1. 引言

随着木材加工产业的迅速发展,木材胶粘剂的需求量也在不断地增长。脲醛树脂(UFR)由于其具有成本低,颜色浅,能快速固化,有良好的粘合强度和耐热性等优点,常用作人造板材、砂布的胶粘剂、玻璃纤维粘合剂、涂料的交联剂等[1] 。但是UFR中游离甲醛含量较高,其原因是脲醛缩聚反应中存在游离甲醛及羟甲基、亚甲基醚和半缩甲醛等可降解生成甲醛的物质或结构单元,其游离和分解或降解的甲醛会慢慢从人造板材中释放出来,致使室内甲醛含量长期超标,特别在热固化制板的时候会溢出强烈刺激性气味的甲醛。

众所周知,甲醛不仅对鼻黏膜、视黏膜及上呼吸道均有刺激作用,而且还会引起皮炎、肝脏病变、致癌及致突变等多种疾病。近年来,随着人们物质生活不断提高,环境友好材料的开发越来越受到人们的重视,特别是GB18580-2001室内装饰装修材料、人造板及其制品中甲醛释放限量的制订,并于2002年7月1日起强制执行,对人造板甲醛释放量进行严格限制。因此,研究低游离甲醛含量的UFR是现阶段脲醛树脂应用开发研究的主要方向[2] [3] 。要降低UFR中的甲醛含量,可以从下面两个方面入手:一方面是使反应尽可能地彻底,另一方面是改善树脂分子的结构,从而有效地使聚合物中的不稳定基团尽可能地减少[4] 。目前可以通过下面三方面来降低脲醛树脂浆料的甲醛含量:1) 降低甲醛与尿素的摩尔比;2) 改进合成工艺:在摩尔比不变的前提下,尿素分多批次投料可以降低甲醛的含量;3) 添加甲醛捕捉剂[5] 。

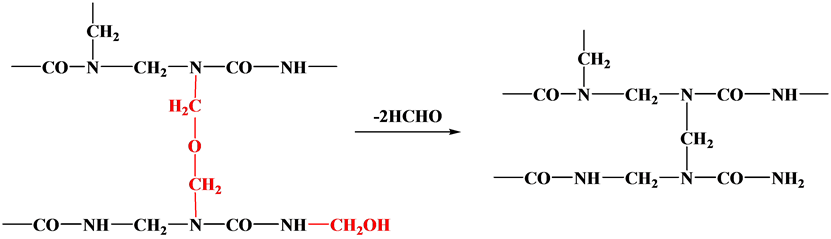

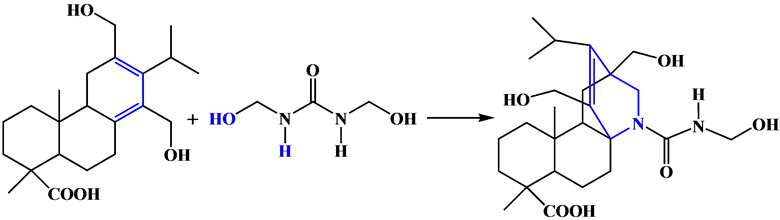

松香及其衍生物以其特有的结构、优异的特性,成为制备高分子材料的重要原料来源[6] [7] 。本研究拟采用羟甲基松香为原料,并将其应用在脲醛树脂的缩聚反应中,在脲醛树脂的缩聚反应中引入疏水性枞酸(松香主要成份)作为侧链基团,对UFR进行结构单元的改性。由于枞酸分子中存在着共轭双键,易与羟甲基脲发生缩合形成共聚物[8] ,同时,甲醛改性松香中的羟甲基也易于与亚胺基缩合。三种缩合方式使羟甲基松香与脲醛树脂交联形成三维网状结构,有效地改善脲醛树脂的分子结构,降低脲醛树脂释放甲醛的速度。脲醛缩聚反应和羟甲基松香制备的反应方程式如下所示。

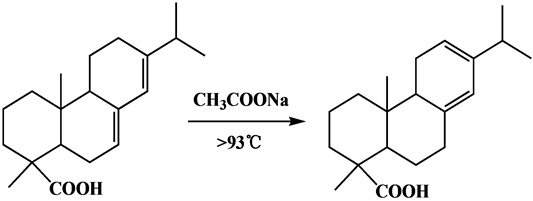

根据文献报道[9] ,枞酸在CH3COONa作为催化剂的条件下,于>93℃下发生异构化反应生成海松酸,反应方程式如下。

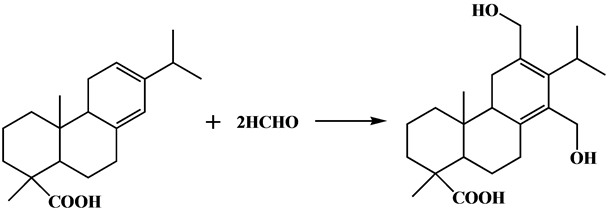

异构化所制的海松酸与甲醛溶液发生加成反应,生成12,14-二羟甲基海松酸(即羟甲基松香),反应如下式所示。

实验中采用传统的碱–酸–碱工艺合成方法,在制备过程中研究了不同的酸性催化剂、碱性催化剂、甲醛/尿素(F/U)投料比、硫脲的添加量等工艺条件对制得的脲醛树脂浆料中游离甲醛含量、固含量所产生的影响进行评价,实验所制得的产品是一种满足环保要求和市场需求的脲醛树脂浆料。实验中发生的羟甲基松香与脲醛共聚合反应,根据文献报道[9] ,羟甲基松香与二羟基缩脲反应生成具有六元环稳定结构的尤戎(Uron)化合物,有利于保护聚合物单元结构中分解或降解的基元结构,其反应方程式如下。

2. 实验部分

2.1. 药品与试剂

尿素、甲醛(36%~38%)、乙酸钠、草酸、邻苯二甲酸酐、六次甲基四胺、硫脲、NaOH、H2SO4、HAc、甲酸等,试剂均购自中国医药集团,选择CP级试剂,水溶液均用去离子水配制。

2.2. 仪器与设备

FA2004电子分析天平(上海海康电子仪器厂)、SHZ-D(Ⅲ)循环水式真空泵(巩义市予华仪器有限责任公司)、SZCL-1型数显智能控温磁力搅拌器(巩义市予华仪器有限责任公司)、202-1型电热干燥箱(上海市上海县第二五金厂)、PHS-3C型数显酸度计(上海雷磁分析仪器厂)、722分光光度计(上海凤凰光仪设备有限公司)。

2.3. 实验步骤

1) 在三口烧瓶(回流冷凝管、温度计和进料口)中加入0.35 g(约占总质量的0.5%)羟甲基松香,并加3.5 ml的正丁醇将其溶解,加入15 ml水、9.5 ml甲醛,再加入碱性催化剂25%的六次甲基四胺(HTMA),此时pH在7.0~8.0之间。加热至70℃后分三批加入尿素,每批2 g,间隔15 min,共计用时45 min。

2) 用酸性催化剂5% H2SO4调节使反应物的pH接近于6.0,依次加入6批1 g的尿素,各反应5 min,共计用时30 min。

3) 用25% HTMA调节pH 在8.0左右,加入最后一批尿素3 g反应20 min,同时添加适量的硫脲。总计加入15 g尿素,分10批次投料。

4) 待反应体系自然冷却至接近室温后,出料。该反应完全后,若浆料的pH < 7.0,则采用滴加30% NaOH调节pH至8.0,而后再出料。

2.4. 甲醛含量的测定

准确称取0.3~0.4 g脲醛树脂浆料,溶解过滤,滤液定容至200.00 ml,取2.00 ml稀释至50.00 ml,移取5.00 ml溶液于干燥烧杯中,加入2.00 ml乙酰丙酮显色液,在80℃温水浴5 min,冷却,用分光光度计在波长415 nm下测定其吸光度值[10] 。

2.5. 固含量的测定

用分析天平准确称取0.4~0.5 g的样品m1于称量瓶中,放入电热干燥箱中,于120℃ ± 1℃条件下干燥120 ± 1 min,取出称重m2,采用式(1)计算固含量S%[11] 。

(1)

(1)

3. 实验结果与讨论

3.1. 甲醛含量工作曲线的绘制

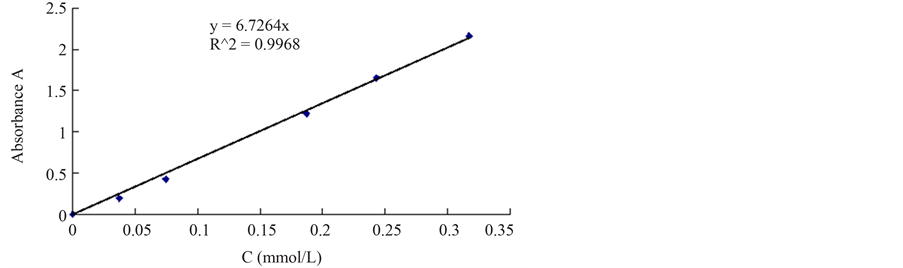

移取标定的甲醛溶液1.00 ml于500.00 ml容量瓶中定容,浓度约为15 ppm,分别移取15.00 ml、10.00 ml、7.00 ml、4.00 ml、2.00 ml的甲醛溶液于25.00 ml容量瓶中,配成10 ppm、8 ppm、6 ppm、4 ppm、2 ppm的作为测定工作曲线的甲醛浓度。各移5.00 ml于干燥的50 ml烧杯中,加入2.00 ml乙酰丙酮溶液,密封置于80℃温水浴5 min,自然冷却后用分光光度计测定其吸光度值,所得工作曲线如图1所示。

3.2. 市场产品中的甲醛含量的测定

实验中首先对福建省某化工企业所生产的C1、C2两种样品中的甲醛含量进行测定,实验结果如表1所示。从分析结果可以看出,目前市场脲醛树脂浆料产品中甲醛的含量严重偏高,是潜在的污染源。

3.3. 不同的酸性催化剂对脲醛树脂浆料中甲醛含量的影响

实验中采用不同的酸溶液作为脲醛缩聚反应中的酸性阶段的催化剂,实验结果如表2所示。从表2的数据可以看出,采用5% H2SO4作为脲醛树脂制备的酸性催化剂,所制得的脲醛浆料的甲醛含量最低,其固含量中等,因此选用5% H2SO4作为脲醛树脂缩聚反应中酸性阶段的催化剂。

3.4. 醛尿比对脲醛树脂浆料中甲醛含量的影响

实验中甲醛(F)与尿素(U)的不同摩尔比对制得的脲醛树脂浆料中甲醛含量的测定结果如表3所示。从表3数据可以看出,当采用F/U = 1.6时,所制得的脲醛树脂浆料所含游离甲醛的含量较低,其固含量中等,而且放置30 d后其游离甲醛含量仍然比较低,因此选择F/U = 1.6作为脲醛树脂缩聚反应的投料比较为合适。对于采用F/U = 1.4投料比的产品虽然甲醛含量最低,但其固含量尚未达到40%,因此不适宜作为板材胶黏剂脲醛树脂浆料。

Figure 1. Work curve of the formaldehyde content

图1. 甲醛含量工作曲线

Table 1. The formaldehyde content of the products on the market

表1. 市场产品中的甲醛含量

Table 2. Effects of different acid catalyst on the formaldehyde content of UFR Slurry

表2. 不同的酸性催化剂对脲醛树脂浆料中甲醛含量的影响

3.5. 添加剂硫脲对脲醛树脂浆料中甲醛含量的影响

硫脲作为一种脲醛树脂浆料中甲醛的捕捉剂,可以有效地减少脲醛树脂浆料中甲醛的含量。实验中选择了不同硫脲含量制得的脲醛树脂浆料,结果如表4所示。从表4数据可以看出,当选择添加量为1.0%的硫脲作为脲醛树脂浆料产品中的甲醛捕捉剂时,所得到的脲醛树脂浆料中甲醛的含量最低,放置30 d后甲醛含量也相对较低。虽然其他硫脲添加量制得的脲醛树脂浆料甲醛含量也相对较低,固含量也符合要求,但从成本上看,选择1.0%硫脲添加量较为合适,产品完全符合作为板材胶黏剂的要求。

3.6. 不同的碱性调节剂对脲醛树脂浆料中甲醛含量的影响

实验中选择HMTA作为碱性的调节剂,与采用5%和10% NaOH溶液做对比,测定脲醛树脂浆料中甲醛的含量,实验结果如表5所示。从表5数据可以看出,当选择采用HTMA调节甲醛溶液的pH值,所得到的脲醛树脂浆料中甲醛的含量相对于NaOH作为pH调节剂都较低,而固含量几乎相当,放置30 d后的甲醛含量也相对最低。通过实验还发现HMTA的添加方式对甲醛含量的影响不太明显,但当HTMA的添加量达到50%的时候,所得的脲醛树脂浆料易固化,放置30 d后完全固化,因此选择25% HTMA作为甲醛溶液的pH调节剂是较为理想的选择。

Table 3. Effects of different ratio of urea and formaldehyde on the formaldehyde content of UFR Slurry

表3. 不同的F/U投料比对脲醛树脂浆料中甲醛含量的影响

Table 4. Effects of different additional content of thiourea on the formaldehyde content of UFR Slurry

表4. 不同的硫脲添加量对脲醛树脂浆料中甲醛含量的影响

Table 5. Effects of different basic containing agent on the formaldehyde content of UFR Slurry

表5. 不同的碱性调节剂对脲醛树脂浆料中甲醛含量的影响

4. 结论

实验研究发现,采用分10批次加入尿素的方法能够有效地降低脲醛树脂浆料中的甲醛含量,通过对不同酸性催化剂、碱性调节剂、F/U投料比、硫脲的添加量等工艺条件下所制得的脲醛树脂浆料中甲醛含量和固含量的测定筛选出最优的工艺条件。实验中添加了0.5%的羟甲基松香,选择F/U = 1.6的投料比,采用5% H2SO4作为酸性催化剂,选择25% HMTA作为pH调节剂,同时添加1%硫脲作为甲醛捕捉剂,最终采用30% NaOH溶液调节产品的pH值。通过实验所得的工艺条件能够有效地降低脲醛树脂浆料中甲醛的含量,而且相对市场中的产品而言,游离甲醛的含量降低了将近5倍。

本实验所制得的脲醛树脂浆料中游离甲醛含量为1.09%,固含量 > 40.0%,如果将其用作板材生产的胶黏剂,其板材中游离甲醛的含量低于国家E1标准,可以实现低甲醛环保型人造板材的生产。

致 谢

本实验在研究过程中得到了黄紫洋老师的悉心指导,同时得到课题组成员的帮助。此外,本项目也得到福建省大学生创新创业计划项目(201310394067)对本实验的资助。

基金项目

2013年福建省大学生创新创业训练计划项目(201310394067)。

NOTES

*通讯作者。