1. 引言

信息、通信技术和高功率激光系统等光学领域对透镜成像质量、光学性能、高损伤阈值等的需求日益增长 [1] [2] [3] [4]。与传统成像光学系统不同,在高功率激光系统中,低频的波前畸变误差将直接决定激光束的聚焦性能;中频波纹度将导致光束的高频调制与系统的非线性增长,造成光学元件的丝状破坏和降低光束的可聚焦功率,目前,广泛使用功率谱密度(PSD) [5] [6] [7] 来评价中频段波前质量;高频粗糙度降低系统的信噪比。强激光及高分辨率探测等领域光学系统综合性能的提升,要求空滤透镜的加工质量不断提高,并实现全空间频段误差控制 [8] [9] [10],保证光学加工的超精密和确定性水平。此外,无论是通讯卫星、精密雷达、夜视仪等装备,均需要超高性能光学元件。

为保证高功率激光装置光学系统的性能,要求空间滤波器透镜的加工精度小于1/3波长。但空滤透镜米级口径、数十米长焦距的特点,使得近年来发展的很多高精度的光学测试方法,如相位测量偏折术 [11] [12] [13] [14]、朗奇光栅法 [15] [16]、夏克–哈特曼方法 [17] [18] 等方法无法满足实际应用需求。

为满足美国NIF工程中对空间滤波器透镜的使用需求,美国利弗莫尔国家实验室(LLNL)使用透镜光测试系统(LOTS)测量空间滤波器透镜的焦距和透射波前 [19]。然而,大口径球面镜加工困难,且造价高昂,尤其是凸面镜的制作和检验非常复杂且困难。

计算全息法(CGH) [20] [21] [22] 通过计算机辅助设计可产生任何需要的振幅和位相的波前,在光学测试领域已被广泛应用 [23] [24] [25] [26]。近年来,随着现代光刻技术的发展,使得通过离子束刻蚀或激光直写 [27] - [32] 等方法制作高精度、高分辨率的CGH用来测量大口径长焦距透镜透射波前的方法可行。

在之前的工作 [33] 中,我们研究了长焦透镜的低频波前检测,实验结果表明,这种方法是可行的,并且精度高。本文利用CGH方法测量功率谱密度(PSD) [34],并对该方法的测量误差进行了定量分析。与斐索干涉法相比,CGH法的结构非常简单紧凑,易于调整,因此具有较高的精度。此外,实验结果和理论分析表明,对于焦距超过30 m、通光口径为Φ410 mm的球面透镜,其均方根误差小于1 nm。

2. 测量方法

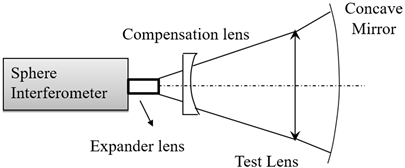

对于带像散等畸变的透镜的波前PSD检测,传统上使用补偿法测量,光路如图1所示,从干涉仪出射的球面波依次通过补偿透镜和测试透镜传输,输出的平行光被参考平面反射后原路返回。

Figure 1. Experimental setup of the compensation method

图1. 补偿法测试光路

干涉法是通过与被检面的理想形状完全匹配的非球面做比较得到被测透镜的波前。该方法为零位补偿检测,需要引入辅助的补偿镜,且两个表面共轴调整要求非常苛刻,因为两个面都有严格限定的轴,在校验过程中必须使这两个轴重合。且对于大口径长焦透镜的检测,该方法不能有效缩短测量光路,使得光路调校更加困难。因此,长期以来,大口径长焦距透镜中低频波前无法定量检测,而我们提出的CGH法另辟蹊径,可给出高精度检测结果,且方法简便、易操作。

2.1. CGH法测量原理

测量光路如图2所示,由相移干涉仪、待测透镜和CGH组成。

Figure 2. Experimental setup of the CGH method

图2. CGH法测量光路

当进行透镜波前PSD测试时,干涉仪输出的准直平行光通过标准平面镜时,一束由标准平面镜参考面反射形成标准参考光束,另一束透过被测透镜、经波带片反射沿原路返回形成测试光束;测试光束与标准参考光束发生干涉,调整空间滤波器透镜,使干涉条纹最少,即可测量得到空间滤波器透镜透射波前。

2.2. CGH的设计与制作

设计CGH的几何示意图如图3所示。

根据费马等光程原理,计算菲涅尔波带片的位相分布。从平面干涉仪出射的平行光经被测透镜、菲涅尔波带片的所有光线的光程均相等,即有:

(1)

其中,C为常数,

为经CGH反射后的波前位相差。由此可得:

(2)

根据位相分布方程得到CGH的各环带半径参数,从而使用激光直写、离子束刻蚀等方法制作菲涅尔波带片。

Figure 3. Geometric diagram for the design of CGH

图3. 设计CGH的示意图

2.3. PSD的计算

PSD是波前各频率分量傅里叶频谱振幅的平方,u(x, y)为波前相位畸变,Lx × Ly为采样面积,PSD二维的定义形式为 [34]:

(3)

(4)

其中,x、y为坐标,νx、νy是其对应的空间频率。

3. 实验

通过小口径验证实验和与大口径补偿法测试进行对比实验,验证CGH方法测试的有效性。

3.1. 小口径验证实验

被测透镜直径80 mm,焦距1500 m。CGH法测试光路如图2所示。CGH的1级曲率半径设计为1200 m,故透镜-CGH间距为300 mm,总的测量光路小于500 mm。

而使用传统的干涉检测法,测量光路如图4所示。使用动态球面干涉仪,并选取与被测透镜f-#匹配的标准球面镜,且在待测透镜后还需一个标准反射平板RF。总光路长度超过3000 mm。

Figure 4. Experimental set up of the Fizeau interferometry method

图4. 干涉法测长焦透镜波前检测光路

CGH法由二元衍射元件CGH提供和待测透镜透射波前匹配的波面,使得由透镜透射的波前经过CGH反射,再透过待测透镜后能原路返回,并与干涉仪TF反射的波前干涉,通过解析干涉条纹,得出待测透镜的加工质量。由于采用静态干涉检测,且光路短,其测量误差主要取决于CGH的加工误差。而传统的干涉检测,采用球面干涉仪,且必须选取与待测透镜f#匹配的标准透镜,再由标准反射镜反射,才能组成干涉光路。相对CGH法,系统测量误差大,且由于测量光路更长,调节误差也不可忽略。

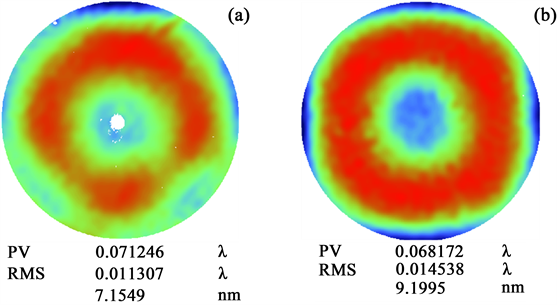

使用CGH法和传统的干涉法测透镜波前PSD1的结果见图5,PSD1分布的通光口径为Φ70 mm。

Figure 5. PSD measured by the CGH method (a) and conventional interferometry method (b)

图5. CGH(a)和传统干涉法(b)测量PSD结果

由图5可见,两种方法测量得到PSD1分布非常一致,PSD1检测结果的RMS值也很相近,从而验证了CGH法测量的准确性。

需指出的是,与CGH法PSD1值为7.15 nm相比,传统干涉法9.20 nm略大些,这是因为该方法测量光路超过3 m,光路调校时像散、慧差等像差无法完全消除,使得结果偏大。

3.2. 大口径比对实验

待测透镜直径430 mm,焦距32 m,前后表面的曲率半径分别为10 m和44 m。

为此,我们设计研制了大口径CGH,其通光口径为410 mm,1级曲率半径为31.5 m,透镜-CGH间距为0.5 m,干涉仪波长为632.8 nm。

从干涉仪出射的平行光透过待测透镜时,波前Seidel像差为0.345λ,此像差需要补偿掉。以使得入射到CGH的光能全部原路返回。

为了更进一步验证CGH法测量的有效性,我们使用补偿光路法与之做比对实验,其光路示意图见图6。鉴于大口径凸面镜的加工非常困难,我们使用大口径凹面镜(直径达600 mm,焦距为5.6 m),配合一块补偿镜,实现大口径长焦透镜波前中低频检测,光路总长度约6 m。由于光路中有3块球面镜,再加上干涉仪输出的球面波,整个光路调节起来相当复杂。

由于该方法采用大口径凹面镜提供反射球面波前,经待测透镜传输后由补偿镜补偿理论像差,再原路返回干涉仪形成干涉检测,不但系统误差较大,且补偿镜、大口径凹面镜均会引入测量误差。同时,由于球面干涉仪出射的为球面波前,补偿镜、待测透镜、凹面镜均为球面元件,整个光路在调节过程中,自由度非常多,从而由于光路调节引入的误差不可忽略。

Figure 6. The beam path diagram of the compensation method

图6. 补偿法测量光路图

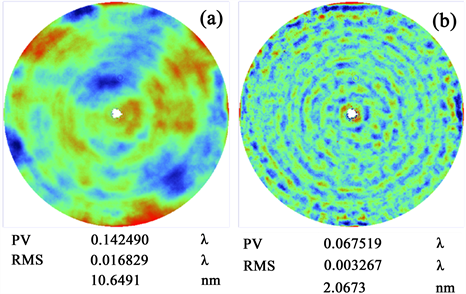

CGH法和补偿法测量结果分别如图7和图8所示。两种方法得到的波前中低频分布非常相似,低频波前PV也很相近,分别为0.142λ和0.150λ (λ = 632.8 nm)。PSD1的RMS值略有不同,这是因为采用补偿法测量时,大口径凹面镜的加工,低频波前可以控制的很好,但中频波前PSD1的加工仍然有相当大的误差,从而为透镜的PSD1检测引入不小的误差。

Figure 7. Wavefront (a) and PSD1 (b) of the lens measured by the CGH method

图7. CGH法测量透镜的低频波前(a)和中频PSD1 (b)

Figure 8. Wavefront (a) and PSD1 (b) of the lens measured by the compensation method

图8. 补偿法测量透镜的低频波前(a)和中频PSD1(b)

总体来说,通过小口径验证实验和大口径比对实验,验证了CGH法测量长焦距透镜波前中低频的有效性,以及测量时光路调节的便捷性,因为CGH法可有效缩短光路,减少光路调节的自由度。

4. 测量误差

CGH法测量误差包括系统误差、CGH的设计误差、加工误差,以及光路调节误差。此章节,我们主要分析中频PSD1测量的误差。

干涉仪的系统误差为0.002 nm,而通过合理设计,CGH设计引入的误差可消除,故此章节主要通过分析CGH的线性模型,分析加工引入的误差和光路调节引入的误差。

4.1. CGH的线性模型

根据夫琅和费衍射理论,近场波前通过简单的傅里叶变换即可得到远场衍射波前。全息图中记录的条纹偏离其理想位置的位移通常称为图形畸变。全息图图形畸变产生的波前相位误差量可以表示为衍射波前函数梯度和图形畸变矢量的乘积。对于线性光栅,m阶光束中光栅图形畸变产生的反射波前相位误差可计算为:

(5)

其中,W为波前相位差,ε为CGH的图形误差,p为CGH的图形周期,m为衍射级次。

结合波前灵敏度函数及PSD的定义,PSD测量误差σPSD可由公式(6)给出:

(6)

其中,SPSD为中频PSD1所覆盖的面积,而SN是低于Nyquist频率的PSD1覆盖的面积,

是CGH加工引入的波前误差的协方差,νh和νl分别为PSD1所对应的高频和低频截止频率。

4.2. 误差分析

CGH的加工误差主要分为两种:基底误差和图形刻蚀误差。基底误差可通过测量CGH的0级波前得到,测量结果见图9,中频波前PSD1的RMS值为0.6472 nm。

Figure 9. The reflective wavefront PSD1 of the hologram

图9. CGH的基底PSD1测量结果

图形误差可更近一步地分为位置偏移误差、占空比误差和刻蚀深度误差。

CGH图形的最小周期为34 μm,0.5 μm (3σ)的图形刻蚀误差,引入的PSD1测量误差为0.3359nm RMS。

实验中使用的CGH,A0 = A1 = 1,占空比为0.5,刻蚀误差为5% (3σ)。由于占空比仅影响0级波前,故在1级测量中,对中频波前PSD1的影响为0。深度刻蚀误差为5% (3σ),根据公式(6)计算得到,在中频波前PSD1测量中引入的误差为0.5711nm RMS。

通过ZEMAX模拟计算,RMS.光路调节过程中,0.2 mm的倾斜偏差引入的中频PSD1测量误差为0.0031 nm RMS,0.04'的角度俯仰偏差引入的中频PSD1测量误差为0.0012 nm RMS,具体见图10。

Figure 10. Error analysis for the CGH test

图10. CGH法测量中频波前PSD的误差

由于各误差分量互不相关,合成误差可以估计为统计平方公差(RSS)法计算,CGH法测量中频波前PSD1误差为0.926 nm RMS。

5. 小结

本文使用CGH法测量大口径长焦距透镜中频波前PSD1,通过与小口径干涉检测法和大口径补偿干涉法的比对实验,验证了该方法的有效性。理论分析与验证实验表明,对焦距超过30 m、口径超过400 mm的大口径长焦距透镜中频PSD1测量误差小于1 nm。该方法测量光路简单,结构紧凑,调节误差小,测量精度高,实现了全空间频段误差无损检测,保证了光学加工的超精密度和确定性水平,从而提高了光学系统的综合性能。

基金项目

国家自然科学基金(11904337)。

NOTES

*通讯作者。