1. 引言

在“三高”实海环境综合作用下,船壳漆发生老化失效,出现粉化、失光、开裂等现象 [1] [2] [3] 。随着技术的进步,船壳漆经历了从单组份醇酸、氯化橡胶、丙烯酸,到双组份丙烯酸、聚氨酯的转变,现阶段聚氨酯类船壳漆成为使用范围最为广泛的船壳漆,氟碳类船壳漆因具有优良的耐候性、耐化学品性和装饰性等优点,脱颖而出,受到广泛关注 [4] [5] 。本文通过IR、SEM、EIS等测试、分析手段,研究氟碳涂层在氙灯老化试验和三亚户外曝晒试验条件下的老化失效行为,并以低频阻抗模值和光泽度为参数,分析不同试验条件对涂层老化的加速作用。

2. 试验方法

2.1. 样品制备

试验所用底漆为环氧防腐涂料(150 μm),面漆为氟碳涂料(80 μm)。试验基材为普通低碳钢,三亚户外曝晒试验采用

250 mm

×

150 mm

× 2 mm大板,氙灯老化试验采用

150 mm

×

70 mm

× 2 mm小板,试板打磨至St3级,刷涂后固化15 d,涂层厚度控制在(230 ± 5) μm。

2.2. 老化试验

三亚户外曝晒试验:在三亚地区进行户外曝晒,按照GB/T9276-1996执行。

氙灯老化试验:使用Q-SUN氙灯老化试验箱(美国Q-Panel公司)测量,按照GB/T1865-2009执行。

2.3. 性能表征

1) 光泽度测试:使用Color-Guide检测仪(德国BYK)测量。

2) FT-IR测试:采用TENSOR27傅立叶变换红外光谱仪测量。

3) SEM测试:使用HitachiS4700型场发射扫描电子显微镜测量。

4) 电化学交流阻抗测试:采用PARSTAT2273电化学工作站进行测试,ZsimpWin软件进行数据分析处理。

3. 试验结果与讨论

3.1. 氟碳涂层的老化失效微观形貌

图1是氟碳涂层氙灯老化试验和三亚室外自然曝晒试验前后的SEM照片。从图1(a)可以看出,未老化的氟碳涂层表面十分平整;氙灯老化191 d涂层表面有较多微孔(图1(b)),三亚室外自然曝晒600 d后,涂层表面平整,仅有一道较浅的裂纹和少数几个微孔(图1(c))。与三亚地区户外曝晒试验相比,氙灯老化试验环境温度更高、紫外辐照更强,涂层更早出现劣化。从扫描电镜照片可以看出,氙灯老化试验和三亚户外曝晒试验后氟碳涂层表面形貌具有很好的一致性,极其相似,而且氙灯老化试验明显加速了氟碳涂层的老化失效行为 [6] 。

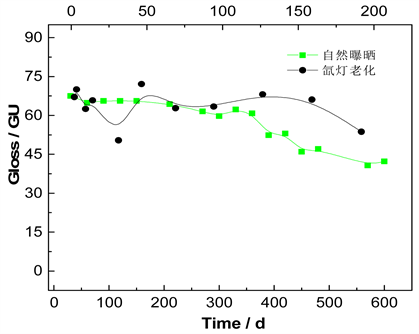

3.2. 氟碳涂层的老化失效光泽度变化

图2是氟碳涂层氙灯老化试验和三亚室外自然曝晒试验前后光泽度随时间的变化曲线。对比两条曲

Figure 1. SEM of fluorocarbon coated samples after 600 d Sanya outdoor exposure and 191 d xenon lamp exposure

图1. 氙灯老化191 d和实海暴露600 d后氟碳涂层SEM照片

Figure 2. Variations of the coating gloss with testing time

图2. 涂层体系光泽度随时间的变化曲线

线可以发现,两种实验条件下,两条光泽度变化曲线变化趋势相同,形状极其相似。并且随着试验时间的延长,两种实验条件下氟碳涂层的光泽度均逐渐下降。整个氙灯老化试验和三亚户外曝晒试验周期内氟碳涂层均维持相对较高的光泽度,这是由于氟碳键能强,表面能低,具有很好的疏水性,使得氟碳涂层光泽度下降较慢,可以说氟碳涂层具有较好的保光性能 [7] [8] [9] [10] 。

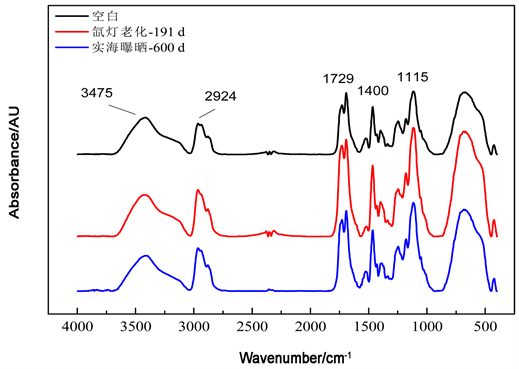

3.3. 红外光谱分析

图3为氟碳涂层面漆经氙灯老化191 d和三亚地区实海曝晒600 d的红外光谱图。氙灯老化191 d和自然暴露600天氟碳涂层试样的光谱图与未老化试样的红外光谱图没有明显区别,特征官能团峰值没有明显变化,说明氟碳涂料试样表面化学成分及结构并没有明显改变,涂层表面未发生明显的粉化降解。

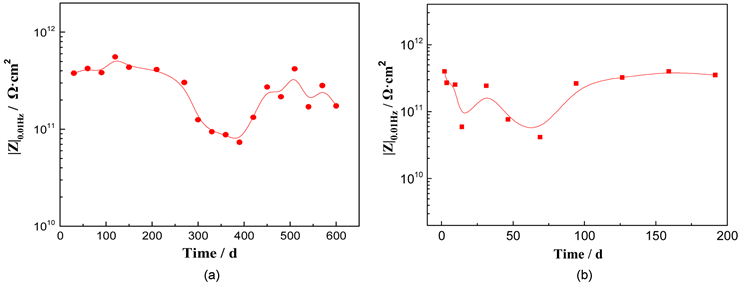

3.4. 交流阻抗测试结果

图4为氟碳涂层配套体系在实海曝晒和氙灯老化试验条件下的低频阻抗值随时间的变化曲线。整个试验周期内氟碳涂层配套体系在0.01 Hz下的阻抗模值(|Z|0.01Hz)始终保持在1010 Ω∙cm2以上,说明涂层具有完好的屏蔽性能,可以保护碳钢基体免受腐蚀介质的侵蚀 [11] [12] 。

Figure 3. Infrared plots of fluorocarbon coated samples for Sanya outdoor exposed and xenon lamp exposure

图3. 三亚户外曝晒和氙灯老化后氟碳涂层红外光谱图

Figure 4. |Z|0.01Hz variations of topside coated fluorocarbon coated samples under different test conditions: (a) Natural exposure test; (b) Xenon lamp exposure test

图4. 氟碳涂层试样的低频阻抗值|Z|0.01Hz的变化曲线:(a) 实海曝晒;(b) 氙灯老化

从图4(a)可以看出,在实海曝晒试验的360 d里,氟碳涂层的低频阻抗值|Z|0.01Hz随试验时间延长逐渐降低,这是由于涂层配套体系面漆微孔及裂纹的增多所致;360 d到520 d低频阻抗值|Z|0.01Hz略有升高,这是由于涂层中颜填料与介质反应阻塞部分孔洞所致 [13] [14] [15] [16] ;520 d以后船壳漆配套体系的面漆已不同程度出现劣化,但低频阻抗值|Z|0.01Hz保持较高水平,在1010 Ω∙cm2以上,可以认为船壳漆配套体系的底漆起到主要作用,有效的阻挡了腐蚀介质对基体碳钢的腐蚀。

从图4(b)可以看出,在整个试验周期里,氙灯老化试验条件氟碳涂层配套体系的低频阻抗值|Z|0.01Hz变化规律与实海曝晒试验相近。表现为最初阶段的低频阻抗值|Z|0.01Hz随试验时间延长逐渐降低;第二阶段,低频阻抗值|Z|0.01Hz略微升高;然后是低频阻抗值|Z|0.01Hz保持相对稳定。但主要区别在于,氙灯老化试验,四种船壳漆涂层配套体系的低频阻抗值|Z|0.01Hz下降速度较快,20 d就降到了最低值,而实海曝晒试验中涂层配套体系的低频阻抗值|Z|0.01Hz下降速度相对较慢,大约360 d才降到最低。EIS结果表明,以低频阻抗值为参数,相对于实海曝晒试验来说,氙灯老化试验同样起到了加速船壳漆配套体系腐蚀失效的作用。

4. 结论

1) 通过SEM观察发现,氙灯老化试验与三亚户外曝晒试验后氟碳涂层的微观形貌相近,光泽度变化规律一致。相对于三亚户外曝晒试验,氙灯老化试验对氟碳涂层老化失效具有明显的加速作用。

2) 氙灯老化试验与三亚户外曝晒试验后虽然氟碳涂层体系配套体系面漆出现微孔裂纹等缺陷,但配套体系的防锈底漆依旧可以很好地保护基体不被腐蚀。