶态结构时,可以明显的看出该薄膜的硬度和弹性模量都落在了Zone 2中,并且,硬度和弹性模量达到最高约为:7.01 GPa,162 GPa。这完全时归因于非晶态结构特殊的优势,即:没有晶界和位错等缺陷。众所周知,非晶态与晶态合金的变形机制存在本质上的区别,即:由晶态结构中的缺陷流动(位错,滑移)等软化机制转变为非晶中剪切带的流动。而剪切带的形成是由于在外加载荷的作用下,自由体积的流动逐渐形成剪切转变区(STZ),而STZ可以作为剪切带的形核位点。随着载荷的逐渐增大,STZ在流动过程中缺陷体积份数逐渐增高,形成胚胎剪切带。同时,胚胎剪切带需要吸收更高的能量才能形成成熟剪切带。因此,对于Ti80.6Zr6.0V6.9Nb6.5非晶薄膜而言,拥有更高的硬度以及弹性模量。

Figure 5. Thin films Ti97.4Zr0.8V0.9Nb0.8, Ti91.4Zr2.7V2.7Nb3.2, Ti86.9Zr4.0V4.9Nb4.2, Ti80.6Zr6.0V6.9Nb6.5 Elastic modulus and hardness variation with Zr, V and Nb elemental content line graph

图5. 薄膜Ti97.4Zr0.8V0.9Nb0.8、Ti91.4Zr2.7V2.7Nb3.2、Ti86.9Zr4.0V4.9Nb4.2、Ti80.6Zr6.0V6.9Nb6.5弹性模量、硬度随Zr、V、Nb元素含量变化折线图

4. 总结

本文通过磁控共溅射技术,通过控制靶材参数实现调控Zr、V、Nb元素在Ti基薄膜中的成分变化,成功制出具完全非晶态结构的Ti80.6Zr6.0V6.9Nb6.5非晶合金薄膜。该非晶合金薄膜与晶态薄膜相比表现出优异的综合性能,包括:1) 优异的力学性能:高的硬度和弹性模量:7.01 GPa,162 GPa;2) 良好的薄膜质量:高的致密性以及低的粗糙度。同时,从本质上解释了该非晶薄膜具有优异力学性能的原因:1)非晶态结构特殊的优势,即:首先对于非晶而言没有晶界和位错等缺陷,防止了因缺陷而产生的软化机制。2) 力学机制转变,即:由晶态结构中的缺陷流动(位错,滑移)等软化机制转变为非晶中剪切带的流动。但是,对于剪切带的形成是由于自由体积的流动逐渐形成剪切转变区,而剪切转变区可以作为剪切带的形核位点。随着载荷的逐渐增大,剪切转变区在流动过程中缺陷体积份数逐渐增高,形成胚胎剪切带。同时,胚胎剪切带需要吸收更高的能量才能形成成熟剪切带。因此非晶态结构相比于晶态结构拥有更为优异的力学性能。本文主要为Ti基非晶薄膜家族体系提供了一定的研究思路,也为MEMS系统提供了有希望的候选材料。

参考文献