1. 前言

硅钢主要是由铁和硅所组成的含碳量极低的硅钢软磁合金,用于制造各种电机、变压器和镇流器铁芯等电路元件,为了减少涡流,对其表面的绝缘性要求较高,为此,需在其表面涂覆一层绝缘涂层,以增强层间电阻率和防锈性能 [1] [2] 。目前对硅钢绝缘涂料的要求也随着钢产量的增加而增大,并且要求其具有良好的附着力、表面力学性能和加工性能,且具有良好的耐热性,经高温退火后仍具有较高电阻率以及较好的冲片性和焊接性等性质。目前,硅钢绝缘涂料主要有三大类,即无机涂层、有机涂层以及半无机涂层 [3] ,其中半无机涂层在国内应用的比较广泛,具有较好的冲片性和附着性,例如,无机成分为含铬的涂料应属于半无机涂层,因其具有良好的耐蚀性,在国内钢铁市场中占据主导地位 [4] 。含铬硅钢绝缘涂料一般以铬酐为主成膜物质,以提高硅钢板的耐腐蚀性,另外添加氧化镁以提高硅钢板的绝缘性,为了使涂料混合均匀,有利于成膜,还需在硅钢绝缘涂料中添加水性树脂以及相关助剂。本文主要对来源不同的三家公司所提供的含铬硅钢绝缘涂料进行分析,结合其物理性质、耐腐蚀性与绝缘性测试、粒径测试、红外光谱测试以及成分分析以总结出三种含铬硅钢绝缘涂料的性质。

2. 试验部分

2.1. 主要仪器

仪器:QND的涂-4杯,比重瓶,pH计,Malvern Zetasizer Nano ZS90的纳米粒度仪,Nicolet 6700 型傅立叶红外光谱仪,ARL Advant’X Intellipower 3600 X-射线荧光光谱仪。

2.2. 三种含铬硅钢绝缘涂料物理性能测试

1) 颜色、状态:直接观察;

2) 粘度:用型号为QND的涂-4杯对样品进行粘度测试,以时间秒(s)作为计量单位;粘度的大小对绝缘涂料的成膜性能影响较大 [5] ;

3) 比重瓶法测量样品的比重,单位为g/mL;

4) pH:精密pH试纸;

5) 固含量:测量一定量的乳液质量,然后将其可挥发物质自然风干,干燥后固体的质量与原乳液质量的比值即为固含量。

2.3. 三种含铬硅钢绝缘涂料耐蚀性测试

将三种型号的样板放到盐雾箱中,其中盐水浓度为5%,将三种样板在35℃的温度下,放置8 h后取出烘干,观察其表面腐蚀面积。

2.4. 三种含铬硅钢绝缘涂料绝缘性测试

采用型号为BROCKHAUS MESSTECHNIK的表面绝缘电阻测试仪器,测试其电流值各10次,记录各组的平均值,再通过下列公式计算表面绝缘电阻系数:

式中:C——表面绝缘电阻系数,单位为欧姆平方毫米(Ω∙mm2);

IA——每次测得的电流,单位为安培(A);

U——仪器测量时触头所用电压,单位为伏特(V);

R——与每个触头串联的电阻,等于5 Ω。

2.5. 三种含铬硅钢绝缘涂料粒径测试

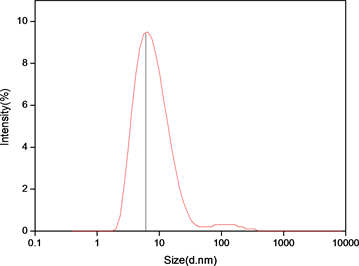

采用型号为Malvern Zetasizer Nano ZS90的纳米粒度仪测试三种涂料的粒径大小。在进行测量时选择的是手动测量(Manual Measurement),当测试样品粒度径时发现样品粒度处于检测限(10 um)以下,认为样品可能为真溶液 [6] 。

2.6. 三种含铬硅钢绝缘涂料红外光谱测试

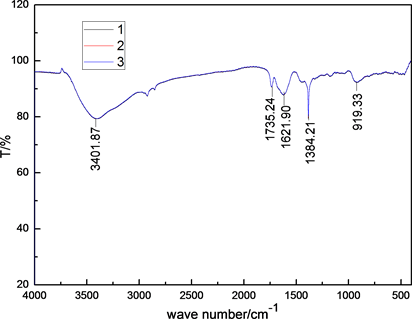

采用美国尼高力公司Nicolet 6700型傅立叶红外光谱仪对三种含铬硅钢绝缘涂料原液进行红外测试,测试前先将溴化钾烘干备用,然后在常温条件下将乳液样品自然风干,若样品中残留有水分,则在低温条件下吹干。取一定量样品,待仪器运行稳定后,以溴化钾的红外光谱图作为空白样,再对烘干后的三种涂料进行红外测试,分析光谱。

2.7. 三种硅钢绝缘涂料样品XRF测试

采用型号为ARL Advant’X Intellipower 3600的X-射线荧光光谱仪对三种涂料进行元素测试分析,由测试数据分析涂料中元素的种类及其含量,并根据铬元素来源于铬酐的CrO3和镁元素来源于MgO,推出三种含铬硅钢绝缘涂料中的CrO3、MgO相对含量及CrO3/MgO比值。

3. 结果与讨论

3.1. 含铬硅钢绝缘涂料物理性能分析

由以上含铬硅钢绝缘涂料物理性能测试结果(表1)可以看出,三种硅钢涂料均为橙色不透明乳液,经涂-4杯测量的粘度在10~13 s,1#硅钢绝缘涂料的粘度偏大,三种绝缘涂料的成膜性能相当,其固含量在25.71%~28.68%之间,比重在1.139~1.154 g/mL之间,由此可看出3#含铬硅钢绝缘涂料固含量较高,为28.68%,1#和2#固含量相差不大,其比重较接近,三种硅钢绝缘涂料pH值在5.5~6.0之间,均呈弱酸性。

Table 1. Three chromium-containing silicon steel insulation coating test results of the physical properties

表1. 三种含铬硅钢绝缘涂料物理性能测试结果

3.2. 含铬硅钢绝缘涂料表面耐蚀性分析

由图1可以看出三种含铬硅钢绝缘涂料表面的腐蚀面积有一定差异,但均小于10%,说明了这三种硅钢绝缘涂料的耐腐蚀性较好。

3.3. 含铬硅钢绝缘涂料表面绝缘性分析

采用电工钢片表面绝缘电阻测量仪对硅钢绝缘涂层绝缘性进行测试,结果如表2。

由表2可以看出三种含铬硅钢绝缘涂料表面都有很好的绝缘性,其中3#电阻值最大,其绝缘性最高。

3.4. 含铬硅钢绝缘涂料粒径测试分析

由图2含铬硅钢绝缘涂料粒径测试结果可知,1#含铬硅钢绝缘涂料的平均粒径为10.95 nm,95.5%的粒子平均粒径在9.108 nm处,仅有4.5%的粒子平均粒径在2775.00 nm范围内;2#含铬硅钢绝缘涂料平均粒径为8.845 nm,96.7%的粒子平均粒径在6.738 nm处,有3.3%的粒子平均粒径在138.6 nm范围;3#含铬硅钢绝缘涂料粒径测试结果得知该涂料的平均粒径为8.584 nm,98.9%的粒子平均粒径在6.532 nm处,仅有0.6%的粒子平均粒径在3217.00 nm范围。说明这三种名称涂料整体粒径大小呈正态分布,粒径较小,分散均匀。粒径的大小主要是由绝缘涂料中水溶性乳液的粒径大小决定的,在成膜较薄的情况下,小的粒径有利于成膜的均匀性。由此可以证明三种乳液分散比较均匀,对后面的应用成膜可以控制。

3.5. 红外光谱分析

对三种含铬硅钢绝缘涂料原液红外光谱测试(图3),1#和2#的含铬硅钢绝缘涂料吸收峰强度相差不大,3#含铬硅钢绝缘涂料的吸收峰强度相对较高。从红外光谱图中,在3400 cm−1左右应属Si-OH伸缩振动峰,1730 cm−1左右应属C=O双键伸缩振动吸收峰,1650 cm−1是C=C双键的伸缩振动吸收峰,饱和碳上的C-H单键弯曲振动吸收峰在1330 cm−1,碳碳双键上C-H的面外弯曲振动吸收峰在900 cm−1。由此可以推断这三种硅钢绝缘涂料可能含有酯基官能团的水性丙烯酸树脂。

图4为三种含铬硅钢绝缘水性涂料在烘干后的固体样品红外光谱图,从图中可以看出与图2的吸收峰位置大致相同,只是峰形缩小,且样品在干燥后吸收峰位置大体一致,从而说明这三种硅钢绝缘涂料使用的是同一种水溶性树脂,初步推论为丙烯酸树脂。

3.6. 氧化物组分分析

由表3可以得出,通过光谱测试发现三种含铬硅钢绝缘涂料干燥后成分基本一致,其主要成分为铬元素和镁元素,铬元素高达52.97%~54.28%,镁元素达11.82%~13.06%。再结合所测得的固含量可知三种含铬硅钢绝缘涂料中含有铬元素在13.62%~15.55%范围内,镁元素在3.20%~3.39%范围内,其中2#含铬硅钢绝缘涂料中铬含量和镁含量均是最多的。三种含铬硅钢绝缘涂料样品中加入的CrO3含量,3#样品的含量最高,1#样品的含量最低;其加入的MgO的含量,3#样品的含量最高,2#样品的含量最低;由此可以得出3#样品CrO3/MgO的比值最大,1#样品的比值最小。总的来说,三种含铬硅钢绝缘涂料中加入

1#

1#  2#

2#  3#

3#

Figure 1. Silicon containing steel corrosion test results of insulation coating surface

图1. 含硅钢绝缘涂层腐蚀试验结果

1#

1#  2#

2#  3#

3#

Figure 2. Three kinds of silicon steel insulation coating particle size distributions

图2. 三种硅钢绝缘涂料粒径分布

Table 2. Test results of insulation resistance on insulating coating surface

表2. 绝缘涂层表面绝缘电阻检测结果

Figure 3. Infrared spectrum of silicon steel insulation coating stock solution

图3. 硅钢绝缘涂料原液的红外光谱图

Figure 4. Infrared spectrum of dried chromium-containing silicon steel insulation coatings

图4. 干燥后含铬硅钢绝缘涂料红外光谱图

Table 3. Content of Cr, Mg elements and oxides in silicon-containing insulating coating stock solution and ratio of CrO3/MgO

表3. 含硅钢绝缘涂料原液中Cr、Mg元素与其氧化物的含量及CrO3/MgO的比值

的CrO3、MgO含量具有一定的差异,但均是使用CrO3为主成膜物质,以增加硅钢绝缘涂料的耐腐蚀性,其加入MgO以增加其绝缘性。

4. 结论

含铬绝缘涂料使用铬酐为主成膜物质以提高硅钢的耐蚀性,在高温烘烤固化期间,氧化镁中镁离子与硅钢板表面的硅反应形成硅酸镁,附着在钢板表面,以提高硅钢的绝缘性;以水性丙烯酸树脂作为分散剂添加到乳液中,使铬酐和氧化镁能更好的分散在水性丙烯酸树脂中。由分析可知,三种含铬硅钢绝缘涂料呈弱酸性,粒径测试结果分析说明乳液的分散性能良好,因此硅钢板表面均匀,主体固体膜物质是微纳米尺度。

而总的发展趋势是有机涂层已被逐渐淘汰,无机涂层将逐渐代替半无机涂层,但是,由于受到各方面条件的限制和无机涂层本身的属性,目前应用较多的仍为半无机涂层。而本文研究的三种含铬绝缘涂料就是主要由铬酐、三氧化铬、氧化镁和水性丙烯酸树脂等组成的半有机涂料,通过涂层工艺的合理控制,使其含铬绝缘涂层具有耐腐蚀性、绝缘性及易于成膜的性质,可以生产出表面质量良好的含铬绝缘涂层,能满足大部分用户的需求。但是,硅钢表面绝缘涂层的研究如同硅钢自身的研究一样,日本、美国和欧洲等国对其技术均进行严格保密。目前,在国内外公开出版的文献中,很难见到该领域技术成果的报导,这也致使笔者撰写该文具有一定的局限性。

基金项目

校企产学研联合科技攻关项目(MS2013019)。