1. 引言

桥梁耐久性就是使用寿命问题。钢筋混凝土桥梁的耐久性不仅与交通工具的荷载作用有关,而且与结构内部因素和环境因素有关。在混凝土劣化、钢筋锈蚀和疲劳荷载的共同作用下,将大大降低结构的使用寿命甚至发生瞬时性倒塌。而钢筋作为桥梁的“骨骼”是诱发钢筋混泥土结构桥梁重大事故的关键因素 [1] [2] 。解决这一问题的关键性就在于:深入探讨锈蚀钢筋的力学性能退化规律。构筑“电化学信号–锈蚀度–变形度–耐久性”时变模型,形成基于电化学信号的快速诊断体统,以此为依据对服役桥梁做出类似于医学上“依据骨龄判断年龄乃至预测寿命”的耐久性预测体系,防患于未然。

2. 前期研究基础

2.1. 加速模拟锈蚀试验锈蚀特征及力学性能退化规律

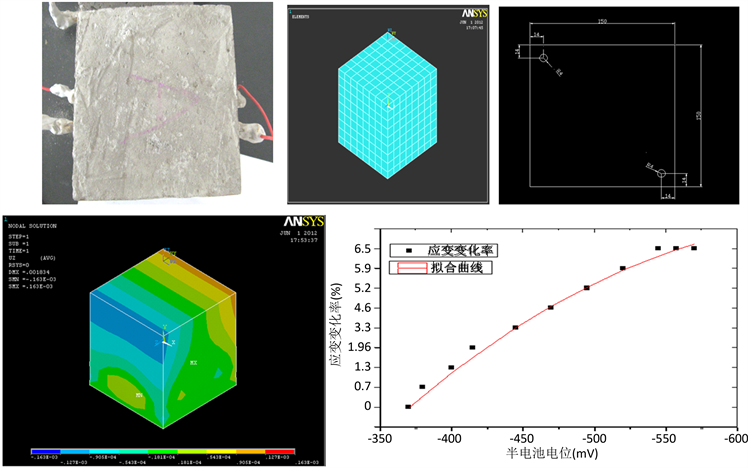

前期通过一系列模拟加速锈蚀正交实验及相应的物理和电化学检测手段,较为系统地研究了钢构件在不同腐蚀环境下的锈蚀速率。实验结果表明:在没有氯离子的环境下,钢构件前期基本以均匀锈蚀为主,后期才发展为局部锈蚀,这时力学性能指标也呈现出与锈蚀情况对应的正相关性;但在含氯离子严重的环境下,初期就表现出不均匀锈蚀状况。这时力学性能指标与锈蚀情况不再具有线性关系而出现急速下降的趋势。失重率检测结果印证了腐蚀程度与力学性能的相关性。分析结果见下图1所示 [3] 。

2.2. 基于电化学检测及有限元技术相结合钢筋锈蚀度计算模型

作者前期还在《基于电化学检测及有限元分析技术的钢筋锈蚀度无损量化方法研究》 [4] 一文中,提出了一种基于电化学检测及有限元分析技术相结合的钢筋锈蚀度无损量化定量评价新方法,设想着将“钢筋锈蚀率–电位信号–钢混结构变形”有效对应起来。为此首先建立了“锈蚀电流密度及电位特征参数与锈蚀速率”之间的关系,实现了钢筋锈蚀度的“量化”计算。在此基础上运用有限元分析技术,结合一个实例,初步构建了混凝土梁的“应变变化率与检测信号”之间的关系模型,探索性地给出了试验钢筋应变值变化情况预测经验公式,并用实验数据验证了所建模型的可靠度,为实现桥梁耐久性预测奠定了相对可信的理论基础和技术支撑。实验结果见下图2所示。

由图2可见:随着腐蚀程度的加深,检测信号电位负值逐渐加大,应变值变化率呈现出与电负性一致的规律性。且预测结果与实际计算值最大误差不超过9%,为预测后期变化趋势奠定了良好的基础。

3. 基于桥梁耐久性的锈蚀钢筋力学性能“时变模型”构筑及宏观/微观机理研究

3.1. 利用有限元技术构建混凝土钢筋力学性能计算“时变模型”

前期了解和讨论的都是已知试件的锈蚀状况及力学性能情况,构建的模型也仅仅是实验室内简单构件的“电化学信号–锈蚀率”之间的关系 [5] 。而实际桥梁的耐久性预测远比实验室内环境要复杂得多,会受到各种各样的外界因素困然,受力情况也比简化的模型要复杂得多。为此,本论文研究重心放在耐久性预测模型的构建上。

Figure 1. Accelerated corrosion test, corrosion characteristics and degradation of mechanical properties

图1. 加速模拟锈蚀试验锈蚀特征及力学性能退化规律

Figure 2. Concrete model and finite element empirical model and stress strain distribution curve

图2. 混凝土模型与有限元经验模型及应力应变分布曲线

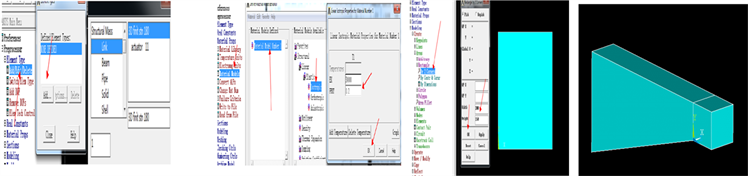

首先通过有限元分析技术,模拟实际桥梁混凝土中钢筋的边界约束条件和受力受载情况,通过给有限元模型设定特定的泊松比、屈服强度等材料属性,求解出原受力状态下钢筋应力变化,以此实现混凝土中钢筋服役性能判断,为耐久性预测提供参考依据。为此,对模型的构建方面又做了一些方法上的更新和调整。考虑到工程实际情况的复杂性,预研中所建模型选取SHELL 181单元作为实体拉升前的中间体,选取SOLID 65为混凝土实体单元,选取梁单元BEAM 18并且设定较小的惯性矩的值就可近似模拟钢筋单元。选取对应单元之后,给定材料参数,赋予材料特定的泊松比和弹性模量,完成有限元建模前处理工作。下图3是选取模型单元和给材料赋值的前处理工作及实体建模过程及对一个算例的计算结果过程图 [6] 。

将计算结果与案算例实桥年限做对比可知,基本符合实际情况。

3.2. 锈蚀钢筋微观组织与宏观力学性能之间的关系研究

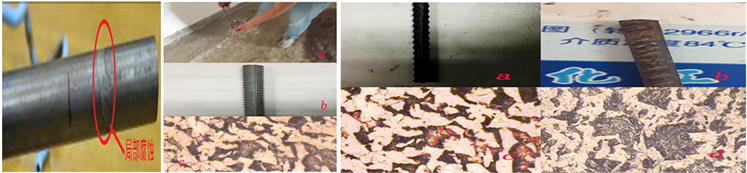

前已所述,可以通过有限元分析技术对特定受力状态下锈蚀钢筋的应力应变进行模拟计算,为钢筋耐久性预测提供参考依据。但是,力学性能的下降规律在不同的条件下是变化的,呈现的规律也并非一成不变的。为此,采集自然环境试件与加速模拟锈蚀试件进行了对比分析,实验结果见下图4所示 [6] 。

研究结果表明:自然环境下的锈蚀与实验室加速模拟锈蚀存在一定的差异。其中,力学性能指标及伸长率均略缓于低于加速模拟,锈蚀程度也比加速模拟要缓慢许多,特别是锈蚀后期,自然环境下试件的锈蚀速度一般都趋于平缓。这表明对对现役桥梁混凝土钢筋在自然环境下的锈蚀特征及分级评价时应考虑到这一因素 [6] 。

为了深入揭示桥梁瞬时倒塌的原因,深入揭示锈蚀钢筋的外在力学性能与内在微观组织之间的关系,本论文还对自然锈蚀钢筋试件及加速模拟锈蚀试件做了微观组织对比分析,见下图5所示 [7] 。

经细致分析可知,自然锈蚀环境下一般呈非均匀局部锈蚀,而加速模拟锈蚀试件则多呈现均匀锈蚀。

(a) 选取单元类型(b) 选取材料属性(c) 建立平面(d) 拉伸实体

(a) 选取单元类型(b) 选取材料属性(c) 建立平面(d) 拉伸实体

(e) 实体切割(f) 插入关键线(g) 划分网格 (h) 加载计算结果

(e) 实体切割(f) 插入关键线(g) 划分网格 (h) 加载计算结果

Figure 3. Selects model elements and input material parameters, establishes shell elements, divides meshes and entity models

图3. 选取模型单元及输入材料参数及建立薄壳单元划分网格及实体模型

(a) 自然环境与实验室试件力学性能对比(b) 自然试件与实验室试件伸长率对比 (c) 自然锈蚀与加速锈蚀对比

(a) 自然环境与实验室试件力学性能对比(b) 自然试件与实验室试件伸长率对比 (c) 自然锈蚀与加速锈蚀对比

Figure 4. Comparison experiment of corrosion resistance between natural environment and accelerated simulation

图4. 自然环境与加速模拟锈蚀力学性能对比实验

(a) 钢构件局部锈蚀表面(b) SEM能谱分析 (c) SEM及(EDS)能谱对比分析

(a) 钢构件局部锈蚀表面(b) SEM能谱分析 (c) SEM及(EDS)能谱对比分析

Figure 5. Microstructure analysis of corroded reinforcement and strain analysis of macro mechanical properties and comparative analysis of natural environment and laboratory results

图5. 锈蚀钢筋微观组织分析及宏观力学性能应变规律分析及自然环境与实验室结果对比分析

局部锈蚀钢筋的组织结构非常松散,晶界完全消失,成为承载最薄弱环节。也即:在不均匀锈蚀情况下出现了力学性能急速退化的现象。这对于原本受力均衡的体系,就出现了支撑的空缺,于是出现或增加了附加弯距。从而导致了承载能力的急剧下降,诱发了桥梁瞬时倒塌的危险。

4. 结论

综上所述,利用有限元分析技术结合电化学检测手段构建预测模型是解决桥梁耐久性预测的基本方法。将“电化学检测信号–锈蚀率–变形度”关联起来,可以实现服役桥梁耐久性的相对精准预测。通过自然环境及加速模拟试验对比分析,深入揭示出锈蚀钢筋的力学性能在不同条件下的退化规律,据此对预测模型做出合理修正;通过微观晶体结构分析,准确判断锈蚀钢筋的局部劣化程度,对剩余寿命做出科学推断。通过算例,可得出以下结论。

1) 自然环境际加速模拟对比实验可知:试件在不同的条件下呈现不同的力学性能退化规律,其中自然环境下以局部锈蚀为主,加速模拟添加下以均匀锈蚀为主。

2) 局部锈蚀条件下的钢筋,其力学性能与锈蚀程度不再呈现线性正相关性。

3) 检测锈蚀断面的微观晶体结构发现,局部锈蚀钢筋的晶界消失,组织松散,基本失去了承载能力,估计这就是力学性能急剧下降,进而诱发桥梁瞬时倒塌的主要原因。

4) 后期将外在宏观变形与材料内在微观结构相关联,有望深入揭示出锈蚀钢筋在复杂应力状态下的应急反应机制及演化机理。真正将“电化学信号–力学性能退化规律–桥梁剩余寿命”关联起来,使“通过钢筋锈蚀程度及力学性能退化规律对混凝土钢筋桥梁的剩余寿命预测”问题如同医学上通过“骨龄”推测“年龄”乃至预测大致寿命问题一样具有科学依据。

基金项目

北京市自然科学基金资助项目(8172047)资助,北京高等学校高水平人才交叉培养“实培计划”大学生科研训练计划深化项目资助,项目名称《基于有限元分析技术的桥梁钢筋混凝土结构耐久性分析研究》,项目编号17032021006,以及北京市级URT项目资助,项目号2017X00012 和2016J00044。