摘要:

HfC陶瓷具有优异的耐超高温性能,在航空航天领域具有广阔的应用前景。本文以四氯化铪、乙酰丙酮、甲醇、1,4-丁二醇为原料合成了HfC陶瓷先驱体。采用元素分析、红外光谱、XPS、TG-MS等对先驱体的组成、结构及无机化过程进行了表征。结果表明:先驱体主要含有Hf、C、O、Cl元素,铪与碳以Hf-O-C键的形式相连。在无机化过程中部分碳链断裂,有大量的小分子逸出。另外采用元素分析、XRD、SEM等对陶瓷产物的组成、结构与性能进行了表征。结果表明:Ar气氛下1600℃处理后产物仍存在氧化铪相,真空条件下1200℃碳热还原发生,1600℃热处理后只有碳化铪陶瓷相。

Abstract:

As an important ultra-high temperature ceramics (UHTCs), HfC ceramics have been considered to be one of the most promising materials for the application in aerospace. A precursor for HfC ceramic was prepared by using hafnium tetrachloride, methanol, acetylacetone, and 1,4-butanediol as raw materials. The composition, structure and pyrolysis process of the obtained precursor was investigated by elemental analysis, Fourier transform infrared (FTIR), XPS and TG-MS. The results show that, the precursor mainly contains Hf, C, O, Cl, with a linear structure of Hf-O-C. The compo-sition, structure and properties of the pyrolysis products were analyzed by elemental analysis, XRD and SEM. It is found that hafnia still remain in the products after being treated at 1600˚C in argon. In addition, the carbothermal reduction had started at 1200˚C, and only HfC existed after the heat treatment of 1600˚C in vacuum.

1. 引言

C/C复合材料惰性气氛下性能优良,但耐氧化性能较差,C/SiC复合材料具有密度低,抗氧化,机械性能优异等特点,但是最高使用温度不超过2000℃ [1] [2] 。因此能在2000℃以上应用的耐超高温材料引起了研究者的兴趣。如TiB2、ZrB2、TaB2、HfB2、TiC、TaC、ZrC、NbC和HfC等。其中,HfC熔点为3890℃,具有高硬度、高热导率、高导电率、膨胀系数等优异性能,高温下其氧化物HfO2具有高的粘度,能形成致密的保护层 [3] [4] [5] ,具有良好的高温抗氧化性能,是耐超高温材料研究的一个重要方向。

HfC的制备工艺主要有化学气相沉积法 [6] 、化学气相浸渍法、等离子喷涂法、液相先驱体转化法。液相先驱体法制备HfC陶瓷具有工艺周期短、合成温度低、设备简单、所得的HfC陶瓷粒径小,而且该方法可通过对先驱体进行分子设计,制备出所需组成和结构的单相或多相陶瓷颗粒改性的复合材料,从而大幅地提高材料的抗氧化和抗烧蚀性能 [7] 。因而,先驱体法是一种极具潜力的制备方法 [8] 。国内关于先驱体转化法制备HfC陶瓷材料的报道相对较少。Michael等 [9] 采用乙酰丙酮对铪的醇盐进行部分配位取代,再加入碳源,在一定的温度及PH的条件下实现铪酸酯的可控水解,制备了液相HfC先驱体聚铪氧烷。该方法可以在1500℃完成碳热还原,但合成需加入外加碳源且陶瓷碳含量较高。Cai等 [10] 用聚乙酰丙酮铪,酚醛树脂,硼酸,聚硅烷等制备得到HfB2/HfC/SiC/先驱体,经1500℃热解得到HfB2/HfC/SiC/C复相陶瓷,该方法中聚乙酰丙酮铪只提供了铪源需加酚醛树脂提供碳源。Lu [11] 等采用液相前驱体转化和等离子体活化烧结(PAS)相结合的方法合成了超细碳化铪粉。Cheng等 [12] 用HfCl4与双氰胺,二甲基甲酰胺,合成了HfC(N)陶瓷先驱体,经1500℃烧结得到HfC(N)陶瓷,陶瓷产率为44.6 wt%,但是该路线合成工艺较苛刻,成本较高。综上,相对于传统方法,先驱体转化法实现了更低的温度烧结得到碳化铪陶瓷。但同时也存在合成过程条件要求较高,不易控制,制备成本较高以及陶瓷产物碳含量较高等问题,碳含量高不利于材料的高温抗氧化性能。

本文以四氯化铪、乙酰丙酮、甲醇、1,4-丁二醇为原料合成了HfC陶瓷先驱体,对其组成、结构进行了表征。随后将先驱体经热解转化制备了HfC陶瓷,研究了陶瓷产物的组成、结构与性能。该先驱体具有制备工艺简单、适合批量生产、成本较低的优点,在聚合物浸渍热解工艺制备超高温陶瓷基复合材料上有很好的应用前景。

2. 实验方法

2.1. 实验原料

氯化铪(HfCl4),纯度 ≥ 98%,百灵威科技有限公司。乙酰丙酮(C5H8O2) (Hacac),天津市科密欧化学试剂有限公司,纯度 ≥ 99.5%。甲醇(CH3OH),分析纯,国药集团化学试剂有限公司。1,4-丁二醇(C4H8O2),纯度 ≥ 98%,梯希爱(上海)化成工业有限公司。二甲苯(C8H10)纯度 ≥ 99.0%,国药集团化学试剂有限公司。四氢呋喃(C4H8O)纯度 ≥ 99.0%,国药集团化学试剂有限公司。

2.2. HfC先驱体的合成

将32 g (0.1 mol)的HfCl4和12 g (0.24 mol)乙酰丙酮加入反应瓶中,室温反应1 h。再加入60 mL (过量)的甲醇(溶剂),反应两小时后再滴加4.5 g (0.1 mol)的1,4-丁二醇,加热到60℃回流2 h得到红褐色液态HfC先驱体溶液,再对先驱体溶液进行70℃真空干燥得到深褐色HfC先驱体固体PHCO。

2.3. HfC陶瓷的制备

将固体先驱体PHCO在Ar气氛下,以10℃/min的速率升温至1000℃得到热解后的陶瓷PHCO-1000,再将PHCO-1000在氩气气氛或抽真空条件下以10℃/min的速率分别升温至1200℃,1400℃,1600℃,保温1 h,得到氩气气氛下不同温度热处理的陶瓷产物:PHCO-1200,PHCO-1400和PHCO-1600,以及真空条件下热处理的陶瓷产物:PHCO-1200-V,PHCO-1400-V和PHCO-1600-V。

2.4. 测试与表征

先驱体的红外光谱采用PerkinElmer公司的Spectrum Frontier红外光谱仪进行测量,采用溴化钾(KBr)压片法制样,测量范围400~4000 cm−1。XPS采用Thermo SCIENTIFIC ESCALAB 250Xi光电子能谱仪测得样品的XPS能谱,X射线源为Al Kα线(1361 eV),仪器分辨率为0.6 eV。先驱体的TG-MS联用其中TGA采用法国塞塔拉姆仪器公司生产的SETARAM SETSYS Evolution 16/18型同步热分析仪进行测定。测试在Ar气氛保护下进行,温度范围为室温~1500℃,升温速率为10℃/min,TGA的分辨率为0.03 μg。先驱体热解产物的XRD分析采用德国Bruker AXS公司D8Advance型X-射线衍射仪测量,管电压40 KV,Cu靶(λ = 0.154 nm),测量范围2θ = 10˚~90˚。采用EMIA-320V2型碳硫分析仪测量C元素含量,采用EMGA-820型氧氮分析仪测量O元素含量。ICP-AES法测定先驱体中Hf元素含量。样品的微观形貌采用美国FEI Quanta 200型扫描电子显微镜进行表征。

3. 结果与讨论

3.1. 先驱体的组成与无机化过程分析

氯化铪性质非常活泼,将乙酰丙酮与HfCl4混合后马上发生反应,乙酰丙酮置换掉部分氯,通过氧与铪相连。再加入甲醇,甲醇一方面做为溶剂同时也参与反应。再加入丁二醇,两个醇羟基同样以氧与铪相连,最后得到先驱体PHCO,乙酰丙酮以螯合方式与铪配位,丁二醇两羟基首尾分别与两个铪相连。

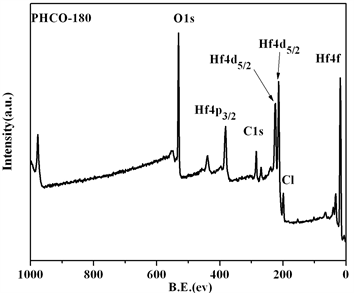

先驱体易溶于甲醇,正丁醇,四氢呋喃等溶剂中。先驱体结构除了C-C,C-O外主要是Hf-O-C。从表1是HfC先驱体PHCO主要元素的含量质量分数分别为21.58%,12.16%,40.3%。在180℃热处理后的先驱体的XPS全图谱(图1)中可以看到有Hf、C、O、Cl的峰,说明先驱体表面含有C、O、Hf、Cl元素。先驱体仍含有Cl元素是由于于HfCl4中Cl没有被完全替换掉,先驱体仍有Hf-Cl存在。

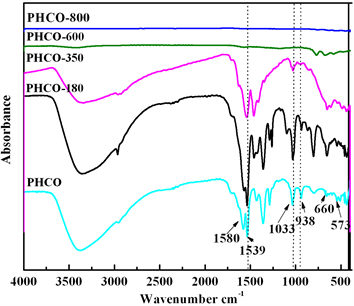

采用红外谱图表征了HfC先驱体及不同温度下热处理后的结构如图2所示,分别为PHCO先驱体与先驱体分别经180℃、350℃、600℃、800℃处理后的样品。PHCO位于3347 cm−1处的吸收峰是-OH的峰,1580 cm−1、1539 cm−1归属于乙酰丙酮中的C=O、C=C,说明乙酰丙酮与铪通过螯合方式相连。位于938 cm−1的峰为C-O-Hf中的C-O键,位于655 cm−1、573 cm−1属于Hf-O键。通过红外图谱可看出先驱体中含有乙酰丙酮配位基团,主链含有C-O-Hf键。该结构有利于碳热还原反应。随着温度升高到180℃乙酰丙酮进一步与铪螯合。到350℃时1580 cm−1左右的乙酰丙酮C=O消失,变为一个宽的C=C峰,同

Table 1. Chemical composition of the precursor PHCO

表1. HfC先驱体的元素组成及含量

Figure 1. XPS pectrum of precursor PHCO

图1. PHCO的XPS光谱

Figure 2. FT-IR spectra of precursor PHCO treated at high temperatures

图2. 不同温度处理后的HfC先驱体的FT-IR光谱

时位于655 cm−1、573 cm−1的Hf-O键的峰变弱变宽,说明有机分子在热处理过程中出现了脱氢现象 [13] ,进而发生了原位碳化。先驱体继续加热到800℃有机物逐渐转化为无机态。

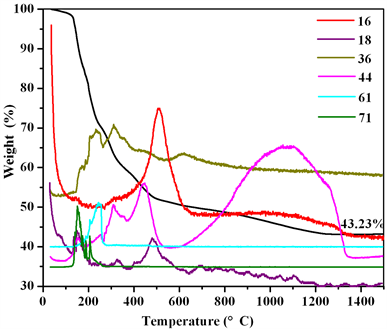

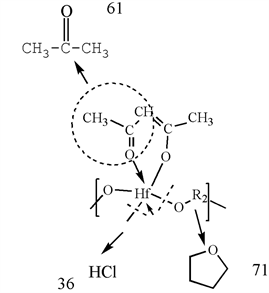

图3是HfC先驱体的TG-MS曲线。HfC先驱体1500℃的陶瓷产率为43.23 wt%。30℃~300℃,有小分子气体水(m/z = 18)、丙酮(m/z = 61)、四氢呋喃(m/z = 71)和氯化氢(m/z = 36)跑出,失重大约33%。丙酮和四氢呋喃分别是乙酰丙酮基团和正丁醇发生分解,分解示例如图4所示。结合红外图中350℃乙酰丙酮的特征峰仍然很明显说明乙酰丙酮并没有完全脱出,并发生原位碳化。300℃~700℃区间内主要有水

Figure 3. TG-MS curves of precursor PHCO

图3. 先驱体PHCO的TG-MS曲线

Figure 4. Structure of precursor PHCO and of its related decomposition products

图4. 先驱体PHCO结构和它分解产物

(m/z = 18)、甲烷(m/z = 16)、二氧化碳(m/z = 44)逸出,失重约16%。700℃以上检测到有CO2逸出,失重约8%。从TG-MS图中可知先驱体热解过程,在300℃之前就有大量含碳小分子逸出,是由于先驱体结构中碳链发生断裂以含碳小分子形式逸出。

3.3. HfC先驱体热解产物分析

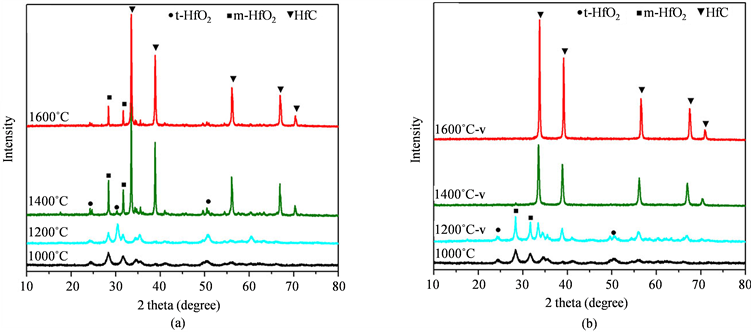

对不同温度热解产物的组成、结构和形貌进行了表征。图5(a)为Ar气氛下不同温度处理后产物的XRD图。从图中可以看出,先驱体1000℃热解产物主要为四方相氧化铪(t-HfO2),此外还存在有少量的单斜晶体氧化铪(m-HfO2)。热解温度为1200℃时,热解产物的相组成无明显变化,主要为t-HfO2,但t-HfO2的峰更尖锐,说明氧化铪结晶度增加。处理温度升高到1400℃时,产物中的出现HfC相,主要是HfO2通过碳热还原反应生成的,碳热还原反应式如式(1)所示。处理温度为1600℃时,产物大部分转化为HfC,结晶度较好,仍存在少量的m-HfO2。

Figure 5. XRD patterns of the ceramics treated at high temperatures, (a) for argon atmosphere, (b) for vacuum condition

图5. 不同温度烧结后的陶瓷XRD谱,(a) 氩气气氛,(b) 真空条件

(1)

为了使碳热还原反应更完全,将1000℃热解后的产物在真空条件下进行处理,真空条件下不同温度热处理后产物的XRD如图5(b)所示,真空条件下1200℃热处理后的陶瓷开始出现了HfC相,1400℃热处理后XRD图中氧化铪相消失,说明真空处理条件有利于碳化铪晶体形成,这主要是因为碳热还原产生的CO气体被及时抽走有利于反应向右进行,从而促使氧化铪转化为碳化铪。1600℃热处理后的陶瓷产物HfC相结晶度提高。

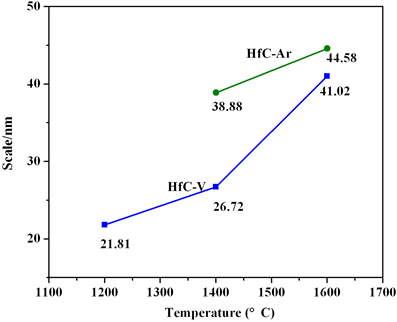

图6是根据XRD衍射谱图,结合Scherrer公式L = Kλ/Dcosθ得出热解陶瓷产物在不同处理方式各温度下HfC的平均晶粒尺寸。相同温度,与氩气气氛相比,真空条件碳化铪的平均晶粒尺寸较小,可能是由于真空条件下低温即可形成碳化铪晶核且形成晶粒较多,使得晶粒不易粗化,从而得到的晶粒尺寸较小。

对不同温度热解产物的元素组成进行了分析,结果如表2所示。真空条件下,PHCO-1600-V,C、O、Hf含量分别为4.59%、1.89%、93.52%,热解产物中仍存在少量的氧,结合XRD谱图中无氧化铪相且碳化铪特征峰向高角度有少量偏移(与标准图谱PDF——658751对照),推测产物中可能还有少部分氧溶解在碳化铪晶格中 [14] 。

图7是氩气气氛热处理后的陶瓷产物PHCO-1200,PHCO-1400,PHCO-1600与真空条件下热处理陶瓷产物PHCO-1200-V,PHCO-1400-V,PHCO-1600-V的SEM图。陶瓷PHCO-1200表面比较均匀、致密,无较大晶体出现。PHCO-1400有大量孔隙判断是碳热还原反应由氧化铪逐渐碳化铪放出气体造成的。PHCO-1600表面形貌与PHCO-1400无太大区别晶粒尺寸为40 nm~200 nm。真空条件下的陶瓷PHCO-1200-V表面不均匀,在小的颗粒中长出较大颗粒,结合XRD判断此温度下碳热还原已经开始,碳化铪与氧化铪共存。PHCO-1400-V比PHCO-1400更致密,气孔较少。PHCO-1600-V烧结后的HfC陶瓷颗粒不规则形结构,大小为20 nm~100 nm,该温度发生进一步碳热还原,陶瓷微观结构存在孔洞,但相对于Ar气氛下的表面空隙更少。分析是由于氩气气氛下由于一氧化碳、二氧化碳等溶解度较低,不易从陶瓷粉体的空洞中跑出,使孔隙较多,真空条件下,使得这些气体在高温烧结过程中跑出,提高了陶瓷产物的致密性。

Figure 6. The size of crystal of HfC ceramics treated at high temperatures (a) for argon atmosphere, (b) for vacuum condition

图6. 两种热处理方式HfC陶瓷晶粒尺寸变化,(a) 氩气气氛,(b) 真空条件

Figure 7. SEM micrographs of ceramics annealed at different temperatures: (a), (c), (e) for ceramics PHCO-1200, PHCO-1400, PHCO-1600, and (b), (d), (f) for ceramics PHCO-1200-V, PHCO-1400-V, PHCO-1600-V

图7. 陶瓷SEM照片(a),(c),(e)分别为PHCO-1200,PHCO-1400,PHCO-1600,(b),(d),(f)分别为PHCO-1200-V,PHCO-1400-V,PHCO-1600-V

Table 2. Chemical composition of ceramics

表2. 陶瓷的化学组成

4. 结论

以四氯化铪、乙酰丙酮、甲醇、1,4-丁二醇为原料合成了HfC陶瓷先驱体PHCO,先驱体在甲醇,正丁醇,四氢呋喃中有很好的溶解性能。先驱体主要含Hf、C、O、Cl和H元素,铪元素主要以C-O-Hf结构键合,该结构有利于碳热还原反应,实现较低温度制备碳化铪陶瓷。先驱体Ar气氛下处理到1500℃的陶瓷产率为43.23 wt%。

1600℃氩气气氛中处理,热解产物大部分转化为HfC,存在少量的m-HfO2。1600℃真空条件下热处理后,只有碳化铪陶瓷相,但仍有部分氧溶解在碳化铪晶格中。HfC陶瓷尺寸大体在20 nm~100 nm范围内。相对于氩气气氛下,真空条件下热处理的陶瓷气孔较少,致密性较高。该先驱体可用于制备HfC陶瓷粉体或通过聚合物浸渍热解工艺制备陶瓷基复合材料。