1. 引言

具有高功率密度、充放电速度快、寿命长和使用温度范围宽等优点的电介质电容器可被广泛应用于心脏起搏器、混合动力电动车辆、航空航天动力系统和电磁弹射炮等领域,现已成为了科研工作者研究的热点之一 [1] [2] [3]。然而,电介质电容器的能量密度和转化效率仍然较低,已成为应用的瓶颈。铁电薄膜材料因具有较高的介电常数和击穿场强,能获得更大的储能密度 [4] [5]。一般来说,有效储能密度

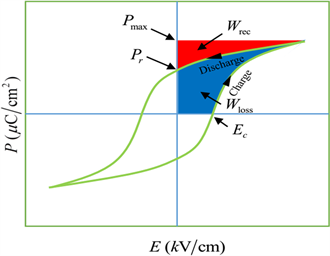

Wrec可以通过电滞回线的积分来计算,如图1所示,其公式可以分别表达为

。E为外加电

场强度,P为极化强度,Pr为剩余极化强度,Pmax为最大极化强度。目前,关于薄膜储能的研究主要集中在铅基(Pb, La)(Zr, Ti, Sn)O3体系,因为含铅材料具有良好的绝缘性和优异的极化特性,且性能优异 [6] [7] [8]。Ma等 [9] 通过化学溶液沉积法在LaNiO3缓冲的Ni衬底上制备了掺镧锆钛酸铅PLZT的弛豫铁电薄膜,将储能密度提高至84.0 J/cm3,该结果为目前见诸报道的含铅薄膜体系中的最大值。然而含铅材料会对人类的健

Figure 1. Schematic diagram of ferroelectric energy storage calculation

图1. 铁电储能计算原理图

康和自然环境造成严重的威胁,随着科学技术的进步和人们环保意识的增强,研发高性能无铅薄膜储能材料是大势所趋 [10]。近来研究表明,钛酸铋钠Na0.5Bi0.5TiO3(NBT)是一类无铅弛豫铁电储能薄膜材料 [11]。其具有较高的ε和Pmax,较小的Pr和极化滞后的“瘦”P-E回线,这些特性使得Na0.5Bi0.5TiO3能够得到较高储能密度和储能效率,现已成为最有潜力的储能电介质薄膜材料 [12] [13]。Instan等 [14] 采用PLD法制备了(100)方向高度择优取向的BaZrxTi1−xO3 (x = 0.3, 0.4, 0.5)铁电薄膜,在3 MV/cm电场下,Wrec达到了156.0 J/cm3。Instan研究表明,相对于多晶薄膜体系而言,外延取向克服了多晶体系的缺陷可以提升薄膜的储能性能。至今,关于单晶外延NBT薄膜性能研究的文献报道较少。基于此,本论文通过磁控溅射法和脉冲激光沉积法,构架了(00l)外延LSCO/NBT/LSCO异质结,研究了电场强度和环境高温对外延取向NBT薄膜铁电电容器储性能的影响。研究结果能为高性能铁电薄膜电介质储能电容器的制备与设计提供实验数据参考。

2. 实验

采用了磁控溅射法和脉冲激光沉积法制备了Pt/LSCO/NBT/LSCO/STO铁电异质结薄膜,具体步骤如下:为去除基片表面的污染,首先将STO基片放入丙酮中,利用超声波清洗10 min,再将其放入无水乙醇中,利用超声波清洗10 min。然后将基片迅速放入实验仪的真空腔中。通过机械泵将样品所在腔体中的内背底真空度抽至20 Pa以下,再用分子泵将真空度抽至2.0 × 10‒4 Pa以下。用磁控溅射法在STO基片上外延生长厚度约为40 nm的LSCO薄膜。LSCO薄膜条件如下:采用纯度为99.99%的LSCO靶材;氩气(Ar)和氧气(O2)流量为100 mL/min,且保持Ar/O2体积比为3:1;功率为70 W;压强保持为1.4 Pa。靶材预溅射20 min,正式溅射1 h。然后将异质结LSCO/STO放入退火炉中,氧气氛围,550℃慢速退火1 h。利用LPD脉冲激光沉积法在LSCO/STO上制备200 nm左右的NBT薄膜。靶材采用Na和Bi都过量10%的Na0.5Bi0.5TiO3陶瓷靶,以防止薄膜制备过程中Na和Bi挥发而导致NBT薄膜中Na和Bi的丢失,纯度为99.99%。NBT薄膜沉积条件如下:O2流量为50 sccm;压强为7.6 Pa;沉积温度为650℃。再用磁控溅射法在异质结NBT/LSCO/STO上外延生长厚度约为40 nm的LSCO薄膜。利用掩膜技术在异质结LSCO/NBT/LSCO/STO上连续生长了面积为7.85 × 10‒5 cm2的点电极。退火炉中,O2气氛围下,550℃快速退火1 min。采用X射线衍射仪(XRD-丹东TD3700)对NBT/LSCO/STO异质结的结构进行了表征。采用铁电测试仪(Radiant Precision LC II)测试样品的铁电性能和铁电储能性能。

3. 结果与讨论

3.1. Pt/LSCO/NBT/LSCO/STO异质结的结构表征

图2为(001)取向的单晶钛STO为衬底制备具有高质量外延结构的Pt/LSCO/NBT/LSCO/STO铁电异质结薄膜的XRD谱。该曲线均对STO(002)衍射峰进行了归一化处理。图中可以直接看出,衍射角2θ在20˚~50˚扫描范围内仅出现了NBT和LSCO薄膜的(001)和(002)两个特征峰。图2插图为φ扫描样品绕衍射晶面法线n的旋转测量,扫描结果每90˚出现一个峰值,表明Pt/LSCO/NBT/LSCO/STO铁电异质结薄膜是高质量的外延结构,与基底STO(001)晶向相同,且为(001)高度择优取向结构。

Figure 2. XRD pattern of NBT/LSCO/STO heterostructure, illustrated with Phi scan of NBT film

图2. NBT/LSCO/STO异质结的XRD图谱,插图NBT薄膜的Phi扫图

3.2. LSCO/NBT/LSCO异质结的铁电性能

Figure 3. (a) Hysteresis loops of NBT films under different electric fields; (b) The relationship between the energy storage characteristics of NBT films and the electric field

图3. (a) 不同电场作用下NBT薄膜的电滞回线;(b) NBT薄膜储能特性与电场的关系

图3(a)为不同电场作用LSCO/NBT/LSCO异质结的电滞回线。图3(a)可以看出LSCO/NBT/LSCO呈现出饱和的电滞回线。表现出P-E循环。正负矫顽电场Ec和正负剩余极化强度Pr具有非对称性,归功于LSCO/NBT和NBT/LSCO界面处理条件不同。随着外加电场强度E的增加,最大极化强度Pm和储能密度Wrec均增大。电偶极矩P与场强的定量关系为:

(1)

式(1)其中ε0为真空电容率、χe为电极化率、εr为相对电容率。由图3(a)可以看出随着电场强度E的增加Pm和Pr呈现线性增加趋势,从而造成储能密度Wrec线性增大。由图3(b)可得,在500 kV/cm、750 kV/cm、1000、1250 kV/cm场强下,NBT薄膜的充放电效率η和有效储能密度Wrec值分别为56.2%、60.5%、63.1%、64.7%和7.2 J/cm3、12.5 J/cm3、18.8 J/cm3、25.7 J/cm3。由此看出,LSCO/NBT/LSCO的η和Wrec随着电场强度的增加而增大。NBT薄膜具有良好的电滞特性,具有弛豫铁电材料的特性,有利于低损耗储能。此外,由图3(a)得出LSCO/NBT/LSCO的击穿强度可高达1250 kV/cm,此时储能密度为25.7 J/cm3。

为了研究外延NBT薄膜的热稳定性,测量了固定E = 1000 kV/cm处随温度变化的P-E环,读取了不同温度下Pr与Pm的变化关系曲线,如图4(a)所示。由图可以看出随着温度的升高,Pr在40℃到120℃之间较为平缓,NBT薄膜异质结的铁电存储性能较为稳定。Li的研究 [15] 表示弛豫铁电体电滞回线会出现“束腰”现象,较高温度时电滞回线回到正常的方形,这在一定程度上将导致Pr在温度低时较温度高时要小,这与图4(a)符合较好。由图4(b)可以看出,环境工作温度在40℃~120℃范围内,LSCO/NBT/LSCO异质结的η和Wrec数值几乎不变,表明LSCO/NBT/LSCO的铁电储能性能具有较好的热稳定性。

Figure 4. (a) Relationship between Pr, Pm and operating temperatures of NBT films; (b) Relationship between energy storage characteristics and frequency of NBT films

图4. (a) NBT薄膜的Pr和Pm随温度的变化曲线;(b) NBT薄膜储能特性与温度的关系曲线

4. 结论

以LSCO作为底电极,通过磁控溅射法和脉冲激光沉积法,在(001)STO衬底上成功制备了Pt/LSCO/NBT/LSCO/STO铁电异质结电容器。X射线衍射图谱表明NBT薄膜为(00l)外延结构。铁电储能性能测试表明,LSCO/NBT/LSCO铁电异质结薄膜储能性能随场强增大而线性增加,且电场强度达到1250 kV/cm时,储能密度为25.7 J/cm3,效率高达64.7%。在电场强度为1000 kV/cm条件下,工作温度在40℃~120℃之间,LSCO/NBT/LSCO的η和Wrec具有较好的热稳定性。研究结果可为高性能无铅铁电储能器件的制备以及实际应用提供实验数据。

基金项目

河北农业大学理工基金(LG201611);河北农业大学自主培养博士科研启动经费(PY201809);河北农业大学大学生创新创业训练计划基金(S202010086026, 2020104, 2020259)。