1. 引言

锻造镁合金具有质量轻、比强度高、耐冲击、抗疲劳性能好,能够近终成型等特点,在汽车和航空行业得到了日益广泛的应用。AZ80镁合金是常用的变形镁–铝–锌系合金,具有良好的力学性能、铸造性能和抗大气腐蚀性能,是Mg-Al系合金里高强度和唯一可进行淬火时效强化的合金,可用于轮毂、座椅框架、方向盘等汽车零部件[1] 。与铸造镁合金轮毂相比,锻造镁合金强度高、韧性好、耐损伤性能较好,由于微观组织无孔洞,耐压力密封性能高[2] 。镁合金轮毂与铝合金轮毂相比,具有质量轻,安全、舒适、节能等特点,但是耐蚀性能较差且制造成本很高,所以目前主要应用于奥迪A8L、宝马M3等高端车型[3] 。镁合金的力学性能取决于工件中相的特性及分布,缺陷的性质、数量和尺寸等[4] 。镁合金锻件表面易出现点蚀缺陷,腐蚀点呈暗灰色粉末状,这些都强烈影响镁合金轮毂的服役性能。

本文通过对模锻AZ80镁合金轮毂不同部位(轮芯、轮辐、外轮缘、轮辋)取样,采用光学显微镜(OM)、扫描电子显微镜(SEM)、微区成分分析(EDS)和室温拉伸力学性能分析,探究模锻AZ80镁合金微观组织的构成和锻造后的力学性能,为提高产品质量提供理论依据。

2. 试验材料及试验方法

2.1. 试验材料

本文的试验材料来自江苏荣镁轮毂有限公司提供的模锻AZ80镁合金轮毂及其对应的压铸母材,采用AZ80高强度镁合金半连续铸锭为原料,表1为轮毂原材料化学成分表。

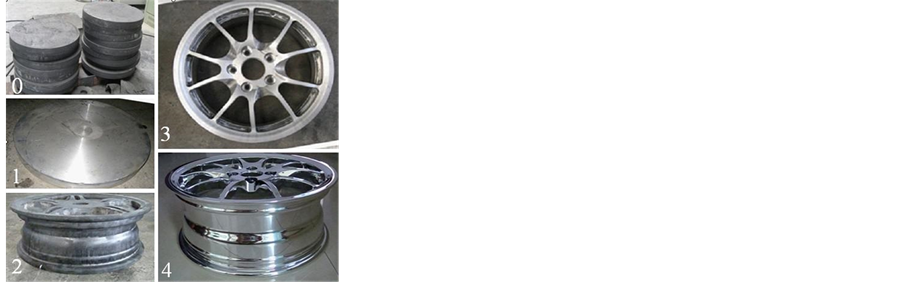

锻造AZ80镁合金轮毂的工艺流程如图1所示,按照0~4的顺序依次进行,简单归纳以下几个步骤:单向锻造(预成形)–模锻成形–热处理–机加工–涂装。其中热处理为人工时效160℃ × 12 h。坯料为圆盘状的半连续铸锭,经过均匀化退火(390℃ × 10 h)处理后,在等温的组合成形模具中进行模锻成形。轮辋部位的最小厚度在4~6 mm之间,最大厚度在轮辐部位,约为25 mm,单只轮毂从装模到脱模时间约为8 min,锻造室温下自然冷却。润滑采用自行配制的石墨基膏状混合润滑防护剂。

Table 1. Composition of AZ80magnesium alloy (wt .%)

表1. AZ80镁合金化学成分(质量分数%)

2.2. 试样制备及检测方法

分别从轮毂的轮芯、轮辐、外轮缘和轮辋(径向和切向)处线切割截取试样,按照国标GB/T228-2002规定的标准拉伸试样,轮辋加工成厚度为3 mm的矩形试样,其他三个部位加工成直径为4 mm的标准圆柱形拉伸试样,测定材料的力学性能。四个部位分别切取尺寸为15 mm × 15 mm × 10 mm试样,经过1000#砂纸打磨、抛光,制成金相试样,采用1.5 g苦味酸 + 5 ml醋酸 + 25 ml酒精 + 10 ml水溶剂腐蚀10~15 s,然后依次用水和酒精清洗,冷风吹干表面后在Olympus BX51M型蔡司显微镜下观察显微组织形貌。另截取尺寸为10 mm × 10 mm × 3 mm的试样浸泡在5%盐水中腐蚀15小时取出,直接观察组织形貌并测算晶粒度。使用JSM-6360LV型扫描电镜观察超高倍(>5000×)的组织形貌,并结合Link-ISIS型能谱仪测量微区化学成分。

3. 结果与分析

3.1. 微观组织分析

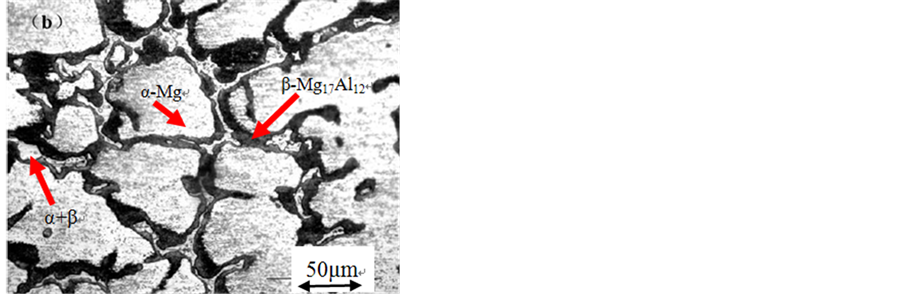

图2为AZ80铸态试样显微组织,由粗大的α-Mg相和沿晶界网状分布的β-Mg17Al12相,其中晶界处白亮的部分为非平衡凝固析出的共晶组织(α + β),而共晶组织周围的黑色轮廓线为共晶反应后在冷却过程中从α相中析出的第二相βⅡ,属于典型的非平衡凝固离异共晶组织。

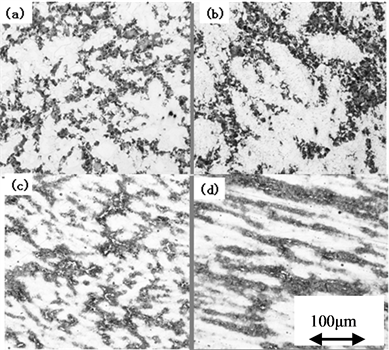

图3(a)-(d)分别对应放大100倍的轮芯、轮辐、外轮缘和轮辋的微观组织。轮芯和轮辐属于小变形区域,基体铸态组织开始变形,晶界上出现动态再结晶等轴细晶[4] ;外轮缘和轮辋属于大变形区域,由于

Figure 1. Technological process of wheel hub

图1. 轮毂加工工艺流程

Figure 2. Microstructure of AZ80 as cast (500×)

图2. AZ80镁合金铸态显微组织(500倍)

变形过程中的应变不均匀性,析出的二次相沿锻造方向具有明显的带状分布特征,产生了明显的流线型带状组织[5] 。由此可以看出,等温模锻后轮毂组织发生了剧烈塑性变形,有利于轮毂综合力学性能的提高。

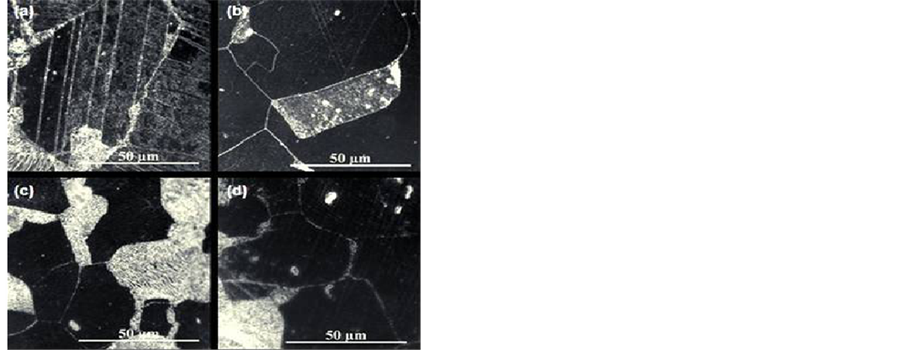

图4所示为轮毂各部分的金相组织,黑色为基体,白色部分为第二相。可以明显看出,随着轮毂部位的由外向内晶粒变细。另外发现:在轮辋的部位出现了典型的机械孪晶,这是由于轮辋处晶粒较为粗大,位错滑移程度大,晶界附近应力集中严重[6] 。镁合金的滑移系比较少,在塑性变形的过程中,需要孪晶加以协调,以使得变形过程顺利进行[7] 。

在图4(c)可以看到,白色部分的组织形貌接近片层状, 主要出现在晶界处并向晶内扩张,在晶内未曾单独形核长大出现。由此可以推测其为β-Mg17Al12的不连续析出所致,如图4(b)所示,可以明显看到胞状组织,胞的前沿近乎球形,与基体有明显的晶界界面分割,胞状组织只向晶内的一侧生长,说明晶胞与不向其长大的晶粒具有共格关系,界面的可动性低;与向其长大的晶粒具有非共格关系,界面的可

Figure 3. Microstructure of four parts (100×): (a) wheel core; (b) spoke; (c) outer rim; (d) rim

图3. 轮毂不同部位的微观组织:(a) 轮芯;(b) 轮辐;(c) 外轮缘;(d) 轮辋

Figure 4. Microstructure of four parts (1000×): (a) wheel core; (b) spoke; (c) outer rim; (d) rim

图4. 轮毂不同部位显微组织(1000倍):(a) 轮辋;(b) 外轮缘;(c) 轮辐;(d) 轮芯

动性高[8] 。

对于AZ80变形镁合金中析出相的形态及特性,前人已经做过大量的研究,Wei-Jen Lai小组的研究表明[9] :该组织为β-Mg17Al12相直接从镁基体中析出的不连续析出沉淀物,没有经过中间GP区,这种析出物根据其生长形貌主要可以分为两种:第一种是包含片层状结构的胞状组织,这种片层组织的生长方向一般垂直于晶界向与自身呈非共格关系的晶粒内部方向生长,只有当整个晶粒都充满析出沉淀相或连续析出相阻碍了非连续沉淀相的生长时,该生长过程才会停止。另一种不连续析出相的形貌,可以看出该析出相的形貌近似于椭球形,这种椭球形结构尺寸大约在1~2 μm左右。

3.2. SEM微观组织分析

图5是SEM扫描后轮毂各部分的微观组织形态,其中白亮部分为片层组织,可以明显的看出,从轮辋到轮芯,白亮片层区域的占比越来越大,轮辋处的片层组织相较于其他部位的片层显得有些特殊,形貌成棒条状,然后随着向轮芯部位的靠近,棒条形貌逐渐减少,取而代之的是片层状形貌的增加,到轮芯部位几乎全由众多小片层组成,片层顺沿的方向上发生短距离有规律的断裂,类似于珠光体般的片层交替机械混合组织[10] 。

为了探明片层组织是否为类似于珠光体的构造方式,对轮毂各部分进行了微区成分分析,结果如表2

Figure 5. Second phase of wheel hub: (a) wheel core; (b) spoke; (c) outer rim; (d) rim

图5. 轮毂各部分第二相组织(a) 轮辋;(b) 轮缘;(c) 轮辐;(d) 轮芯

Table 2. Energy Dispersive Spectrometer analysis

表2. 轮毂各部分EDS分析

所示。虽然片层组织的微观形貌有所差别,在轮辋处主要是以棒状为主;在轮缘和轮辐处以针状、片层状为主;在轮芯处主要以片层状为主,但并未出现如预期的α-Mg和β-Mg17Al12片层交替的机械混合组织(类似于珠光体的构造方式),其Mg与Al的含量只出现了小范围的波动(Mg(86.4~92.9 wt.%),Al(0.7~12.4 wt.%))。当然由于实际扫描电子显微镜的电子束斑大小与片层的厚度(0.2 μm~0.4 μm)相当,尚不能精确地反映出定点分析的实际成分。

3.3. 晶粒度计算

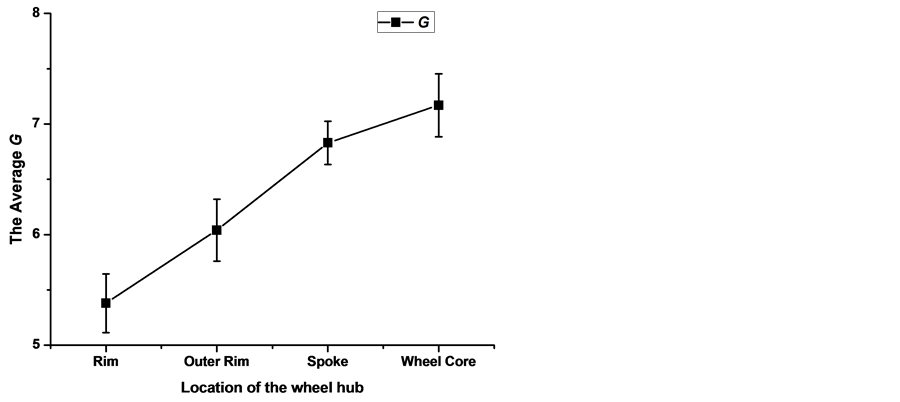

由于镁合金金相腐蚀剂对第二相凸显效果明显,掩盖了晶界特征,为此用盐水进行了侵蚀,尽管表面质量粗糙,但发现凸显晶界效果明显,根据GB/T 6394-2002“金属平均晶粒度测定法”,AZ80镁合金轮毂各部分的晶粒度评定结果表3所示。从图6可以看出,随着轮毂部位的变化,按轮辋→轮缘→轮辐→轮芯方向,晶粒度变得越来越大,这说明其晶粒变得越来越细小。

3.4. 拉伸试验

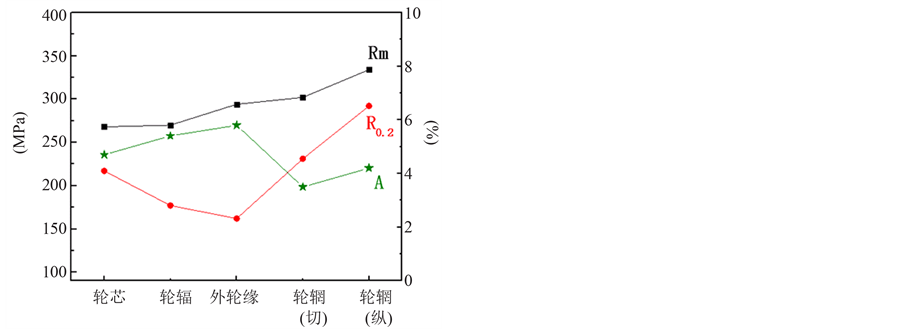

在AZ80镁合金半连续铸坯(径向),轮毂的轮辐(纵向)、外轮缘(切向)、轮芯(径向)和轮辋(径向和切向)处各取3个样品,一共有18个拉伸试样,抗拉强度、屈服强度和伸长率的对比关系如图7所示。

可见,相比铸态AZ80镁合金的力学性能(Rm = 175 MPa, R0.2 = 90 MPa, A = 2%),模锻后的AZ80镁合金轮毂各个部位的抗拉强度、屈服强度、延伸率都有相当大程度的提高,其中轮辋部位综合性能最好,

Table 3. Statistics of grain size

表3. 轮毂各部位晶粒度测算

L:截线法所得的平均截距 G:平均晶粒度 %RA:95%置信度下的相对偏差。

Figure 6. Average grain size of wheel hub

图6. 镁合金各部分晶粒度

Figure 7. Comparison of the mechanical properties in difference parts of wheel hub

图7. 轮毂不同部位的力学性能对比

分别达到了334 MPa、292 MPa、4.2%。另外,轮辐和轮芯的抗拉强度值比较接近,外轮缘的抗拉强度略有升高,轮辋处最高,这主要是由于轮辋部分壁厚最薄(约为5 mm),变形程度最大,说明塑性变形对产品性能有强化作用,变形程度越大强化效果越明显。同一部位不同方向的取样中,纵向的性能也明显由于径向,说明平行于锻造方向强化效果最好。

从拉伸数据可以看出,AZ80镁合金在室温下的强度范围大约在275~325 MPa之间;延伸率3.5~5.8%之间,这也印证了镁合金在室温下的塑性变形能力比较差的事实。抗拉强度按轮辋→轮芯的顺序逐渐下降,而轮辋→轮芯变形程度依次降低,在镁合金热加工过程中,加工硬化现象并不明显。由于轮辋处由孪晶的存在,增大了晶内界面,此时孪晶强化效应占主导地位,有效阻碍了晶内位错的运动滑移,使得轮辋处屈服强度最高;而轮缘、轮辐、轮芯晶粒依次变小,此时晶界强化占据主导地位,使得屈服强度呈现随晶粒尺寸的变小而增大的趋势。

4. 结论

1) AZ80轮毂模锻后的整体晶粒细化,由外向内,即从轮辋→轮芯晶粒尺寸逐渐减小。β-Mg17Al12不连续析出的片层状第二相出现在晶界处并向晶内扩张,这种组织只向晶内的一侧生长,说明晶胞与向其长大的晶粒具有非共格关系,界面的可动性高。

2) 虽然片层组织的微观形貌有所差别,在轮辋处主要是以棒状为主;在轮缘和轮辐处以针状、片层状为主;在轮芯处主要以片层状为主,但并未出现如预期的α-Mg和β-Mg17Al12片层交替的机械混合组织(类似于珠光体的构造方式),其Mg与Al的含量只出现了小范围的波动。

3) 模锻后的AZ80镁合金轮毂各个部位的抗拉强度、屈服强度、延伸率都有相当大程度的提高,其中轮辋部位综合性能最好,抗拉强度按轮辋→轮芯的顺序逐渐下降,轮辋处由于产生了孪晶,所以屈服强度较高,而其他部位屈服强度大小与晶粒尺寸成反比。

NOTES

*通讯作者。