1. 引言

问题的提出某型车辆发动机在进行台架试验时,试验进行350 h后有2台发动机出现了缸盖螺栓(见图1)断裂故障,安装的8个螺栓中有3根发生断裂,呈无规律分布。缸头螺栓为摩托车发动机的关键重要安保件,其螺纹部分作为紧固、传力、连接、承载和调整的关键及基础部位[1] ,广泛应用于汽车和摩托车行业中。螺纹的加工方法主要包括滚压法(搓丝板滚压、滚丝轮滚压)和切削法(铣削、磨削、研磨、攻丝等)[2] ,与切削法相比,滚压法具有材料利用率高,经济效益好,机械性能优良等优点[3] ,因此得到了更加广泛的应用,特别是在汽车、航空和航天等高新工业方面。滚压的制造工艺水平和产品质量直接影响此类零部件的质量和使用寿命,其中螺纹滚压参数的合理选择对螺纹滚压件的成形质量至关重要[4] 。螺纹滚压参数包括滚压力、滚压速度和滚压时间[5] ,还有支承端面对轴心线的圆跳动、滚丝轮外圆对轴心线的圆跳动、滚丝轮中心与工件中心距离。

本文对缸头螺栓断裂分析后采用正交试验法在滚丝机上进行实验,分析了主轴转速、滚丝轮进给速度和支承端面对轴心线的圆跳动、滚丝轮外圆对轴心线的圆跳动、滚丝轮中心与工件中心距离、时间六个工艺参数对滚压后的螺纹是否存在折叠的影响,为螺纹滚压实际生产中的工艺方案改进提供技术依据,并为螺纹滚压精密成形的后续研究提供实验依据。

2. 制造工艺流程

研究对象断裂件工艺路线如下:

材料入厂检查→冷镦→热处理(淬火 + 调质 + 回火)→校直→粗磨外圆→清根→精磨外圆→滚丝→套杆→检验→表面处理(镀彩锌)→包装。

3. 试验过程

3.1. 原材料分析

如表1。

Figure 1. The engine cylinder head bolts

图1. 发动机缸盖螺栓

3.2. EDS分析

对断裂件疲劳区进行EDS分析,测试结果如表1所示,EDS分析图谱如图2、图3,从疲劳源区的成分与基材成份对比,Zn含量较高,说明镀Zn前裂纹就存在(表2)。

Table 1. Chemical composition (%)

表1. 化学成分(%)

Table 2. Broken pieces of test results (%)

表2. 断裂件测试结果(%)

Figure 2. Fatigue source area EDS map

图2. 疲劳源区EDS图谱

Figure 3. EDS map base area

图3. 基材区EDS图谱

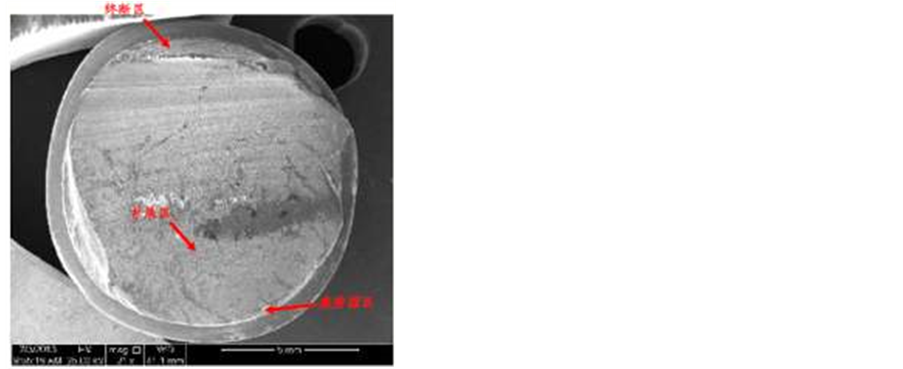

由图4~图7断面金相分析可知,螺纹夹杂物合格,基体显微组织回火索氏体,正常,表面脱碳深度(8.3 um)也符合要求。但疲劳源区螺牙底部存在折叠裂纹(最大长度0.05 mm),裂纹周围无明显氧化,脱碳,且附近螺牙底部都存在这类现象,说明裂纹产生在热处理之后的(滚丝)工序。

Figure 4. Failure surface test color mirrors

图4. 失效面试验彩镜

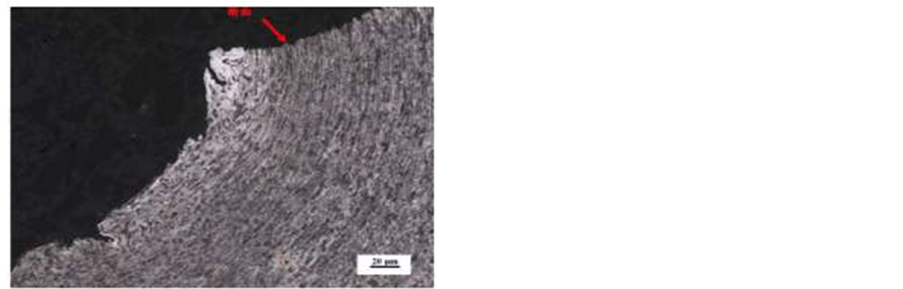

Figure 5. Thread surface microscopic color mirror (50×, water erosion)

图5. 螺纹表面显微彩镜(50×,水浸蚀)

Figure 6. Thread surface microstructure (50×, 4% acid alcohol solution etching)

图6. 螺纹表面显微组织(50×,4%硝酸酒精溶液浸蚀)

Figure 7. Thread surface microstructure (500×, 4% acid alcohol solution etching)

图7. 螺纹表面显微组织(500×,4%硝酸酒精溶液浸蚀)

4. 分析与讨论

失效件化学成分符合GB/T699-1999中45号钢牌号成分规定,失效件芯部硬度及拉伸性能符合客户对该产品的要求。失效件非金属夹杂物、基体区微组织均属正常。虽然螺纹表面脱碳情况符合客户要求,但螺纹部却存在区微折叠裂纹。

经SEM分析,失效面微观形貌呈疲劳特征,属于疲劳断裂。经EDS能谱分析,在疲劳源区发现有较多Zn元素存在,说明该处裂纹产生于镀锌工艺之前。

5. 试验结论

此缸头螺栓件失效属于疲劳断裂主要由于滚丝过程中产生了较多显微裂纹且存在于螺纹底部,极大地降低了螺栓的疲劳强度。建议改进滚丝工艺,定期对生产设备进行校准检验。以确保在螺纹关键部位无折叠裂纹产生。为了改进滚丝机的工艺采用了正交试验方法对滚丝机的工艺参数进行研究。

6. 正交试验的设计

6.1. 实验材料

实验选用45#钢,其性能参数如表3所示。

6.2. 试验设备

本实验所用设备为自制的数控滚轧机。机床型号为ZZ28KJ-20,最大滚轧力为200 kN,单轴进给。滚丝轮为M6x1,45型细牙普通螺纹用滚丝轮。

6.3. 试验方案

用坯料直径设定计算好的试件在滚丝机上滚压M6x1细牙螺纹,不改变设备其他参数,滚丝轮总行程保持相同,滚压过程中保持冷却液开启,通过设置数控系统参数,主轴转速分别取200 rain~、300 min~、400 min~、500 min(注:此转速:勾传动系统电机的转速,而不是滚丝轮的转速);进给速度取35 ram/rain、40 mm/min、45 mm/min、50 mm/min、50 mm/min;支承端面对轴心线的圆跳动取0.01、0.02、0.03、0.04、0.05,滚丝轮中心与工件中心距离mm取−0.3、−0.2、−0.1、0、0.1,滚丝轮外圆对轴心线的圆跳动取0.01、0.02、0.03、0.04、0.05,时间去取1 s、2 s、3 s、4 s、5 s,本试验选L25(56)正交试验方案[6] 。

6.4. 正交试验因子和水平设计

如表4。

6.5. 正交试验结果与极差分析

如表5。

6.5.1. 正交试验结果分析及极差分析

为了便于试验目标的考核,本试验参照了GB/T 90-1985紧固件验收检查、标志与包装(eqvI SO 3269:

Table 3. 45# steel performance tables

表3. 45号钢材性能表

Table 4. Orthogonal test factors and levels

表4. 正交试验因子和水平

Table 5. Orthogonal experimental results (appraisal target, the unit: %)

表5. 正交实验结果(考核目标,单位:%)

1984)、GB/T 1031-1995表面粗糙度参数及其数值(neqI SO 468:1982)、GB/T 2828-1987逐批检查计数抽样程序及抽样表(适用于连续批的检查)、GB/T 3098.1-2000紧固件机械性能螺栓、螺钉和螺柱(idtISO 898-1: 1999)、GB/T 15239-1994孤立批计数抽样检验程序及抽样表、GB/T 5779.3-00紧固件表面缺陷螺栓、螺钉和螺柱特殊要求,螺纹牙底不允许折叠、在螺纹中经以下螺纹牙受力侧面[7] ,即使其起点在中径以上也不允许折叠及尺寸等的合格率作为正交试验的考核目标,螺文合格率以螺纹侧面是否折叠及是否通过通止规的不合格件数与合格件数比表示。

由正交试验结果与极差分析表可知,各因子对镀层中含铬的影响大小顺序为:B > F > E > A > D > C;最佳工艺水平为A2B2C2D1E4F4。

由正交试验结果与极差分析表可看出在影响镀层性能的各因素中,B因子的极差最大,说明转速对滚丝螺纹的质量影响最大,其次是支承端面对轴心线的圆跳动,再次为滚丝轮外圆对轴心线的圆跳动。

6.5.2. 验证试验

为了验证外径正交试验的计算结果,用A2B2C2D1E4F4参数组合进行试验,即进给速度为40 ram/rain,主轴转速为300 min~,精整时间为2 s,滚丝轮中心与工件中心距离为−0.1 mm,滚丝轮外圆对轴心线的圆跳动为0.04,支承端面对轴心线的圆跳动为0.04。通过实验测得该参数下合格率100%,无折叠。同时也对其它参数不同组合进行了6个实验,有3组实验牙底存在折叠,有2组牙侧面中经一下到牙底之间有细小折叠,有1组以中径起点在中径以上有折叠。

验证试验结果表明正交试验的计算分析结果是正确的,因此,若只考虑六因素对外径和牙形折叠的影响,那么A2B2C2D1E4F4合格率最高达100%,为最优方案。

7. 总结

除了上述最佳工艺参数选择以外,造成螺纹折叠的原因还有下列原因:

1) 螺纹线未正确调整,动静搓丝板未匹配;2) 将工件置于两搓丝板间时压力过大(开始加工螺纹时)。当压力过大时螺栓开始滑移而非旋转,当螺栓开始滑移时就产生了折叠(两搓丝板间距离太近);3) 如果不同批的零件同一部分螺纹坯径不均匀也会引起序号1及2描述中所产生的折叠 = 尽可能在同一台设备上镦制并且在一个单独的螺纹设备上加工。由一台设备加工成形(带螺纹)会更好些。这样会确保螺纹坯径不会有变差;4) 加工螺纹时压力不足.其产生原因是两搓丝板距离过远时;5) 不正确的引入(过迟或过早)是因为送料板过长,过短,错误的形状;6) 送料时间与搓丝板的运动时间(过早过晚)不匹配;7) 螺纹坯径是锥形时引起工件不能直接引入到搓丝板间;8) 毛坯杆弯会引起工件不能直接引入到搓丝板间。

8. 结论

1) 从实验数据来看,在其他条件相同的情况下,主轴转速、进给速度、滚丝轮外圆对轴心线的圆跳动、时间、支承端面对轴心线的圆跳动、滚丝轮中心与工件中心距离这六个因素对螺纹外径是有影响的。

2) 影响外径的主要因素是主轴转速,说明转速对滚丝螺纹的质量影响最大,其次是支承端面对轴心线的圆跳动,再次为滚丝轮外圆对轴心线的圆跳动。

3) 六个参数得到优化后,才能保证不出现螺纹折叠。

4) 需严格执行作业标准和设定的工艺参数。