1. 引言

ZnS是一种重要的宽带隙Ⅱ-Ⅵ族半导体材料,在电学、磁学、光学、力学和催化等方面呈现出许多优异的性能,引起了研究者广泛的关注[1] -[5] 。在摩擦学领域中,由于ZnS具有密排六方层状结构,层间剪切力较小,易沿密排面滑移,可以明显改善摩擦副间的摩擦行为,起到减摩耐磨作用,是有效的固体润滑剂之一。司洪娟等人采用纳米电刷镀技术在淬火后45钢表面制备Zn涂层,并对其进行低温离子渗硫处理在其表面得到ZnS固体润滑层表现出良好的减摩性能[6] [7] 。近年来,油溶性ZnS纳米粒子被用作润滑油添加剂,因其能够有效地提高润滑油的减摩抗磨能力,在润滑油纳米添加剂领域被广泛地研究[8] -[12] 。

近来,有人尝试采用水热法在金属表面制备高性能的减摩耐磨薄膜[13] 。水热法是指在特制的密闭反应器(如高压釜)中,采用水溶液作为反应体系,通过对反应体系加热,利用水的自生蒸气压,从而创造一个相对高温高压的反应环境,使通常难溶或不溶的物质溶解并且重结晶而进行无机合成与材料处理的一种有效方法,研究表明,采用水热法制备的纳米材料具有纯度高、分散性好、尺寸均匀、分布窄、无团聚、晶型好、形貌和形状可控等特点[14] ,此外,与其他制备方法相比,水热法具有设备简单,操作方便,成本低廉等诸多优点。特别是采用水热技术在金属表面可一步制备诸如氧化物、硫化物、磷酸盐等薄膜,这里金属基底既作为反应物参与水热反应,同时为相应薄膜的生长提供支持,这极大地增强薄膜与基底的结合强度,同时通过改变水热剂的化学组成可方便实现对薄膜表面形貌的调控。尽管目前有一些文献中曾报道利用水热法在材料表面构筑具有不同形貌的ZnS薄膜,但研究大多仅限于对于薄膜的光致发光等性能的研究[15] -[18] ,很少有人关注ZnS薄膜的机械及摩擦学性能。基于此,本文中,我们在金属锌表面利用水热反应一步制得的ZnS薄膜,并对薄膜的表面形貌、润湿性能及结构组分进行了研究,重点考察了干摩擦条件下ZnS薄膜的摩擦学性能。

2. 实验部分

2.1. 薄膜的制备

切取2 × 2 × 0.25 cm的金属锌片,先后用乙醇和去离子水超声清洗10 min,氮气吹干。将锌片与0.72 g硫脲及40 ml水合肼(7.7%体积比)一起放入容积为50 ml的聚四氟乙烯为衬里的反应釜中180℃下反应8 h,自然冷却至室温。取出金属锌片,分别用乙醇和去离子水冲洗,氮气吹干后备用。

2.2. 薄膜的表征

用Bruker D8 advance型X射线衍射仪对薄膜的结构组成进行分析;用CAM101型接触角测定仪测量薄膜的润湿性能;用Hitachi S-3500N型扫描电子显微镜观察薄膜的表面形貌。利用UMT-3多功能摩擦磨损试验机测定薄膜的摩擦学性能,对偶件为Φ4 mm的GCr15轴承钢球。每次摩擦测试前将上下试样置于乙醇中超声清洗3分钟,每次测试换用新球或换用新的接触面,每个试验组测试3次,最后计算其平均值。实验过程中的摩擦系数由计算机自动记录。实验在室温(20℃~−25℃)、大气环境(相对湿度为40%~50%)条件下进行。采用的实验参数为:载荷为0.5 N,往复行程6 mm,滑动速度24 mm/s。

3. 结果与讨论

3.1. 薄膜的表征

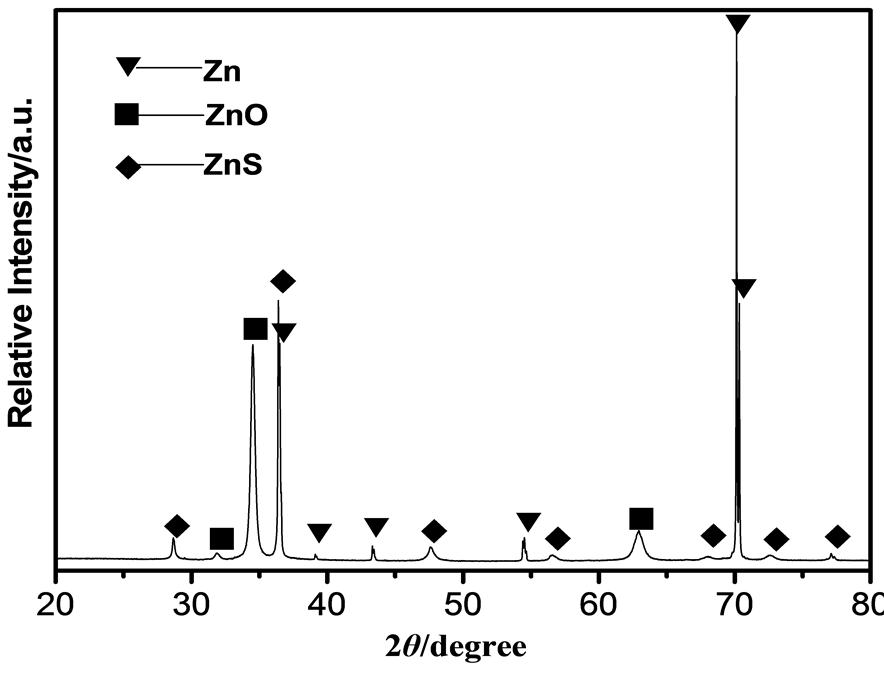

图1给出了金属锌经水热反应得到的ZnS薄膜的XRD图。由图1可以看出:除来自于衬底锌的衍射峰外,其它主要衍射峰可以按照标准衍射卡片指标化为ZnS的衍射峰,另外还有少量ZnO的衍射峰,说明经水热处理后在金属锌表面生成了一层含ZnO的ZnS薄膜。

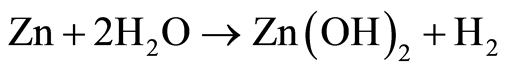

在金属锌表面生成ZnS薄膜的反应机理示于图2中。研究表明[18] ,在水热反应过程中,由于金属

Figure 1. XRD pattern of ZnS film

图1. ZnS薄膜的XRD图

Figure 2. Hydrothermal formation mechanism of ZnS film on the Zinc substrate

图2. 金属锌表面ZnS薄膜的形成机制

锌比较活泼,锌与水合肼中的水分子在升温的初期发生反应,生成Zn(OH)2。Zn(OH)2与硫脲进一步发生络合反应,得到的络合物在180℃加热环境下是不稳定的,会发生分解,得到产物ZnS。

图3(a)和图3(b)分别给出了水热处理前后的锌表面的SEM照片,可以看出未经水热处理的锌片表面光滑,表面上无特殊结构;经过水热反应后,在锌表面上生长了大量的硫化锌颗粒,颗粒的尺寸大约在0.5 μm。

我们同时研究了金属锌片在水热反应处理前后表面润湿性的变化。用3.5 μL的水滴分别滴在被测试样品表面的五个不同位置,测试水滴与表面的接触角并取算术平均值,作为表面与水的接触角。如图4(a)所示,经过超声清洗并氮气吹干后的金属锌表面与水的接触角为67˚,表现出一定的亲水特性;经水热制备的ZnS薄膜与水的接触角为90˚(如图4(b)),表现出疏水性能。显然,由微纳米颗粒组成的ZnS薄膜粗糙结构对于表面存储空气以排斥水的润湿起到了一定的作用。

3.2. 薄膜的摩擦学性能

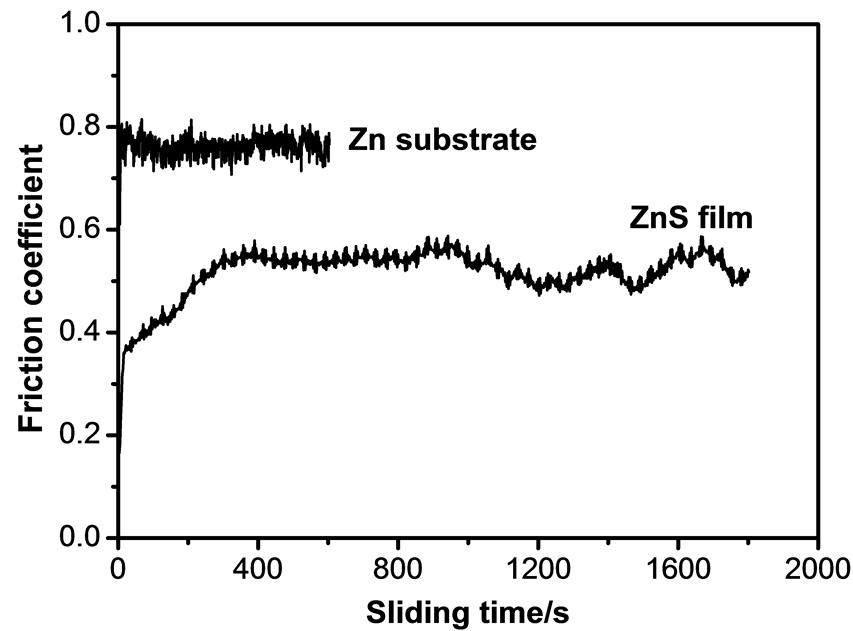

采用UMT-3试验机对制得的ZnS薄膜的摩擦学性能进行了表征。图5给出的水热处理前后的锌表面摩擦系数随滑动时间的变化曲线。可以看出:对于未处理的金属锌,起始的摩擦系数为0.1左右,经过短暂的磨合期后,摩擦系数迅速上升并维持在0.8左右。而ZnS薄膜的起始摩擦系数也为0.1左右,在随后的400 s的滑动中,摩擦系数缓慢上升,随后稳定在0.5左右,直至1800 s中止实验。实验结果表明在金属锌表面制备的ZnS薄膜具有明显的减摩效果,对基体起到了保护作用。

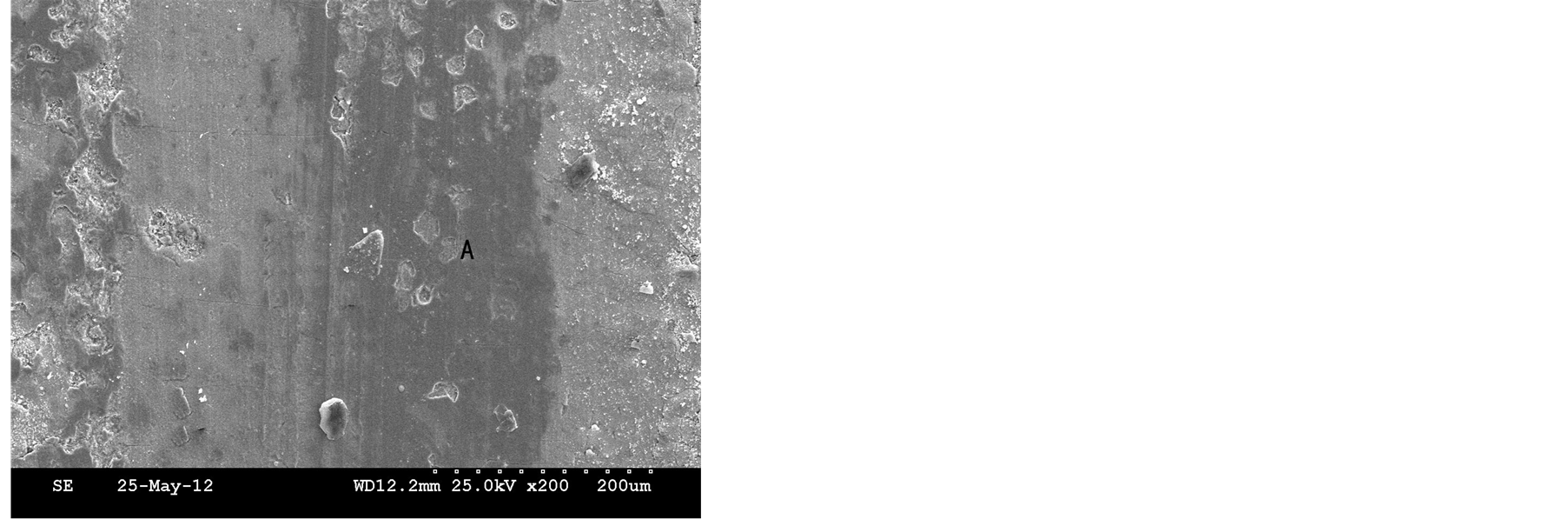

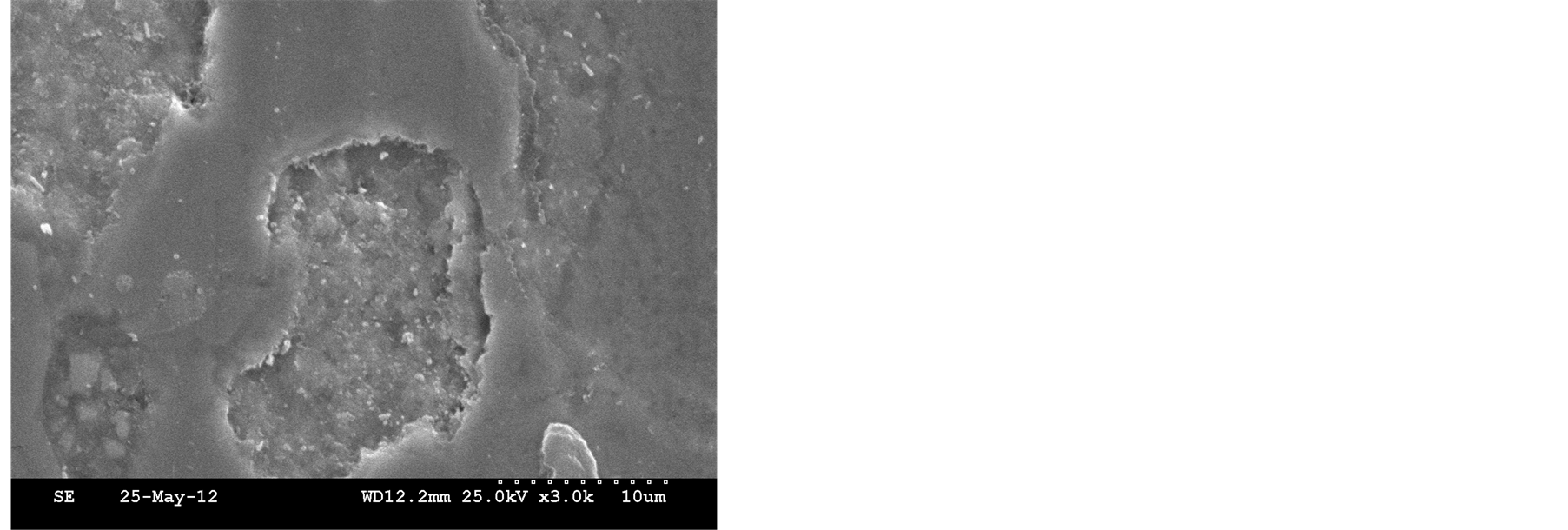

图6给出金属锌及ZnS薄膜滑动结束后的磨痕表面形貌的SEM图片。由图6(a)可见:对于金属锌,

(a) Zn (b)ZnS 薄膜

Figure 3.SEM micrographs of test samples

图3. 测试样品的SEM照片

(a) Zn (b)ZnS 薄膜

Figure 4.Images of water droplet on the surface of test samples

图4. 测试样品表面上水滴的照片

Figure 5. The function of friction coefficient as sliding time for test samples

图5. 测试样品的摩擦系数随滑动时间的变化曲线

(a)Zn sunstrate after 600 s sliding(b)Zinc sulfide film after 1800 s sliding(c)Magnifying image of spot “A” in (b)

Figure 6.SEM micrographs for worn track

图6. 磨痕表面的SEM照片

经历600 s的滑动后,材料产生了严重的磨损,磨痕的平均宽度为478 μm,表面存在明显塑性变形,形成大量磨粒擦伤引起的犁沟,同时磨痕中存在细小磨粒粘附。而硫化锌薄膜经过1800 s的滑动后,磨痕的平均宽度只有395 μm (图6(b)),比滑动只有600 s的金属锌的磨痕相对要窄,磨痕表面较为光滑,只可见因轻微擦伤形成的浅而细的犁沟,这与其较低的摩擦系数相一致。同时,从其磨痕的照片中可以看到许多类似“斑块”的结构,将图6(b)中标有“A”处的“斑块”放大后发现,依然有硫化锌颗粒未遭到破坏(图6(c))。这进一步证明了制备的ZnS薄膜可以有效增加表面的耐磨性能,进而对基底起到了保护作用。

4. 结论

1) 通过水热反应,在金属锌片可一步构筑ZnS薄膜,薄膜由尺寸在0.5 μm的微纳米颗粒组成了一定的粗糙织构;

2) ZnS薄膜的接触角达到90˚,表现出疏水性能。这是由于微纳米颗粒组成的ZnS薄膜粗糙结构对于表面存储空气以排斥水的润湿起到了一定的作用;

3) ZnS薄膜的起始摩擦系数为0.1左右,在随后的400 s的滑动中,摩擦系数缓慢上升,随后稳定在0.5左右,直至1800 s中止实验,表现出了减摩耐磨特性,对基底起到了明显的保护作用。

致 谢

山东省自然科学基金(ZR2012EEL10)资助项目。

NOTES

*通讯作者。