1. 引言

钛及钛合金具有良好的耐蚀性、密度低、无毒、热稳定性和比强度高等众多优于普通金属的特性,是具有较大发展前途的新型结构材料[1] -[4]。现在不仅成为航空航天工业中不可缺少的结构材料,在造船、化工、冶金、医疗等方面也获得了广范应用[5] [6] 。但钛及钛合金的化学活性高,在空气中极易生成一层薄且透明的天然氧化膜。由于膜层较薄,其耐蚀性、导电导热性、焊接性、耐损性等性能较差[7] ;同时,天然表面氧化膜的存在致使镀覆层与基体的结合力差,限制了其应用范围。

为了改善和提高钛及钛合金表面的使用性能,通常需要在其表面进行精饰处理[8] -[10],最常用且比较简单的方法是化学氧化处理,从而提高和改善基体与涂覆层的结合力,以及表面的耐蚀性和装饰性[11] -[14]。

因此本文采用Na3PO4-NaF-CH3COOH溶液体系对TC4钛合金进行有效表面转化膜处理,并对成膜物质及涂层性能进行分析。

2. 实验

2.1. 材料

试验采用3 mm厚的TC4钛合金板材,退火状态,其化学成分(w%t)为:Al-5.5,V-4.3,其余为Ti。试样尺寸为25 mm × 25 mm × 3 mm。

2.2. 试剂及仪器

氟化钠(天津市协和吴鹏色谱科技有限公司)、氟化钾(天津市协和昊鹏色谱科技有限公司)、氢氟酸(上海申博化工有限公司)、硝酸(成都金山化学试剂有限公司)乙酸(重庆江川化工有限公司)、无水乙醇(重庆川东化工有限公司)、磷酸三钠(重庆川江化学试剂厂)。以上试剂均为分析纯。

101-2A型电热鼓风恒温干燥箱(天津市泰斯特仪器有限公司)型号HTP-312 (上海花潮电器有限公司)85-2恒温磁力加热搅拌器(金坛市富华仪器有限公司)。

2.3. 磷酸盐转化膜的制备

2.3.1. 实验前处理

钛合金试样的处理流程为:砂纸逐级打磨→乙醇除油→蒸馏水清洗→酸洗→蒸馏水清洗→干燥→待用。

其中酸洗处理的工艺参数为:25 ml HNO3 + 4 ml HF混合加水至100 ml,反应温度50℃,反应时间20 min。

2.3.2. Na3PO4-NaF-CH3COOH体系转化膜的制备

称取4.5 g磷酸三钠和3.0 g氟化钠混合后放入容器中,加入6.2 ml乙酸并加水至100 ml,在恒温磁力加热搅拌器上搅拌均匀,使之完全溶解后将处理好的钛合金样品放入,在室温下反应充分后取出钛合金试样,得到Na3PO4-NaF-CH3COOH体系转化膜,烘干,密封,待用。

2.4. 分析测试

实验中采用数码相机拍摄铝合金转化膜的图像,分析转化膜着色情况;用XRD对钛合金磷酸盐转化膜进行物相分析,采用SEM对样品微观形貌进行观察,使用其配备的EDS分析膜层的元素成分,利用喷漆涂层-划痕法表征样品的附着力性能。

3. 结果与讨论

3.1. 未处理钛合金和经Na3PO4-NaF-CH3COOH体系经处理后的形貌图

如图1所示(a)未处理钛合金表面呈银白色金属光泽,(b)经Na3PO4-NaF-CH3COOH体系处理后的钛合金表面膜层较薄,呈浅灰色。

3.2. 转化膜外观形貌及SEM分析

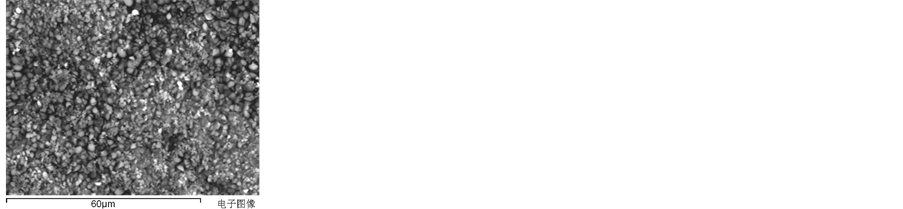

从(图2)SEM图中可以看出:(a)为未经过转化液处理的TC4钛合金样品的电镜扫描图片,可明显观测到样本表面存在孔状缺陷和长短不一的条纹,扫描电镜分析显示孔状缺陷区域约为0.1 mm,能够被人眼识别,初步分析可能是加工过程中造成的表面损伤,长短不一的条纹可能是打磨过程形成的划痕。

随着反应的进行,膜层不断增长,界面由基体/溶液转化成膜层/溶液,界面的性质发生了变化,磷酸盐处理掉了表面的微裂纹,阻止了微裂纹尖端的进一步发育,提高了表面涂层附着部位的比表面积。

磷的沉积一方面增加了膜层的致密性,另一方面可能起到封孔剂的作用,降低孔隙度。结晶过程成为了膜层增重的主要因素。图(b) Na3PO4-NaF-CH3COOH体系下的黑色转化膜层除不规则的分布一些深陷的小孔洞外,大体上是均匀稳定多孔性的,组织致密。

3.3. 转化膜的元素组成分析

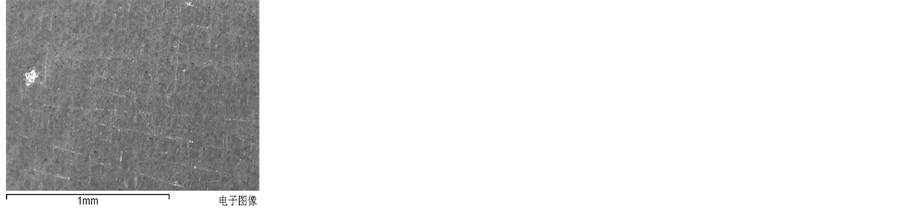

根据图3 Na3PO4-NaF-CH3COOH体系转化膜表面EDS谱图和元素重量、原子百分比图,可以分析本实验所制备转化膜的主要元素成分及其含量(表1),按原子百分比氟和钛的含量较高,分别占据了61.56%及15.69%,膜层由钛与其它元素复合组成;其它三种元素含量从高到低依次为15.35%、7.07%、0.33%,可以推测本实验制备的转化膜层主要以氧化物存在;氟元素起表面活化作用,促进膜的生成。

(a)

(a) (b)

(b)

Figure 1. Untreated titanium alloy and after dealing with the Na3PO4-NaF-CH3COOH solution system of topography

图1. 未处理的钛合金和经过Na3PO4-NaF-CH3COOH溶液体系处理后的形貌图

(a)

(a) (b)

(b)

Figure 2. SEM images of untreated titanium alloy and after dealing with the Na3PO4-NaF-CH3COOH solution system

图2. 未处理的钛合金和经过Na3PO4-NaF-CH3COOH溶液体系处理后的SEM图像

Figure 3. EDS spectra of titanium alloy after dealing with the Na3PO4-NaFCH3COOH system of surface

图3. 钛合金经过Na3PO4-NaF-CH3COOH体系处理后的表面EDS谱图

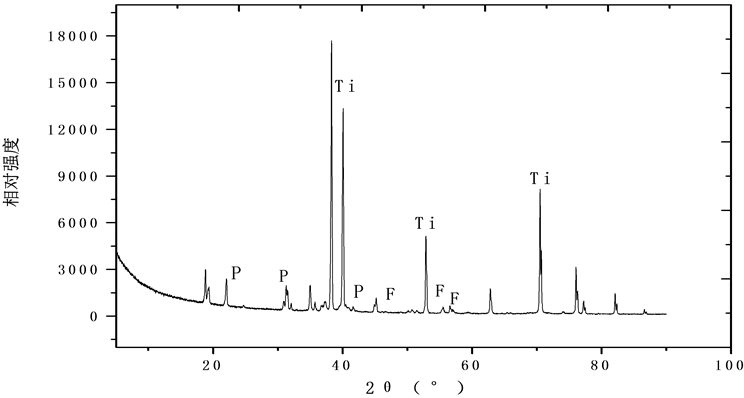

3.4. 转化膜物相分析

如图4所示,Na3PO4-NaF体系的XRD分析可以看出钛合金表面生成了氧化钛膜,膜主要由Na3tiF6相、TiO2相和基体钛相等组成,图谱中衍射峰尖锐且强度较强,说明制备的磷酸盐转化膜结晶性能良好,结晶过程成为了膜层增重的主要原因。

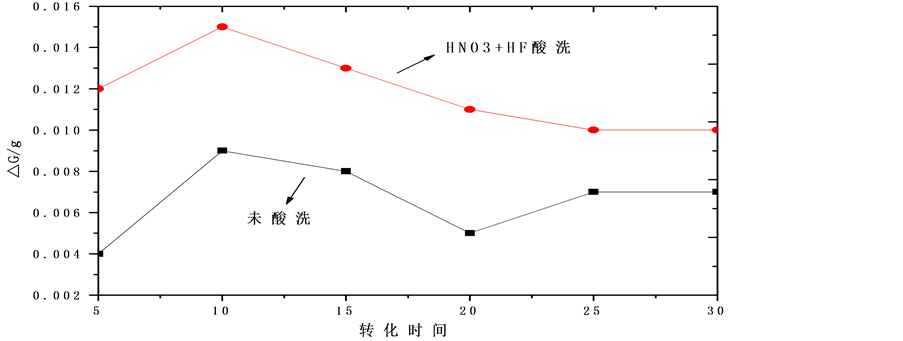

3.5. 转化时间对磷酸盐转化膜转化速率的影响

将钛合金试样在不同时间里转化成膜,通过称量成膜前后试样的质量变化,标定转化时间对膜层增

Table 1. Element weight and atomic percentage

表1. 元素重量及原子百分比

Figure 4. XRD spectra of titanium alloy after dealing with the Na3PO4-NaF-CH3COOH solution on the surface

图4. 钛合金经过Na3PO4-NaF-CH3COOH溶液体系处理后表面的XRD谱图

重的影响。

图5显示了在5~10 min时间段内,钛合金试样的增重值逐渐增加,10 min时都达到最大值,而经酸洗处理的钛合金增重效果较为明显;在10~20时间段,钛合金成膜效果都呈降低的趋势,在25~30 min时间段转化速率趋近于0,试样的重量几乎未再发生变化,可能是随着转化时间的延长表面晶体的增长抑制了磷酸盐转化膜的进一步生成,而磷酸盐转化液对钛合金有成膜保护的同时,随着时间的延长转化液

也对其有一定的腐蚀,使其重量减轻。

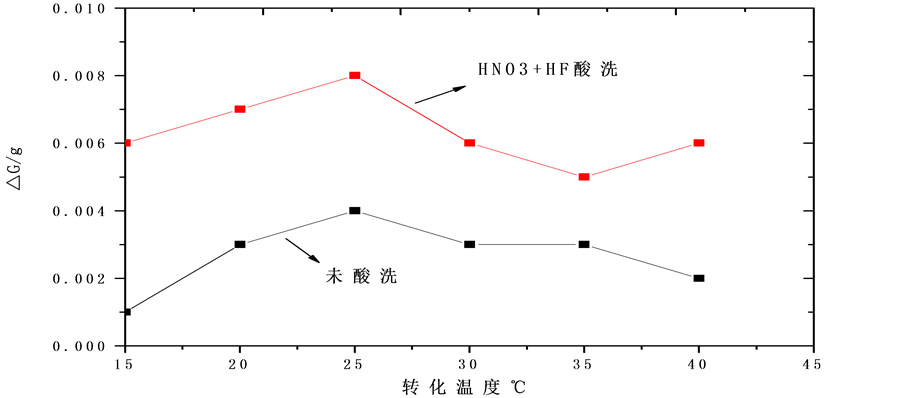

3.6. 转化温度对磷酸盐转化膜转化速率的影响

将钛合金试样在不同温度下转化成膜,通过称量成膜前后试样的质量变化,标定转化温度对膜层增重的影响图6显示了在15℃~25℃温度区间内,随着转化温度的升高,钛合金表面成膜速率变快,在25℃时都达到了最大成膜增重值,而经过酸洗处理的钛合金成膜增重较为明显;但在25℃~30℃温度区间内,随着转化温度的升高,钛合金成膜都分解了一小部分,转化膜的制备是一个腐蚀与生长同时进行的过程。

Figure 5. titanium alloy and conversion coating weight contrast figure in the Na3PO4-NaFCH3COOH solution

图5. 钛合金在Na3PO4-NaF-CH3COOH溶液下转化膜随时间的增重

Figure 6. The titanium alloy and conversion coating weight increased with the temperature in the Na3PO4-NaF-CH3COOH solution system

图6. 钛合金在Na3PO4-NaF-CH3COOH溶液体系下转化膜随温度增重

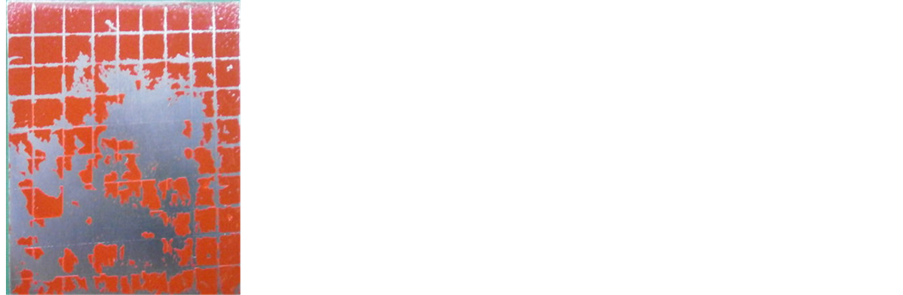

3.7. 钛合金样品的涂层附着力性能

将未经处理与磷酸盐处理后的钛合金涂漆与划格试验,测试磷酸盐转化膜对基体与外层表面漆的结合力。具体方法为:用划格刀划格,在划格的涂层上压粘玻璃纸胶带,再将胶带拉起,得到的效果图如下。

从图7可以明显看到,未经处理的钛合金涂层沿划割边缘大碎片剥落,一些方格部分或全部出现脱落,涂覆性能差。而经磷酸盐处理的钛合金只出现少许涂层脱落,经过磷酸盐处理的钛合金在表面形成的转化膜对基体金属与表面漆结合力的提升有明显的改善效果。根据转化膜SEM形貌图,经过表面处理的钛合金表面粗糙,与有机涂层能够更好结合。

4. 结论

1) 钛及钛合金表面磷酸盐处理,可常温操作,控制容易,成本较低,易批量生产。

2) 经过酸洗过后的钛合金在25℃、10 min的Na3PO4-NaF-CH3COOH体系处理条件下成膜效果最好,

(a)

(a) (b)

(b)

Figure 7. Untreated titanium alloy and after dealing with the Na3PO4-NaF-CH3COOH solution adhesion performance contrast figure

图7. 未处理的钛合金和经过Na3PO4-NaF-CH3COOH溶液处理后附着性能对比图

膜层呈浅灰色,致密均匀,而转化膜的制备亦是一个腐蚀与生长同时进行的过程。

3) TC4钛合金在Na3PO4-NaF-CH3COOH体系下转化膜有较好的吸附能力,主要用作油漆和镀覆层的底层或中间层,还能有效提高表面的耐久性及装饰性,有助于提高涂层比表面积,增加了后续涂覆工艺,涂层的牢固性。

项目基金

贵州省科学技术基金(黔科合J字[2013]2206号);贵州省国际科技合作计划项目(黔科合外G字[2013] 7017号);贵阳市白云区科技计划项目(白科合同[2013]号);贵州师范大学博士科研启动金。

NOTES

*通讯作者。