1. 引言

轧辊是轧钢厂消耗量最大的配件之一,轧辊在使用后常见修复方法有重车法和堆焊法来达到修复孔型,但重车和堆焊都有一定的缺憾:重车以牺牲轧辊外径为代价,直至使用到最小辊径为止;而堆焊则易出现裂纹或表面硬度不均等缺陷。现提出采用激光熔覆修复轧辊的方法,提高轧辊的重复使用率,以达到降低生产成本的目的。

2. 材料的准备及实验方法

2.1. 基材准备

利用线切割切取20 × 40 mm的半钢轧辊小样8件,其半钢轧辊的成分见表1。

2.2. 金属陶瓷超细复合粉末的准备

为了改善轧辊表面涂层与基材之间的结合强度,选用金属陶瓷超细复合粉末,以获得高耐磨性的复合涂层,金属陶瓷超细复合粉末的配比见表2。

2.3. 实验方法

按照Y2O3的含量:0 wt%、0.5 wt%、1.0 wt%、1.5 wt%、2.0 wt%、2.5 wt%、3.0 wt%配制复合粉末,按配备好的合金粉末成分,在玛瑙研钵中碾磨2 h以上,使之充分均匀混合。将试样用打磨机打磨以除去表面的氧化膜,然后用丙酮清洗。在常温下将配制好的熔覆层粉末均匀涂敷于表面,厚度约1.2 mm左右。

采用高功率密度(104~105 W/cm2)的激光,在极短的时间内(10−2~10−3 s)合金粉末与基体表层金属快速交互作用,使金属表面局部区域在瞬间被加热到相当高的温度使之熔化后,借助冷态金属基体的吸热和传导作用,使得已熔化的表层金属快速凝固。熔凝得到细小的铸态组织,从而构成一种新的复合材料。熔覆层具有抗氧化性、抗热裂性、高硬度和耐磨性,充分发挥基体与合金粉末的优势,弥补相互间的不足[1] -[3] ,获得了较好的合金熔覆层。

3. 实验结果与分析

3.1. 激光熔覆修复工艺

工艺流程:线切割轧辊基材→打磨基材→丙酮清洗打磨部位→涂敷熔覆层,厚度约1.2 mm→激光熔覆。

确定激光熔覆工艺参数:宽带,功率3.0 kw,速度3 mm/s。

3.2. 熔覆层组织分析

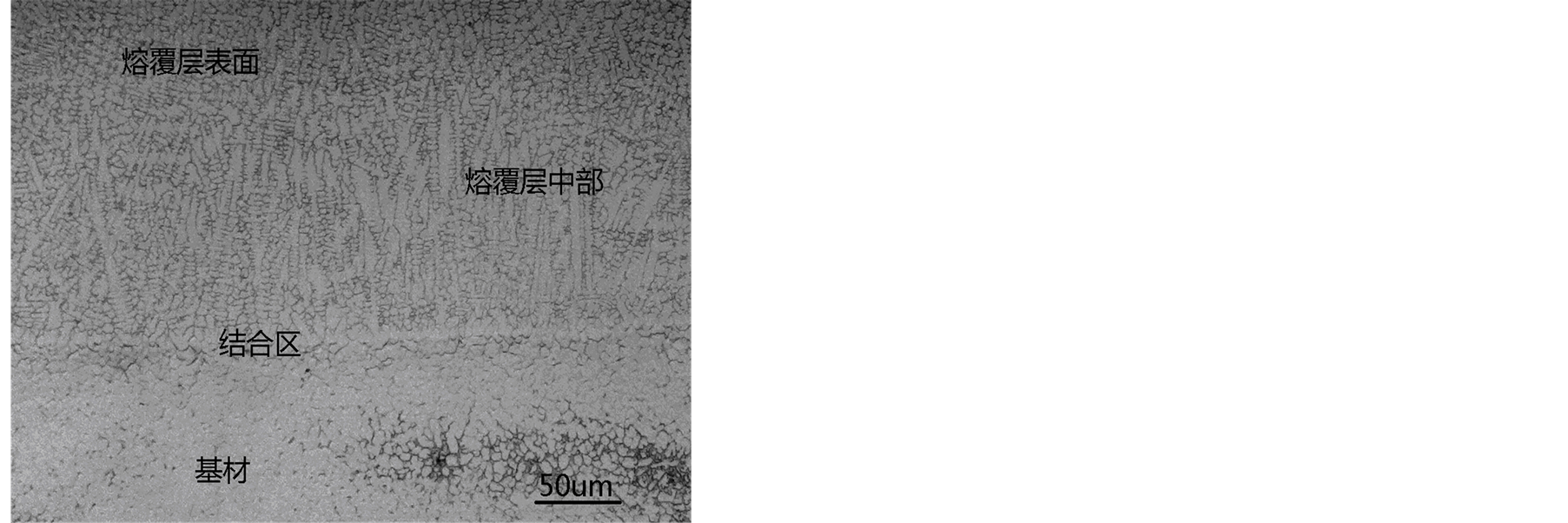

根据激光熔覆工艺得出其熔覆层的形貌如图1所示,由里及表依次为基材→结合区→熔覆层底部→

Table 1. The chemical composition of base material semi-steel roller (wt%)

表1. 基材半钢轧辊的化学成分(质量百分比%)

Table 2. Ultrafine metal ceramic composite powder proportion (wt%)

表2. 金属陶瓷超细复合粉末配比(质量百分比%)

Figure 1. The rupture in the cladding layer 500×

图1. 熔覆层内的组织形貌500×

熔覆层中部→熔覆层表面,可以看出结合区为白亮组织,在靠近结合区的熔覆层底部为胞状晶和柱状晶,在熔覆层中部一般为细小的树枝晶,靠近表层为细小等轴晶。

对熔覆层组织观察可以看出,温度梯度与凝固速率决定着凝固组织的形貌[4] -[6] ,白亮带的形成是在激光熔覆过程中,由于熔池与冷金属接触,冷速很快,凝固首先以无晶核的方式直接在基底上通过晶体外延附生的方式生长出一层平面晶。随着结晶过程的进行,过冷区的存在破坏了平面的稳定性,从而向两侧和前沿排出溶质,不稳定的平坦固/液界面就破裂成一种稳定的的胞状晶。随着过冷区变宽,晶粒就转化成了柱状枝晶,在金属溶液内形成大量的晶核,导致晶粒自由生长而形成了等轴晶。

3.3. 稀土氧化物Y2O3的含量对熔覆层组织的影响

图2分别为a~g号试样熔覆层中部的显微组织,由图可知:添加稀土氧化物的熔覆层组织(b~g)均比未添加稀土氧化物的熔覆层组织(a)细小。由图2进一步看出,(c)相对于(b、d、e、f、g)而言,晶粒更细化一些;(e、f)相对而言,组织又变得略粗大。总体而言,当Y2O3含量在1.0 wt%时,熔覆层组织最细小。

Y2O3的微量的活性Y3+离子易吸附于晶核表面,阻碍晶粒的长大,细化枝晶组织,抑制结合区的柱状晶。但过量的Y3+离子会降低熔池中液态合金的流动性,Y3+离子与杂质元素形成的难熔化合物不易从熔池中上浮,在熔覆层的晶界处发生偏聚,使得熔覆层晶粒变得较粗大。

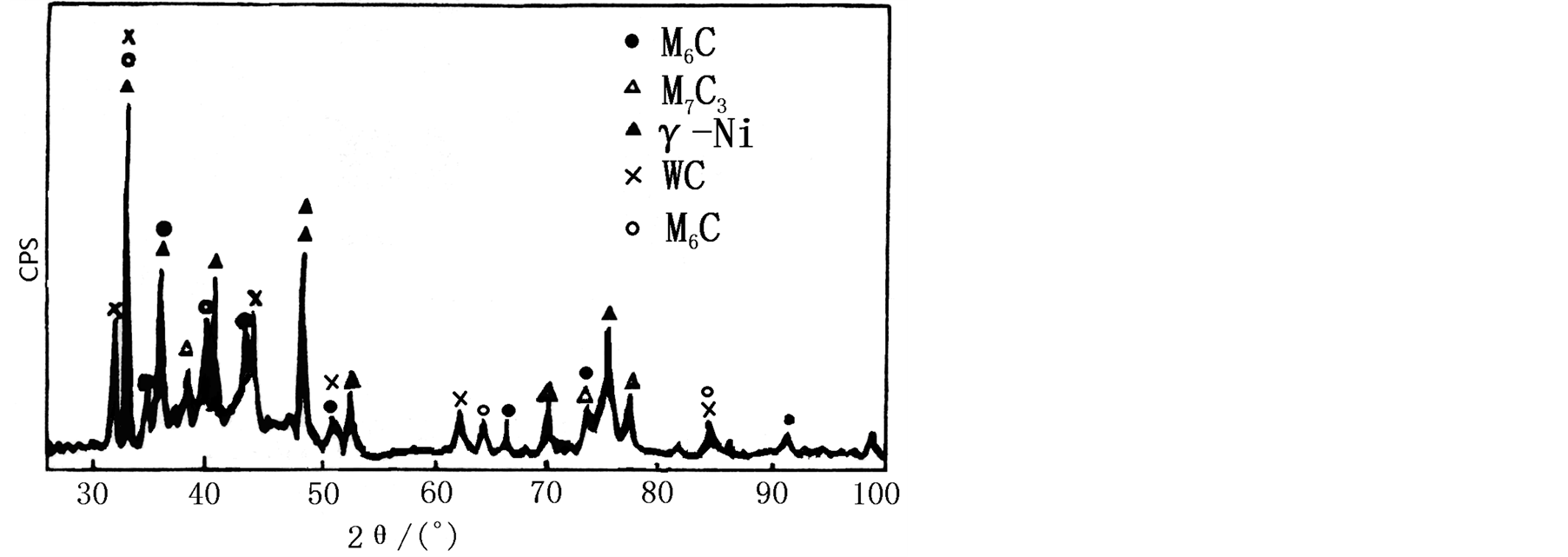

3.4. 激光熔覆涂层组织组成

图3为复合涂层中部的X射线衍射结果,可以看出,复合涂层相组成为M6C、γ-Ni、Ni3B、M7C3、WC以及W2C。

图2. Y2O3对熔覆层组织的影响200×

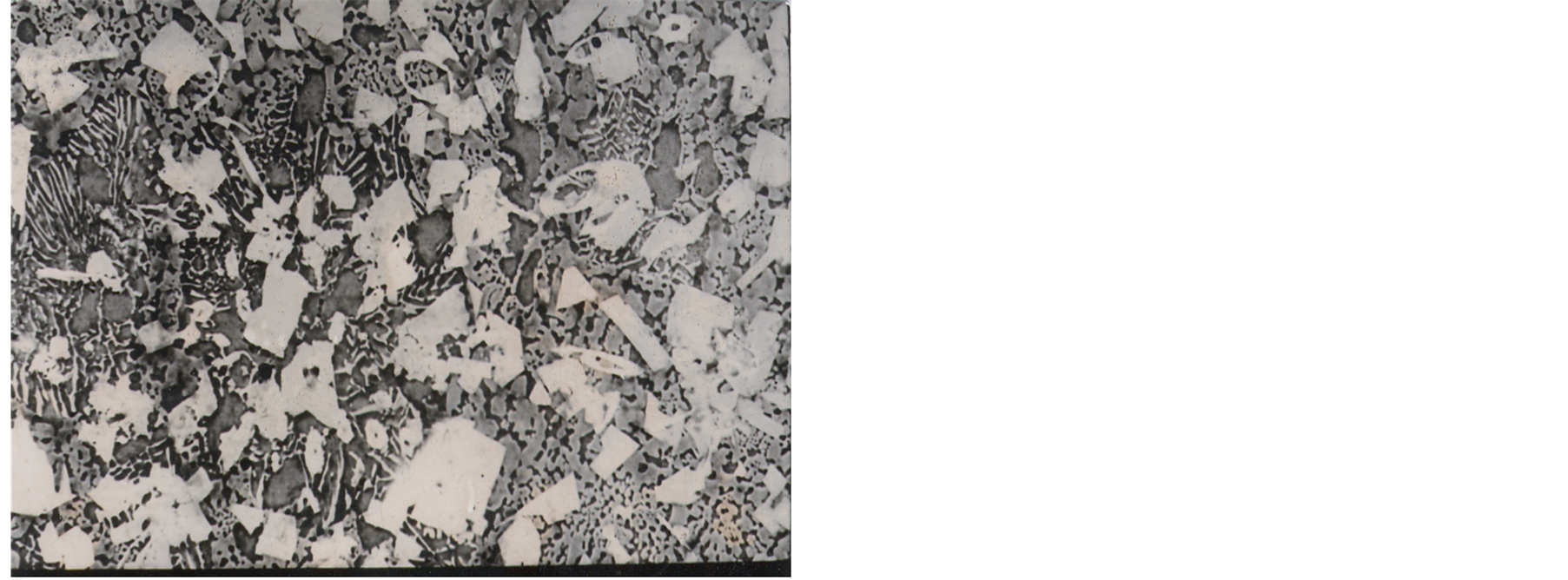

图4为复合涂层内组织形貌,可以看出,涂层内主要为基体组织γ-Ni,基体组织γ-Ni上分布着凝固结晶析出的不同尺寸大小的合金碳化物。这些碳化物加强了与周围Ni基合金基体组织之间的结合强度,有助于提高复合涂层的综合机械性能。

结合X射线衍射分析,能谱分析及显微硬度分析结果,可以确定基体组织为γ-Ni,不规则的白色块状析出物为M7C3及M6C,白色三角形析出物为WC,深灰色析出物为W2C。

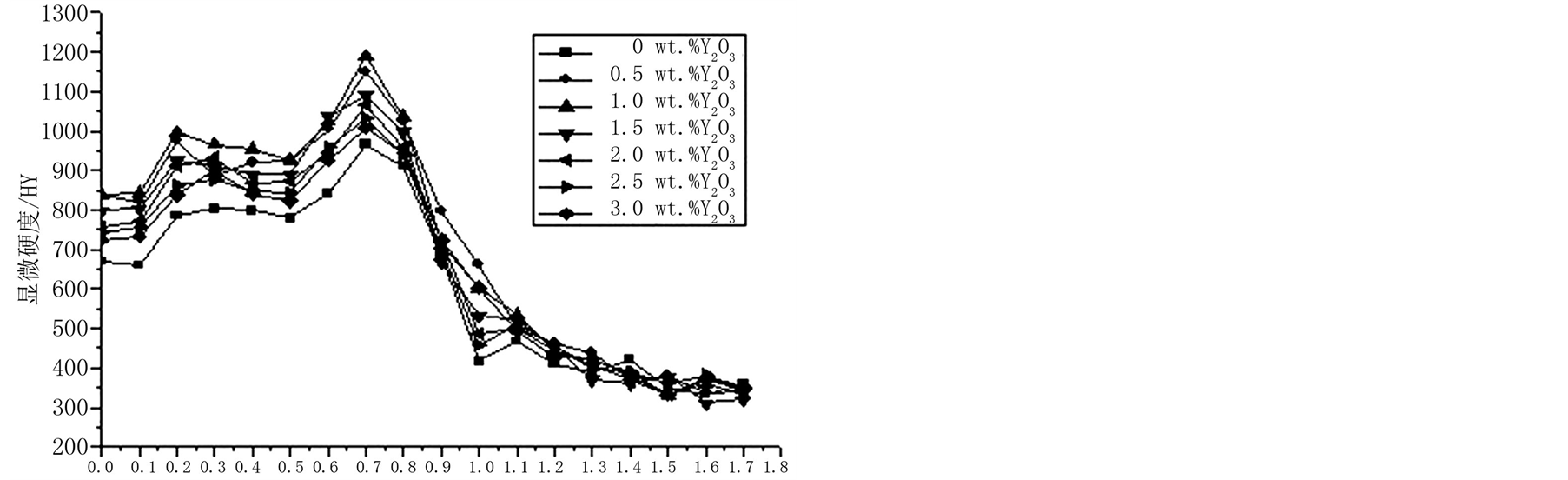

3.5. 激光熔覆涂层的显微硬度分析

试样基材及熔覆层的显微硬度值如表3,其熔覆层显微硬度分布曲线如图5所示。

由图可知,当Y2O3添加量在0~3.0 wt%变化时,随着Y2O3含量的增加,熔覆层硬度值逐渐变大,当Y2O3含量在1.0 wt%时,硬度值最高,然而,当Y2O3含量大于1.0 wt%时,熔覆层的硬度值随着Y2O3含量的增加而降低。

当Y2O3含量在1.0 wt%时,熔覆层组织最细,在激光熔覆层中出现含稀土化合物的硬质相,对提高熔覆层硬度有一定的作用[7] 。

3.6. 耐磨性分析

在MMS-2A屏显摩擦磨损试验机上进行摩擦磨损试验。表4是磨损前后质量的变化。

Figure 3. XRD results in central coating

图3. 涂层中部X射线衍射结果

Figure 4. The rupture in the composite coating

图4. 复合涂层内组织形貌

Figure 5. Microhardness distribution of the coating

图5. 熔覆层显微硬度曲线

Table 3. Substrate and the cladding layer microhardness

表3. 基材及熔覆层显微硬度(HV)

Table 4. Quality changes before and after wear and tear

表4. 磨损前后质量的变化

由表可知,加入Y2O3后,激光熔覆层的耐磨性能得到了显著的改善。a试样磨损量最大,耐磨性最低;Y2O3含量为1.0 wt%的C试样磨损量最小,耐磨性最高;可以看出,熔覆层的组织、硬度与耐磨性有较好的对应关系。

4. 结论

采用激光熔覆技术,对磨损轧辊进行熔覆修复,通过实验研究及应用,取得了如下的结论:

1) 成功配制激光熔覆修复轧辊的合金粉末材料,在加入1.0 wt%的Y2O3合金粉末材料激光熔覆后,硬度、耐磨性能得到了显著的改善。

2) 激光熔层由里及表依次为基材→结合区→熔覆层底部→熔覆层中部→熔覆层表面,可以看出结合区为白亮组织,在靠近结合区的熔覆层底部为胞状晶和柱状晶,在熔覆层中部一般为细小的树枝晶,靠近表层为细小等轴晶。

3) 熔覆层由M6C、γ-Ni、Ni3B、M7C3、W2C以及WC组成,熔覆层中存在的这些物相对提高熔覆层的硬度、耐磨性、抗高温氧化性起到了积极的作用。