1. 引言

我国铁矿储量丰富,但由于贫矿多富矿少,矿石类型复杂、伴(共)生组分多,导致这些复杂铁矿资源开发利用程度低[1] [2] 。由于铁矿石长期依赖进口,铁矿石价格的不断上涨已严重制约了我国钢铁行业的发展,因此努力开发我国已有的铁矿资源成为当务之急。我国宁乡式鲕状赤铁矿储量丰富,鄂西的宁乡式鲕状赤铁矿储量占宁乡式铁矿总量的53.57%[3] ,但是由于该矿石结构复杂、铁矿物嵌布粒度极细、伴生粘土矿物多、铁品位低及含磷高,基本上

没有得到有效开发利用。

目前针对这类矿石的脱磷进行了大量研究[4] ,包括物理选矿、化学选矿、焙烧磁选等。传统选别工艺主要包括浮选、磁选等联合作业,该工艺难以获得能够满足高炉冶炼所需的铁精矿,且铁回收率较低[5] ;化学分选主要有酸浸及微生物浸出,该工艺脱磷效果明显,但处理能力小、生产周期长[6] ;一般磁化焙烧因技术经济指标差,已属于淘汰工艺;一般煤基直接还原能获得铁品位较高的铁精矿,但精矿磷含量偏高,还原时间长,一般在30~120 min,并且还原剂用量大[7] 。针对以上问题,本文主要在传统回转窑煤基直接还原的工艺基础上,在实验室条件下研究高温快速还原工艺中铁与磷的反应行为,从而为开发高效低耗的高磷鲕状赤铁矿高温快速还原新工艺提供理论依据。

2. 原料性能与研究方法

2.1. 原料性能

本试验所用原料主要是铁矿石、还原剂、熔剂及添加剂。铁矿石是国内某地鲕状赤铁矿,其化学成分如表1所示,该矿属于高磷低硫低铁酸性矿石。

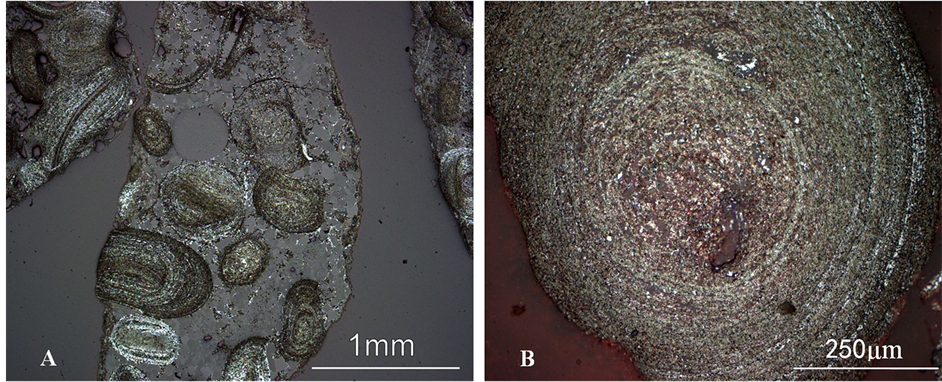

将铁矿石在光学显微镜下观察,结果如图1所示。从图可知,该矿鲕粒结构明显且分布密集,赤铁矿由嵌布粒度极细的针状晶体交织成絮状,再相互连接成环带,较难选别。对原矿进行磷的化学物相分析,结果如表2所示。由此可见,磷主要以磷灰石的形式存在,极少部分的磷存在于铁矿物中。

试验使用的还原剂为褐煤。还原剂主要性质如表3及表4所示。将还原剂磨至−0.074 mm备用。试

Table 1. Chemical composition of iron ore (%)

表1. 铁矿石化学成分(%)

LOI*-loss on ignition

Figure 1. Optical microscope pictures of the oolitic hematite ore

图1. 鲕状赤铁矿显微结构

Table 2. Chemical phases and distribution of phosphorus in oolitic hematitie (%)

表2. 铁矿石中磷的赋存状态及分布(%)

Table 3. Main chemical composition of coal ash (%)

表3. 还原剂灰份的主要化学成分(%)

Table 4. Proximate analysis results of coal

表4. 还原煤工业分析结果

Mad:水分;Aad:干基灰分;Vdaf:挥发份;FCad:固定碳含量;DT:变形温度;ST:软化温度;HT:半球温度;FT:流动温度。

验所用的熔剂是分析纯Ca(OH)2,添加剂为分析纯Na2SO4。

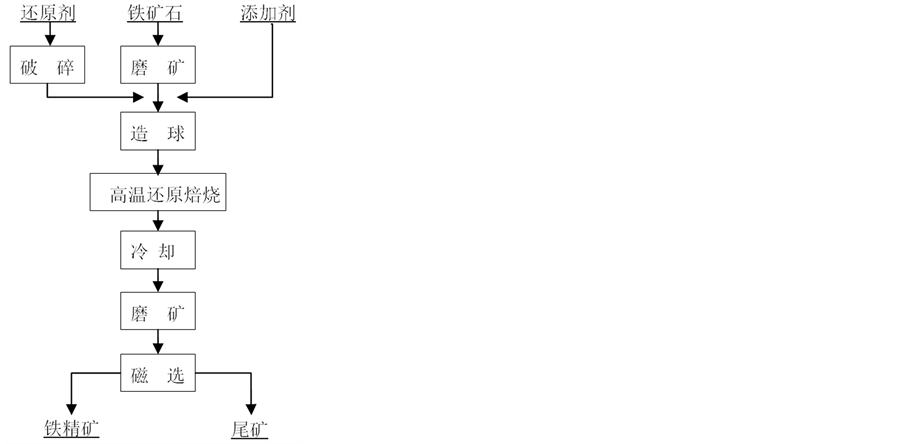

2.2. 研究方法

本实验采用高温快速还原-磁选工艺流程,如图2所示。将铁矿石磨至−0.074 mm占77.27%,与还原

Figure 2. The experimental flowsheet

图2. 试验工艺流程图

剂、熔剂及添加剂按一定比例混合后造球,生球粒度10~12 mm。生球在105℃恒温鼓风干燥箱烘干6小时备用。取55 g左右干球放入100 mL刚玉坩埚,待马弗炉升到一定温度后将坩埚放入其中,马弗炉炉膛规格为55 × 21 × 15 cm,等马弗炉升到预定温度,保温一段时间后取出,放入通氮气的冷却罐中进行冷却。焙烧球团经人工破碎至−1 mm,均匀取样20g于锥形球磨机中球磨,矿浆浓度50%,磨至−0.074 mm含量至95%以上,使用磁选管磁选后得到铁精矿。

本试验的主要评价指标为磷还原挥发率、磁选脱磷率、铁精矿铁品位和回收率、精矿磷含量等。

(1)

(1)

式中: ——磷挥发率/% m1——还原焙烧矿质量/g m0——还原焙烧前球团质量/g P1——还原焙烧矿磷含量/% P0——焙烧前球团磷含量/%

——磷挥发率/% m1——还原焙烧矿质量/g m0——还原焙烧前球团质量/g P1——还原焙烧矿磷含量/% P0——焙烧前球团磷含量/%

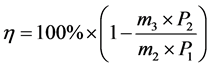

(2)

(2)

式中: ——磁选脱磷率/% m2——球磨还原焙烧矿质量/20g m3——磁选铁精矿质量/g P1——还原焙烧矿磷含量/% P2——磁选精矿磷含量%

——磁选脱磷率/% m2——球磨还原焙烧矿质量/20g m3——磁选铁精矿质量/g P1——还原焙烧矿磷含量/% P2——磁选精矿磷含量%

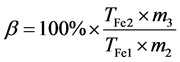

(3)

(3)

式中: ——铁回收率/% TFe1——还原焙烧矿全铁含量/% TFe2——铁精矿全铁含量/% m2——球磨焙烧矿质量/20g m3——磁选铁精矿质量/g

——铁回收率/% TFe1——还原焙烧矿全铁含量/% TFe2——铁精矿全铁含量/% m2——球磨焙烧矿质量/20g m3——磁选铁精矿质量/g

3. 结果与分析

3.1. C/Fe

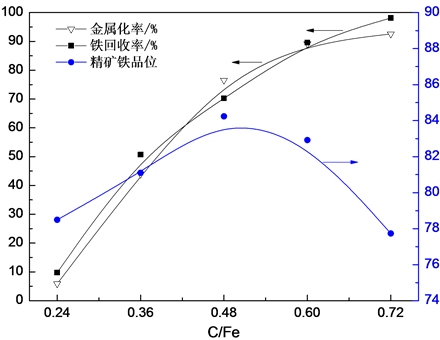

图3为C/Fe (质量比)对铁与磷分选效果的影响。由图可见,随着C/Fe的增加,还原气氛增强,金属化率和铁回收率逐渐升高,精矿铁品位呈先上升后下降的趋势,在C/Fe为0.48时达到最大值84.24%。这是由于球团内配碳量过高会导致在较短的还原时间内部分碳未反应完全,残碳与灰分降低了磁选精矿的铁品位。此外,由于Fe2O3比磷灰石易还原[8] ,C/Fe较低时,主要是Fe2O3还原,只有少量磷灰石被还原,大部分磷灰石可通过磁选脱除,随着C/Fe的增加,大量磷灰石被还原,被还原的磷易进入铁相,导致磷灰石的挥发率及磁选脱磷率降低,而精矿中磷的含量逐渐增加。综合各项指标,推荐合适的C/Fe为0.48。

3.2. 还原温度

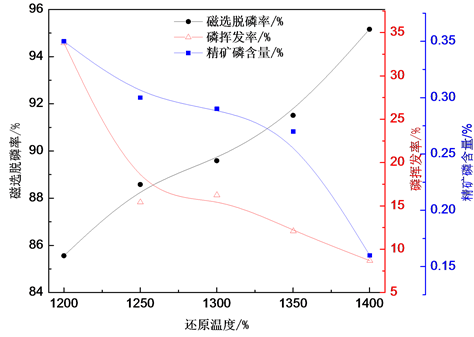

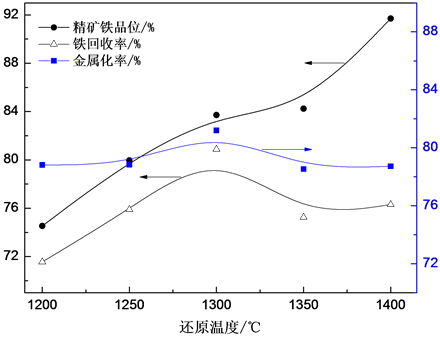

还原温度对铁与磷分选效果的影响见图4。由图可见,随着还原温度的提高,精矿铁品位逐渐升高,铁回收率先上升后缓慢下降,金属化率保持在78%左右,磁选脱磷率逐渐增加,磷挥发率和精矿磷含量逐渐下降。由于铁的还原反应为强吸热反应,因此提高还原温度,有利于铁氧化物的快速还原。由于球团中加入了一定量的CaO和Na2SO4,提高焙烧温度,促进了其与脉石的反应,改善了脱磷效果。但当还原温度达到1400℃时,球团处于熔融状态。因此推荐合适的还原温度为1350℃。

3.3. 还原时间

还原时间对铁和磷分选指标的影响如表5所示。由表可知,在固定C/Fe和焙烧温度的情况下,随着还原时间的延长,铁精矿磷含量逐渐下降,磷挥发率和磁选脱磷率逐渐升高,铁精矿铁品位逐渐下降,金属化率随还原时间的延长而降低,导致铁的回收率降低。这是由于反应容器并未完全密封,随着反应的进行,还原剂逐渐消耗,还原气氛逐渐减弱,被还原的铁又被氧化,导致金属化率下降。因此推荐适

Figure 3. The effect of C/Fe on concentration and dephosphorization (Reduction temperature 1350℃, Reduction time 15min, basicity 2.4, 10%Na2SO4)

图3. C/Fe对提铁脱磷效果的影响(还原温度1350℃,还原时间15 min,碱度2.4,10%的Na2SO4)

Figure 4. The effect of roasting temperature on concentration and dephosphorization and Magnetic separation (reduction time 15min, C/Fe 0.48, basicity 2.4, 10%Na2SO4)

图4. 焙烧温度对提铁脱磷效果的影响(还原时间15 min,C/Fe 0.48,碱度2.4,10%Na2SO4)

Table 5. The effect of roasting time on dephosphorization and Magnetic separation

表5. 焙烧时间对脱磷及磁选效果的影响

宜的还原时间为10 min。

3.4. 球团碱度(CaO/SiO2)

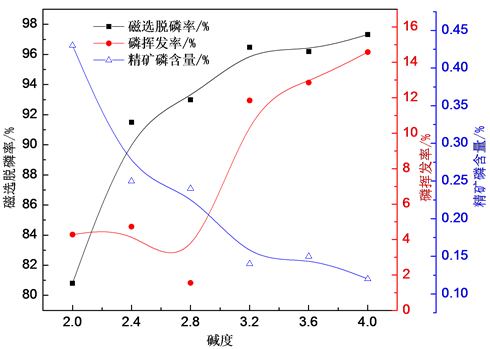

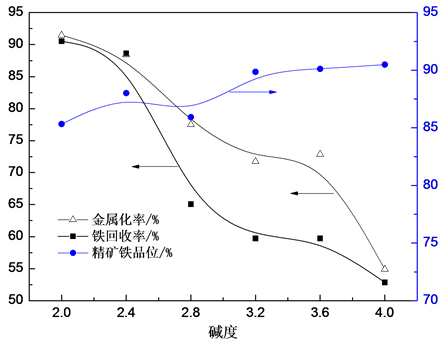

球团碱度对铁与磷分选效果的影响见图5。由图可见,随着球团碱度的提高,金属化率和铁回收率逐渐下降,磁选精矿铁品位缓慢提高,磁选脱磷率逐渐上升,磷挥发率在碱度大于2.8时开始逐渐升高,精矿中磷含量逐渐下降。有研究指出,低碱度条件下,加入的CaO与SiO2结合,提高了FeO的活度,这有利于铁的还原[9] 。但是碱度过高,会导致渣量增加,加入的CaO与矿石中的SiO2、Al2O3等形成高熔点物质,不利于铁相的扩散富集,造成磁选精矿铁品位和铁回收率逐渐下降。综合提铁及脱磷的各项指标,选择适宜的碱度为2.4。

3.5. 添加剂

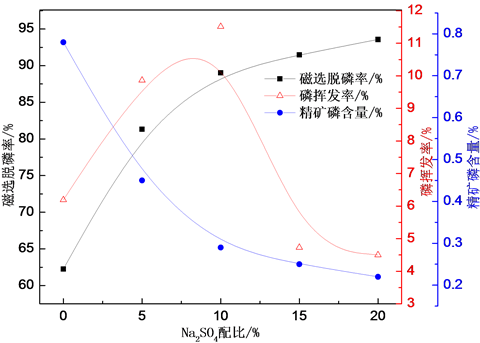

添加剂Na2SO4配比对铁和磷分选效果的影响见图6。由图可知,随着添加剂配比的增加,金属化率缓慢下降,精矿铁品位逐渐上升,加入钠盐添加剂可以为铁的聚集长大提供液相桥,增加了磁选精矿的铁品位,但加入Na2SO4的球团在还原过程中易形成FeS,不利于金属化率的提高[10] ,而且从成本上考虑,添加剂量不宜过高。随着添加剂配比的提高,精矿磷含量逐渐下降,磁选脱磷率逐渐升高,磷挥发率先升高后下降,在配比10%时达到最高值11.51%。有研究表明[8] ,为改善酸性渣的脱磷可加入Na2O代替CaO,一般认为苏达渣脱磷产物为Na3PO4,而Na3PO4比Ca3PO4更加稳定。加入的Na2SO4可与磷灰石、SiO2等在高温下反应生成相应的钠盐,减少了磷灰石的还原。综合提铁与脱磷指标,推荐适宜的添加剂配比为15%。

Figure 5. The effect of basicity on concentration and dephosphorization(Reduction temperature 1350℃, Reduction time 15min, C/Fe 0.48, 15% Na2SO4)

图5. 碱度对提铁及脱磷效果的影响(还原温度1350℃,还原时间10min,C/Fe 0.48,15% Na2SO4)

Figure 6. The effect of Na2SO4 on concentration and dephosphorization (Reduction temperature 1350℃, Reduction time 15min, C/Fe 0.48, basicity 2.4)

图6. Na2SO4配比对提铁脱磷效果的影响(还原温度1350℃,还原时间10min,C/Fe 0.48,碱度2.4)

3.6. 磨选条件

调节磨选条件,结果如表6所示。由表可知,磨选制度对脱磷率影响不大,在磨矿时间10 min、磁场强度为1000 Gs的条件下,磨选后铁回收率可达91.37%,铁精矿品位可达94.06%。

4. 结论

(1) 该铁矿石为典型的高磷鲕状赤铁矿,矿石呈鲕粒结构,鲕粒内矿物嵌布粒度微细,铁矿物与脉石矿物呈环状分布,有用矿物无法单体解离,导致常规选矿方法不能有效脱除磷及富集铁。

(2) 在较强的还原气氛中,磷灰石与赤铁矿都极易被还原,被还原的磷单质挥发脱除率较低,大部分与金属铁反应进入金属铁相。提高球团碱度,形成高熔点物质抑制一部分磷进入铁中。加入钠盐添加剂一方面可以促进铁晶粒的聚集长大,另一方面抑制了部分磷灰石的还原。

(3) 在还原温度1350℃、还原时间10 min、C/Fe为0.48、碱度2.4、Na2SO4配比15%的条件下,通过一段磨选,可获得铁精矿铁品位94.06%、铁回收率91.37%、精矿磷含量0.25%的最佳指标。在较高的

Table 6. Effects of grinding-separation process fineness on the Fe-P separation

表6. 磨选条件对铁磷分离的影响

碱度条件下,铁的金属化率有待进一步提高。

致 谢

感谢湖南省长沙市中南大学资源加工与生物工程学院钢铁冶金系和国家火炬计划基金项目(2011GH 561685)的支持。