1. 引言

纳米金属材料[1] -[3] 具有其他传统金属材料所不具备的超乎寻常的力学、电学、热学、磁学等性能,从而被广泛应用于航空航天、汽车制造、核工业以及电子制造行业。人们发现,将界面结构引入纳米金属材料将对材料的力学性能有很大程度的提高,如纳米多晶金属的晶界[4] 、孪晶界[5] 、堆垛层错[6] 以及旋转晶界[7] 等等。以孪晶为例,孪晶界作为一种晶体的面缺陷,它既可以像晶界那样阻碍位错的运动,使材料获得高强度;同时,孪晶界又能提供足够的空间用以储存位错,避免局部剪切应变集中现象的过早出现,使材料获得较高的塑性和韧性。而随着人们对纳米金属材料的认识不断全面、深入,人们意识到纳米金属材料界面上的先前缺陷将对材料的力学性能产生极大的影响。目前,人们对纳米金属晶体的先前结构缺陷,如空缺[8] 、掺杂原子簇[9] 或裂缝[10] 进行了较为细致的研究,研究结果表明,对于空缺而言,相同空缺比下Mg晶粒越大其屈服强度越低;而掺杂入Fe中的Cr原子簇可以阻碍螺旋偶极的形成从而强化材料;裂缝在Al中的传播会受裂缝与孪晶、堆垛层错所成角度而影响。Gao等人结合分子动力学方法和蒙特卡洛方法研究掺杂于均匀铁晶界内的铜原子簇与晶界之间的相互作用时发现,在晶界吸收掺杂铜原子簇后,铜原子簇倾向于形成尺寸大但密度低的状态[11] 。Ren和Xu使用基于第一性原理的分子动力学模拟,发现结合之前的先前点缺陷可以大大降低界面缺陷密度,从而增强界面的结合强度[12] 。然而,界面缺陷和界面缺陷密度对材料力学性能影响的研究依然相对较少,很多现象仍有待进一步揭示。

本文通过分子动力学模拟方法研究了在含有孪晶和堆垛层错的铜纳米线中,界面缺陷和界面缺陷密度对铜纳米线力学性能的影响。发现了界面缺陷及界面缺陷数量密度对铜纳米线力学性能影响的一些规律,该研究为制备高性能的纳米金属铜提供了一定的理论依据。

2. 模型及方法

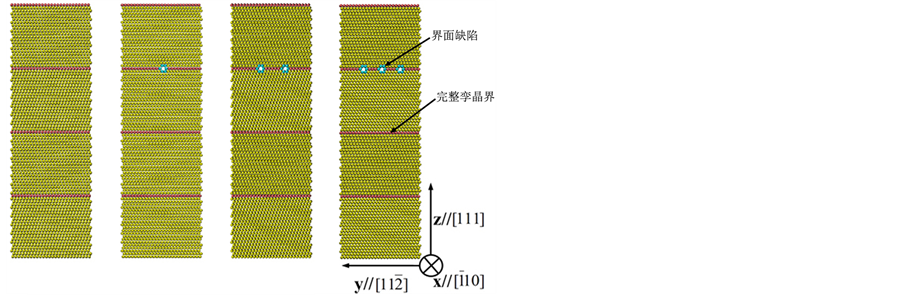

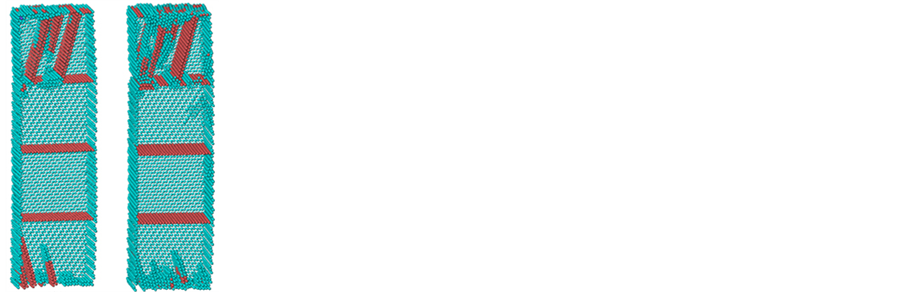

图1给出了包含有孪晶的铜纳米线原子结构图。其中,图1(a)是不带有界面缺陷的铜纳米线;图1(b)~(d)是分别带有1,2,3列界面缺陷的铜纳米线。图1(a)的初始模型是通过两步生成的:第一步是将两块铜单晶按孪晶的位置对应关系结合,形成一个孪晶单元;第二步就是将这个孪晶单元重复一遍,得到纳米

(a) (b) (c) (d)

(a) (b) (c) (d)

Figure 1. Initial atomistic schematic of twinned copper nanowires containing interfacial defect (FCC, HCP and nonstructure atoms are colored yellow, red and cyan, respectively.) (a) Without t interfacial defect; (b) With one row of interfacial defect; (c) With two rows of interfacial defect; (d) With three rows of interfacial defect

图1. 含有界面缺陷的孪晶铜纳米线的初始构型(黄色代表FCC结构原子,红色代表HCP结构原子,蓝色代表其他类型原子) (a) 界面不含缺陷;(b) 界面含1列界面缺陷;(c) 界面含2列界面缺陷;(d) 界面含3列界面缺陷

线型的初始模型。初始模型的x,y,z轴方向分别是<−1 1 0>,<1 1 −2>,<1 1 1>。其中,对x和y方向施加自由边界条件,其尺寸分别是5.7 nm和5.8 nm。纳米线沿z轴方向拉伸,对z轴方向施加周期性边界条件,纳米线沿z轴方向的尺寸为18.3 nm。界面之间的距离固定为4.6 nm。而图1(b)~(d)则是在图1(a)的基础上,去掉孪晶面平行于<−1 1 0>方向上的1至3列原子。包含有堆垛层错界面的铜纳米线的生成方式与此相同。该研究采用Mishin [13] 的势函数来描述铜原子之间的相互作用,该势函数能够很好地契合实验数据,被广泛应用于纳米金属铜力学性能的分子动力学模拟研究[14] 。本模拟时间步长为3 fs,采用“热浴法”使系统的温度稳定在0.01 K,并采用Velocity-Verlet [15] 算法求解原子运动方程。

模拟的过程为:在恒温恒压条件下,首先让初始模型弛豫至稳定平衡态,稳定平衡态即使系统能量处于最低的稳定状态;在模型的z方向施加0.001的均匀应变,在x,y方向保持零压。然后再让系统弛豫一段时间,使系统达到新的平衡态。重复以上位移载荷加载、拉伸弛豫过程,使原子受力处于准静态状态。

为了能更好的观察缺陷的生长扩张以及缺陷与临近界面的相互作用,采用公共近邻分析法CAN [16] 对不同的原子结构进行颜色标记:面心立方(FCC)结构原子标记为黄色;六角密堆积(HCP)结构原子标记为红色;其他原子结构标记为淡蓝色,这有助于我们分析各种不同的变形机制。利用集成了CNA的开放性可视化工具OVITO (open visualization tool)能够进一步观察铜纳米线在拉伸过程中的原子演变过程。

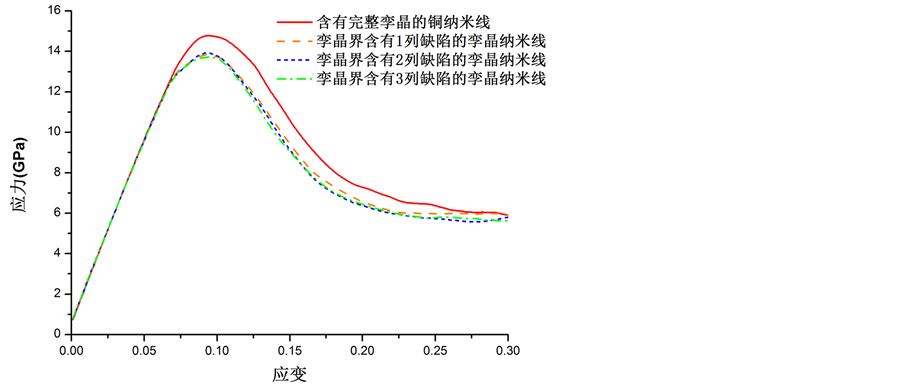

本文计算应力时采用维里定理[17] [18] 推倒出的平均应力,表达式如下:

其中, 表示平均应力。

表示平均应力。 代表的是所有原子的体积和;公式的前半部分代表了第

代表的是所有原子的体积和;公式的前半部分代表了第 个原子的动能分量,后半部分是原子间相互作用力。

个原子的动能分量,后半部分是原子间相互作用力。 ,

, ,

, 分别指的是第

分别指的是第 个原子的质量和速度,

个原子的质量和速度, 代表第

代表第 个和第

个和第 个原子之间的相互作用力,其中

个原子之间的相互作用力,其中 表示的是原子坐标分量。

表示的是原子坐标分量。 表示第

表示第 个和第

个和第 个原子沿

个原子沿 方向的矢量差。

方向的矢量差。

3. 结果及讨论

3.1. 孪晶界面缺陷对铜纳米线力学性能的影响

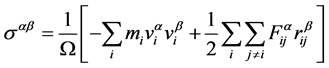

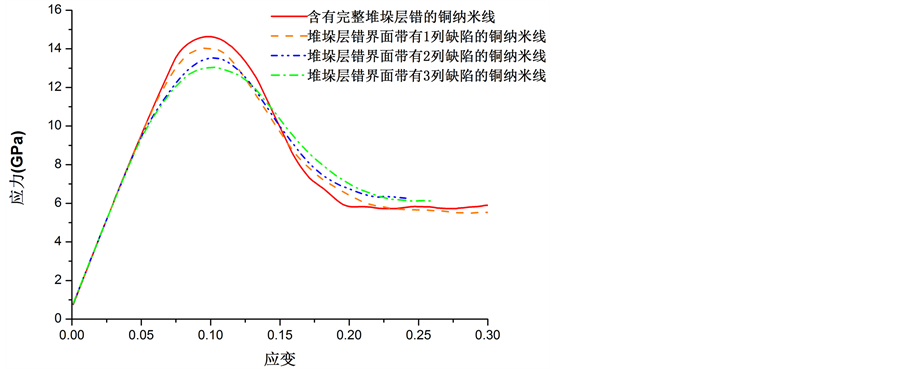

本文首先研究了孪晶界面缺陷对包含有孪晶的铜纳米线力学性能的影响。图2给出了包含有孪晶的

Figure 2. Stress-strain curves of twinned copper nanowires with various rows of interfacial defect under tension loading

图2. 含有孪晶的铜纳米线在拉伸过程中的应力应变曲线

铜纳米线在拉伸加载下的应力应变曲线。由图2可知,无论纳米线的孪晶界面是否含有缺陷,无论缺陷数量密度大小,其应力变化趋势相似:随着应变的增加,其应力值首先线性增加到某一数值,随后随着继续加载,应力逐渐减小至某一趋于稳定的数值。应力值最高点即铜纳米线屈服点,以屈服点为界,可以将应力应变曲线分为两个连续的阶段,即弹性阶段和塑性阶段。从图2可以观察到,对于孪晶界面带有缺陷的铜纳米线,其应力值均明显低于不含界面缺陷的铜纳米线的屈服强度;然而缺陷密度对铜纳米线屈服强度的影响并不明显。为了探究含有界面缺陷的铜纳米线在拉伸载荷下的力学行为以及界面缺陷密度对其力学行为的影响,图3给出了包含有孪晶的铜纳米线在不同拉伸应变下的原子结构图。图3(a)给出了孪晶界面含有1列缺陷的铜纳米线在拉伸应变为0.072时的原子结构图。从图3(a)可以看出,位错首先从缺陷所在孪晶界面所相邻的完整孪晶界处发射,这与不含界面缺陷的纳米线的变形行为完全不同。对于不含有界面缺陷的铜纳米线,其位错发射于孪晶界面与自由表面交界处,如图3(d)所示。图3(b)是孪晶界面存在2列缺陷的铜纳米线在拉伸应变为0.072时的原子结构图,与图3(a)一样,位错均是发射与缺陷所在孪晶面相邻的完整孪晶界。这种完全不同的变形行为主要是因为孪晶界缺陷的出现降低了该孪晶界对位错成核和滑移的阻碍能力,从而使得与包含有界面缺陷的孪晶界相邻的完整孪晶界成为了位错源[19] [20] 。因此,位错会优先从与缺陷界面相邻的孪晶界成核并传播。图3(c)给出了孪晶界面含有3列缺陷的铜纳米线在拉伸应变为0.069时的原子结构图,值得注意的是,在图3(c)中,位错并不是首先发射于界面缺陷所在孪晶面相邻的完整孪晶界,而是发射于孪晶界与自由表面交界处。众所周知,位错发射的难易程度与临界成核应力大小有关,临界成核应力越小,位错越容易发射。由图3(c)中可以看出,靠近自由表面附近的界面缺陷与自由表面之间形成了内禀层错,而内禀层错与自由表面交界处的均匀成核应力更低,所以位错优先从这一区域发射。图4(a)和图4(b)分别给出了含有1列和3列界面缺陷的孪晶铜纳米线在达到屈服强度时的原子结构图,此时拉伸应变分别为0.093和0.094。由图中可见,虽然孪晶界面缺陷降低了其对位错成核和滑移的阻碍能力,但含有界面缺陷的孪晶界仍能有效阻碍位错的运动。当位错穿透含有界面缺陷的孪晶界时,应力随之缓慢下降。对比图4(a)和图4(b)可知,界面缺陷对孪晶阻碍位错滑移的能力影响不明显,这也是界面缺陷密度对铜纳米线屈服强度影响较小的原因。

3.2. 堆垛层错界面缺陷对铜纳米线力学性能的影响

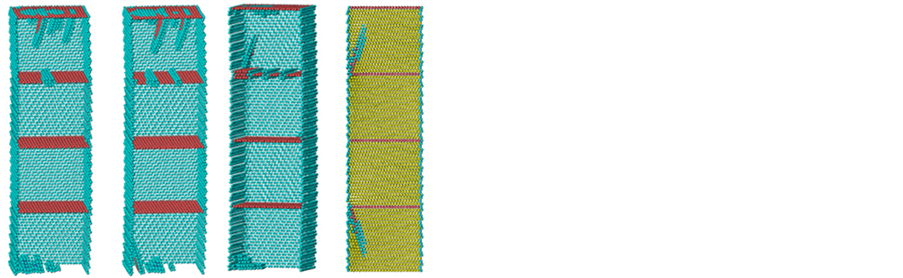

此外,本文还研究了堆垛层错界面缺陷密度对铜纳米线力学性能的影响。图5给出了包含有堆垛层

(a) (b) (c) (d)

(a) (b) (c) (d)

Figure 3. Atomic configuration of selected twinned copper nanowires with various rows of interfacial defect under (a) 0.072 (with one row of interfacial defect) (b) 0.072 (with two rows of interfacial defect) (c) 0.069 (with three rows of interfacial defect) (d) 0.084 (without interfacial defect)

图3. 含有界面缺陷的孪晶铜纳米线在拉伸应变为(a) 0.072 (1列缺陷);(b) 0.072 (2列缺陷);(c) 0.069 (3列缺陷);(d) 0.084 (不含界面缺陷)下的原子图

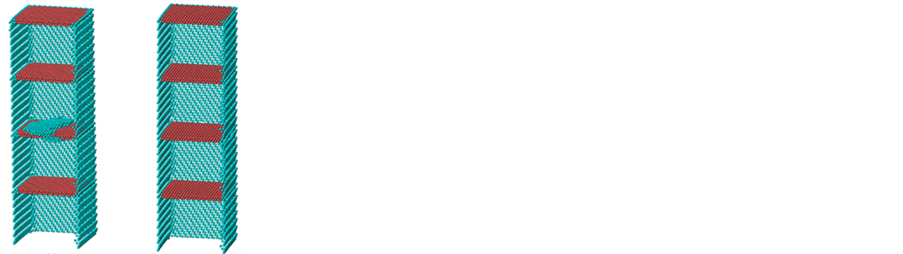

(a) (b)

(a) (b)

Figure 4. Atomic configuration of selected twinned copper nanowires with various rows of interfacial defect under (a) 0.093 (with one row of interfacial defect) (b) 0.094 (with three rows of interfacial defect)

图4. 含有界面缺陷的孪晶铜纳米线在拉伸应变为(a) 0.093 (1列缺陷);(b) 0.094 (3列缺陷)的原子图

Figure 5. Stress-strain curves of copper nanowires containing stacking fault with various rows of interfacial defect under tension loading

图5. 含有堆垛层错的铜纳米线在拉伸过程中的应力应变曲线

错的铜纳米线在拉伸加载下的应力应变曲线。从图5可以看出,对于含有堆垛层错的铜纳米线,不含有界面缺陷的铜纳米线的屈服强度比含有界面缺陷的铜纳米线的屈服强度要高。此外,铜纳米线的屈服强度随着界面缺陷密度的增加而减小,这与前面研究的包含有孪晶的铜纳米线的结果不同。图6给出了包含有1列缺陷的铜纳米线在不同应变下的原子结构图。从图6(a)可以看出,含有界面缺陷的铜纳米线在初始弛豫后,界面缺陷发生了变形,这说明六角密排结构缺失2列以上原子的时候,结构不再稳定,原子的位置会发生不规则变动。堆垛层错上的先前界面缺陷在弛豫后已经被原子填充,并且形成了平行于堆垛层错界面的位错,如图6(a)所示。值得注意的是,随着继续载荷,平行于堆垛层错界面的位错紧贴着堆垛层错界面平行在堆垛层错与自由表面的交界处滑出,形成了原子台阶,如图6(b)所示。当应变达到0.066时,由于在原子台阶处过早的出现了应力集中,所以位错首先在此处成核并发射(图7(a))。图7给出了包含有堆垛层错的铜纳米线在不同拉伸应变下的原子结构图。图7(a)~(c)分别是包含有1,2,3列界面缺陷的铜纳米线在拉伸应变为0.066、0.054、0.051时的原子结构图。图7(d)是不含界面缺陷的铜纳米线在拉伸应变为0.090时的原子结构图。从图7中可以观察到,含有1列缺陷的铜纳米线在位错发射时堆垛层错得以“复原”,其余两个模型在原来含有界面缺陷的堆垛层错上都形成了外禀层错。外禀层错的形成主要是因为位错在堆垛层错中向堆垛层错与自由表面的交界处平行于(1 1 1)面发射。相关文献表

(a) (b)

(a) (b)

Figure 6. Atomic configuration of selected copper nanowires containing stacking fault with one row of interfacial defect under (a) 0.000 (b) 0.036

图6. 含有1个界面缺陷的堆垛层错纳米线在拉伸应变为(a) 0.000;(b) 0.036下的原子图

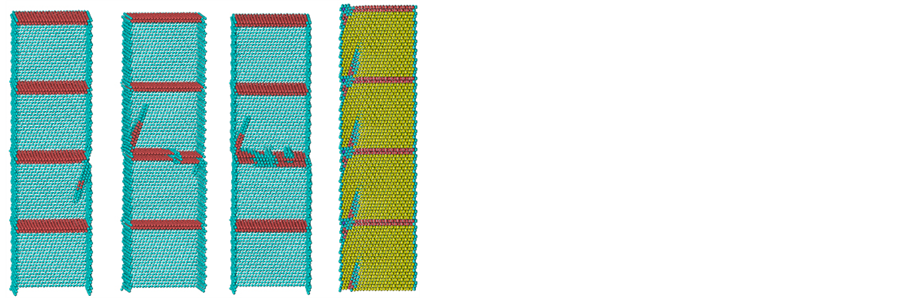

(a) (b) (c) (d)

(a) (b) (c) (d)

Figure 7. Atomic configuration of selected copper nanowires containing stacking fault with various rows of interfacial defect under (a) 0.066 (with one row of interfacial defect) (b) 0.054 (with two rows of interfacial defect) (c) 0.051 (with three rows of interfacial defect) (d) 0.090 (without interfacial defect)

图7. 含有界面缺陷的堆垛层错铜纳米线在拉伸应变为(a) 0.066 (1列缺陷);(b) 0.054 (2列缺陷);(c) 0.051 (3列缺陷);(d) 0.090 (不含界面缺陷)下的原子图

明[21] ,堆垛层错对位错具备一定的吸收能力,其吸收能力主要取决于几何相互作用和位错速率。本模拟中,堆垛层错对位错吸收的能力是有限的,这也就是含有一列界面缺陷的堆垛层错会得以复原而含有两列以上界面缺陷的堆垛层错会形成外禀层错的原因。外禀层错与自由表面交界处的均匀成核应力很低,所以位错将优先从该区域发射(图7(b)和图7(c))。对于不含界面缺陷的堆垛层错纳米线,位错的发射则不具备优先性。如图7(d)所示。从图7(a)~(c)可以看出,当堆垛层错界面增加到2列缺陷以后,原始层错随着位错的滑移转变为外禀层错,这导致了铜纳米线屈服强度的明显降低。从图7(c)可以观察到,而当堆垛层错界面具有3列缺陷时,随着对铜纳米线的加载,在外禀层错与自由表面的交界处出现了于外禀层错面平行的位错,外禀层错伴随着位错的出现使得铜纳米线的屈服强度进一步降低。

4. 结论

本文利用分子动力学模拟方法,对界面带有缺陷的孪晶、堆垛层错的铜纳米线的力学性能进行了模拟研究。在模拟中,采用EAM势函数描述铜原子间的相互作用。通过模拟拉伸过程,分析了界面缺陷密度对铜纳米线变形行为的影响。研究结果表明:界面缺陷将导致包含有孪晶的纳米线屈服强度下降,但界面缺陷密度对包含有孪晶的铜纳米线的屈服强度影响很小;然而,包含有堆垛层错的铜纳米线的屈服强随着界面缺陷密度的增大而减小。对于包含有孪晶的铜纳米线,位错成核与界面缺陷所在的孪晶界面相邻的完整孪晶界,而对于包含有堆垛层错的铜纳米线,位错成核与缺陷界面和自由表面的交界处。模拟结果还表明,界面缺陷和界面缺陷密度对铜纳米线的杨氏模量影响很小,而且这种现象与铜纳米线中是包含堆垛层错还是孪晶无关。该研究对制备高性能的铜纳米线提供了一定的理论依据。

资助信息

国家自然科学基金(批准号:10902083)、教育部新世纪优秀人才支持计划(批准号:NCET-12-1046)和陕西省青年科技新星支持计划(批准号:2012KJXX-39)的资助。