1. 引言

转子是双螺杆压缩机的核心,是本文主要的研究对象,也是压缩机设计和建模的重点与难点。阳螺杆的优化设计首先要根据转子的型线来进行研究。目前有比较优秀的压缩机螺杆转子型线SIGMA型线、ECOSCREW型线复盛型线SRM-D型线、χ-II型线JLB型线等,这些主要采用圆弧、椭圆等及其包络线光滑连接而成,它们都被一些外国的螺杆压缩机公司所掌握[1] 。

近几十年来我国相继引进了大、小多套螺杆压缩机系统,在一些系统上,如丁二烯抽提装置、苯乙烯装置、火炬气回收系统、低温制冷系统等都相应地选用了一些国外专业生产厂家,如英国的豪顿(HowDNE)、日本的神钢(KOBESTELL)、德国的戈哈哈(GHH)、美国的A-C公司生产的螺杆压缩机组,这些机组的设计、制造技术代表了目前世界上螺杆式压缩机的先进水平,而我们对这些机组的认识也走过了相当一段路程[2] [3] ,在设备选型、使用、检修上都曾出现过各种失误,原因就是我们对其原理、结构、特性等存在着认识上的不足。我国在转子的型线设计上的整体水平也相对落后。“单边不对称摆线–销齿圆弧型线”,是我国的国标型线[4] -[7] 。在采用类似于外国的一些型线技术时,虽然有消化吸收后推导出新的型线,但是在综合性能方面我国与外国还是存在着比较大的差距。

经过人们多年对螺杆转子的理论分析和试验研究,通过不断的总结,可以定义出如下的螺杆转子型线的初步设计原则,在设计的初期,应尽量满足以下要求和条件[8] [9] :

(1) 压缩机螺杆转子存在一对阴阳转子,为了得到型线的啮合要求,则其转子型线上的组成齿曲线要是共轭曲线,且满足啮合定律。即型线任何位置的接触点的共法线一定通过节点。

(2) 转子之间的接触线长度应较短并且连续。连续的接触线意味着转子间没有间隙,而为了减少压缩气体的泄漏,减少间隙,转子型线的接触线应保持连续。但是在实际情况中,不可能出现这种情况,因为如果没有间隙,转子在运动时会发生干涉,为了防止这种干涉,转子间一定会有间隙。这个间隙带对应着理论上的接触线,为了减少间隙带上气体的泄漏,接触线长度应该尽量缩短。

(3) 在转子型线生成完成后,会出现一个泄漏三角形,这个泄漏三角形会导致气体的泄漏,使得压缩机的性能受到影响,所以要尽量使设计得到的转子型线上的泄漏三角形的面积尽量小。

(4) 应使的压缩机吸气端口处的封闭容积尽量小。由于封闭容积的存在,影响着螺杆压缩机的一些性能,如增加了功耗、增大了噪声等。所以在设计转子型线时,就应当把如何减小封闭容积考虑在内。

(5) 另一个型线要素齿间面积在设计转子型线时,应考虑将其尽量的增大。在压缩机的工作过程中,压缩的气体都存在于齿间面积中,其大小能够反映出压缩机的工作效率,同时齿间面积越大,其压缩的气体也就越多,这样的话泄漏的气体对整个压缩过程来说影响将减小[10] [11] 。

2. 圆弧包络线的相关方程的推导

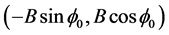

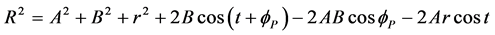

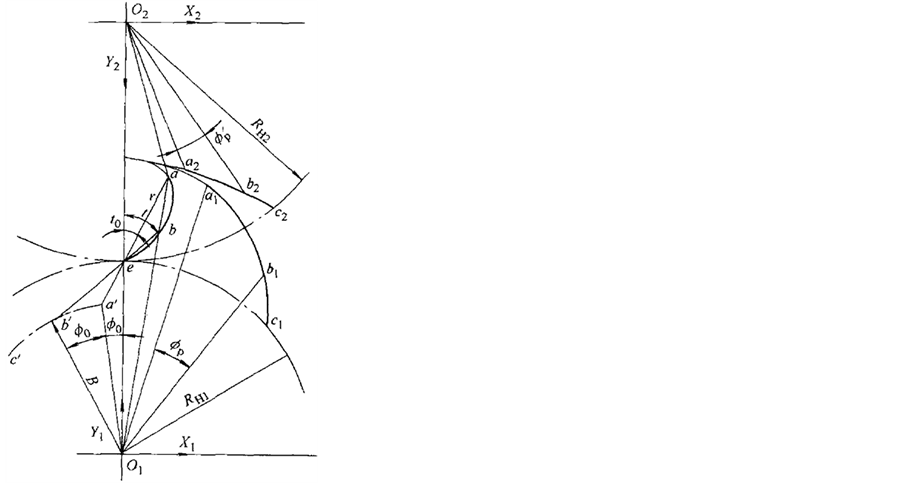

如图1、图2所示,发生圆半径为 ,螺杆I的节圆半径

,螺杆I的节圆半径 ,

, ,螺杆2的节圆半径为

,螺杆2的节圆半径为 包络半径为r,摆点半径为B,即包络圆弧的圆心为

包络半径为r,摆点半径为B,即包络圆弧的圆心为 ,发生圆的发生圆的转动角度为

,发生圆的发生圆的转动角度为 [12] -[14] 。

[12] -[14] 。

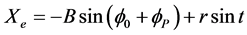

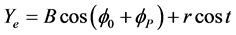

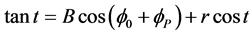

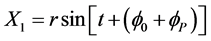

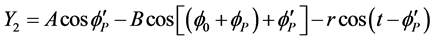

圆弧的包络线的啮合线是abc,不论 角度如何,圆半径r都需要经过节点e。因此圆弧包络线的啮合方程式为:

角度如何,圆半径r都需要经过节点e。因此圆弧包络线的啮合方程式为:

(1)

(1)

(2)

(2)

其中

(3)

(3)

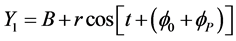

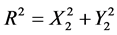

螺杆I的圆弧包络线 的方程是从啮合线方程旋转回

的方程是从啮合线方程旋转回 角度,表示在坐标系

角度,表示在坐标系 上的方程为:

上的方程为:

(4)

(4)

(5)

(5)

显然,上面参数方程是一圆弧形。转角 从0变化到

从0变化到 ,其中:

,其中:

(6)

(6)

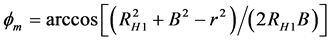

螺杆II的圆弧包络线 的方程是从啮合线方程旋转回

的方程是从啮合线方程旋转回 角度,表示在坐标系

角度,表示在坐标系 上的方程为:

上的方程为:

(7)

(7)

(8)

(8)

其中:

(9)

(9)

上述结果与文献[1] 中的包络法推导结果一样,但用包络条件则要复杂得多。

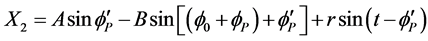

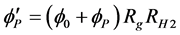

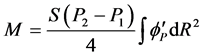

设计从动螺杆的齿形,希望其气压扭矩总和M等于零或稍小于零,因此需要计算圆弧包络线的气压扭矩。

从上面推导过程可看到圆弧包络线的齿形断面积与啮合线面积之差为 ,因此其气压扭矩为:

,因此其气压扭矩为:

(10)

(10)

式中: 为压差,S为螺杆的长度,

为压差,S为螺杆的长度, ,经推导得:

,经推导得:

(11)

(11)

Figure 1. Envelope of short arc

图1. 短圆弧包络线

Figure 2. Envelope of long arc

图2. 长圆弧包络线

3. 双螺杆压缩机流场模型的建立

阴阳转子相互配合,由阳转子带动阴转子转动。设计出转子端面的型线后,分别结合螺旋角、轴径等的相关参数建立出螺杆的三维模型,将端面型线以旋转中心为轴线沿着螺旋扫掠,即得到了螺杆转子的三维模型,改进后的螺杆实体模型如图3所示,参数如表1所示。

利用布尔运算建立双螺杆压缩机的流场模型,其中包括出气口流场、压缩机螺杆腔流场和排气口流场,如图3(a)~图3(f)所示。利用三维软件将其装配,得到双螺杆压缩机三维流场模型,如图3(e)所示。

再将三维模型以parasolid文件导出,得到可以让Gambit处理的文件。利用前处理Gambit软件对其进行前处理。分别将三个流场的相应接触面定义为interface,来实现各部分流场之间的连通。然后对其进行网格划分。划分结果如图3(f)所示。三个流场区域的网格单元数量及网格划分方法如表2所示[15] -[17] 。

4. 双螺杆压缩机流体动力学分析

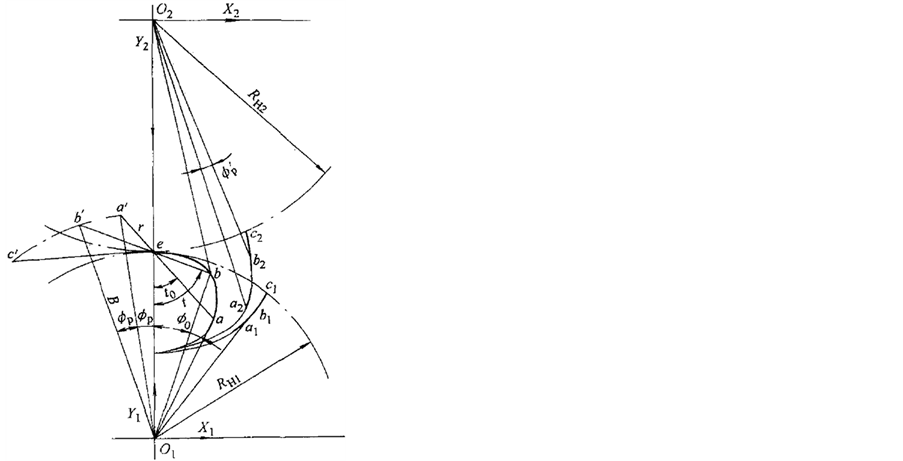

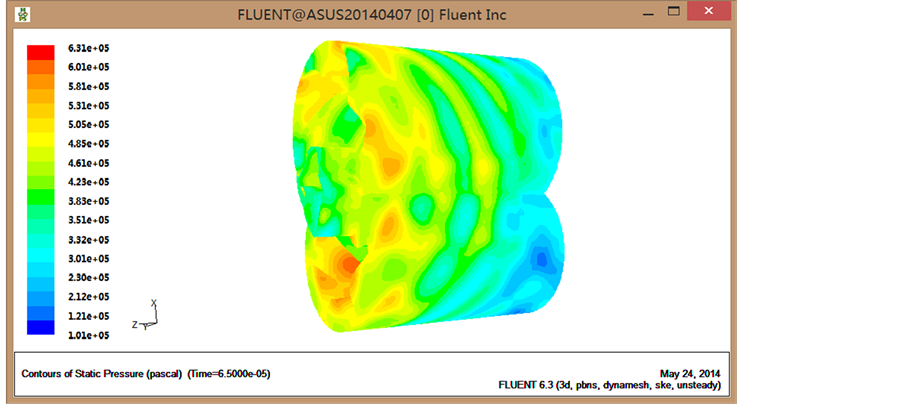

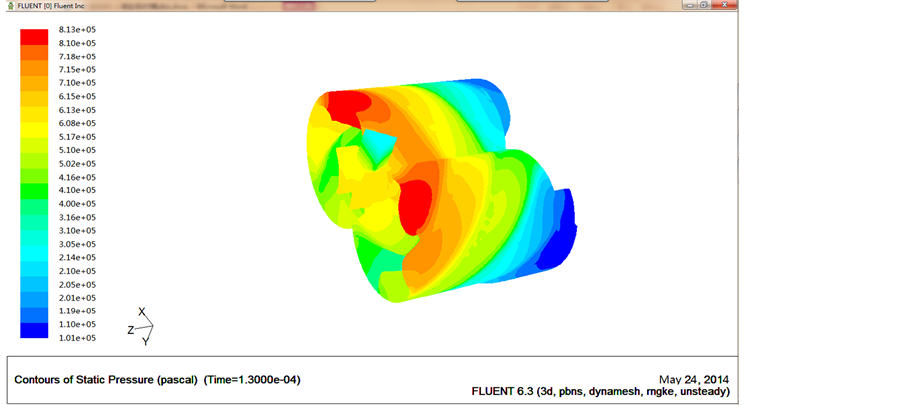

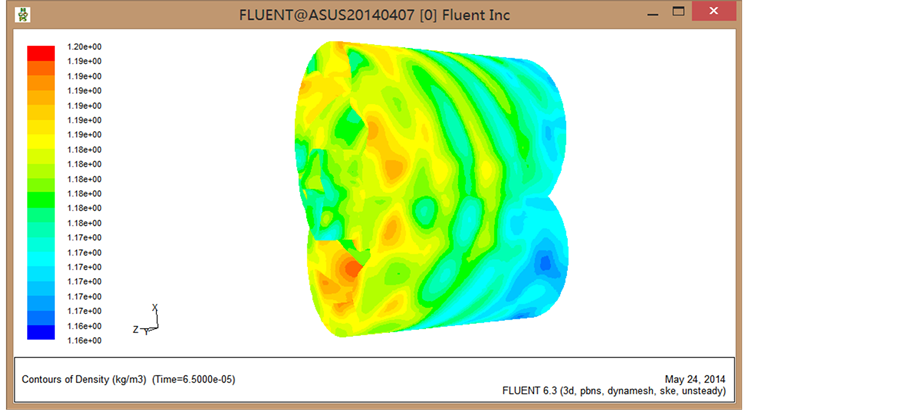

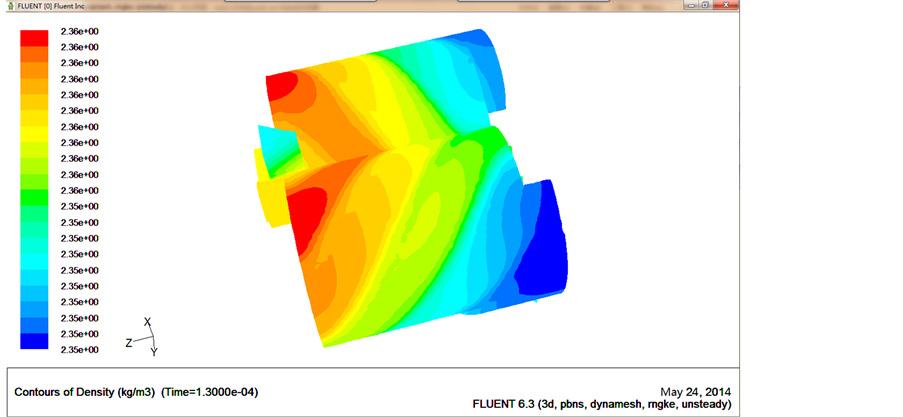

用专业流体分析软件Fluent对双螺杆压缩机内部流场进行数值仿真分析,转子工作转速为3000 r/min,并对其他相关参数进行设置。设计出的圆弧包络线双螺杆压缩机转子型线与边不对称摆线-销齿圆弧式双螺杆压缩机转子型线与新型线的流场压强分布规律如图4所示。

综合上面的4(a)~4(d)几张图片分析和表3比较结果来看,在同等仿真环境和参数设置中改进后的型

Table 1. The relevant data of male & female rotor profiles’ measurement and modeling

表1. 阴阳转子的型线测量与建模的相关数据

Table 2. The parameters of meshed fluid model

表2. 流体模型网格划分参数

(a)

(a) (b)

(b) (c)

(c) (d)

(d)

Figure 4. The results of the twin-screw compressor flow field analysis: (a) The pressure distribution in the compressor before improvement; (b) The pressure distribution in the compressor after improvement; (c) The fluid density distribution in the compressor before improvement; (d) The fluid density distribution in the compressor after improvement

图4. 双螺杆压缩机流场分析结果:(a) 改进前压缩机内压力分布图;(b) 改进后压缩机内压力分布图;(c) 改进前压缩机内流体密度分布图;(d) 改进后压缩机内流体密度分布图

Table 3. The contrast of the twin-screw compressor flow field analysis before & after improvement

表3. 改进前后流体分析结果比较

线所形成的最大压力值要高于改进前的型线所对应的最大压力值提高了34.1%,在密度场中改进后的流体密度也大于改进前的密度提高了将近1.17倍,综合压力场、密度场的分析结果可以看出改进后的型线的双螺杆压缩机的性能得到了提高。

5. 结语

本文利用圆弧包络线曲线参与构造转子型线,实现了齿廓线的光滑过渡与啮合,并通过控制点和齿廓线方程参数的修改,实现了新型转子型线的优化改进,克服了传统转子型线设计过程中各段齿廓线修改困难的问题。借助流体仿真快速模拟现实的优点,对单边不对称销齿圆弧式双螺杆转子型线及基于其开发的新型线模拟仿真并比较分析表明:新型线的高压区与低压区的最高压强差扩大明显,排量也有所增加,说明新型线设计有一定的可取性,但新型线仍存在不足之处,可依据比较结果对新型线进行优化并再次模拟仿真。将自由曲线理论与计算流体力学理论结合运用于双螺杆转子型线设计中,利用仿真结果指导由自由曲线参与构建的新型转子型线的修改,直至获得仿真性能优良的转子型线,再搭建实体实验验证结果的双螺杆压缩机转子型线设计方法,可达到缩短设计周期、提高新型线设计效率、降低设计成本的效果。